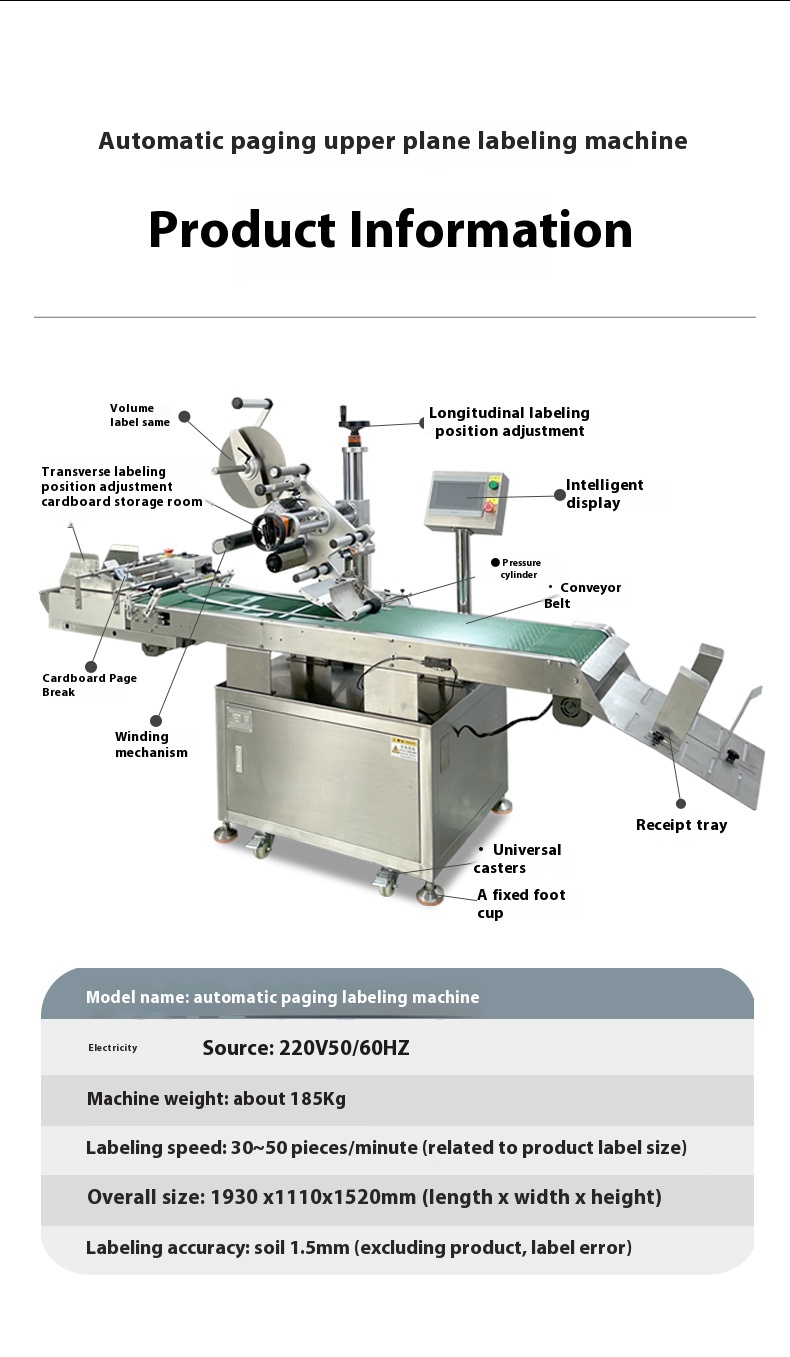

The fully automatic page-separating labeling machine significantly improves production efficiency and product quality through its characteristics of high-speed operation, high precision, intelligence, and low loss.

Release date:2025-05-21

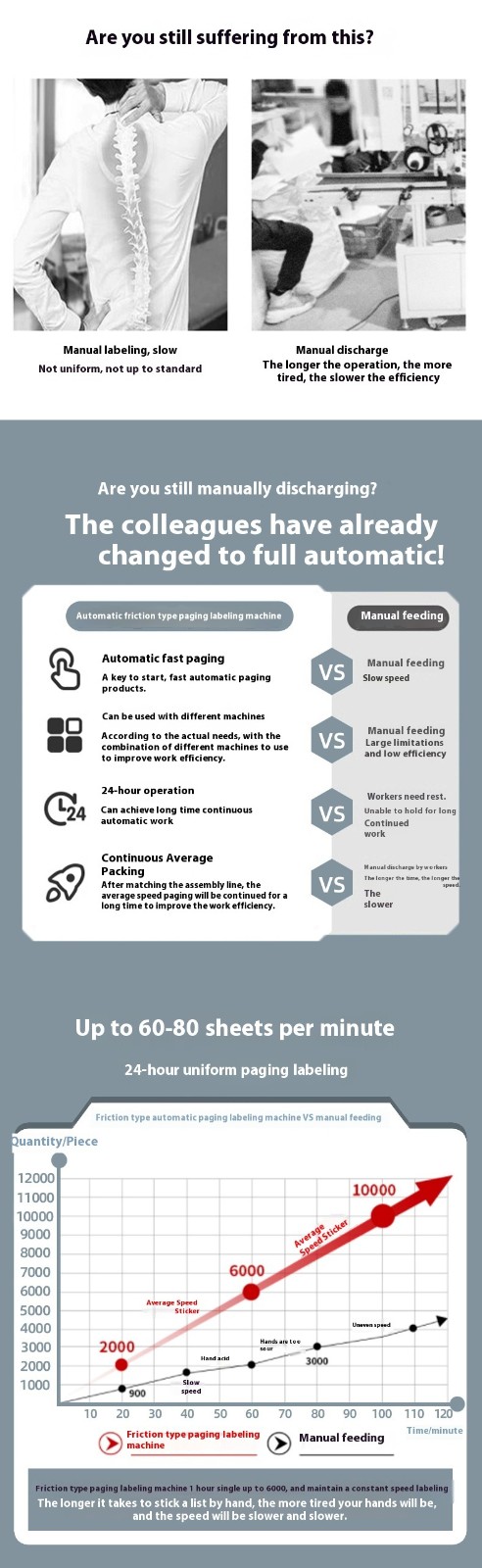

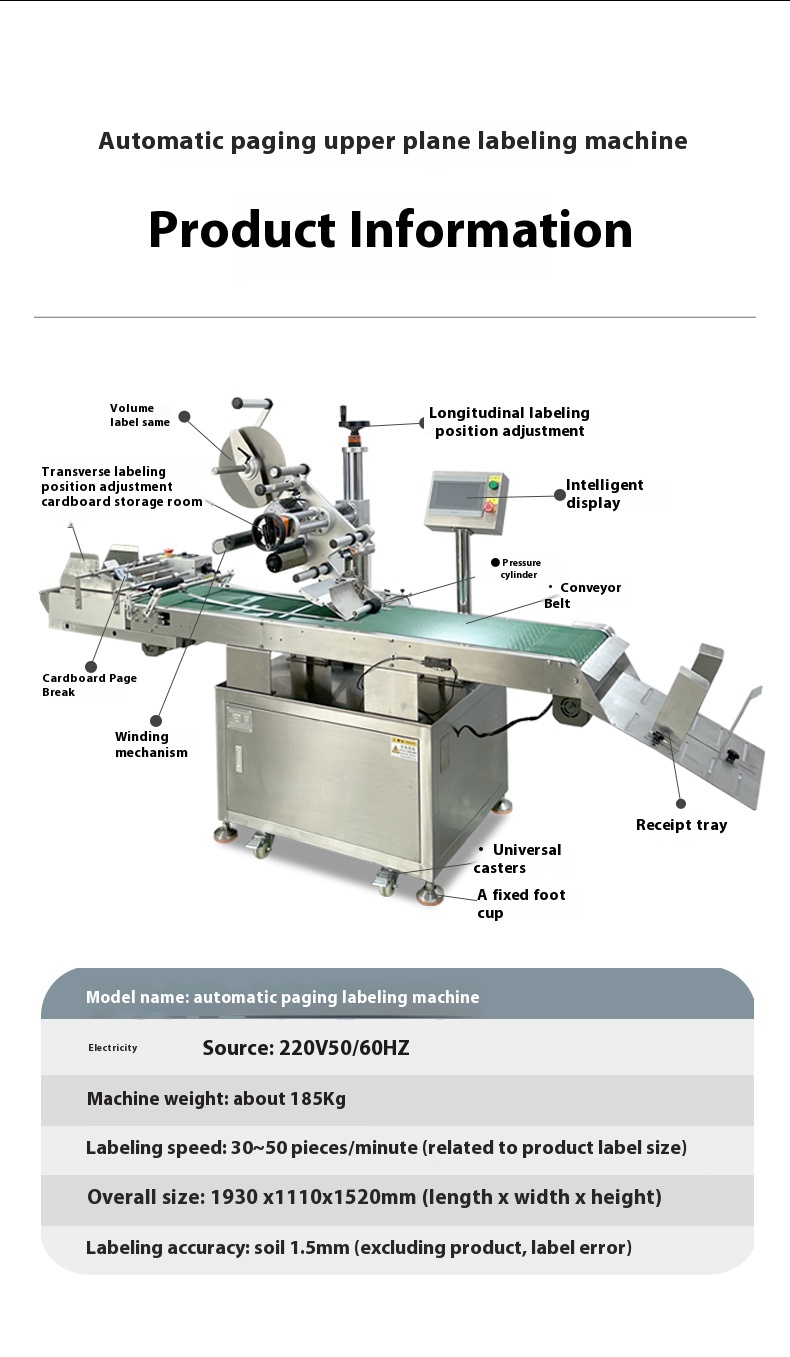

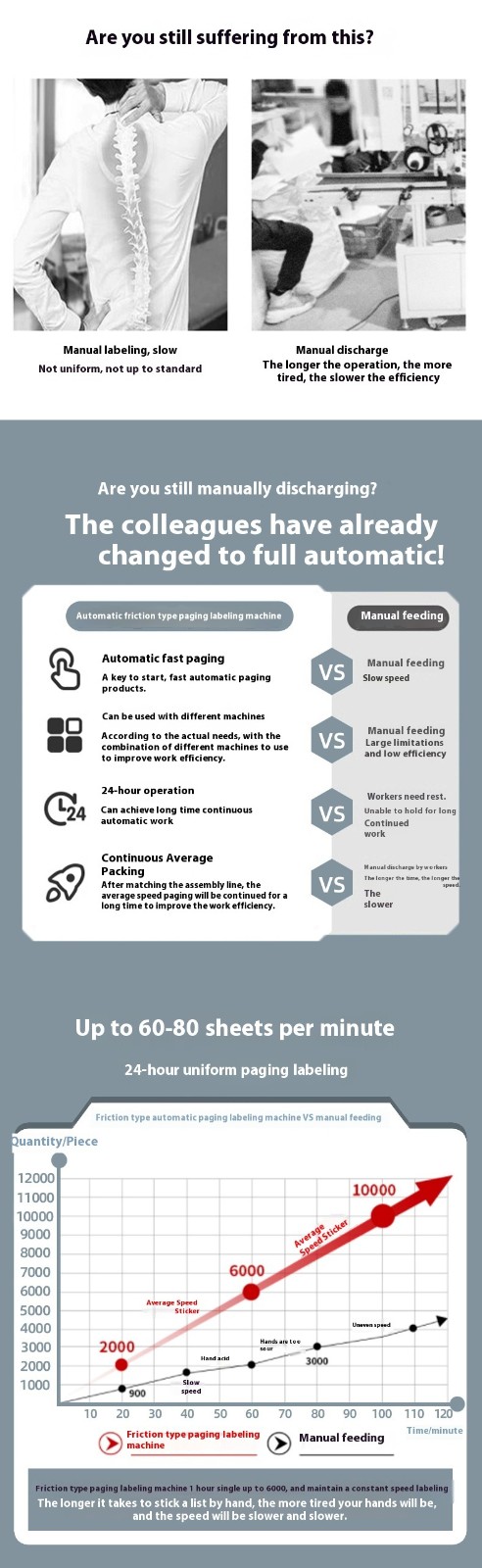

- Labeling speed can reach 50–120 pieces per minute (higher for some models), far exceeding manual labeling efficiency (approximately 10–20 pieces per minute), making it particularly suitable for large-scale assembly line production.

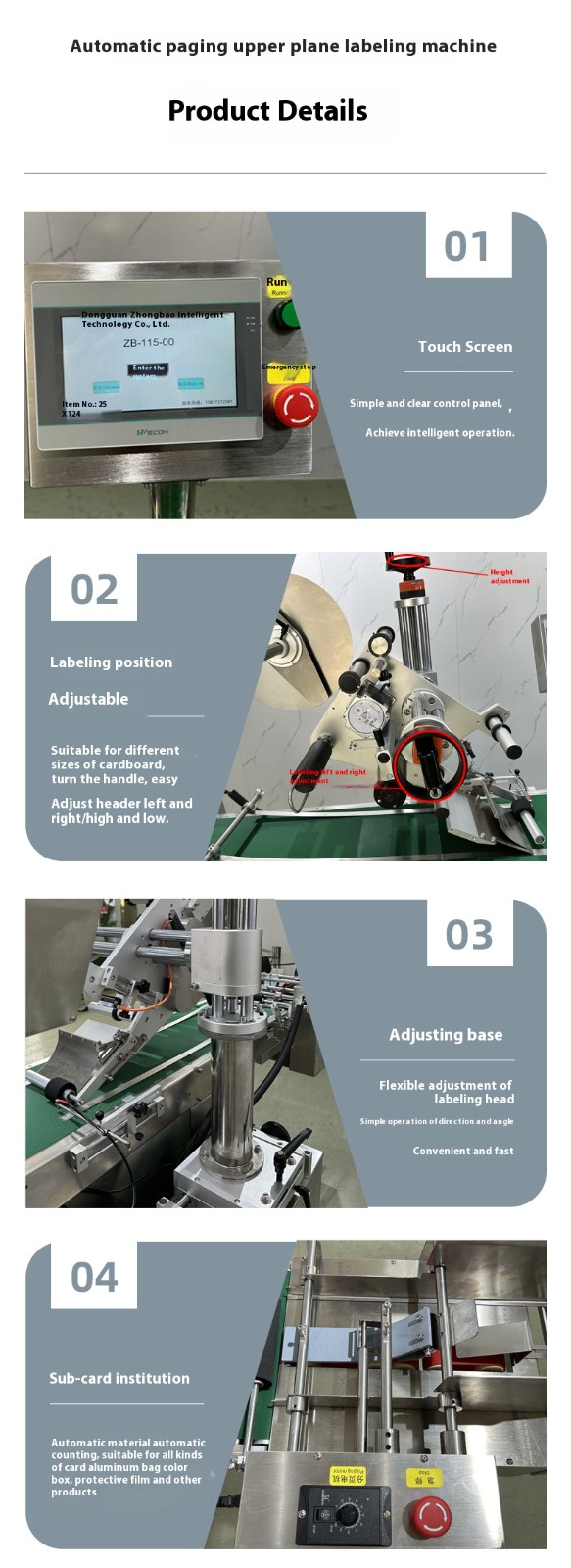

- Automatically completes the entire process of "page separation → conveying → labeling → material collection" without manual intervention, reducing downtime and waiting time.

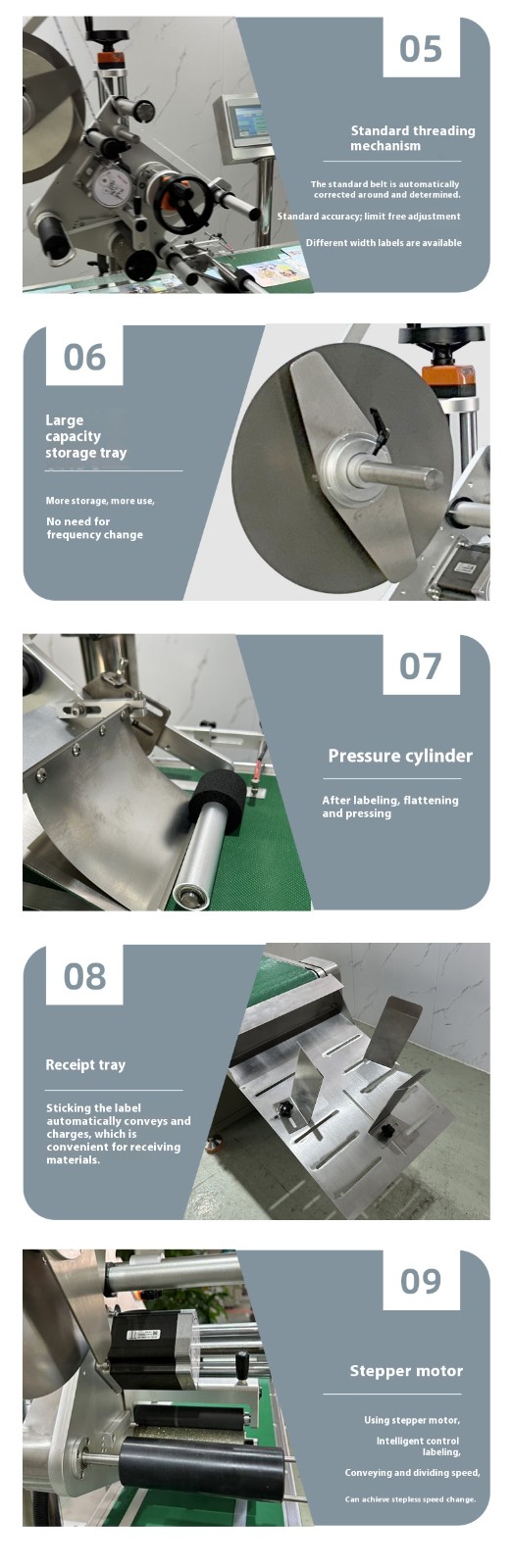

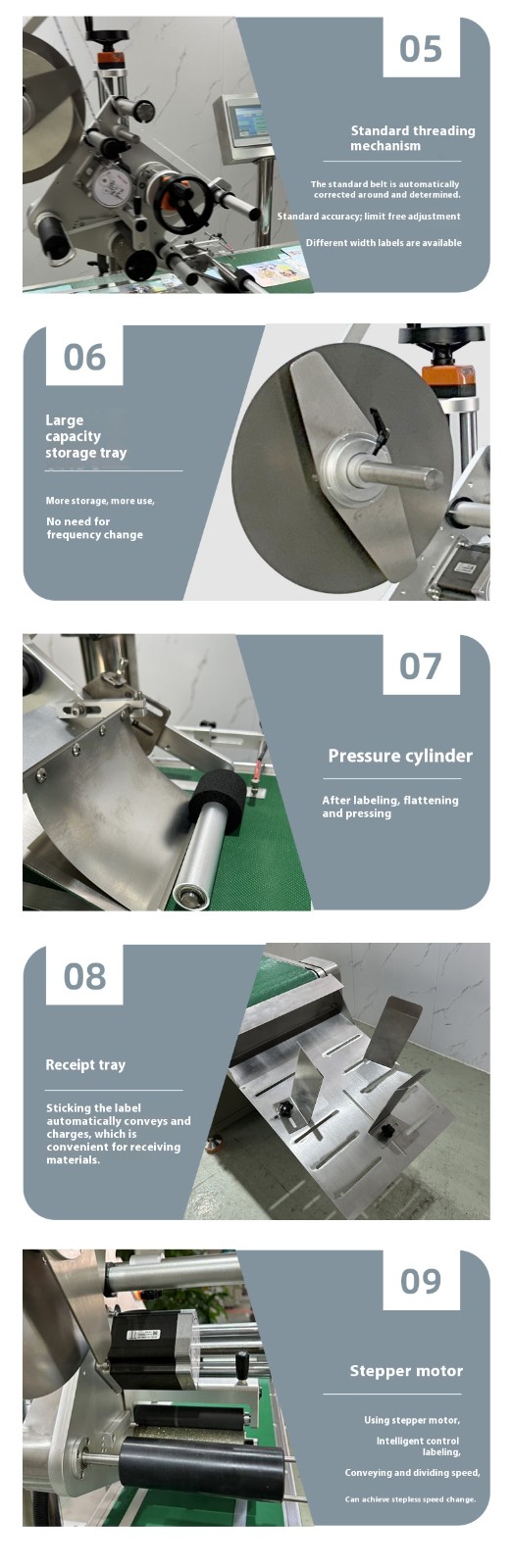

- The equipment is driven by servo motors or stepper motors, featuring high operating precision and stability, capable of 24-hour uninterrupted operation to ensure production continuity.

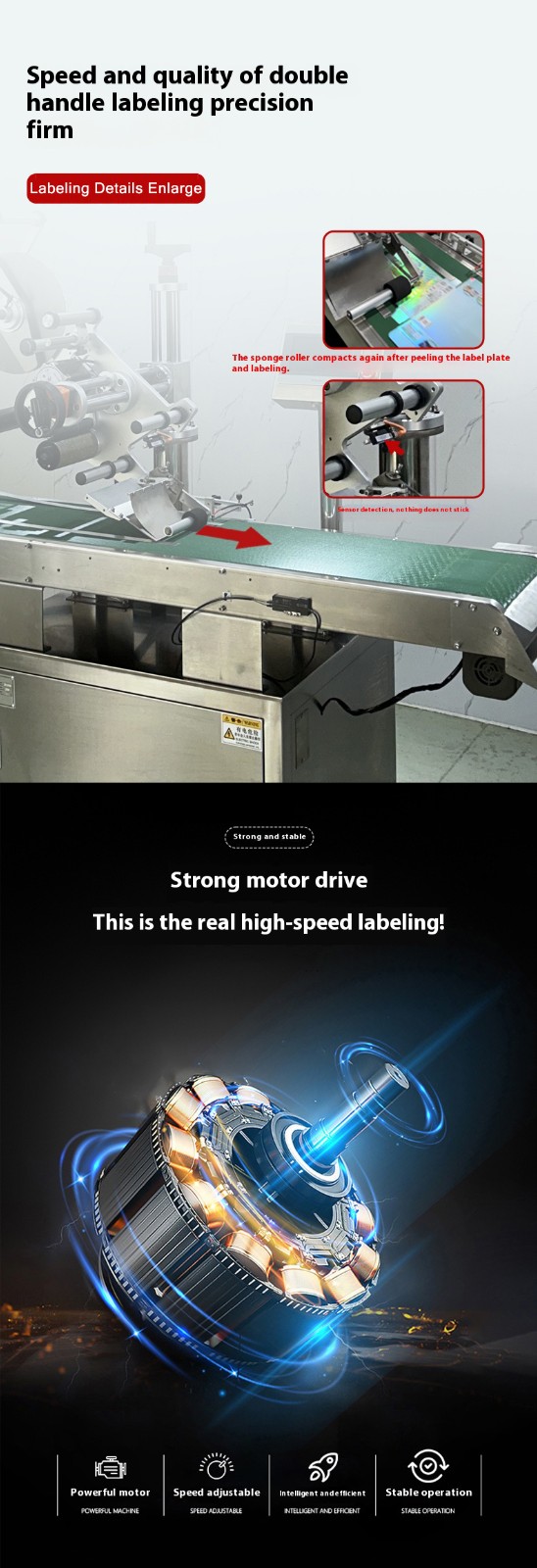

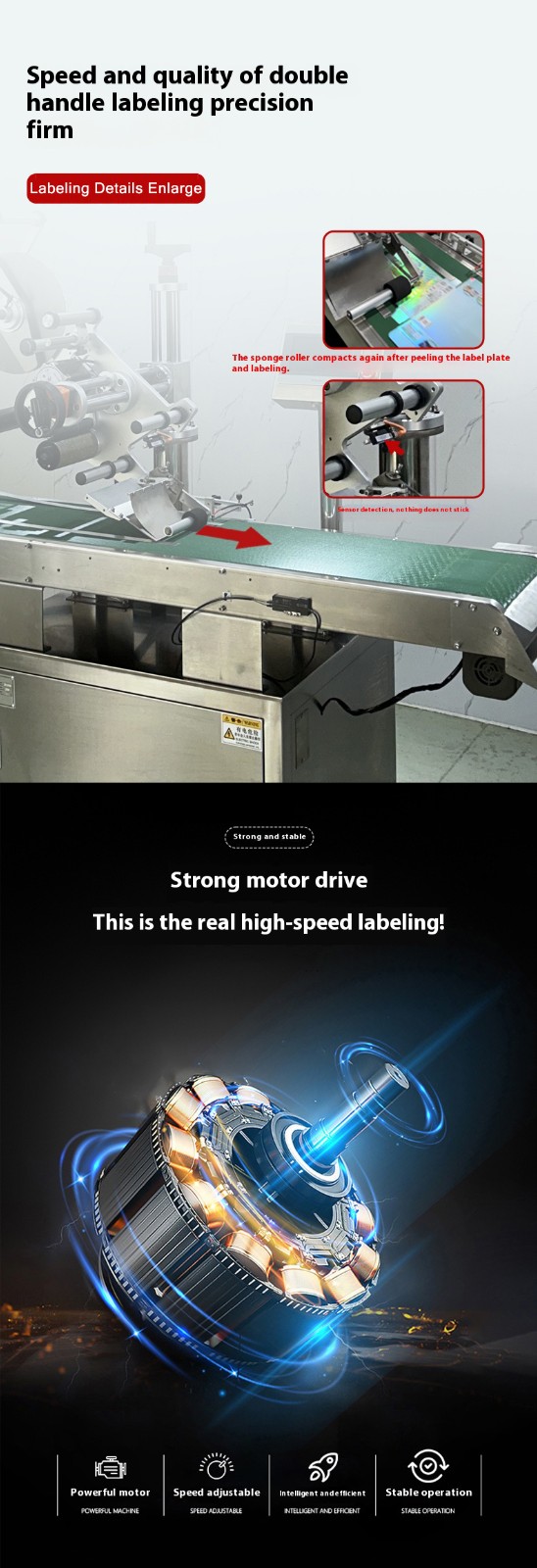

- Labeling accuracy can reach ±1mm. Through real-time product position detection by sensors and precise control of label attachment angles and positions via the PLC control system, it avoids common issues of 歪斜 (skewing) and deviation in manual labeling.

- Labels are flat without bubbles, and the label covering rollers automatically press to ensure firm adhesion, enhancing product appearance consistency.

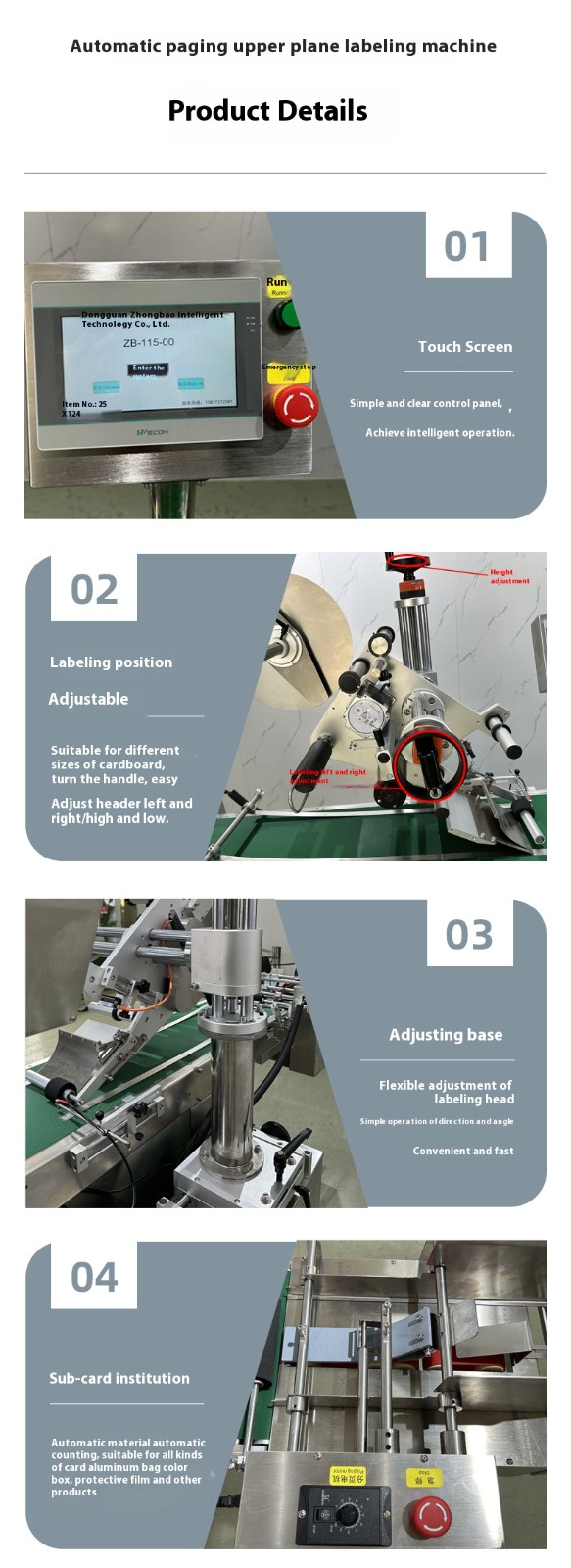

- Can label flat surfaces, large-curved surfaces, and irregular surfaces (such as cards, packaging bags, books, etc.), and is compatible with various label materials like paper, transparent film, and metal foil, offering wide applicability.

- Features no-object no-labeling (avoids label waste), automatic label missing correction (detects label shortages and alarms to stop the machine), and automatic error prevention (alarms when label content mismatches products), reducing manual supervision costs.

- Real-time monitoring of production data (e.g., labeling quantity, failure rate) with data export support for convenient production management.

- Touch-based operation interface (e.g., color LCD screen) with intuitive parameter settings (e.g., label length, spacing, labeling position), allowing novices to get started quickly without complex training.

- Supports one-key product specification switching. When changing labels or adjusting labeling positions, preset parameters via the program can complete the changeover in less than 10 minutes.

- One device can replace 3–5 manual labelers, offering obvious advantages in scenarios with high labor costs or labor shortages.

- Reduces manual contact with products, minimizing contamination risks (e.g., in food and pharmaceutical industries).

- Precise control of label conveying avoids label waste caused by human error in manual labeling (waste rate can be reduced by over 50%).

- Low equipment maintenance costs, with key components (e.g., motors, sensors) made of industrial-grade durable materials for long service life.

- Wide range of applicable product sizes (e.g., product length 40–350mm, width 80–280mm). By adjusting mechanical structures such as conveyor belt width and page-separating baffles, it can quickly switch between different specifications of packaging boxes, bags, cards, etc.

- Supports installation of thermal coding/inkjet devices to print variable information such as production dates, batches, and QR codes simultaneously, reducing post-processing steps.

- Integrates automatic feeding, automatic material collection, and multi-side labeling devices to achieve "labeling + sorting + stacking" integration, meeting complex process requirements (e.g., multi-label attachment for cosmetics, multi-side information labeling for electronic products).

- In industries with high labeling compliance requirements (e.g., pharmaceuticals, food), the equipment ensures clear label content (e.g., batch numbers, expiration dates, regulatory codes) and uniform positioning, meeting certification requirements such as GMP and FDA.

- Through integration with production management systems, it records data such as labeling time and label content for each product, facilitating quality traceability and process optimization.