The core advantages of the dual-frequency conversion heat shrink wrapping machine over the conventional fixed-frequency heat shrink wrapping machine are concentrated in precise controllability, packaging adaptability and finished product stability.

Dual-frequency Conversion Independent Control for Adaptation to Multiple Products and Film Materials

Conventional heat shrink wrapping machine: The conveying speed and heating power are of fixed gears or single-frequency conversion control. Linked adjustment is required during regulation, making it impossible to accurately match packaging films of different properties and product sizes. Packaging is prone to problems such as uneven film shrinkage, film scalding and product deformation.

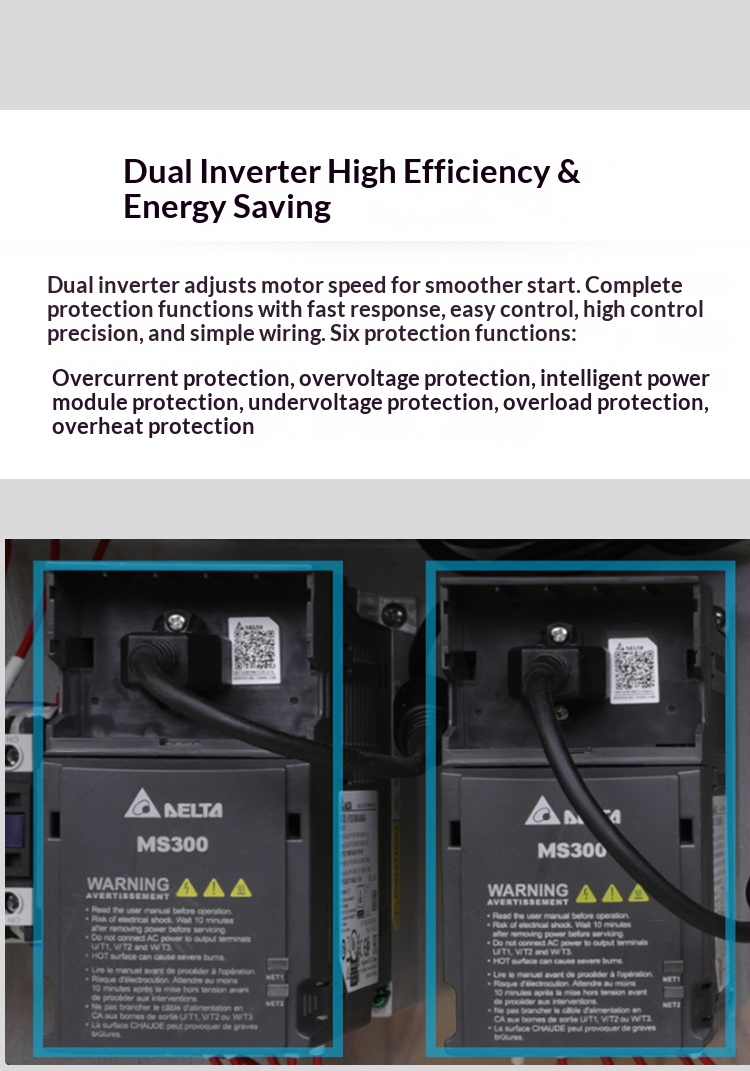

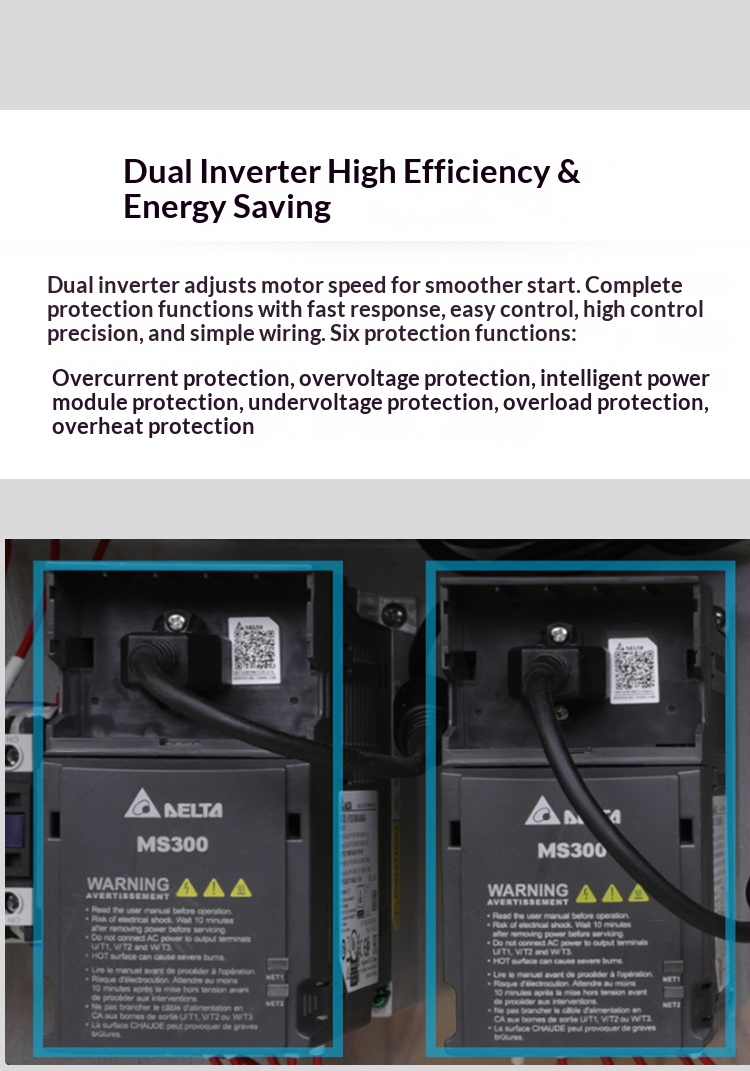

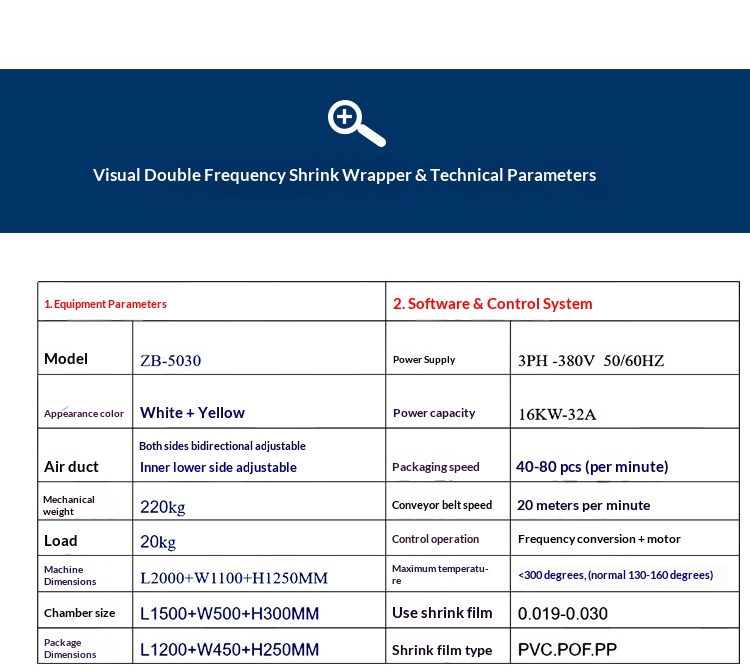

Dual-frequency conversion heat shrink wrapping machine: Equipped with two independent frequency converters to separately control the conveying motor and the heating/hot air motor, it achieves stepless speed regulation and precise temperature control. For different products and film materials, the conveying speed or heating power can be adjusted independently without linked commissioning, resulting in stronger adaptability. It is particularly suitable for the production scenarios of multi-category and small-batch.

More Stable Shrinkage Effect and Higher Yield Rate

Conventional heat shrink wrapping machine: The stability of hot air velocity and temperature is poor, and local temperature differences are prone to occur in the shrinking furnace, leading to wrinkles, air bubbles and poor adhesion on the film surface. Especially for irregularly shaped products (such as hardware with edges and corners, special-shaped packaging boxes), the packaging effect is unsatisfactory.

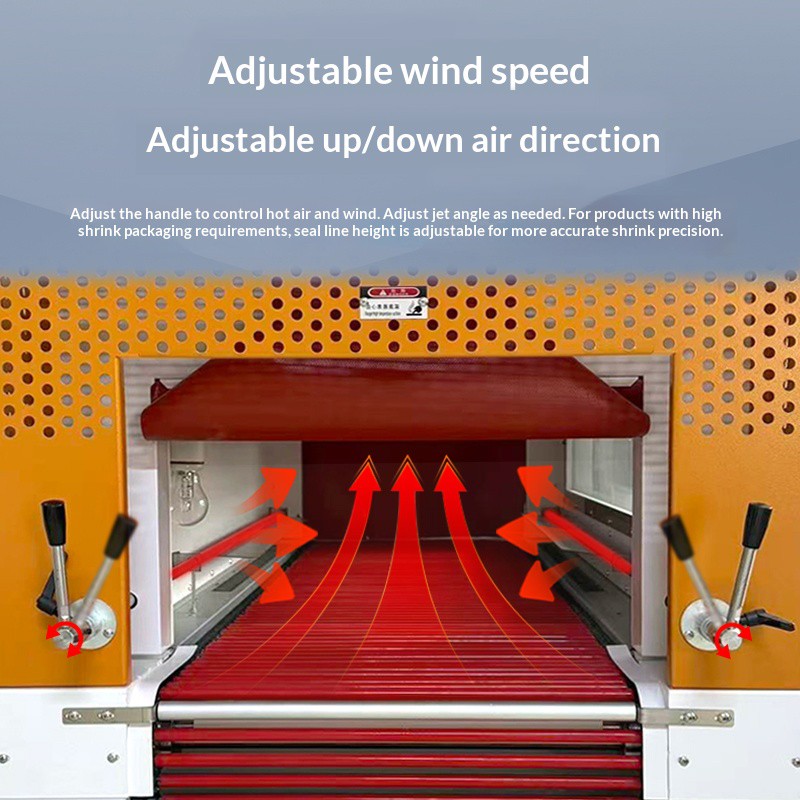

Dual-frequency conversion heat shrink wrapping machine: The rotation speed of the hot air motor can be precisely adjusted through the frequency converter to control the air volume and the uniformity of air velocity. Combined with the temperature control system, it ensures a more stable temperature field and air field inside the shrinking furnace. The film is subjected to uniform force during shrinkage, resulting in flat and smooth finished product surfaces without wrinkles or scald marks. Even irregular products can achieve tight adhesion, greatly improving packaging aesthetics and yield rate.

Additional Features

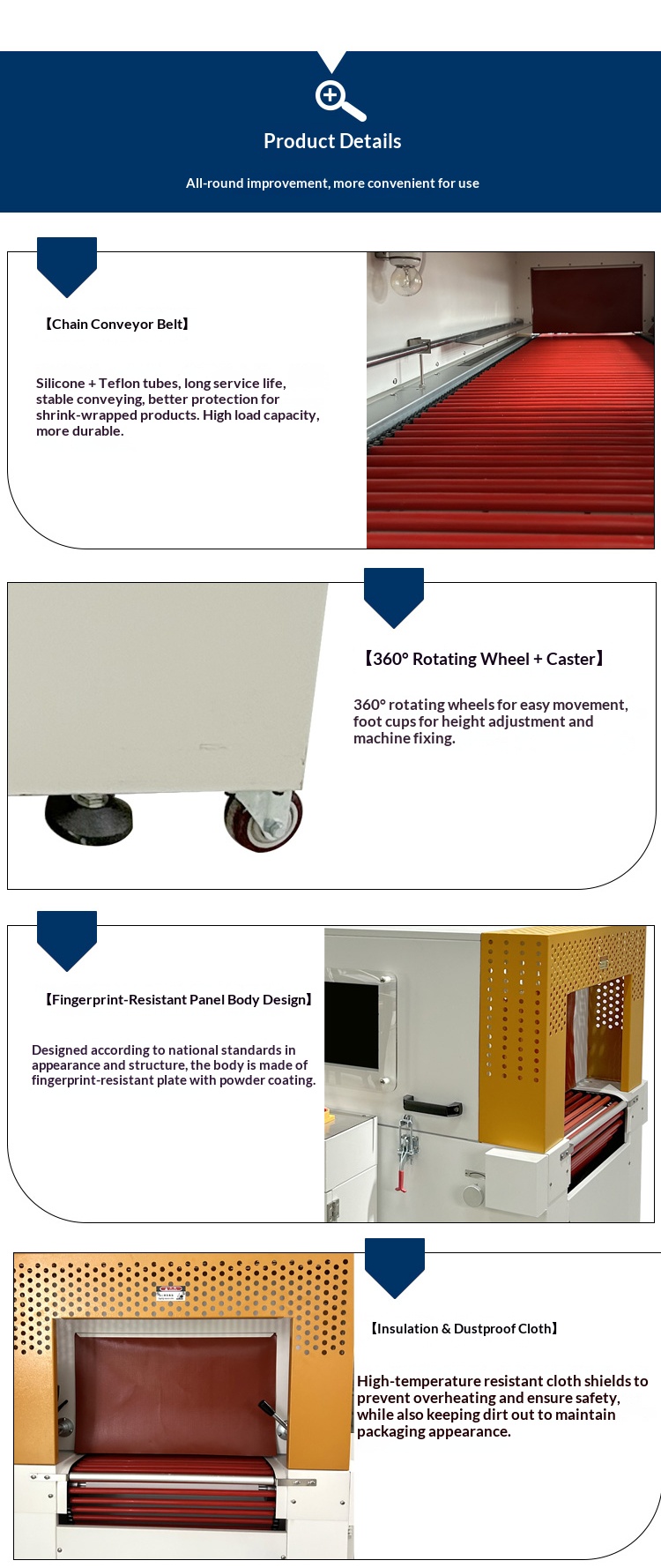

- Dual-frequency conversion control: Adopting two frequency converters, it enables stepless adjustment of conveying speed and air motor power separately. With stable speed regulation performance, it can better meet the requirements of different products and packaging films, achieving an ideal packaging effect.

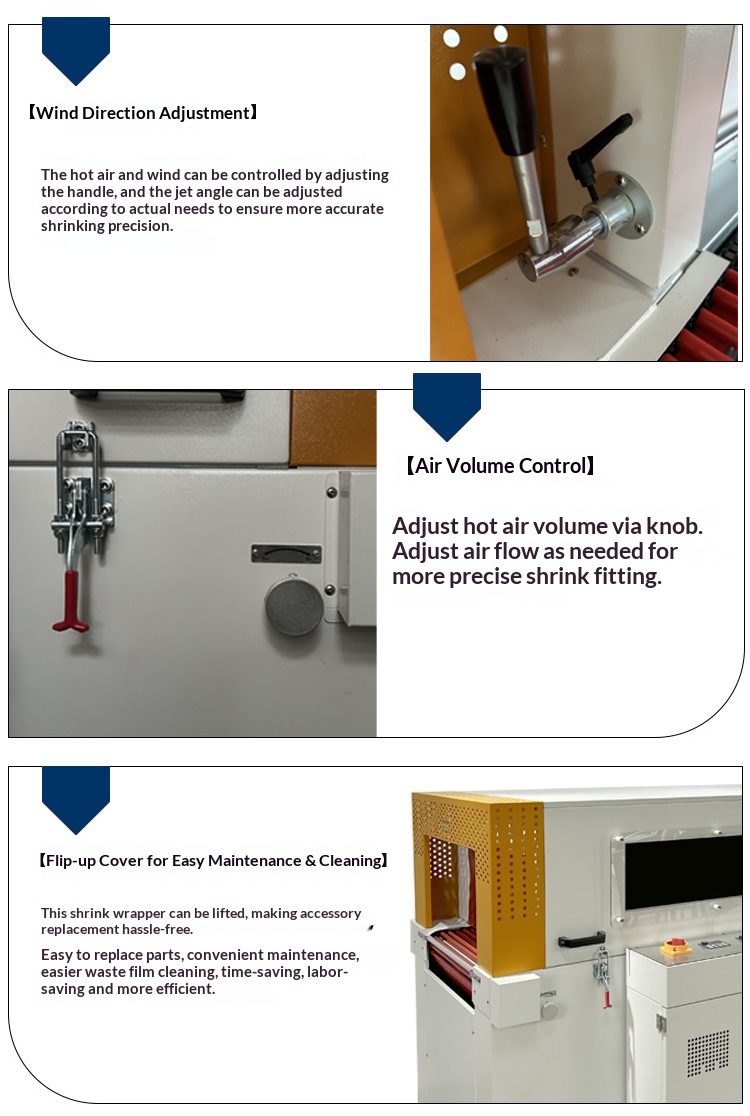

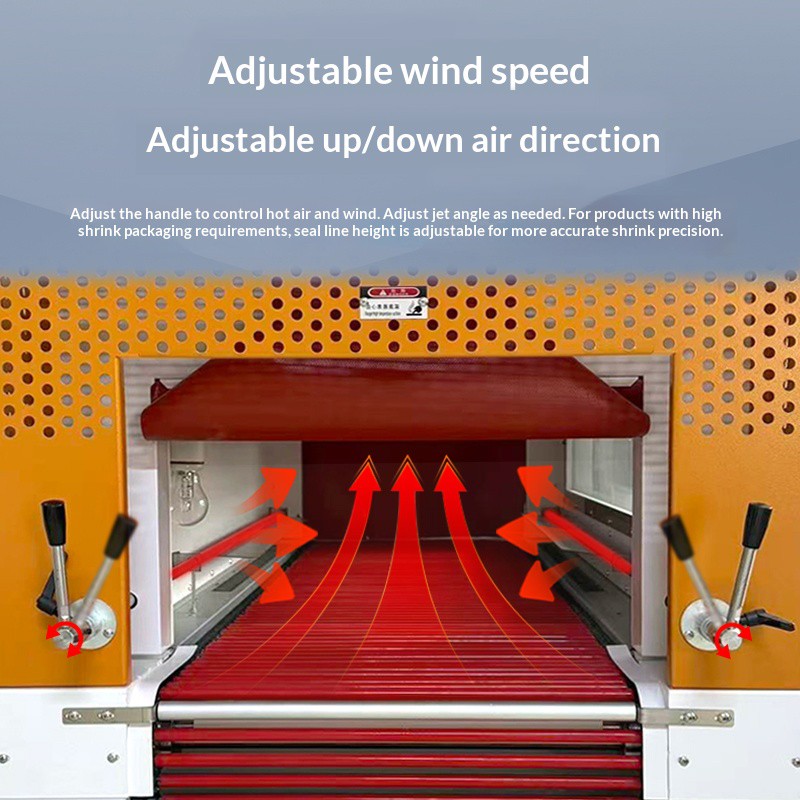

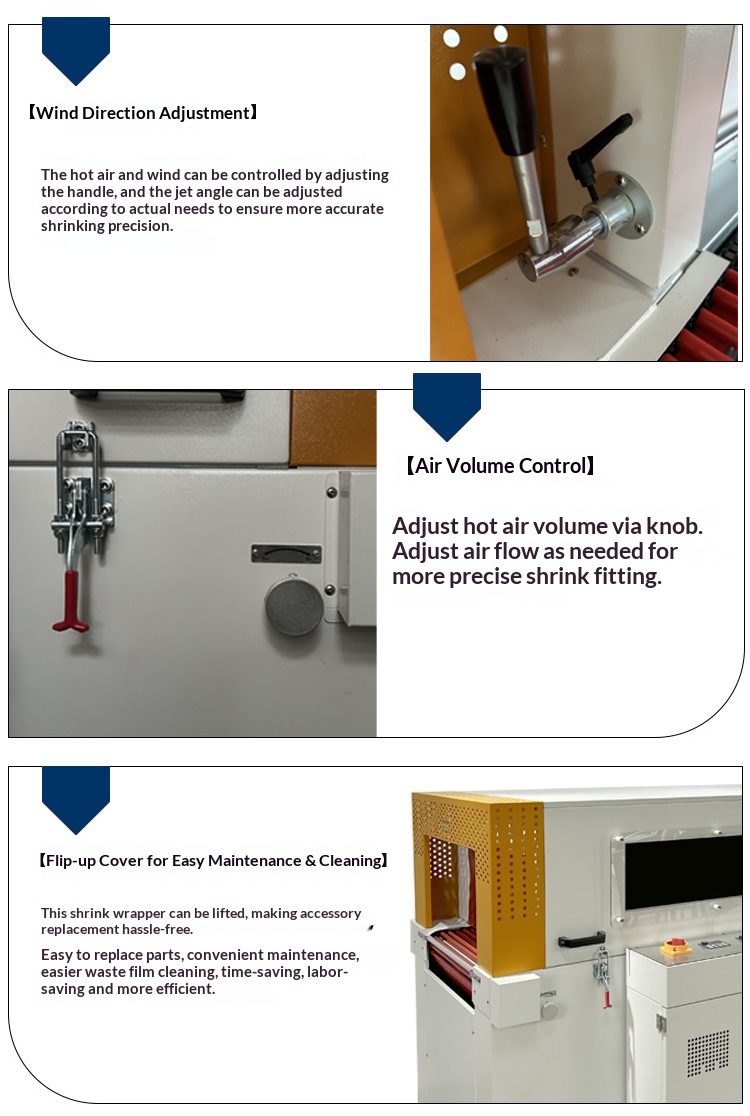

- Excellent shrinkage effect: It usually adopts the hot air circulation heating method, combined with the air duct design with adjustable air direction, to ensure uniform temperature inside the shrinking furnace. This allows the film to shrink evenly and fit tightly to the product, achieving a flat and attractive packaging effect.

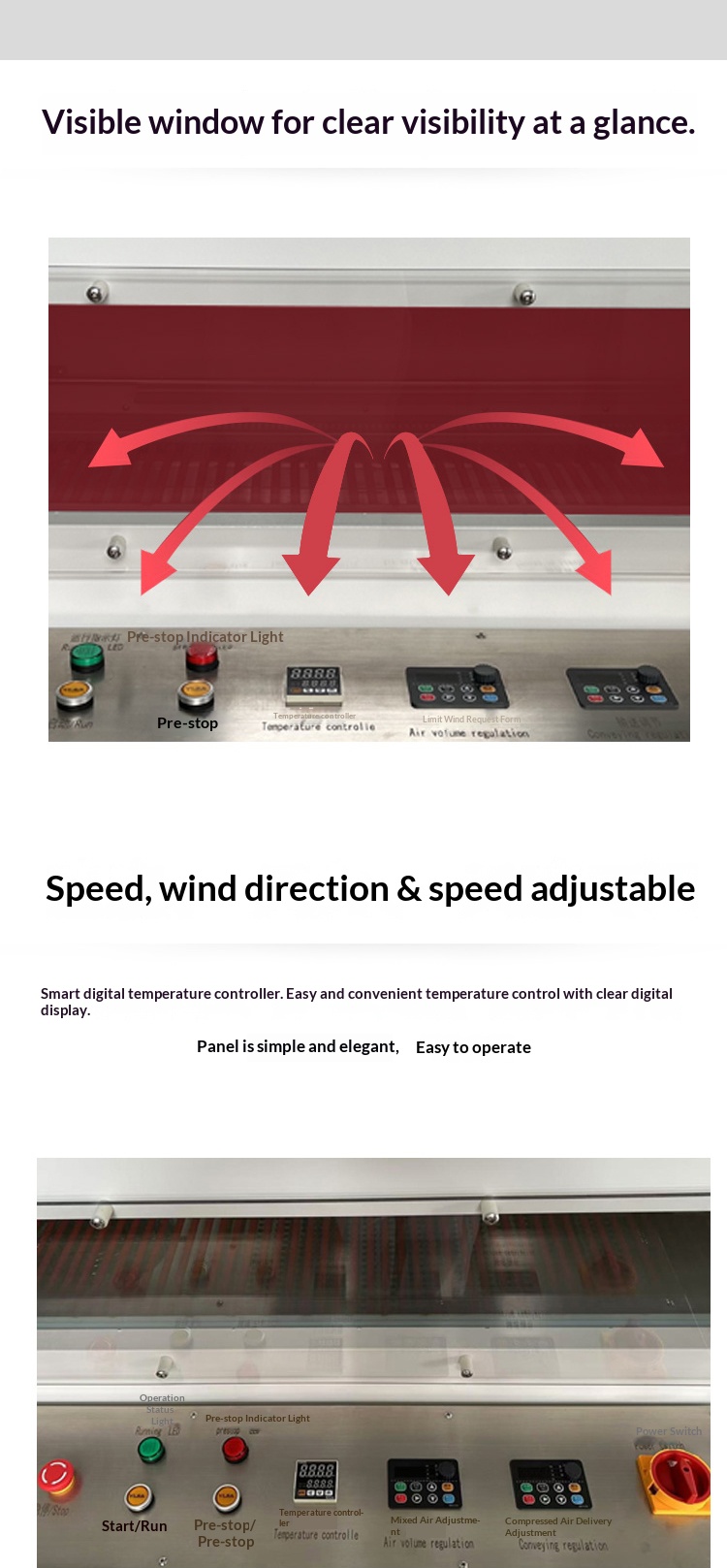

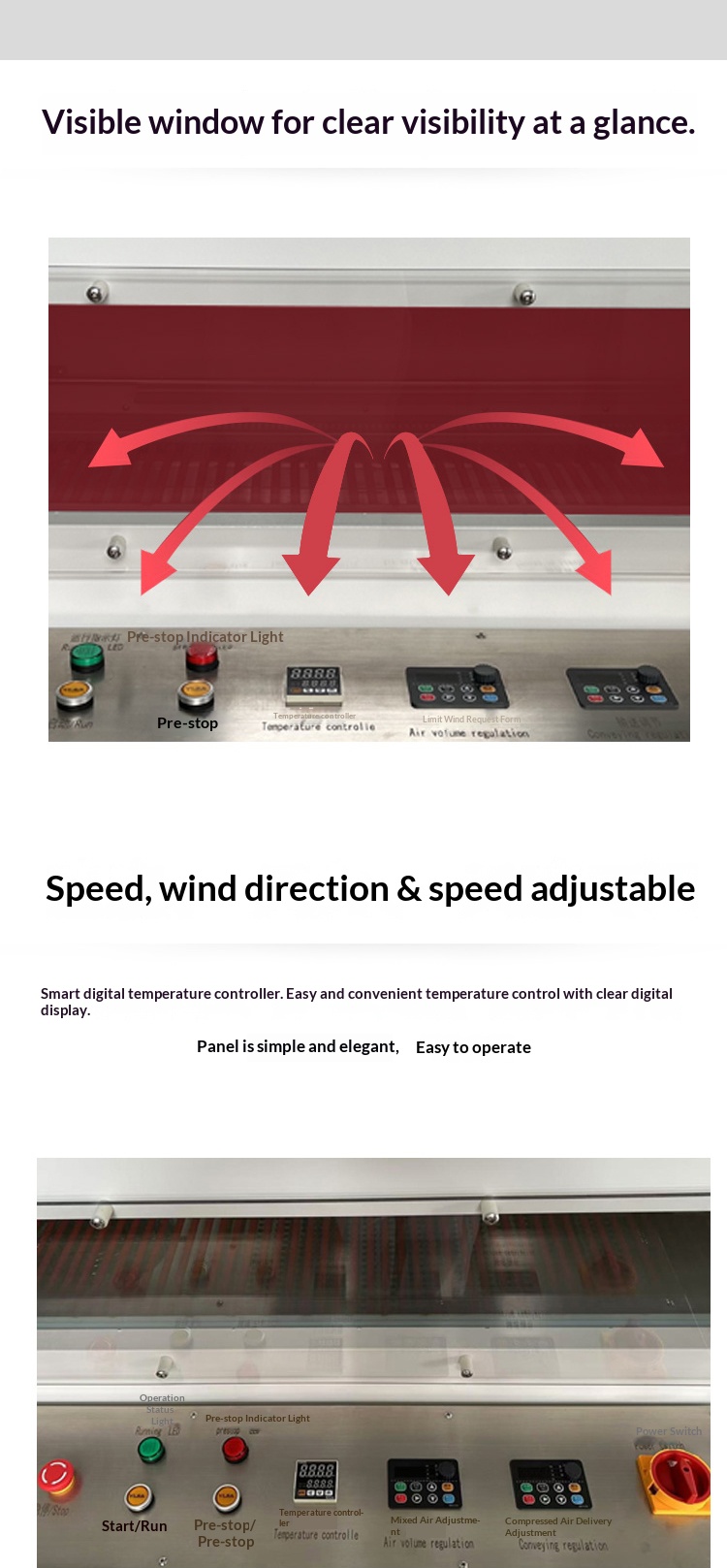

- Precise temperature control: Equipped with a high-precision temperature controller (e.g., Omron digital display temperature controller), it features controllable temperature with direct display of shrinkage temperature and high temperature control accuracy. It can effectively avoid packaging defects caused by excessively high or low temperature.

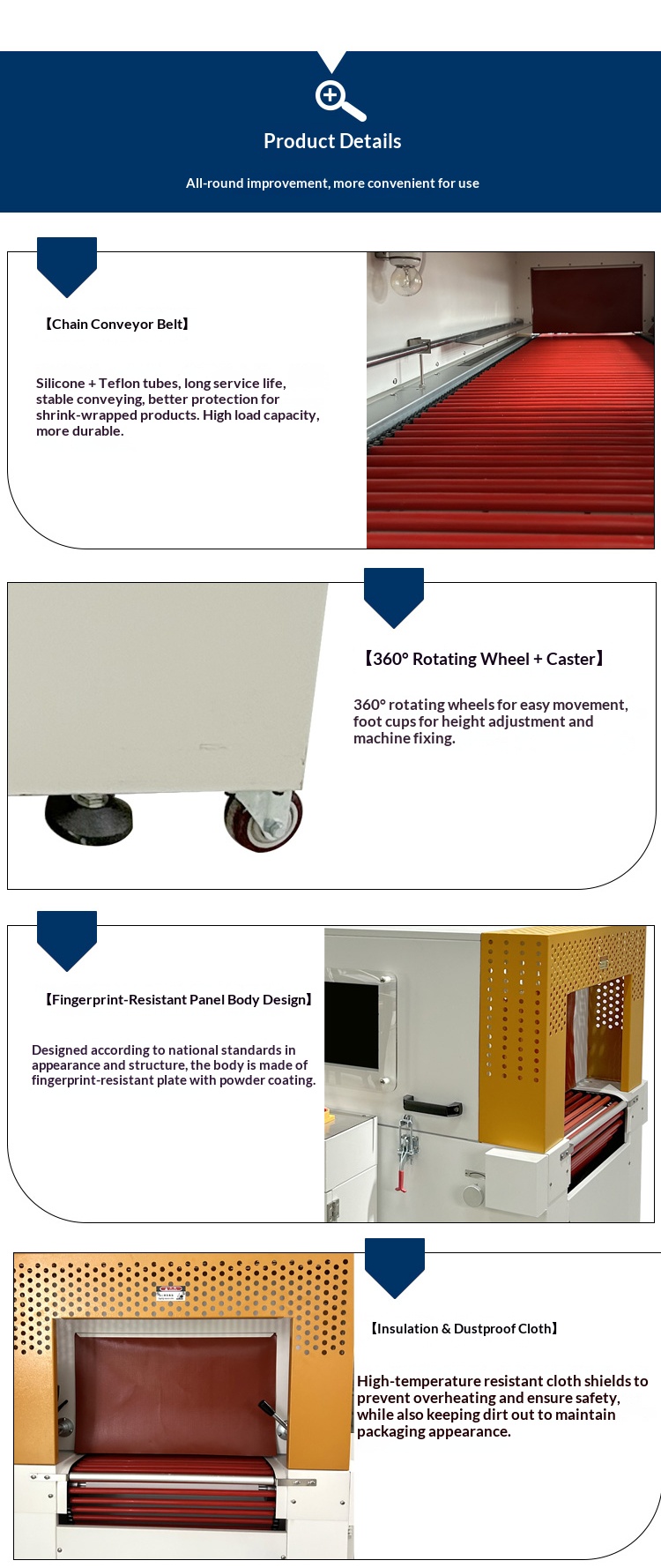

- Stable conveying system: The conveying system adopts new-type rollers covered with imported fiber sleeves or high-temperature resistant silicone tubes, which have the characteristics of high temperature resistance, wear resistance, no film scalding and no deformation for long-term use. In addition, the rollers can be selected to rotate or not to meet the shrinkage requirements of different products.

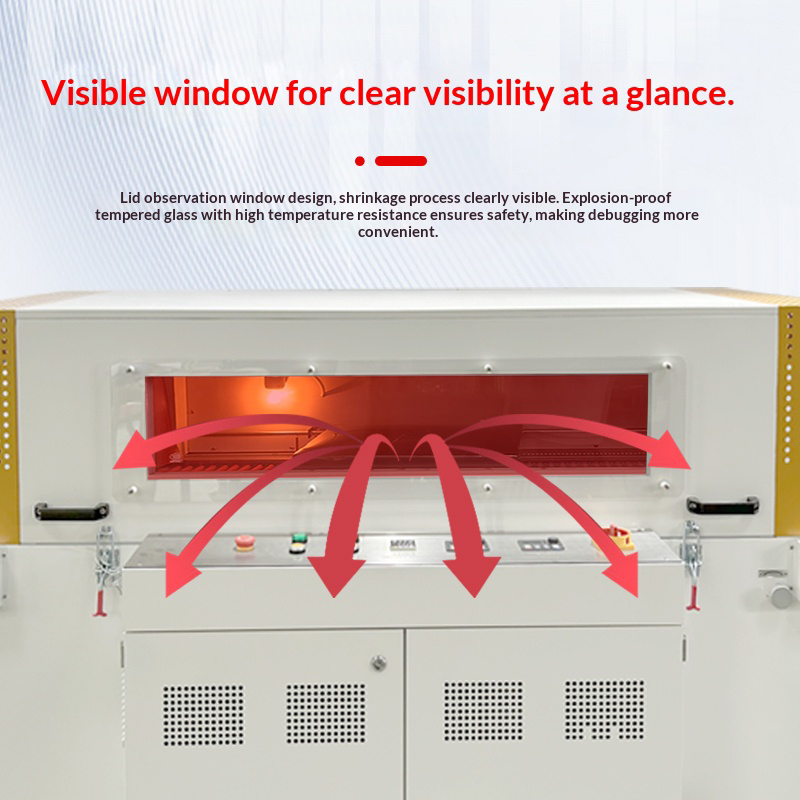

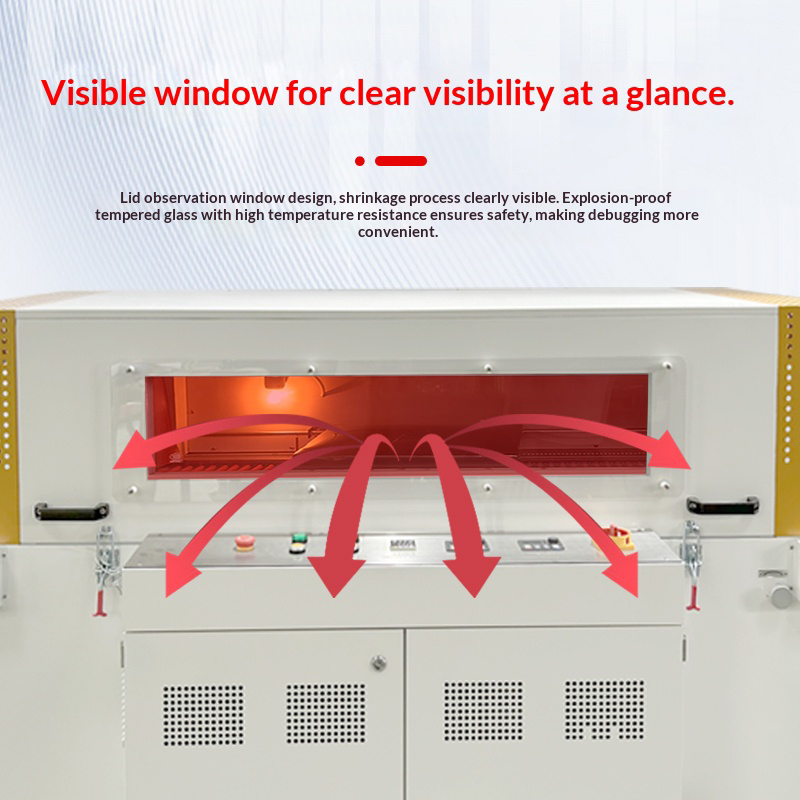

- Visual window design: The equipment is equipped with a visual window, allowing operators to clearly observe the shrinking process, facilitating timely detection and adjustment of problems during packaging to ensure packaging quality.

Application Scope

The dual-frequency conversion heat shrink wrapping machine is widely used in industries such as food, beverage, medicine, daily chemicals, electronics, electrical appliances, stationery and toys. It can package various regular or irregular items including glass bottles, cartons, toys, electronic components and daily necessities. The applicable packaging films include POF, PVC, PP, PE, etc.

Advantages Embodiment

- Speed-temperature collaborative optimization: The dual-frequency conversion system realizes collaborative optimization of conveying speed and heating temperature, which not only improves packaging efficiency, but also ensures film shrinkage quality, reduces the residence time of products in high-temperature environment and lowers the risk of product damage.

- Flexible personalized packaging settings: Thanks to the independent control of conveying speed and heating temperature, the dual-frequency conversion heat shrink wrapping machine can easily realize personalized packaging settings to meet diversified packaging needs.