A steam shrink machine is a device that uses high-temperature steam to heat and shrink packaging materials. Water is converted into high-temperature steam, which is then delivered to the shrink tunnel through pipelines. After being wrapped with heat shrink film, the product enters the shrink tunnel, where the steam is evenly sprayed onto the film surface, causing the film to shrink rapidly upon heating and cling tightly to the product surface. Once the product exits the steam zone, the film is either naturally cooled or quickly shaped by a cold air system, resulting in a tight package.

- Steam Generator: Equipped with heating elements, a water tank and a pressure control system, it can efficiently generate stable steam. Some models support automatic water replenishment.

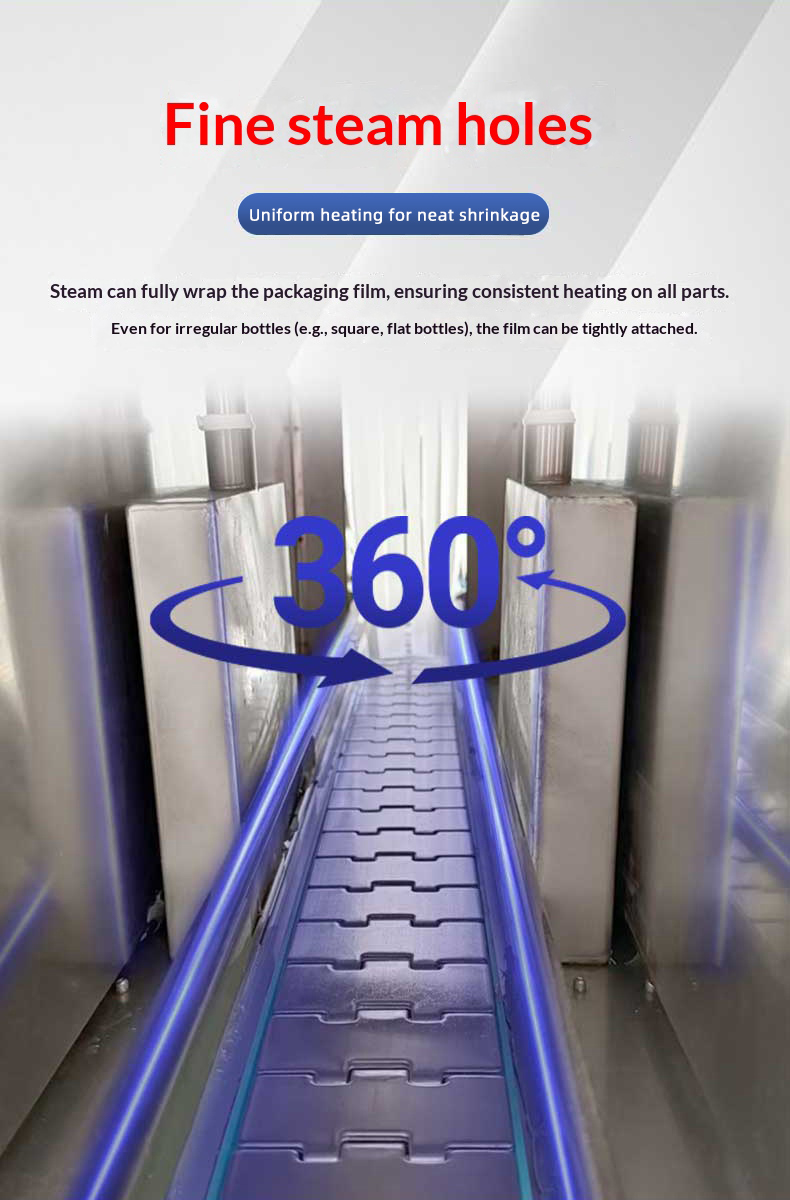

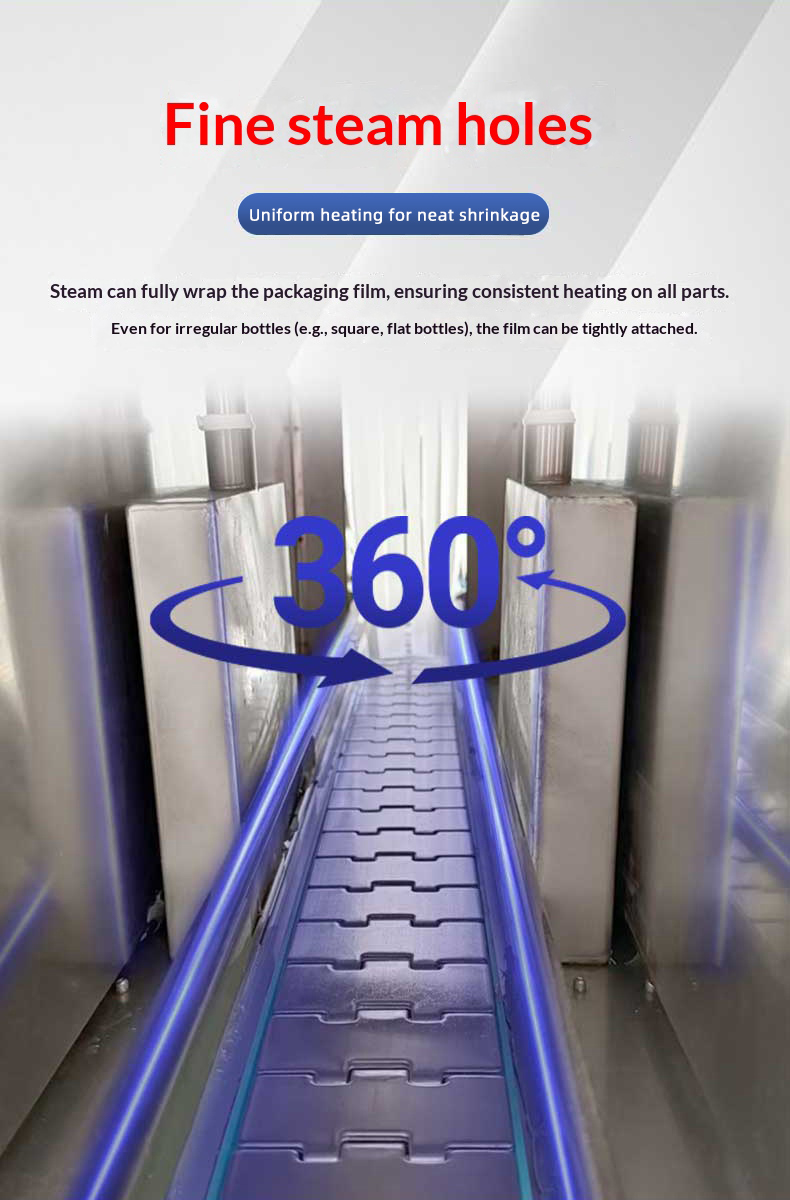

- Shrink Tunnel: Built-in with steam injection holes or nozzles, its length and width are adjustable according to product dimensions to ensure uniform steam coverage.

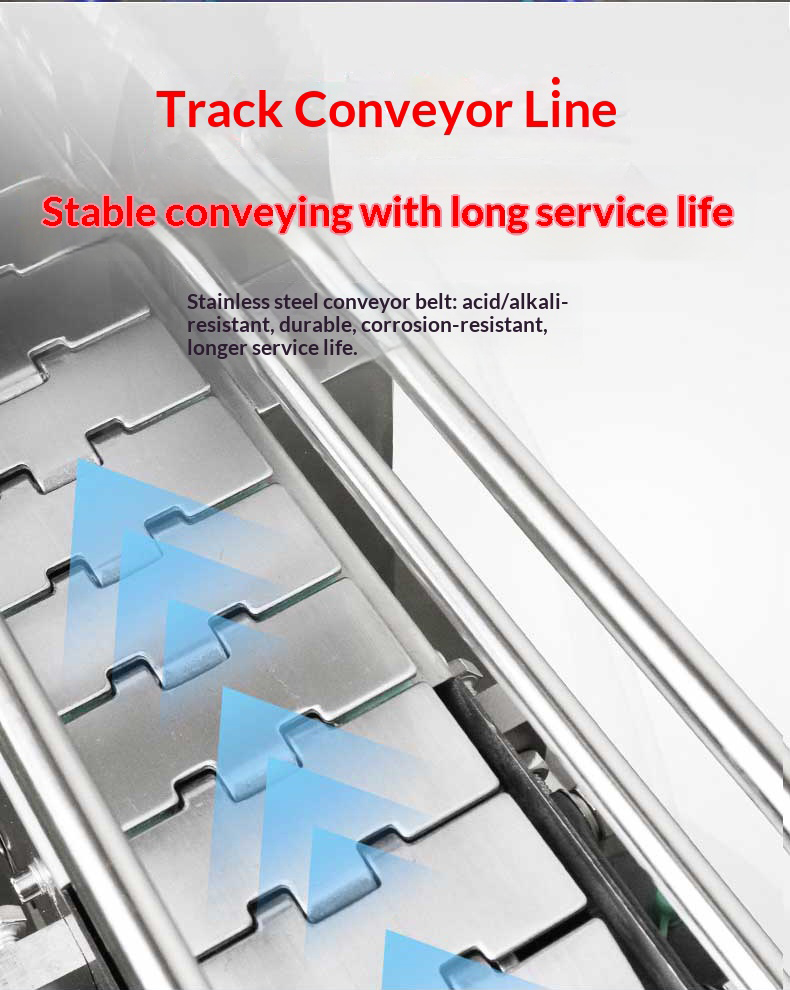

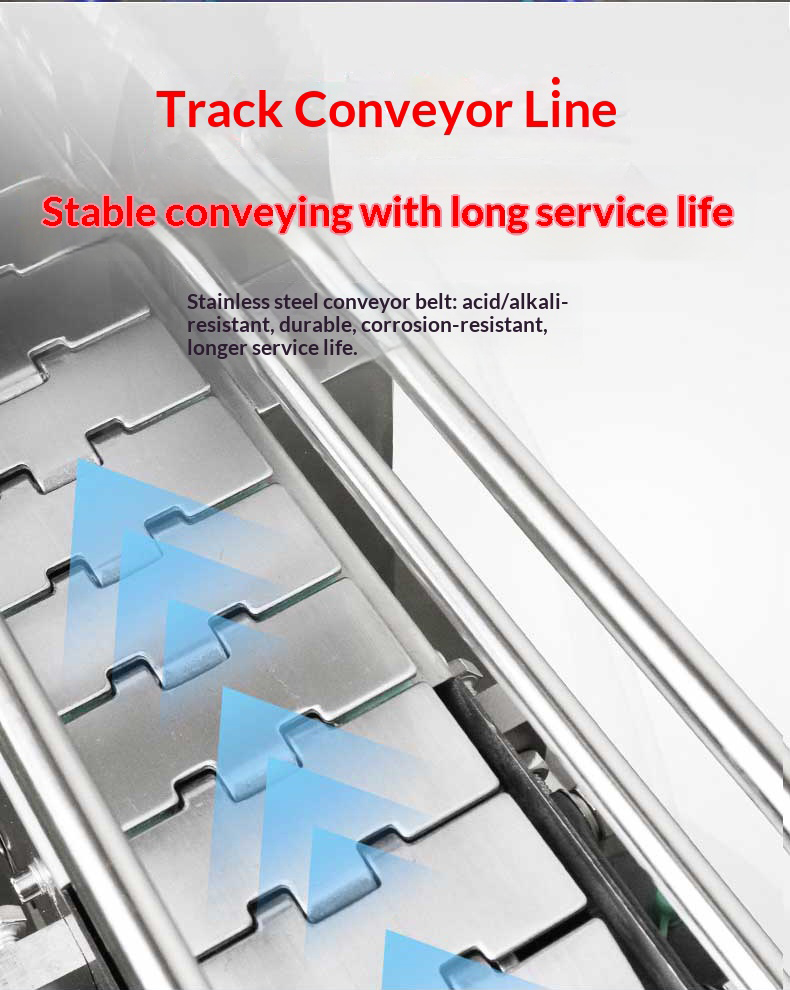

- Transmission System: Adopts mesh belts, chain plates or rollers to convey products. The speed is variable-frequency adjustable to meet different production capacity requirements.

- Control System: Integrated with PLC or touch screen, it allows setting parameters such as steam temperature, pressure and conveying speed, and supports automatic start/stop and fault alarm functions.

- High-Efficiency Shrink Effect: Excellent steam temperature uniformity ensures the packaging film is heated evenly, delivering superior shrink results. The finished products boast a neat, tight and highly conforming package appearance.

- High Shrink Efficiency: Steam enables the packaging film to shrink rapidly, significantly improving production efficiency. It is particularly suitable for large-scale packaging operations.

- Wide Applicability: Compatible with various common shrink films such as PE and PVC, it can meet the packaging needs of different industries and products.

It is widely used in the food and beverage industry for packaging bottled water, beverages, etc.; in the pharmaceutical and daily chemical industries for dust-proof packaging of boxed medicines, cosmetic sets, etc.; in the daily necessities and industrial supplies industries for packaging tissues, tools, etc.; as well as in the e-commerce logistics industry for rapid wrapping of irregularly shaped goods.

Steam enables the packaging film to shrink rapidly, significantly improving production efficiency and making it ideal for large-scale packaging operations. Compared with the traditional hot air shrink technology, steam heating has the core advantages of high heat transfer efficiency and uniform film heating.

In terms of shrink effect, hot air shrinkage is limited by the uneven flow of hot air, which tends to cause local overheating or underheating. This leads to wrinkles, bubbles on the film surface after shrinking, or loose shrinkage at the edges and corners, affecting the packaging appearance. In contrast, steam has excellent permeability and diffusibility, which can evenly wrap every part of the product and the film, ensuring synchronized and uniform heating of the film. After shrinking, the film can closely fit the product surface. Whether it is regular bottled products or irregular special-shaped parts, it can achieve a smooth and flat packaging effect, greatly reducing the defective rate.

In terms of applicable scenarios and film compatibility, hot air shrink technology is more suitable for thicker films with lower shrink requirements. With its high heat transfer efficiency and uniform shrink effect, steam shrink technology is more compatible with various common shrink films such as PE, PVC and POF. It is especially suitable for large-scale continuous production lines in the food and beverage, daily chemical and pharmaceutical industries. It can not only meet the high-capacity packaging demand, but also ensure the stability of packaging quality. Meanwhile, it has advantages in energy consumption control, conforming to the cost reduction and efficiency improvement requirements of industrial production.

In continuous production lines, the equipment can realize high-speed conveying at 20-50 meters per minute, and a single machine can complete the packaging of thousands of products per hour, easily matching the mass production needs of food and beverage, daily chemical products and other industries.