The sealing effect of the can and box tape sealing machine is mainly reflected in seal tightness, firmness, aesthetics, and stability, with its performance closely related to equipment capabilities, parameter settings, and operation maintenance. The specific analysis is as follows:

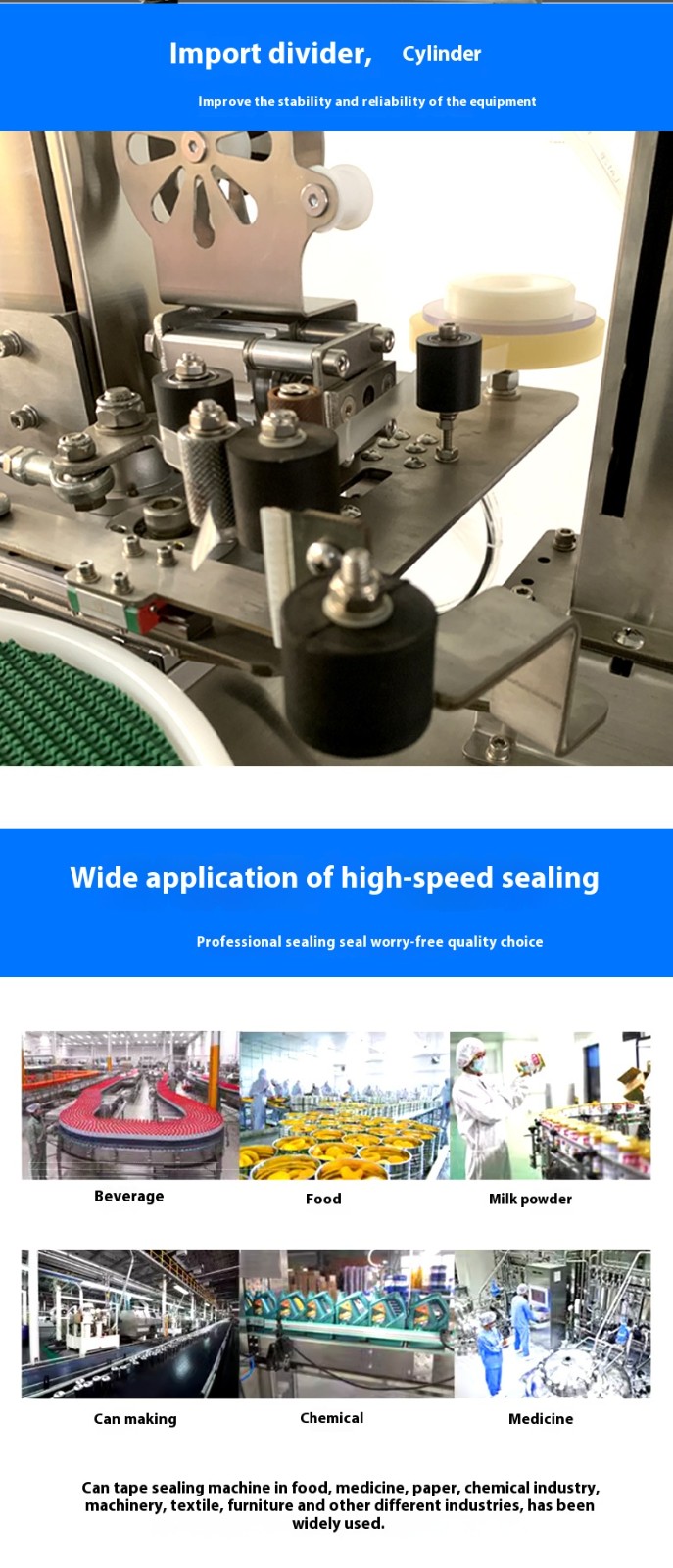

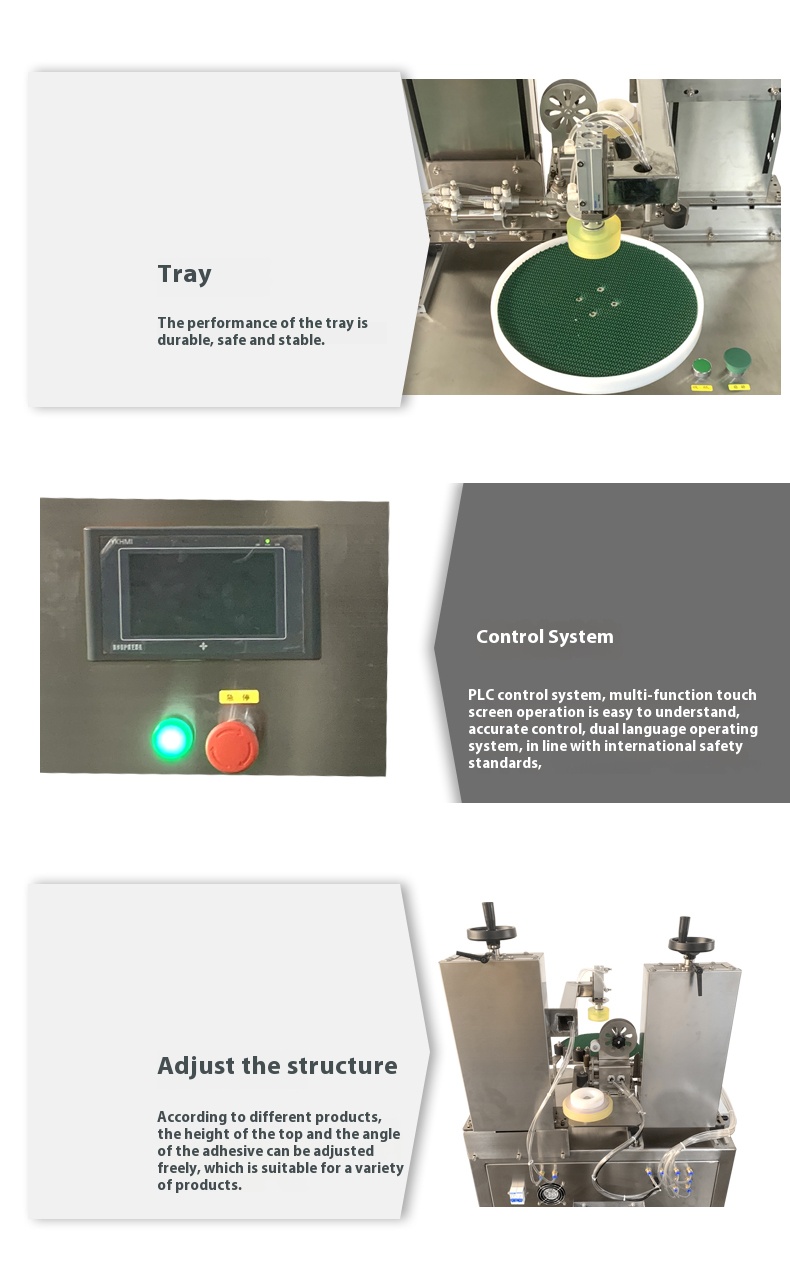

- The equipment uses a pressing bar system (such as rubber pressing bars or metal pressure plates) to apply uniform pressure to the tape, ensuring it closely adheres to the surface of cans/boxes. This effectively eliminates air and reduces bubbles, even on irregular surfaces (such as curved surfaces or edges).

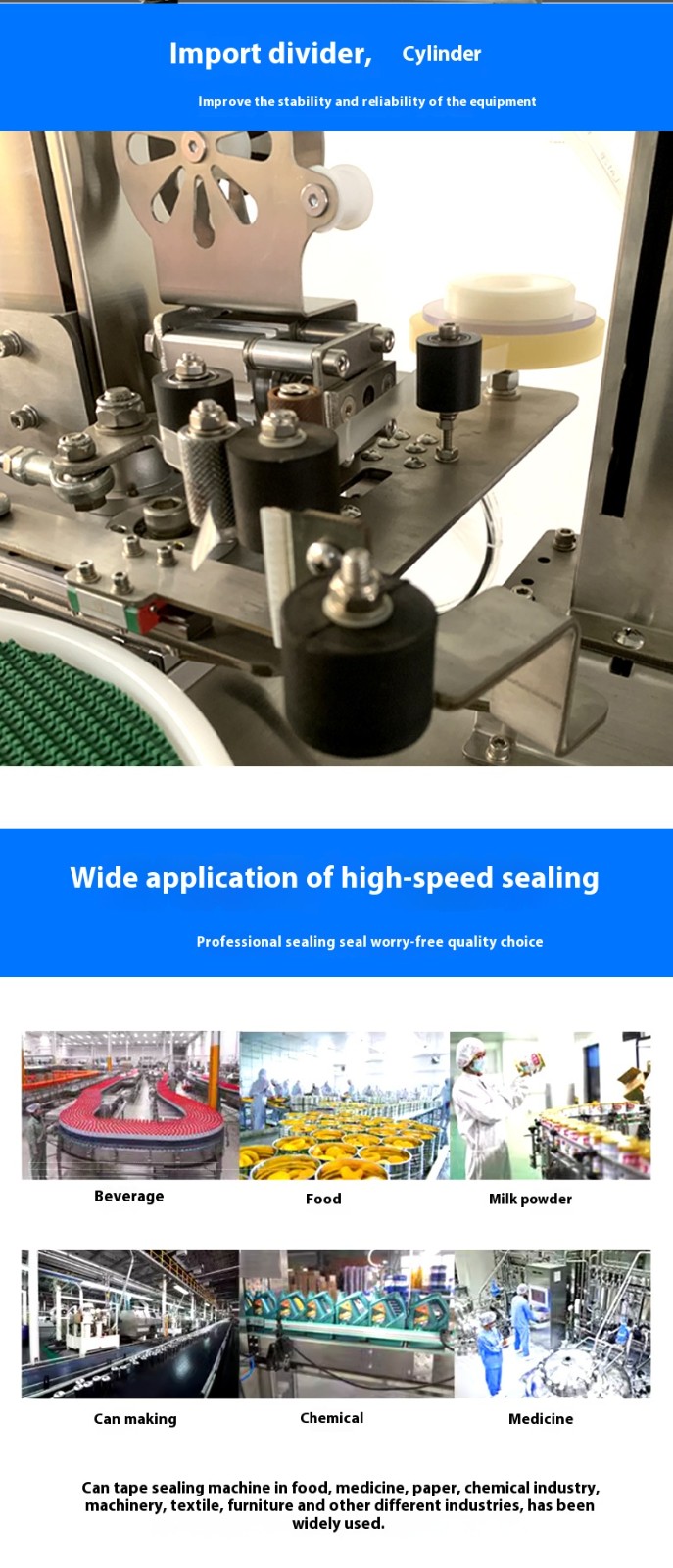

- Example: When sealing mooncake iron boxes in the food industry, the tape completely covers the lid joints to prevent moisture and insect infestation.

- The machine supports various tape types (e.g., transparent tape, cloth-based tape, anti-counterfeit tape), allowing users to select high-adhesion or waterproof tapes based on packaging needs to further enhance sealing performance.

- Example: For moisture-proof sealing of skincare product cans in the cosmetics industry, waterproof tape can be used with increased pressing cycles to strengthen the sealing layer thickness.

- The equipment precisely controls tape feeding length and bonding position to ensure the tape fully covers the sealing area (e.g., top edges or multi-surface joints), avoiding detachment due to too short or offset tape.

- Example: For medicine packaging boxes, the sealed tape must withstand vibration and extrusion during transportation. The machine can adjust pressing force (e.g., air cylinder pressure) to make the tape tightly bond with the paper box fibers, making it difficult to tear off.

- Some models support secondary pressing or multi-channel sealing (e.g., simultaneously applying tape to the top and side surfaces), forming a "cross-shaped" or "grid-shaped" sealing structure to significantly enhance impact resistance.

- Example: When sealing metal cans for electronic components, multiple layers of tape prevent lid loosening caused by collisions, protecting internal components.

- The equipment uses photoelectric sensors or visual inspection systems to precisely position cans/boxes, ensuring the tape is centered and edges are aligned, with an error typically controlled within ±1–2mm to avoid skew or wrinkles.

- Example: When sealing gift boxes (e.g., high-end tea cans), the neatly applied tape can be directly displayed as outer packaging without additional decoration.

- Serrated knife cutting or thermal cutting technology is used to ensure neat, burr-free tape edges, avoiding the roughness of traditional manual cutting. Some models can also iron the tape edges to further improve appearance quality.

- Example: After sealing cosmetic boxes, the smooth tape surface, combined with printed tape (e.g., brand logos or anti-counterfeit information), enhances brand recognition.

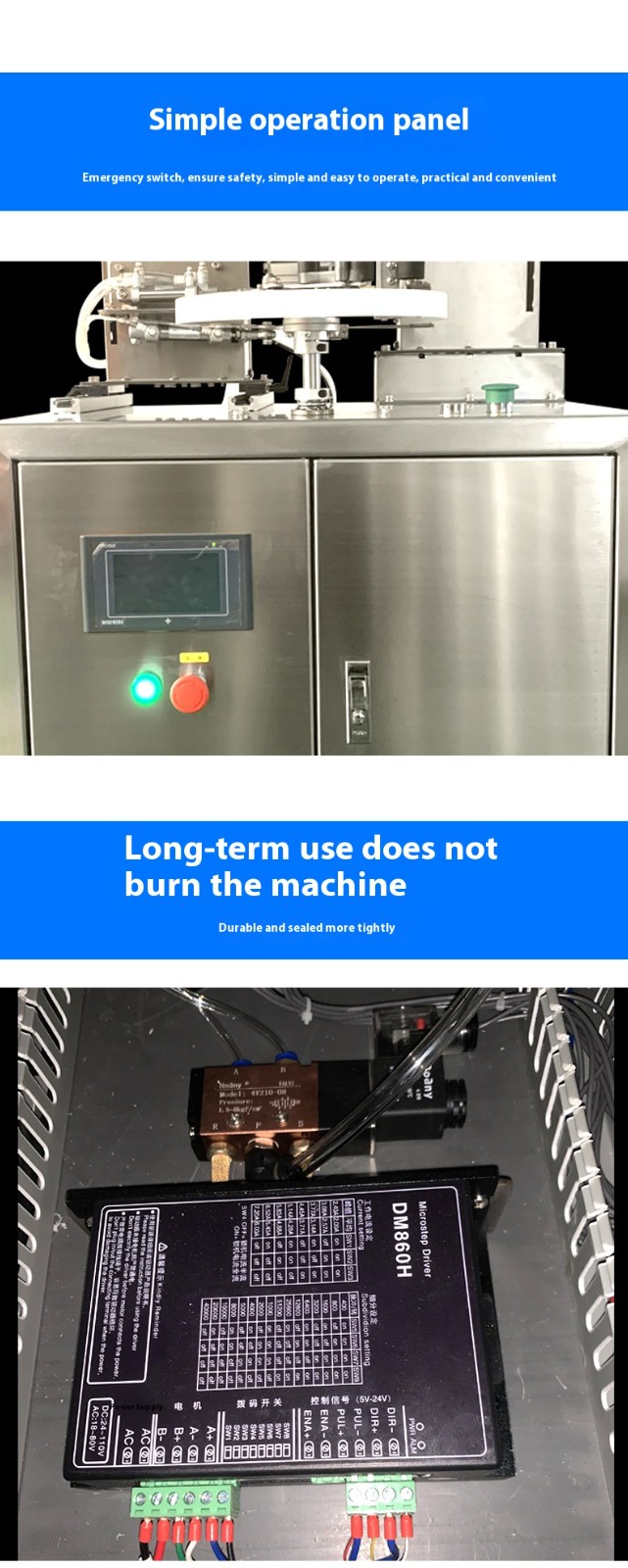

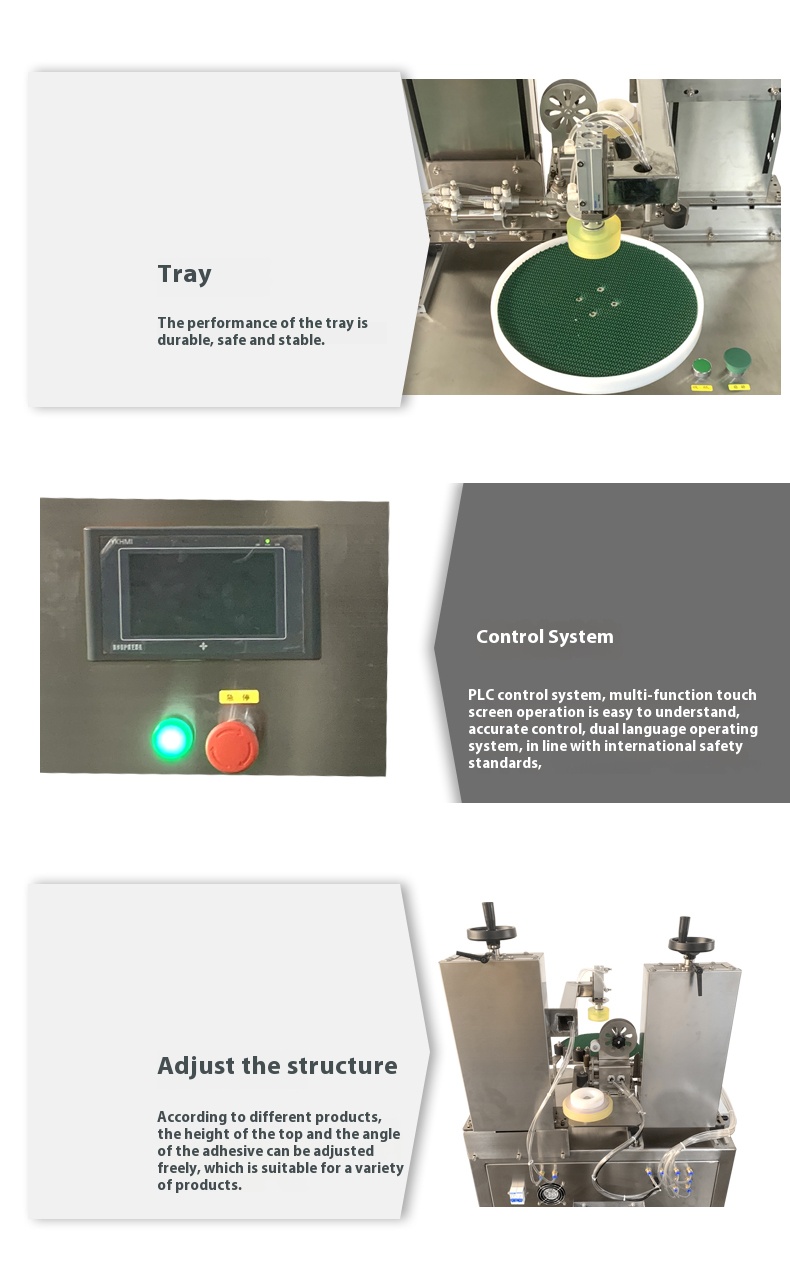

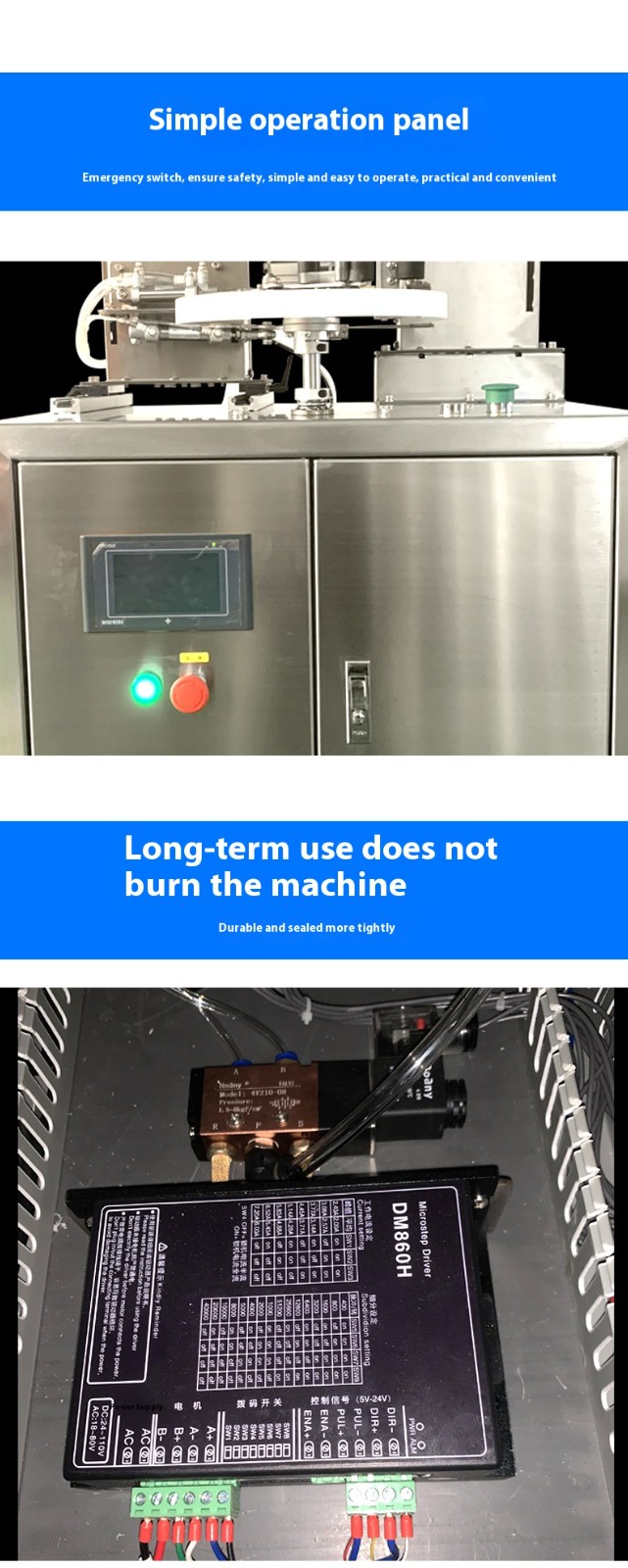

- Parameters (such as tape length, pressing time, and conveying speed) are preset through a programmable logic controller (PLC) or touchscreen system, ensuring highly consistent sealing effects for the same 规格 (specification) of cans/boxes and avoiding randomness in manual operations.

- Example: In a biscuit production line, thousands of biscuit boxes per hour have completely uniform sealing positions and tape tension, reducing quality control risks.

- The equipment’s built-in sensors continuously monitor tape stock and container positioning. In case of anomalies such as tape breakage or container skew, the system automatically stops and alarms to prevent batch production of non-conforming products.

- Example: When detecting incomplete tape bonding due to size deviations in a container, the machine can automatically reject the product and adjust parameters to maintain overall production stability.

- Tape tension: Excessive tension may break the tape, while insufficient tension may cause poor adhesion. Tension needs to be dynamically adjusted according to tape material.

- Pressing speed and force: Higher pressure is required to ensure adhesion during high-speed production, while lower pressure can be used during low-speed production to avoid damaging containers (e.g., paper box deformation).

- Container surface cleanliness: Oil stains or dust on the sealing area may cause tape detachment, requiring proper pre-treatment (e.g., dust removal).

- Tape shelf life and storage environment: Moist or expired tape loses adhesion, necessitating regular quality checks.

- Regularly clean residues (such as adhesive stains or debris) on pressing bars and conveyor belts to avoid affecting adhesion.

- Timely replace worn cutting knives and pressing bars to ensure operational accuracy.

The can and box tape sealing machine delivers industrial-grade sealing effects. With high automation and precise debugging, it achieves reliable sealing, neat appearance, and strong consistency, making it widely suitable for scenarios requiring high packaging quality (e.g., moisture-proof and anti-counterfeit packaging for food and pharmaceuticals, shock-proof protection for electronics). In practical applications, reasonable equipment selection, standardized operation, and regular maintenance can further optimize sealing quality and enhance production efficiency and product competitiveness.