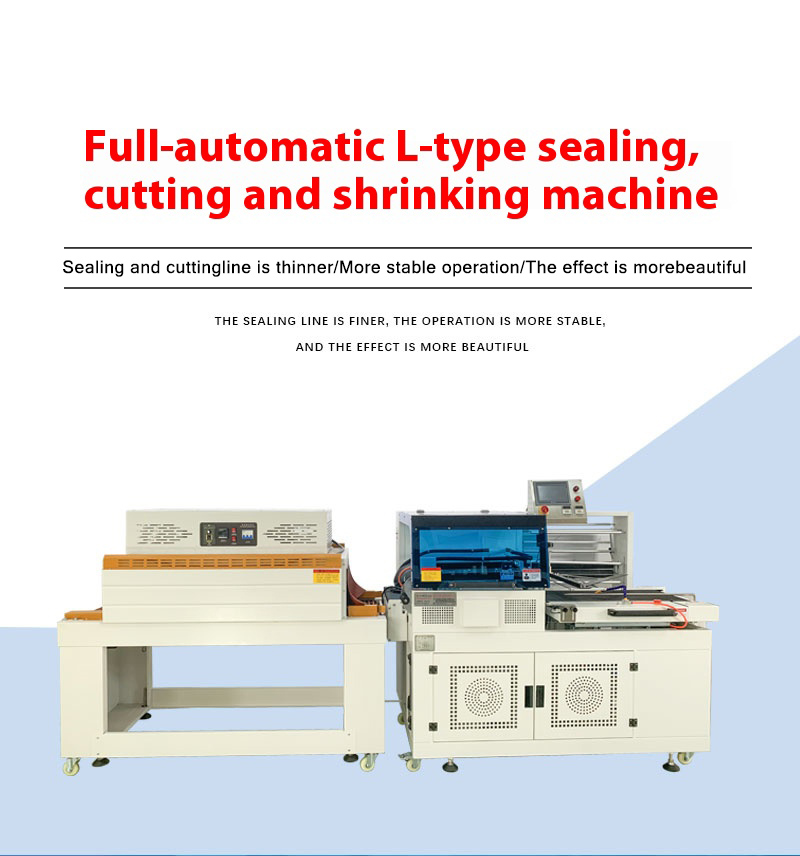

The working process of the automatic L-shaped sealing and cutting heat shrinkage machine mainly consists of several links, including product conveying, film supply and positioning, sealing and cutting, heat shrinkage, and finished product output. The following is a detailed introduction:

Product Conveying

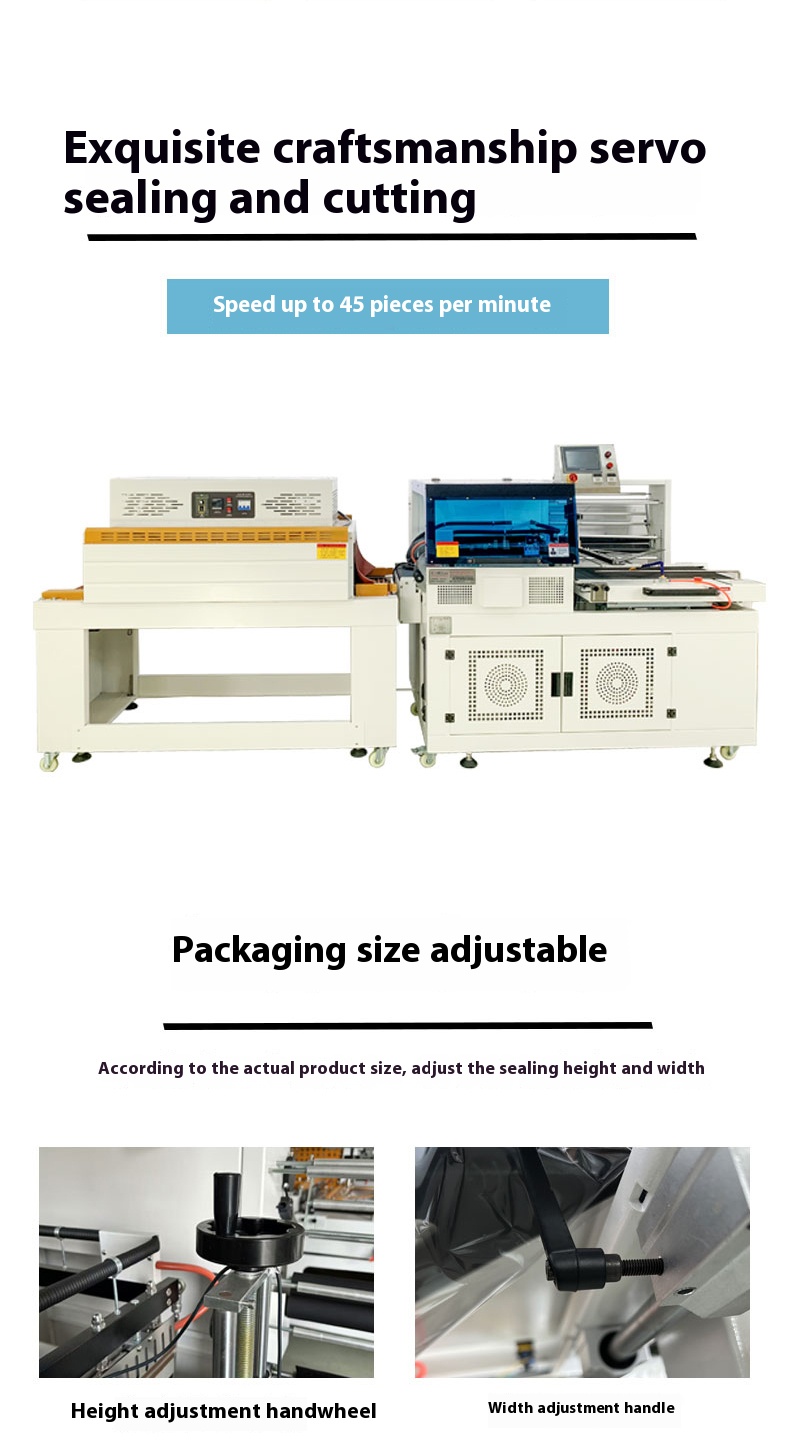

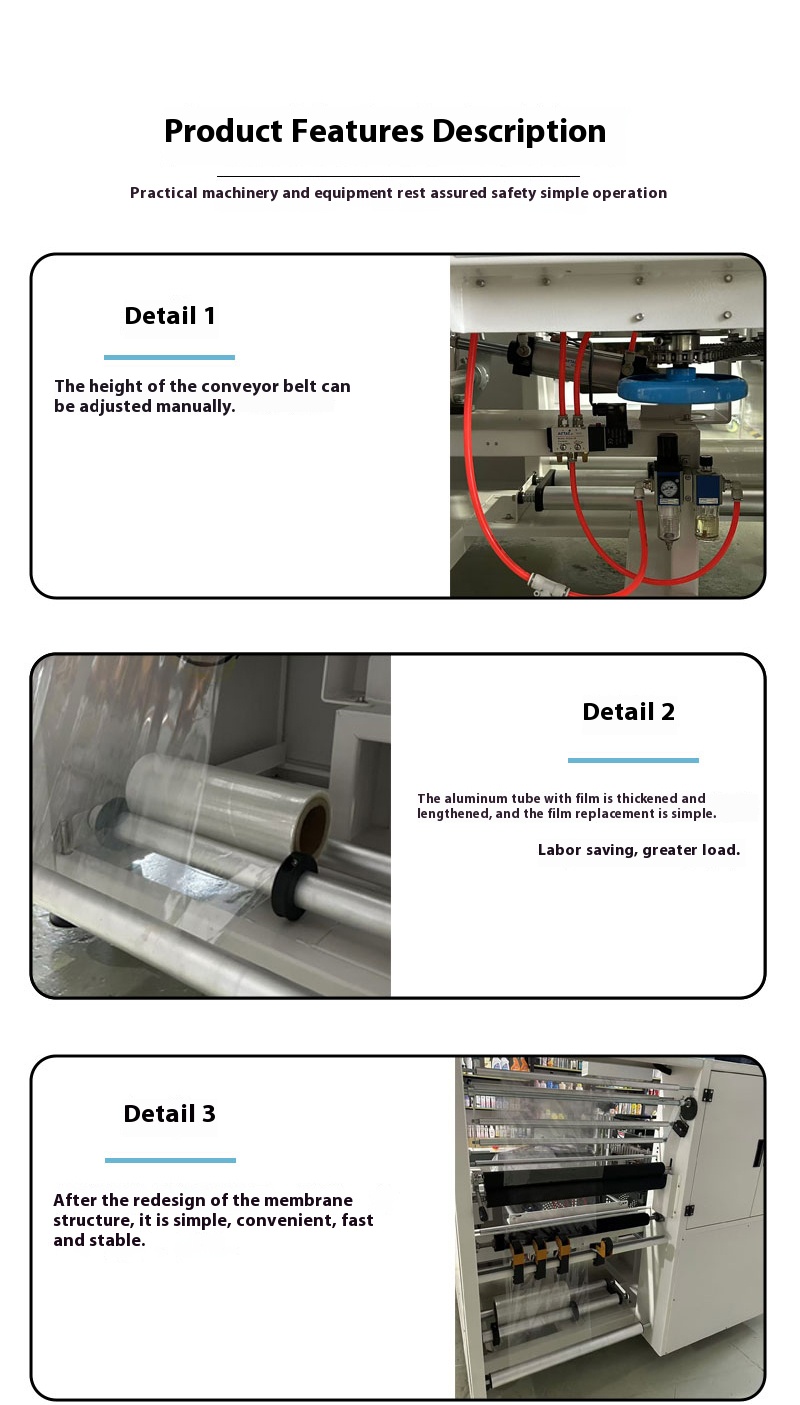

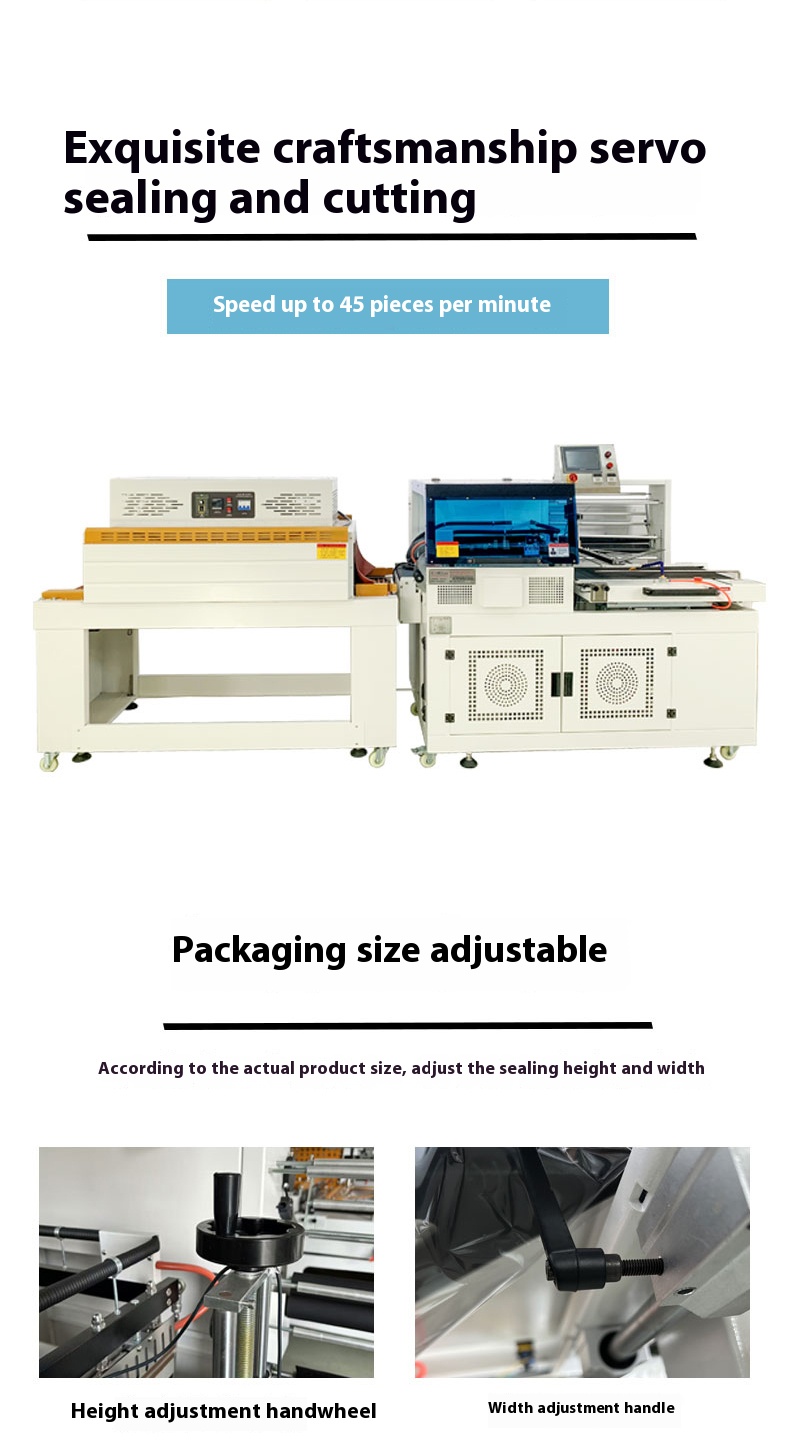

Products to be packaged are manually placed on the feeding conveyor belt. Driven by a motor, the conveyor belt runs smoothly at a set speed, transporting the products at a uniform speed to the sealing and cutting station. Some equipment may also be equipped with an automatic alignment device to ensure that the products are neatly arranged during the conveying process, which facilitates subsequent sealing and cutting operations.

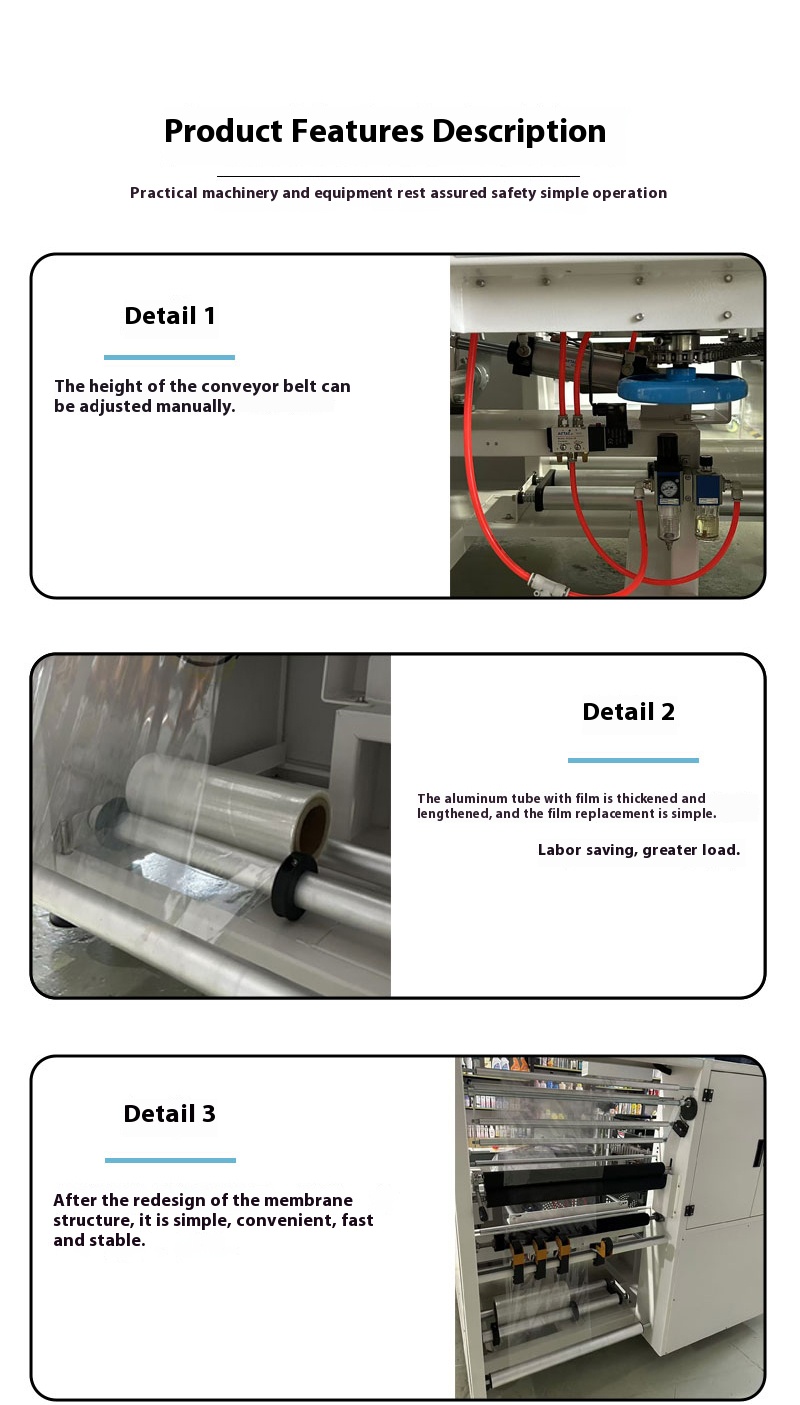

Film Supply and Positioning

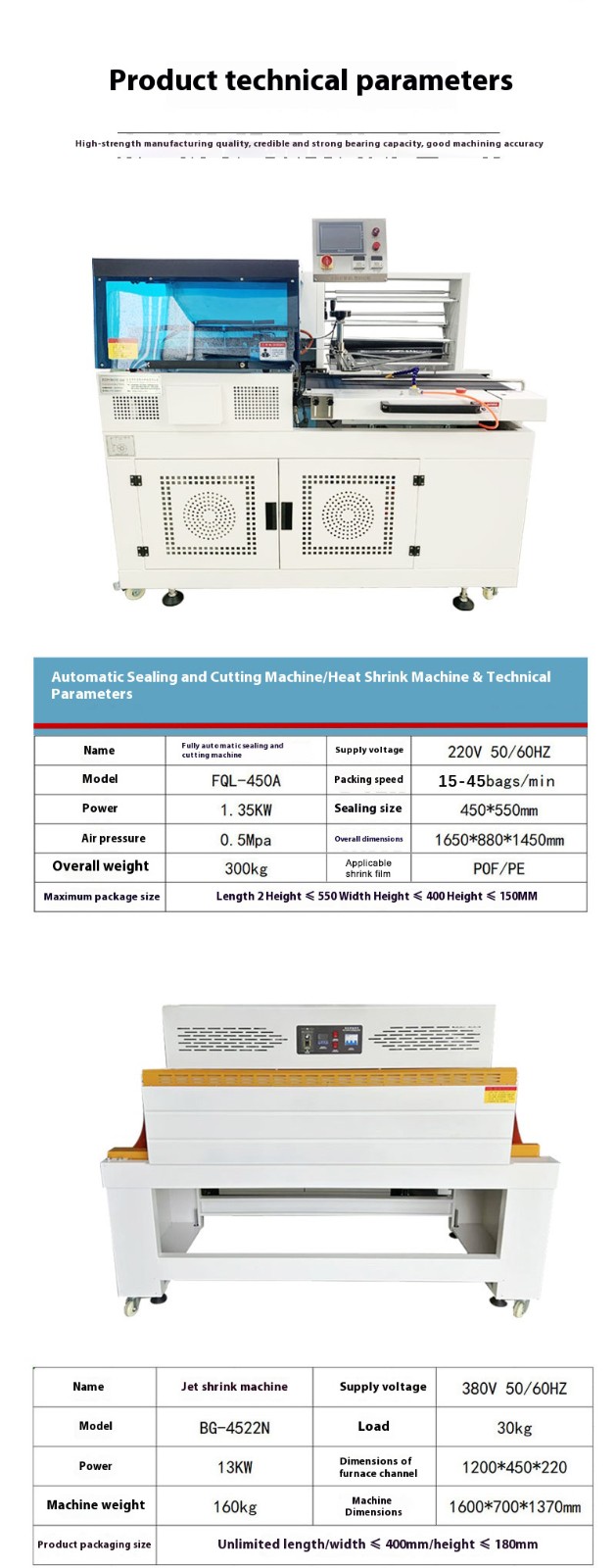

The packaging film is usually mounted on a film reel. Through a series of guide rollers and a tension control system, the film is accurately conveyed to the sealing and cutting position. During this process, the tension of the film is precisely controlled to prevent the film from becoming slack or being overstretched. Meanwhile, the equipment will accurately detect the position and size of the products through photoelectric sensors or other positioning devices, so as to determine the cutting length and position of the film, ensuring that the film can wrap the products accurately.

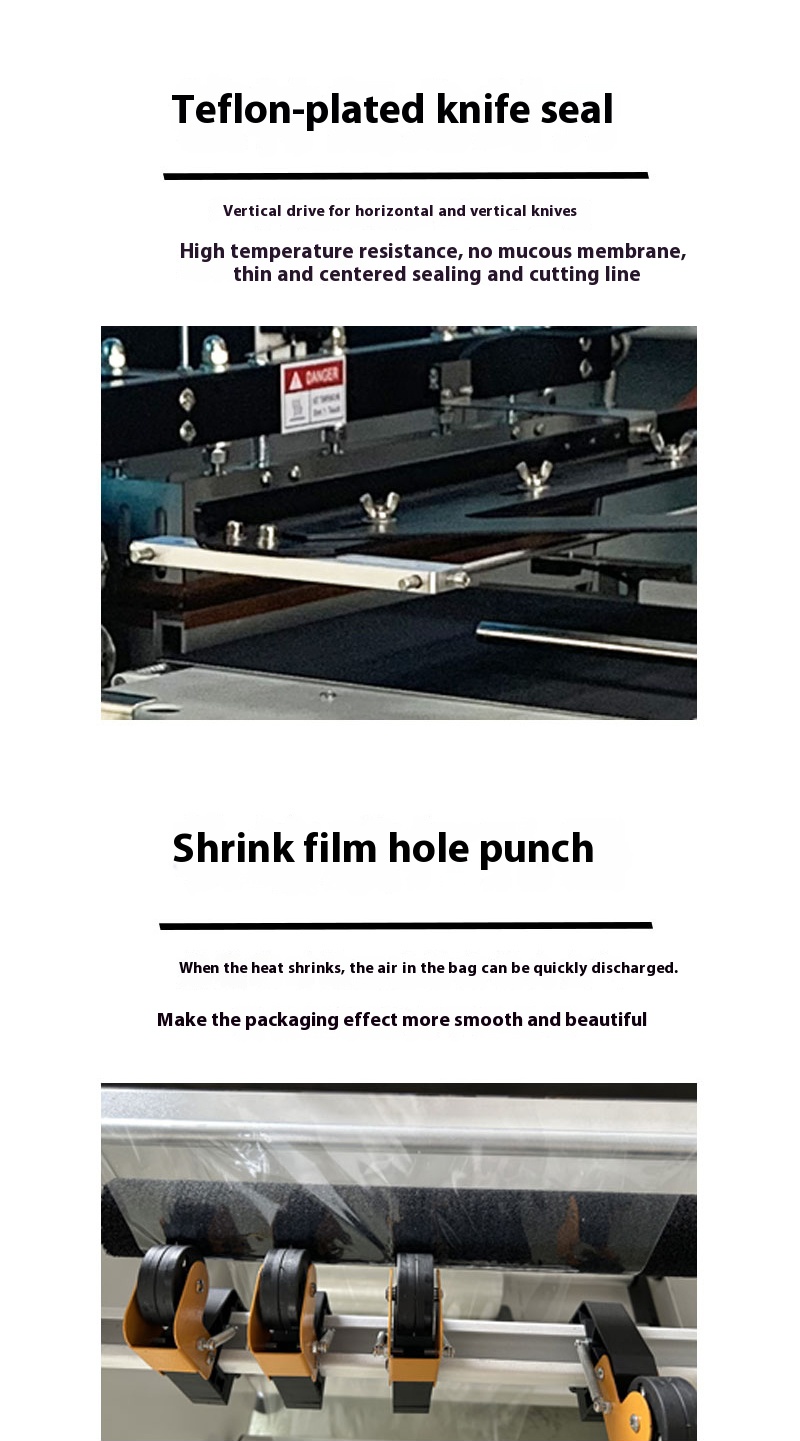

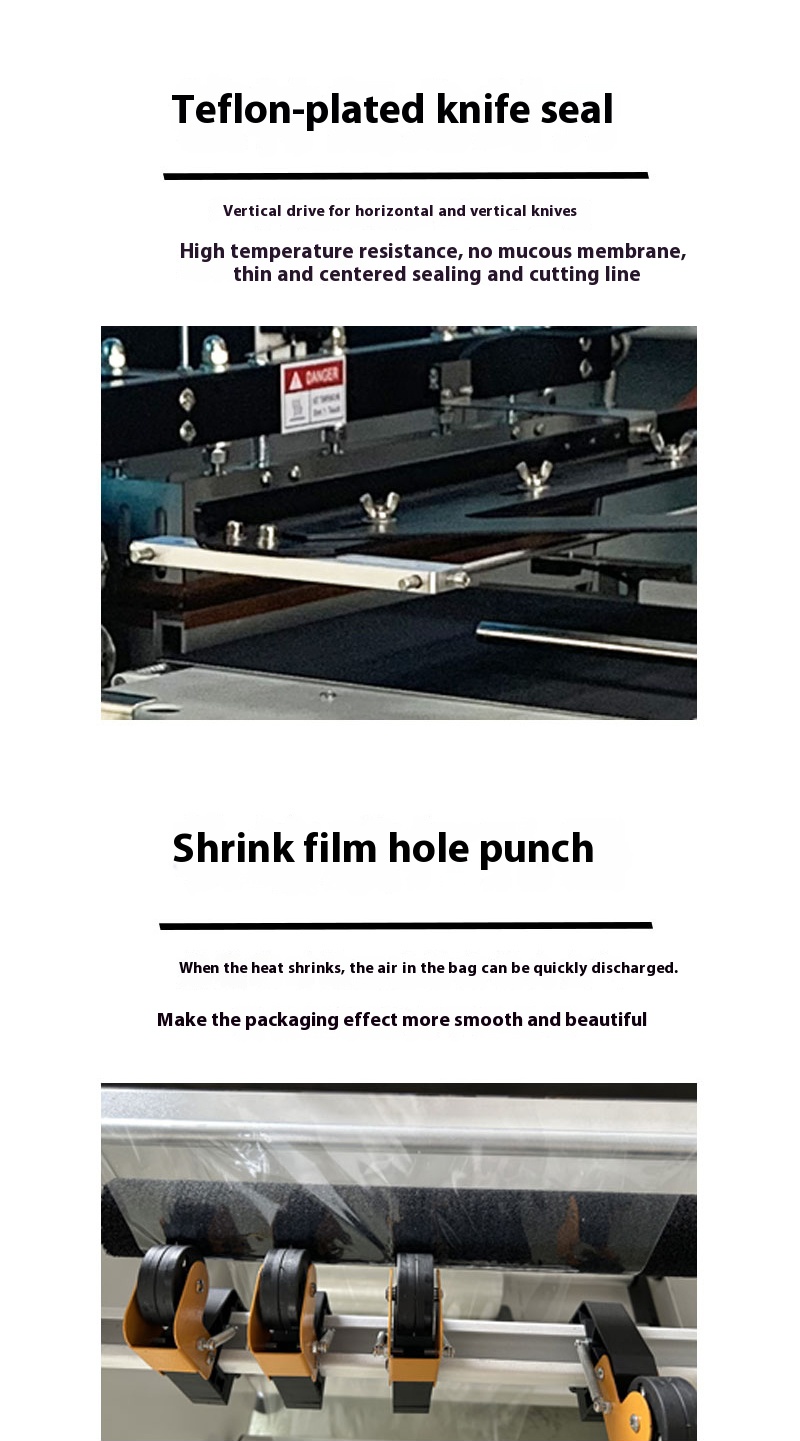

Sealing and Cutting

Once the products are conveyed to the designated position and the film is also accurately positioned, the L-shaped sealing and cutting knife quickly descends under the action of a cylinder or other driving devices, and seals and cuts the film along the contour of the products. When in operation, the sealing and cutting knife heats and pressurizes the film, causing the edges of the film to melt and bond together rapidly, forming a sealed packaging area. After the sealing and cutting is completed, the sealing and cutting knife will quickly rise and return to its initial position, ready for the next sealing and cutting operation.

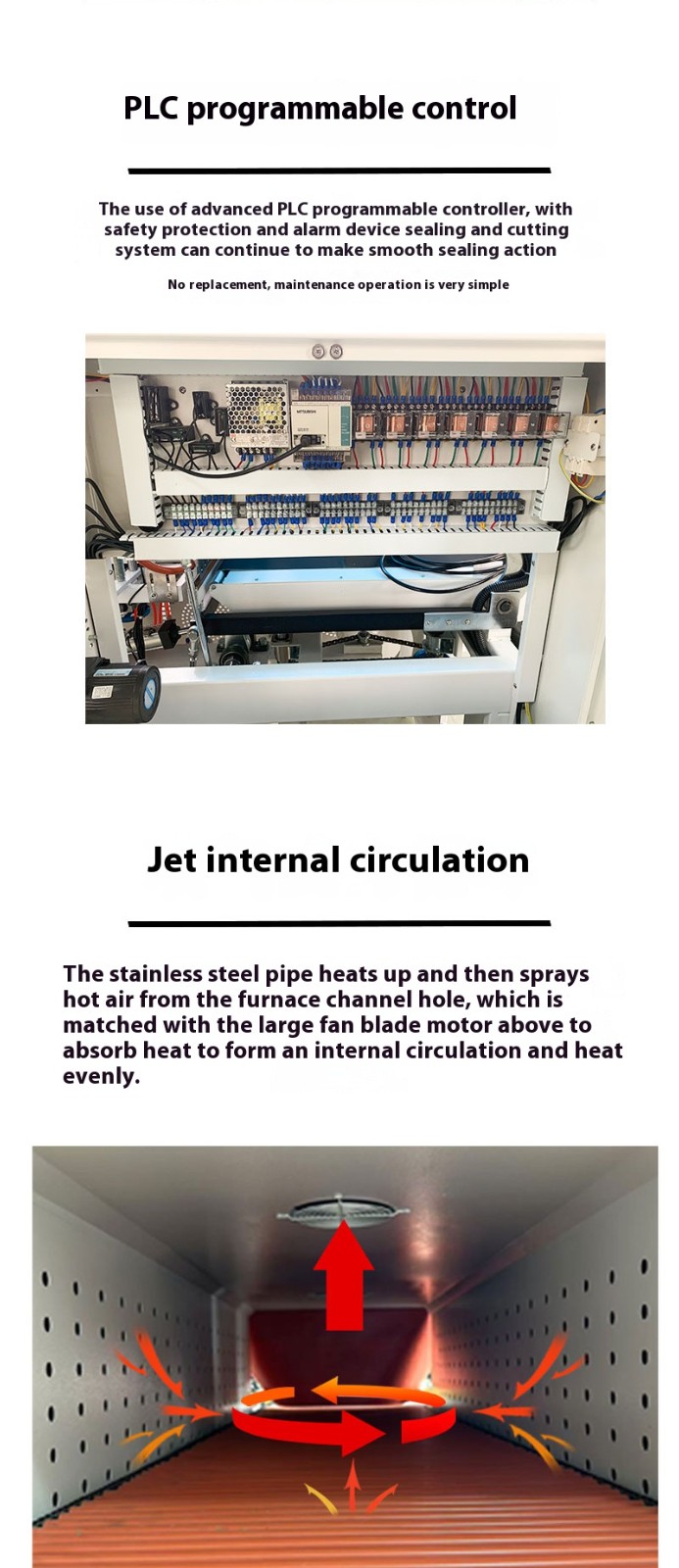

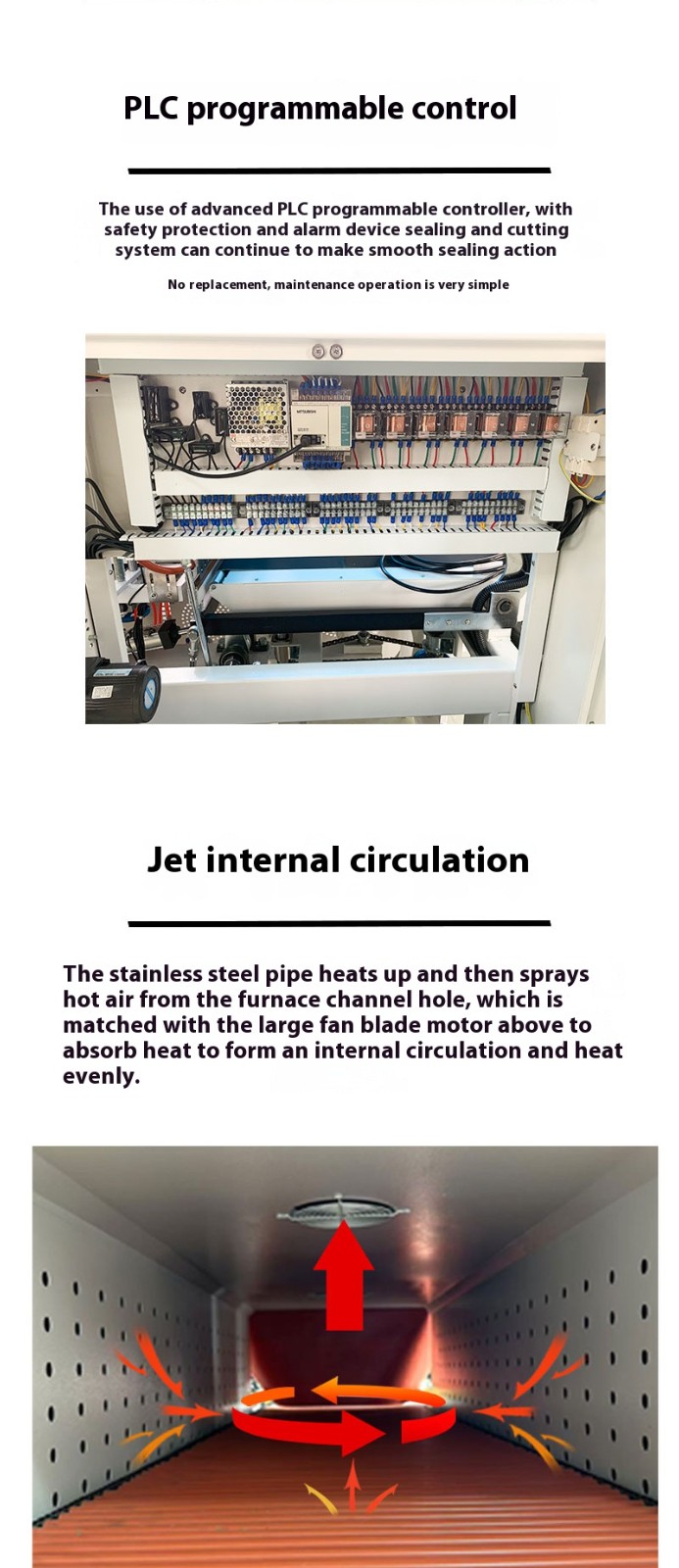

Heat Shrinkage

The products with the film wrapped around them after sealing and cutting enter the heat shrinkage channel. The heat shrinkage channel is equipped with heating elements and a circulating fan. The heating elements will heat the air in the channel to a set temperature, generally ranging from 120°C to 200°C. The specific temperature depends on the material of the packaging film and the requirements of the products. The circulating fan makes the hot air form a uniform airflow in the channel. The products slowly pass through the heat shrinkage channel on the conveyor belt, and the film gradually shrinks under the action of the hot air, closely fitting the surface of the products to achieve an ideal packaging effect.

Finished Product Output

The products that have undergone heat shrinkage are sent out from the discharge conveyor belt at the other end of the heat shrinkage channel, completing the entire packaging process. At this time, the packaged products can directly enter the next process, such as labeling, boxing, etc., or be directly stored in the warehouse. Some auxiliary devices, such as cooling fans, may also be installed on the discharge conveyor belt to quickly cool the packaged products, making it easier for subsequent processing and handling.