The main performance characteristics of automatic carton opening and bottom sealing machines can be analyzed in detail from core dimensions such as efficiency, precision, adaptability, operational experience, safety, stability, maintenance cost, and intelligence:

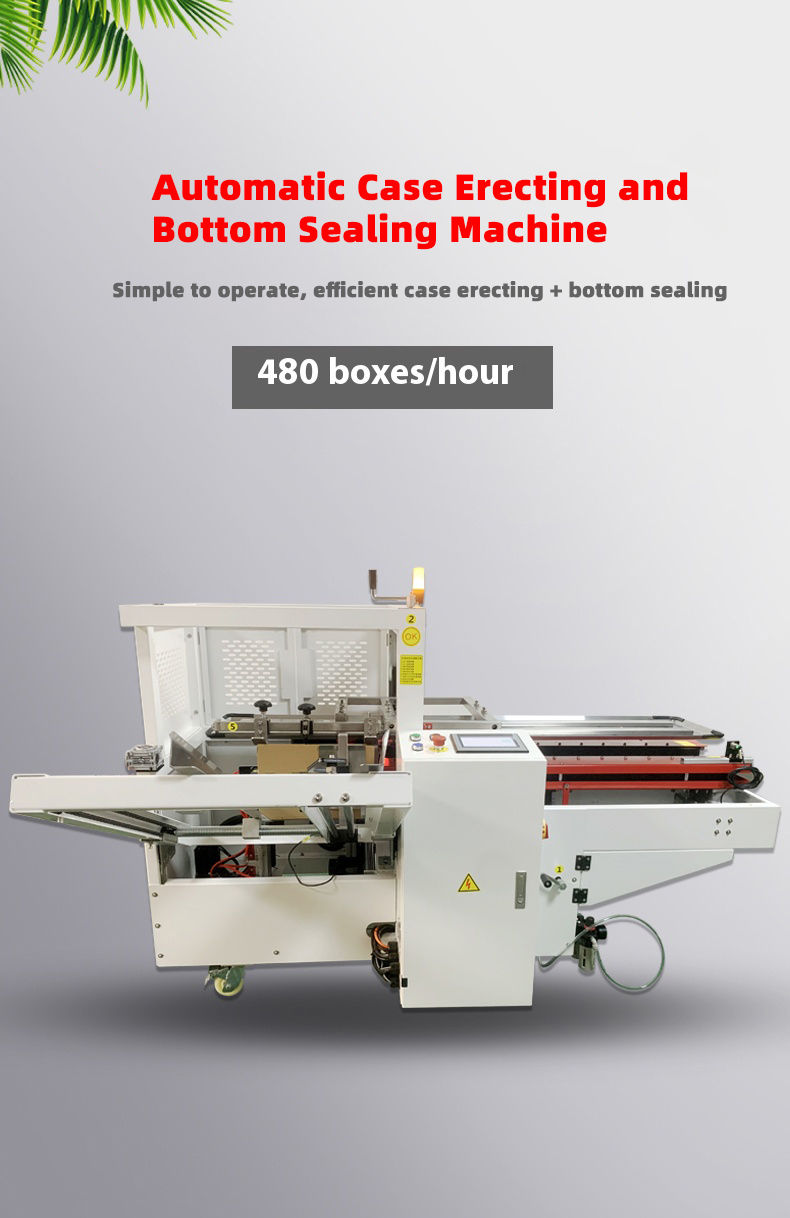

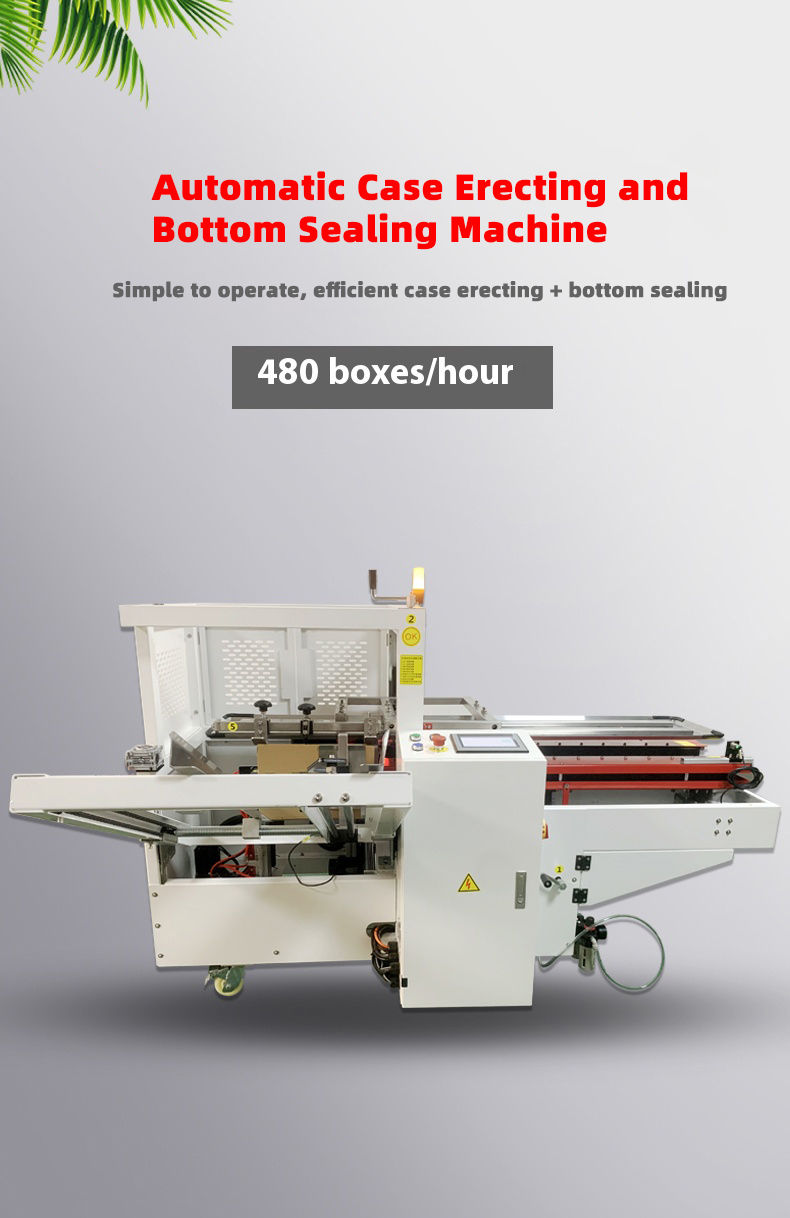

- Completes 15–30 cartons per minute of opening and sealing operations (specific to carton specifications and equipment models), enhancing efficiency by 3–5 times compared to manual labor and significantly shortening production line cycles.

- Supports continuous operation, enabling 24-hour uninterrupted production when integrated with assembly lines, meeting the high-throughput demands of industries such as e-commerce, food, and beverages.

- Full-process automation without manual intervention: seamlessly completes carton picking → shaping → flap folding → bottom sealing, reducing time loss from manual handling and adjustment.

- Utilizes a servo motor + precision guide rail transmission system with positioning errors ≤ ±1mm, ensuring cartons are vertically shaped with four corners and flat, offset-free bottom seals.

- Modular design: carton-opening suction cups and flap-folding claws are customized for carton dimensions, precisely matching crease lines to avoid incomplete folding or excessive compression damage.

- Tape adhesion or hot-melt adhesive coating position error ≤ ±2mm, with uniform glue application and sealing firmness exceeding 99%, effectively preventing carton cracking during transportation.

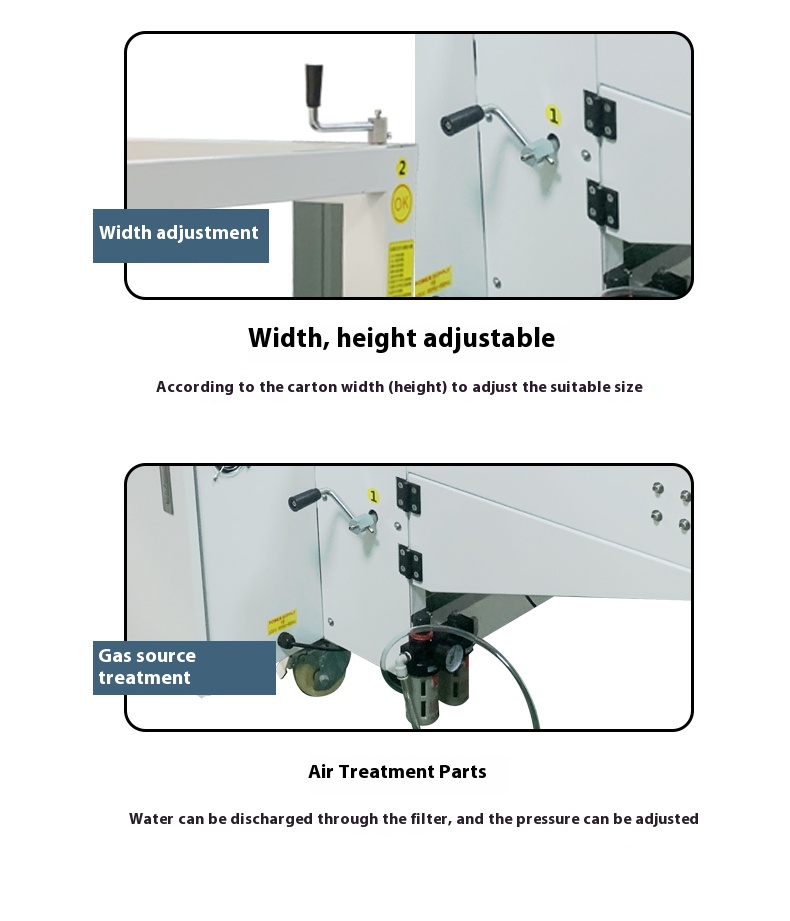

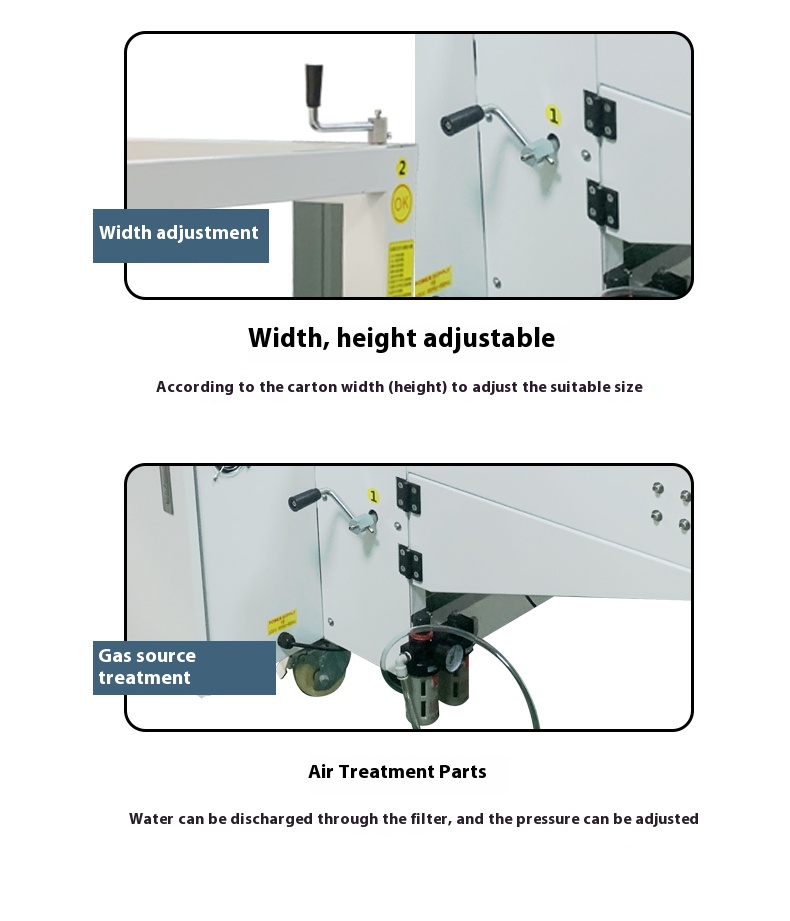

- Wide carton size range: length 150–600mm, width 100–500mm, height 100–400mm (customizable for different models). Quick specification changes (10–15 minutes) via fast-change mechanisms (e.g., adjustable guide rails, modular molds).

- Compatible with 3-ply/5-ply corrugated cartons and special materials (e.g., moisture-proof, heavy-duty cartons). Pressure sensors automatically adjust folding force to avoid crushing thin cartons or unclear creases on thick cartons.

- Food industry: Meets hygiene standards with 304 stainless steel + food-grade silicone contact components to prevent contamination.

- Electronics industry: Equipped with static elimination devices to avoid electrostatic damage to precision components.

- Logistics industry: Supports rapid bottom sealing of large cartons, integrated with weighing sensors for "packaging–weighing–sealing" linkage.

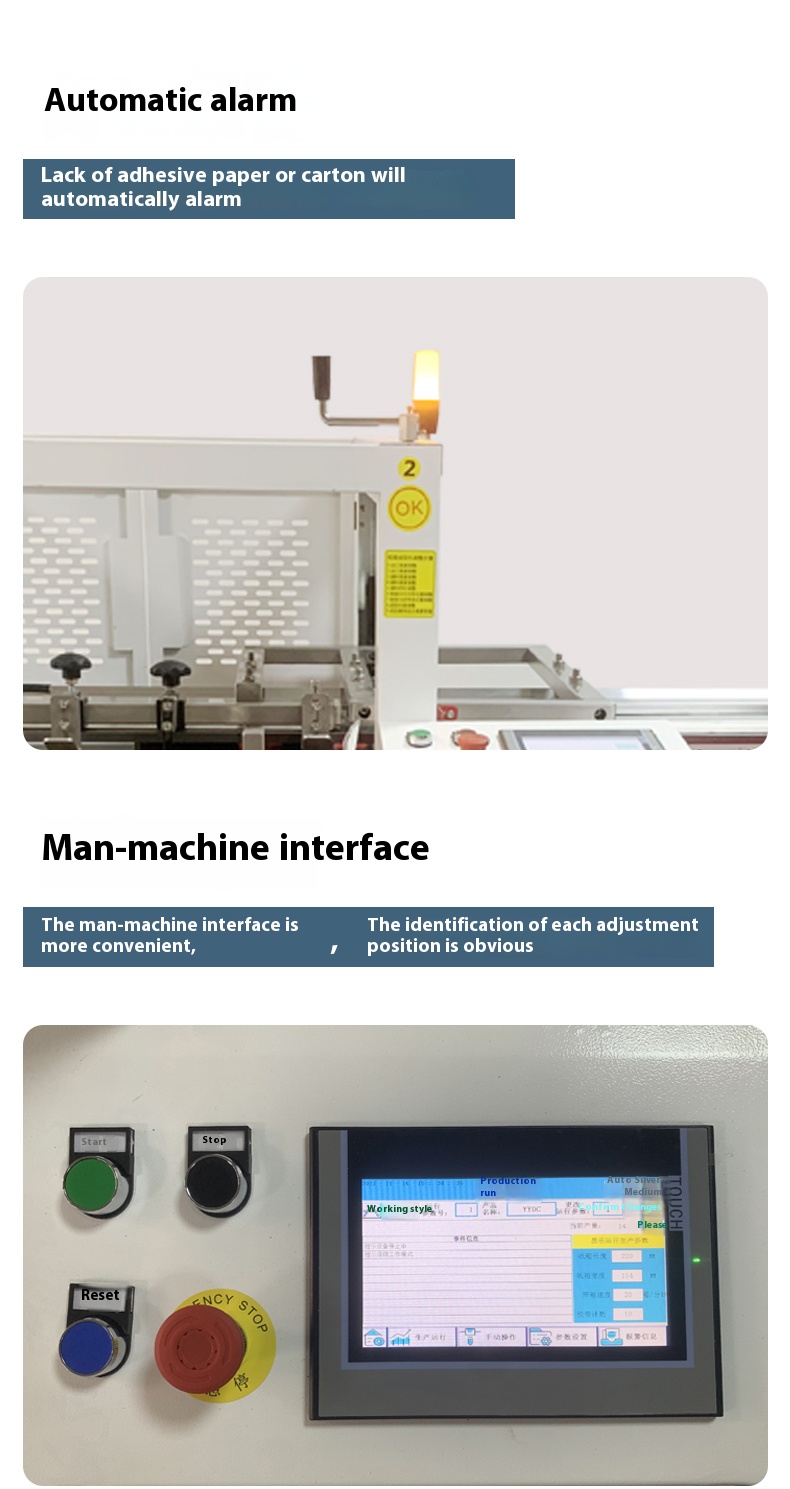

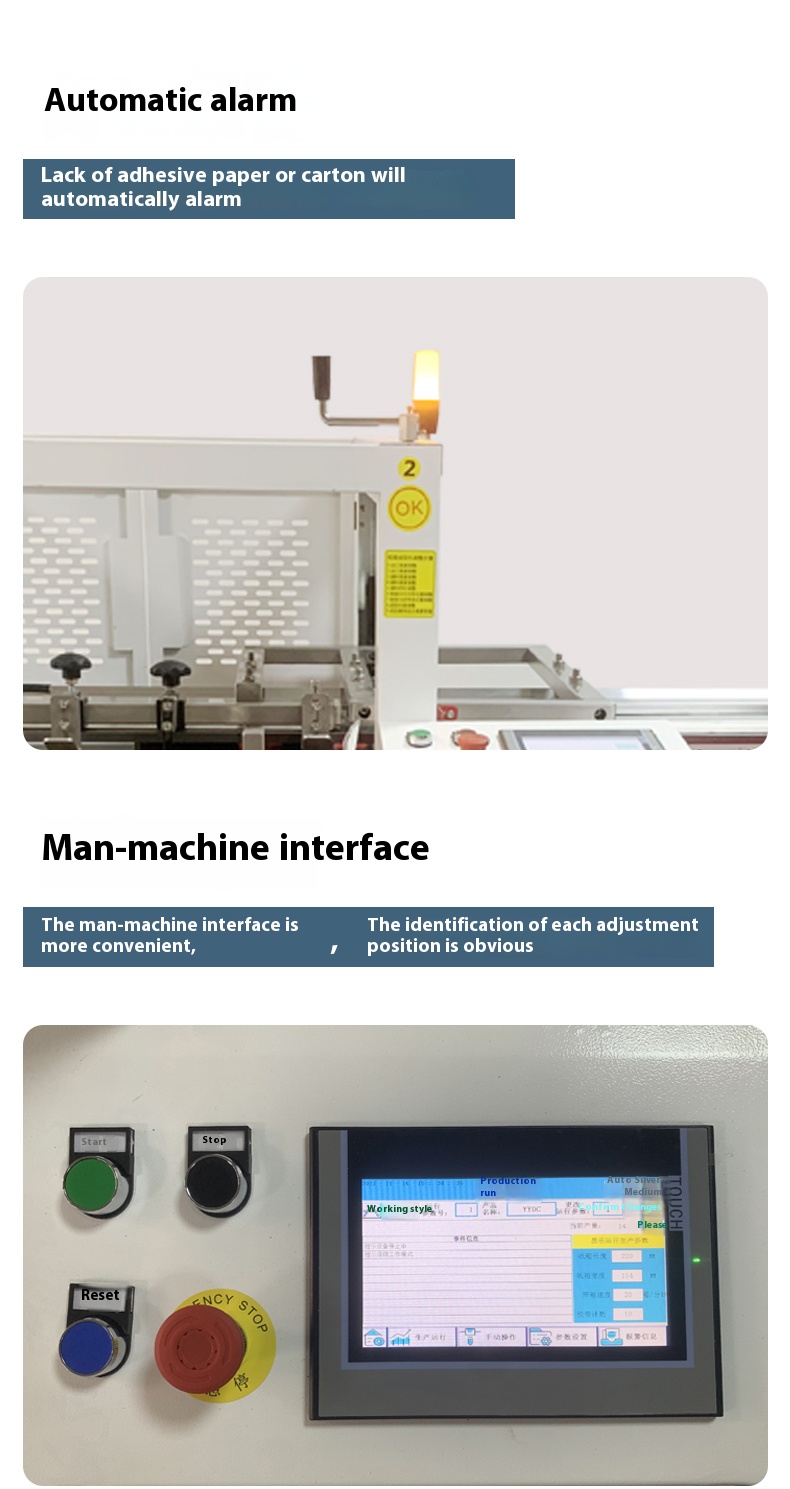

- Features a color touchscreen HMI supporting multi-language switching (Chinese/English, etc.). The interface intuitively displays real-time data such as equipment status, fault codes, and production counts.

- Convenient parameter setting: stores 50+ specification parameters, automatically matching mold positions and suction cup strokes when recalled to reduce manual debugging time.

- Requires no professional technicians; ordinary workers can operate independently after 30 minutes of training, reducing labor costs.

- Full-machine protective fencing + safety door locks: automatically lock during operation, with immediate shutdown and alarm if opened forcefully.

- Moving parts (e.g., gears, conveyor belts) are equipped with anti-pinch guards to reduce accidental contact risks.

- Material shortage alarm: automatically stops and alerts when carton storage is below set levels.

- Overload protection: triggers power-off protection when motor current exceeds rated values to prevent equipment jamming.

- Fault self-diagnosis: PLC system monitors component data in real time, stopping operation and displaying fault codes for anomalies (e.g., low air pressure, sensor misalignment), guiding maintenance.

- Core components from international brands: e.g., Panasonic (Japan) servo motors, FESTO (Germany) pneumatic components, HIWIN (Taiwan) guide rails, ensuring smooth long-term operation with failure rates < 0.5 times/1,000 hours.

- Machine frame made of thickened steel plates + welding technology, stress-relieved via aging treatment, with a load capacity exceeding 500kg and excellent vibration/impact resistance.

- Automatic lubrication systems at key points (e.g., guide rails, bearings) reduce manual maintenance frequency.

- Quick-release designs for wear parts (e.g., suction cups, tape cutters) enable replacement in ≤5 minutes, lowering maintenance costs by 30% compared to similar equipment.

- Supports OPC UA/MODBUS protocols for integration with factory MES systems, real-time uploading of production data (e.g., output, yield, fault records) for remote monitoring and scheduling.

- Optional vision inspection systems: real-time photo detection of sealing quality (e.g., tape offset, insufficient glue) with automatic rejection of defective products.

- Integration with robot packaging linkage: connects with robotic arms for fully unmanned "carton opening–packaging–sealing" workflows.