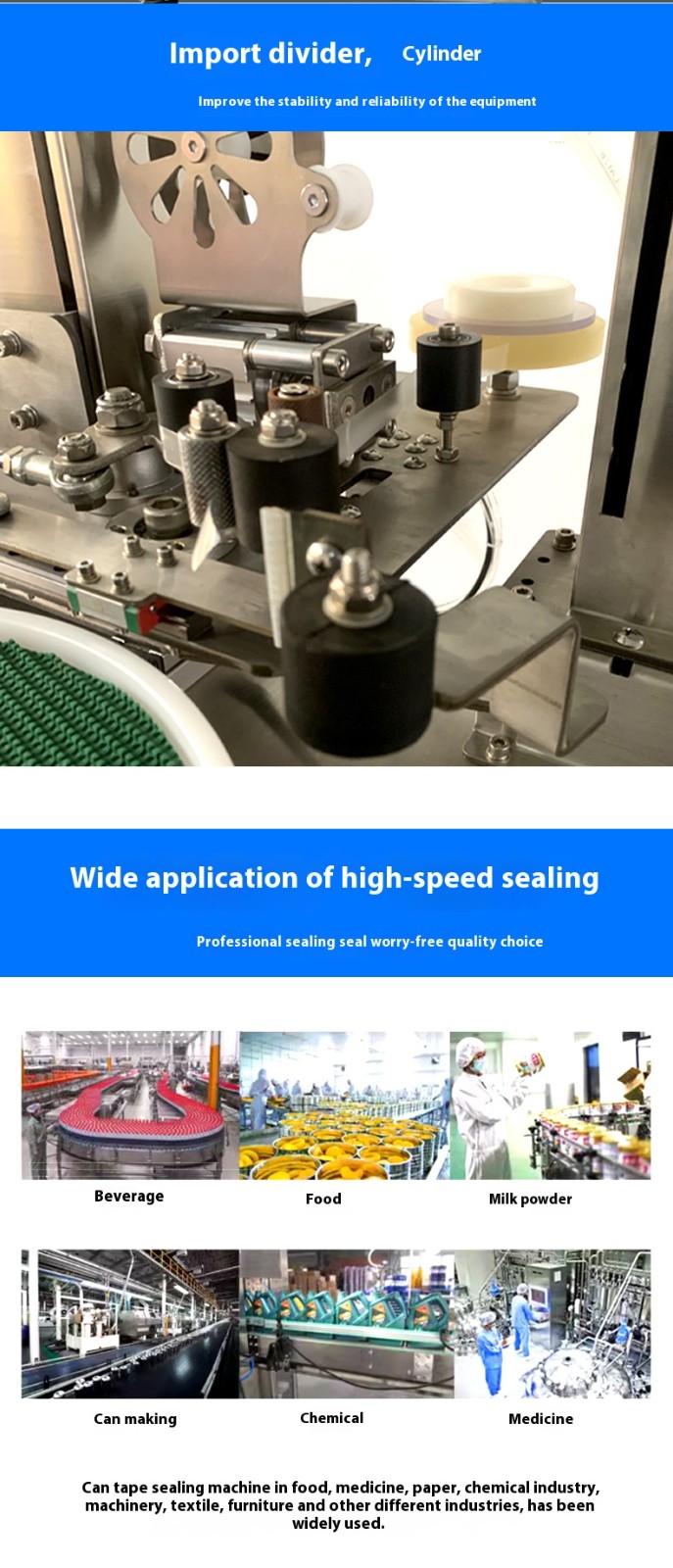

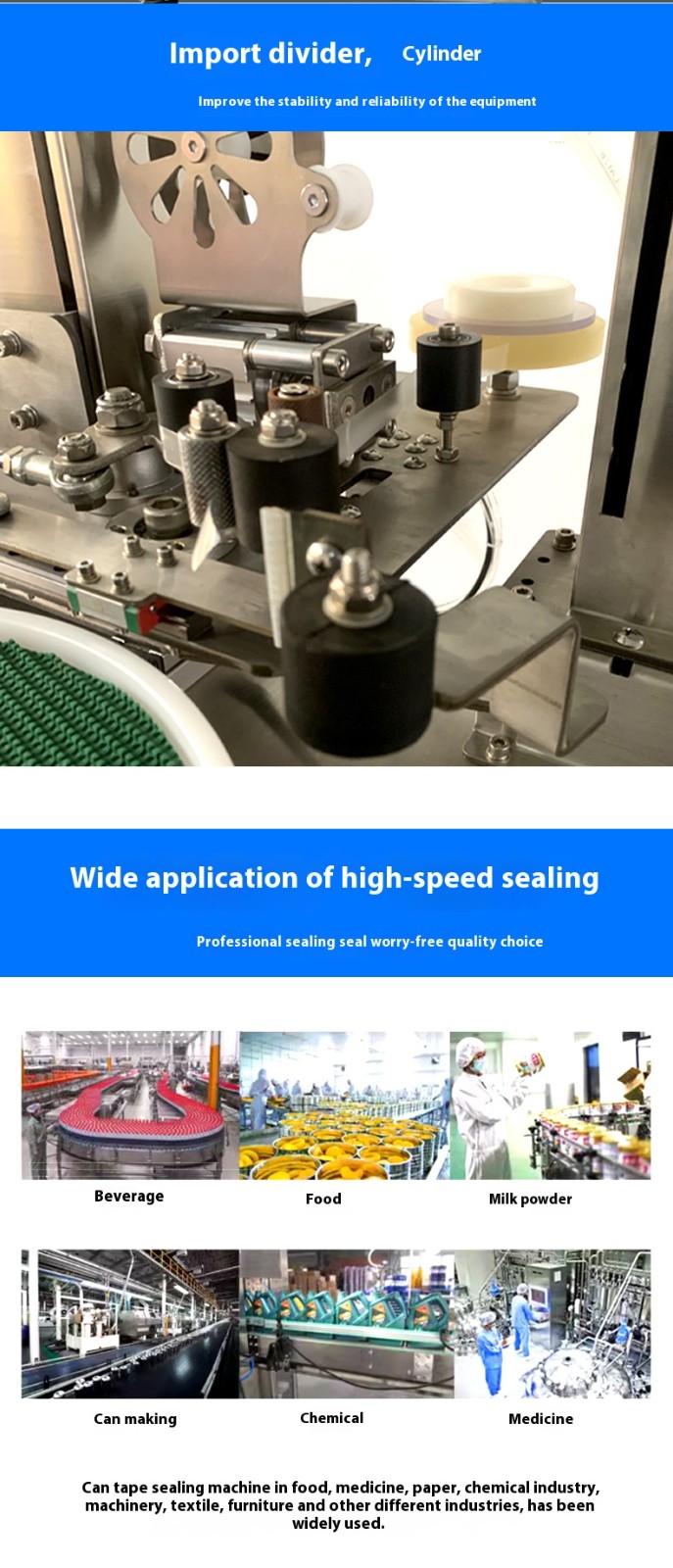

Working Principle of Automatic Can and Box Tape Wrapping Machine

Manual Positioning and LoadingThe operator places the cans and boxes to be packaged on the positioning fixture of the equipment workbench, and adjusts them via the fixture or manually to ensure the cans and boxes are centered and stable, preventing displacement during the wrapping process.

Start-up and Tape FeedingAfter pressing the start button, the equipment's power system drives the tape supply shaft to operate. The tape is conveyed to the edge of the can/box opening through guide wheels. Meanwhile, the tension controller is activated to accurately adjust the tape tension, preventing the tape from loosening, stretching or breaking.

Rotary Wrapping and LaminationThe turntable motor under the workbench drives the cans and boxes to rotate at a constant speed. The initial end of the tape is pre-laminated on the surface of the cans and boxes, realizing annular wrapping with the rotation of the cans and boxes. The number of wrapping turns can be preset through the control system to meet different sealing requirements.

Rolling and ReinforcementDuring the wrapping process, the pressing roller device rolls closely against the surface of the cans and boxes, compressing the tape tightly onto the outer wall of the cans and boxes, eliminating air bubbles, and enhancing the tape's adhesion and sealing effect.

Automatic Cutting and FinishingWhen the preset number of wrapping turns is reached, the cutter device automatically cuts the tape. At the same time, the finishing pressing roller compresses and fixes the end of the tape to prevent loosening.

Manual UnloadingAfter wrapping is completed, the equipment stops, and the operator removes the packaged cans and boxes to start the next cycle.

Efficiency Improvement

The sealing speed is 3–5 times faster than manual operation, greatly improving production efficiency.

The equipment adopts a motor-driven + intelligent transmission structure, completely breaking away from the speed limit of manual packaging and achieving high-speed and stable sealing operations. The sealing speed of semi-automatic models can reach 10–15 pieces per minute, while fully automatic models can even reach 20–30 pieces per minute. Compared with the manual packaging speed of 3–5 pieces per minute, the efficiency is directly increased by 3–5 times. Meanwhile, the equipment supports 24-hour continuous operation without rest and is not affected by operator fatigue, making it easy to meet the centralized production needs of large-batch orders. It effectively breaks through the bottleneck of manual production capacity and helps enterprises significantly increase the total daily output and shorten the order delivery cycle.

Stable Quality

The tape is wrapped evenly with consistent sealing effect, avoiding individual differences caused by manual operation.

Manual packaging is susceptible to operator proficiency and sense of responsibility, leading to problems such as inconsistent tape tightness, uneven overlapping, and skewed sealing. In contrast, the can and box tape wrapping machine relies on precision PLC control + constant tension system, which allows presetting the number of wrapping turns, tape tension and lamination pressure, ensuring consistent tape wrapping trajectory and moderate tightness for each can and box. Equipped with an elastic pressing roller device, it can closely attach the tape to the surface of cans and boxes, eliminating air bubbles and wrinkles to achieve standardized sealing effect. It can accurately meet the moisture-proof requirements of the food industry and the sealing compliance requirements of the pharmaceutical industry, greatly reducing the rework and rejection rates caused by unqualified packaging, and improving the consistency of product ex-factory quality.

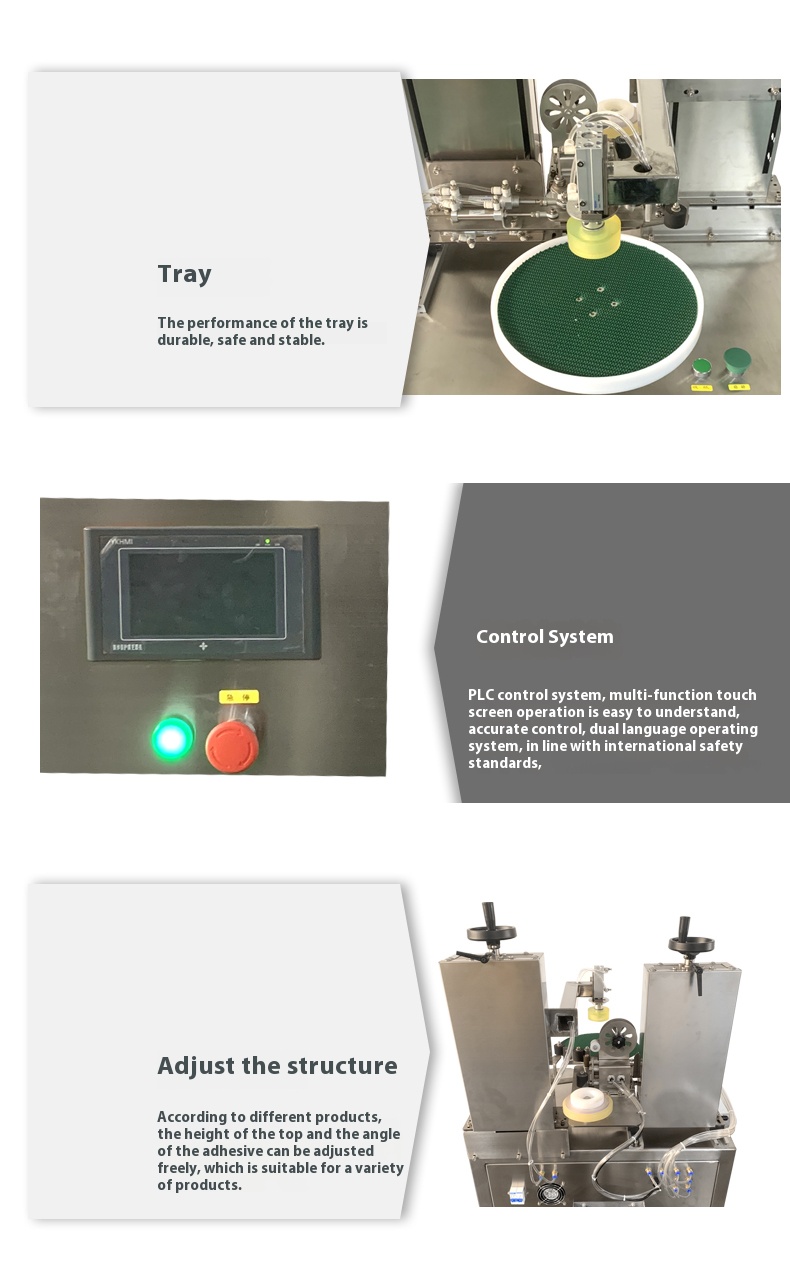

Easy Operation

It adopts touch screen control with intuitive parameter adjustment, enabling operators to take up their posts after simple training.

The equipment is equipped with a high-definition touch screen human-machine interface, which converts complex mechanical operations into visual parameter settings that can be mastered without professional programming knowledge. For cans and boxes of different specifications, users only need to input parameters such as diameter and height on the screen, or directly retrieve pre-stored parameter templates to quickly switch production modes. Core operations such as start, pause and emergency stop are all one-button designed with simple and easy-to-understand processes. Operators can work independently after half a day of simple training, greatly lowering the enterprise's employment threshold and training costs, and is especially suitable for production scenarios with high personnel turnover rates.

Strong Adaptability

It can be adapted to cans and boxes of different materials (tin cans, cartons, plastic boxes) and different shapes.

The equipment adopts modular design + adjustable fixtures, with strong compatibility. It can be easily adapted to cans and boxes made of various materials such as tin cans, cartons and plastic boxes, and also supports the sealing of containers of different shapes including round, square, polygonal and special-shaped ones. For cans and boxes of different specifications, production changeover can be completed only by replacing special positioning fixtures or adjusting the running path of the mechanical arm. The whole process does not require complex tools and can be finished within 10 minutes, perfectly adapting to the flexible production needs of multi-variety and small-batch production. It helps enterprises flexibly respond to changes in market orders and avoid production capacity waste caused by insufficient equipment compatibility.

Cost Saving

It reduces tape waste, lowers labor costs and improves overall packaging efficiency.

The equipment achieves cost reduction and efficiency improvement for enterprises from two core cost dimensions: labor and consumables.

- Labor Cost Saving: 1 semi-automatic model can replace 2–3 packaging workers, and 1 fully automatic model can replace 4–6 workers. Calculated based on the per capita monthly salary and social security costs, a single equipment can save tens of thousands to hundreds of thousands of yuan in labor expenses every year, with significant long-term cost reduction effects.

- Consumable Cost Saving: Through precise tension control and wrapping path planning, the equipment strictly controls the tape overlap rate at 5%–10%. Compared with the 20%–30% overlap rate of manual packaging, it can save 15%–20% of tape consumables.

- Hidden Cost Saving: Standardized packaging reduces the rejection rate and rework rate, cutting down material loss and working hour waste caused by packaging defects, and further improving the overall packaging efficiency of enterprises.