When operating a pneumatic sealing, corner-cutting, and heat shrinkage packaging machine, the following safety precautions should be noted:

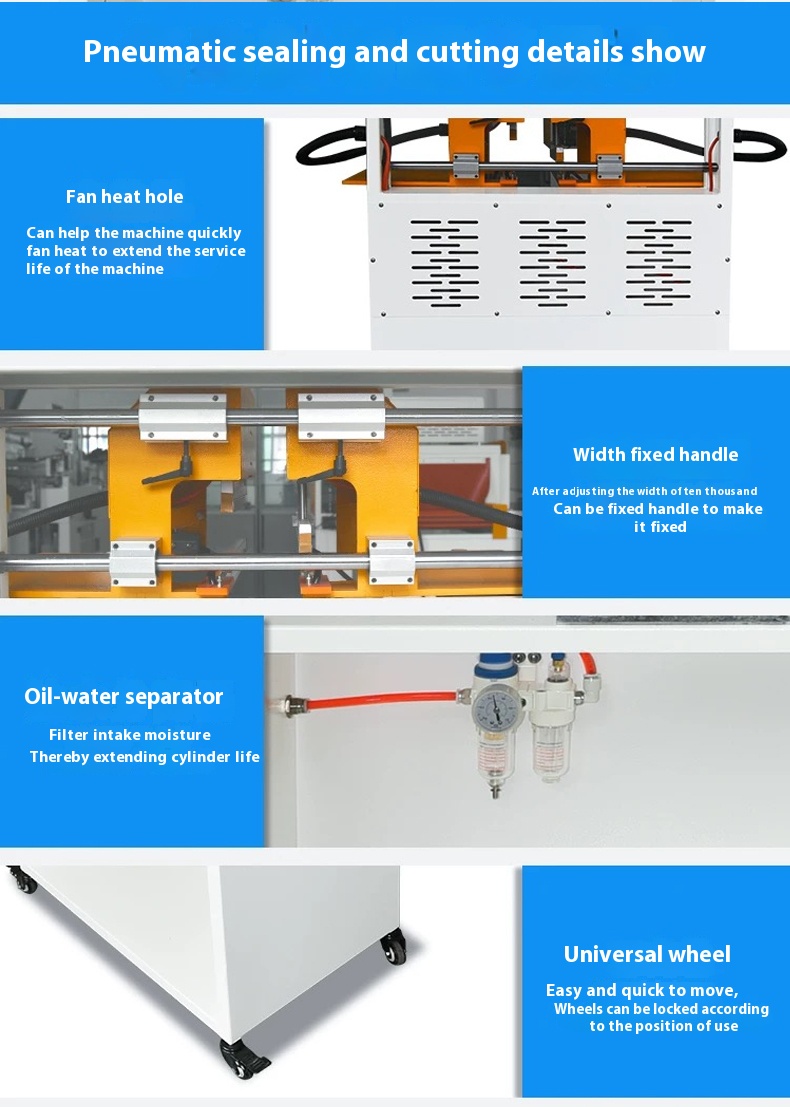

Equipment Installation and Environment: When installing the equipment, ensure that it is placed stably in a dry and well-ventilated area. Leave enough space around it for easy operation and maintenance, and keep it away from fire sources, water sources, and flammable and explosive materials. At the same time, the equipment should be reliably grounded to prevent electric shock accidents.

Personnel Training: Operators must receive professional training, be familiar with the operation process, performance, and safety precautions of the equipment. Those who have not received training are strictly prohibited from operating.

Use of Protective Equipment: During operation, operators should wear necessary protective equipment, such as high-temperature-resistant gloves to prevent scalding, and safety goggles to prevent the eyes from being injured by flying debris of the packaging material during corner-cutting.

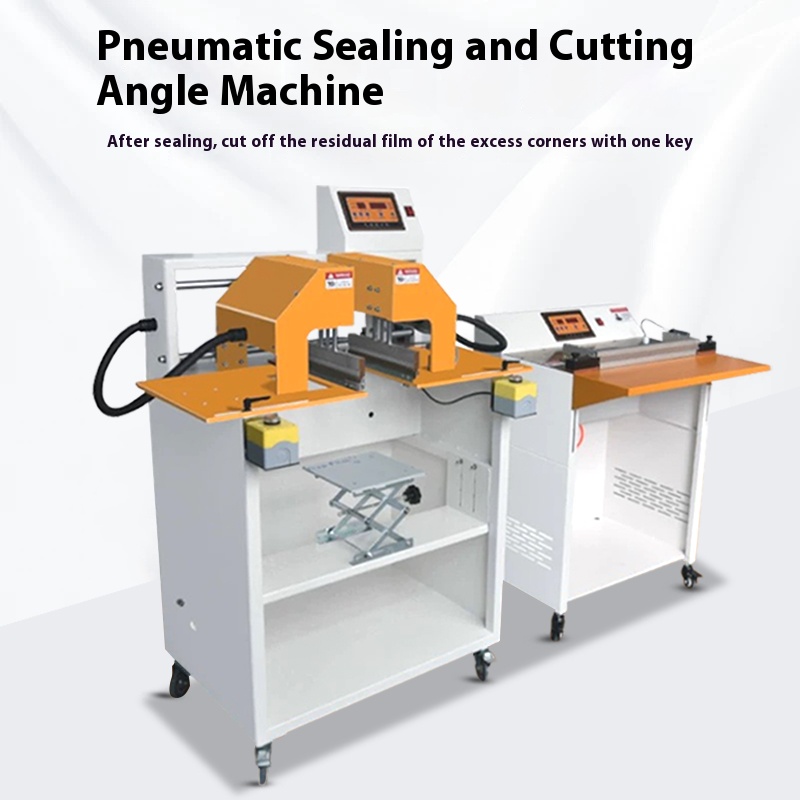

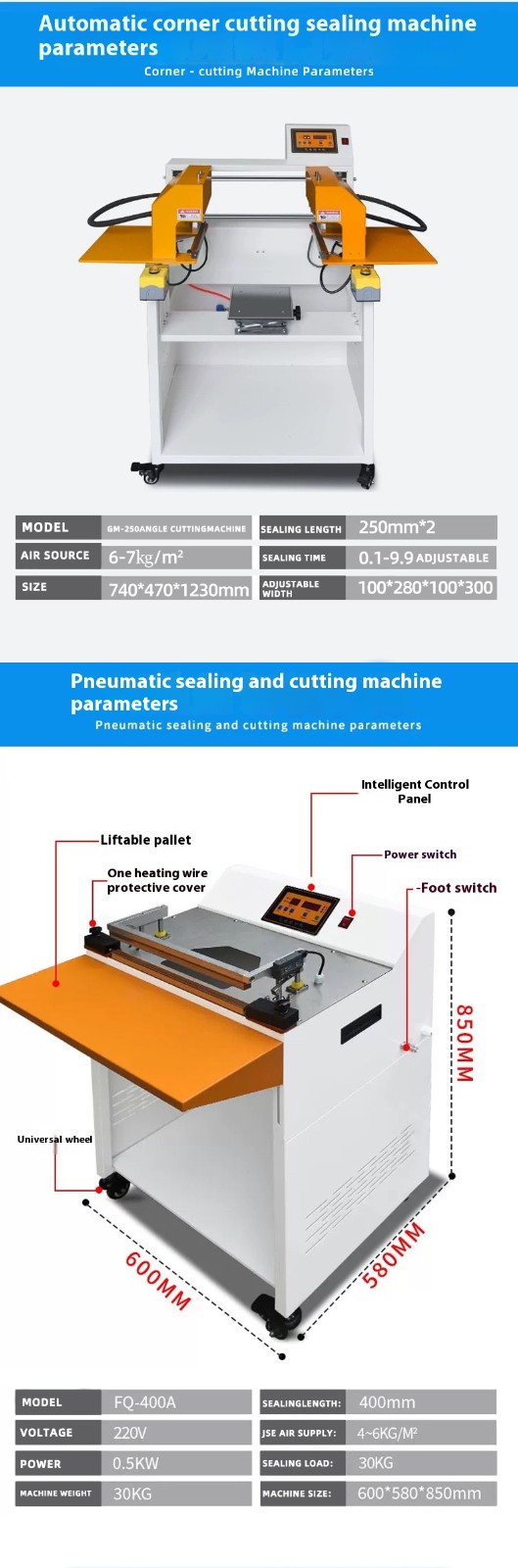

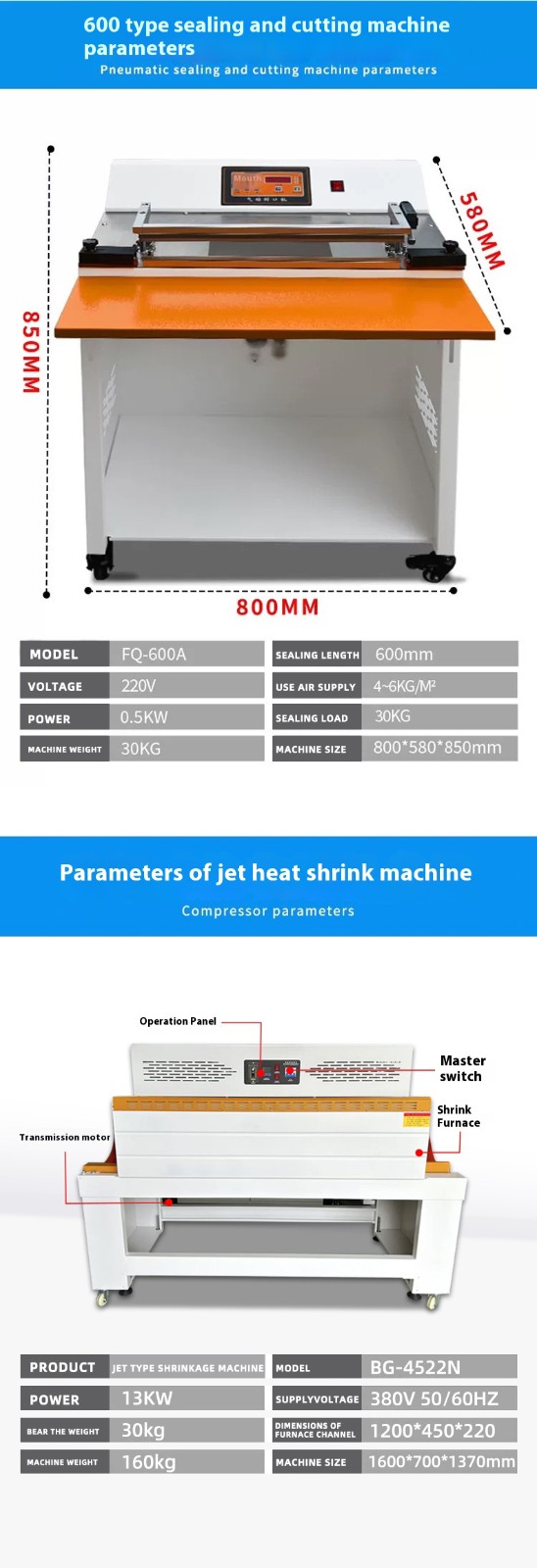

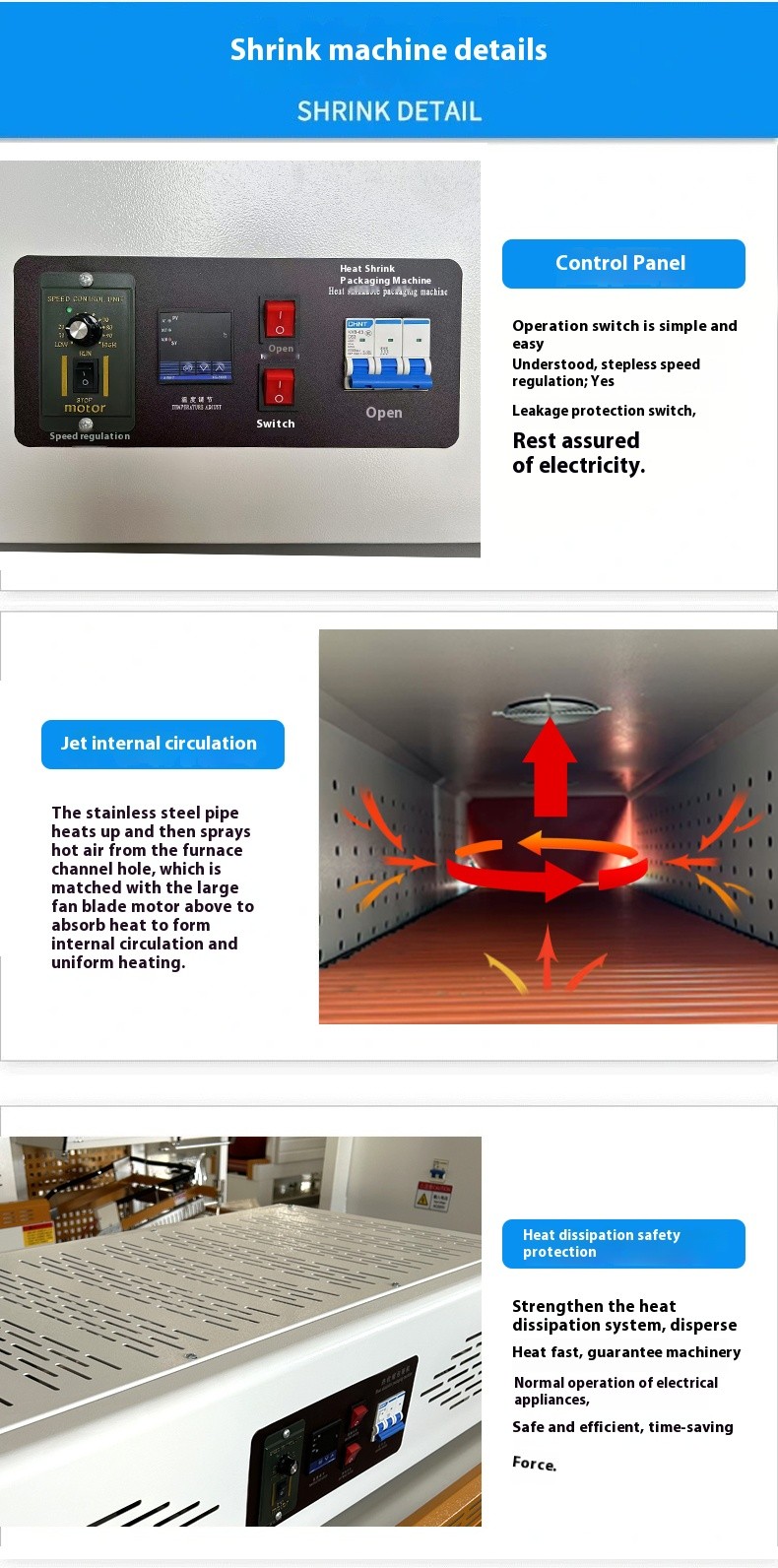

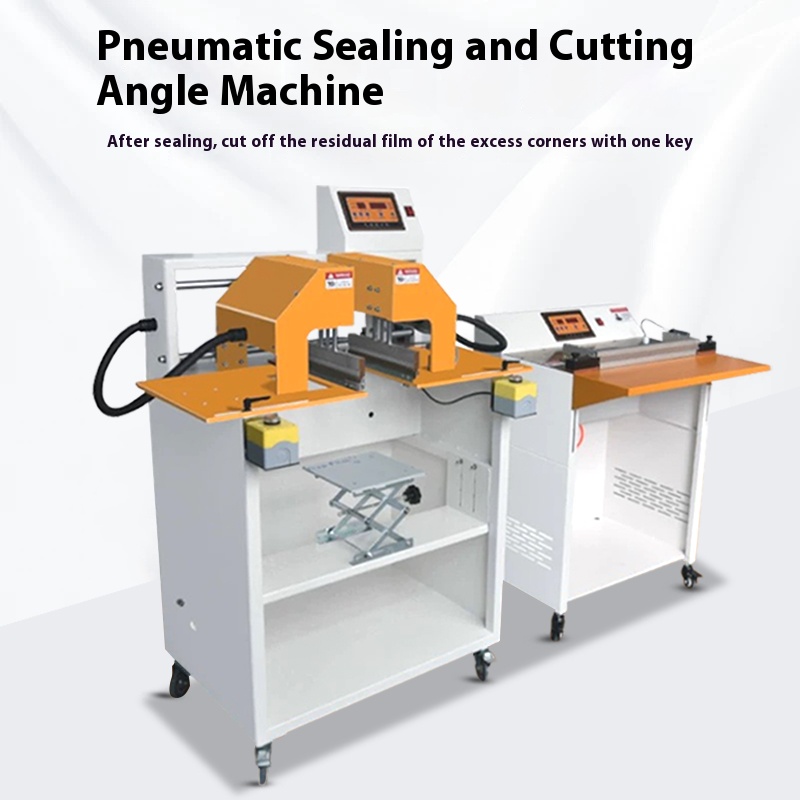

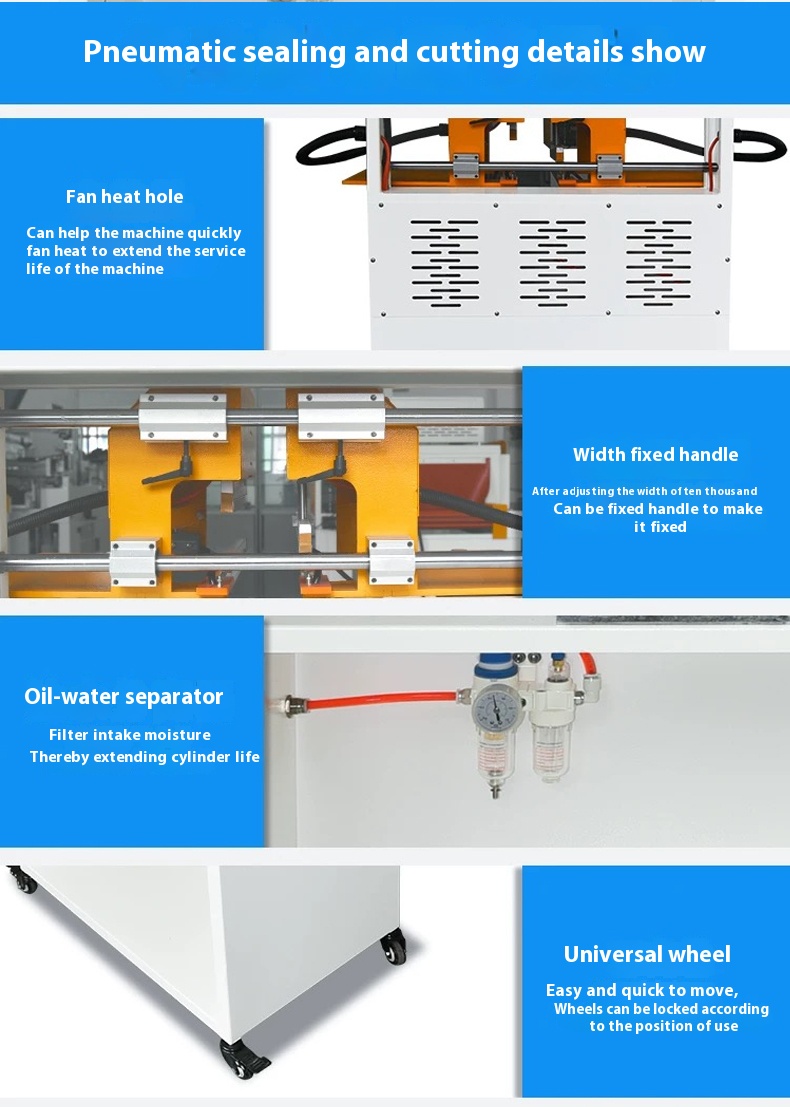

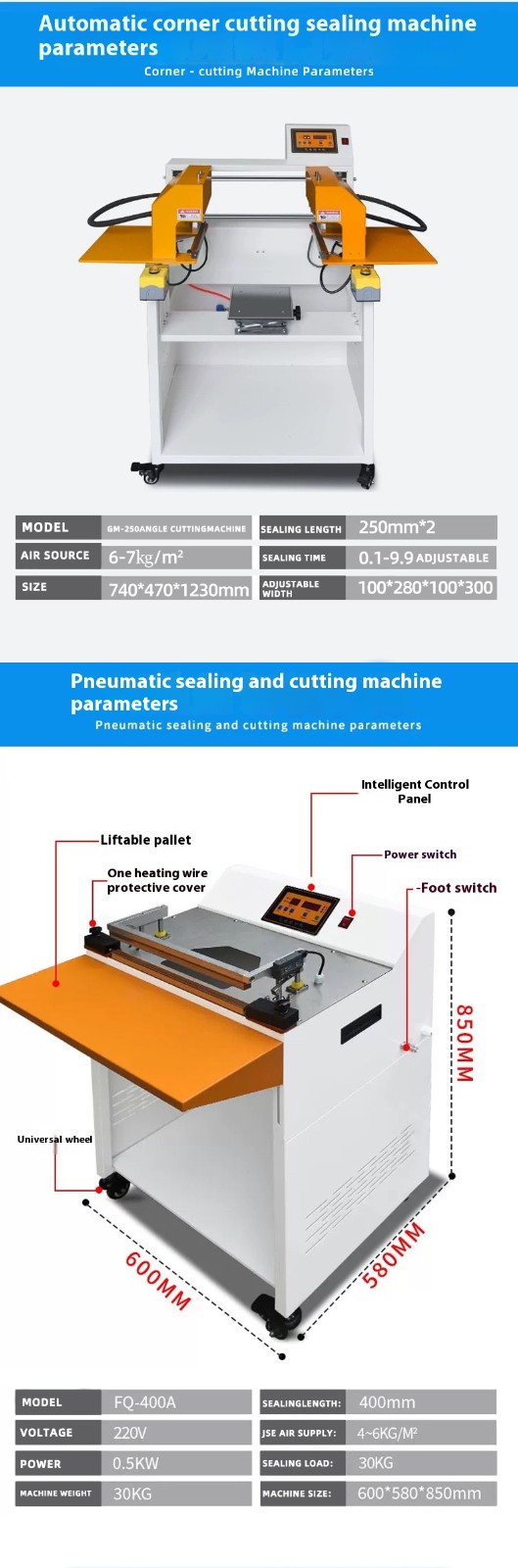

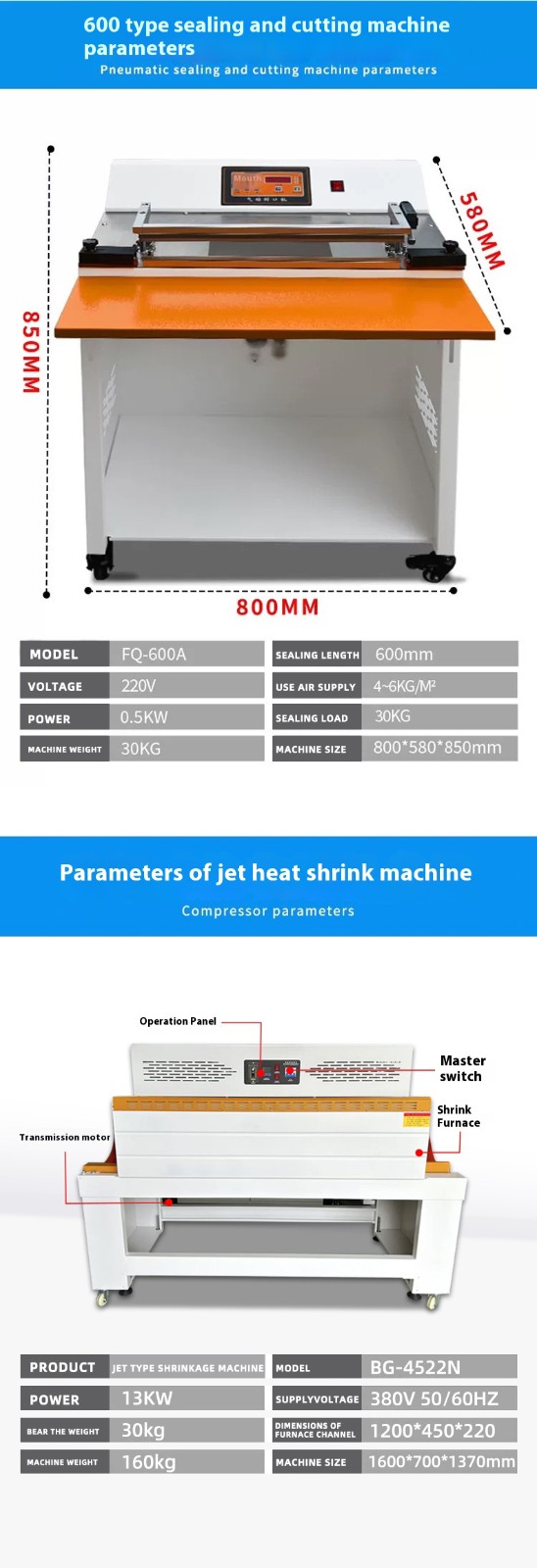

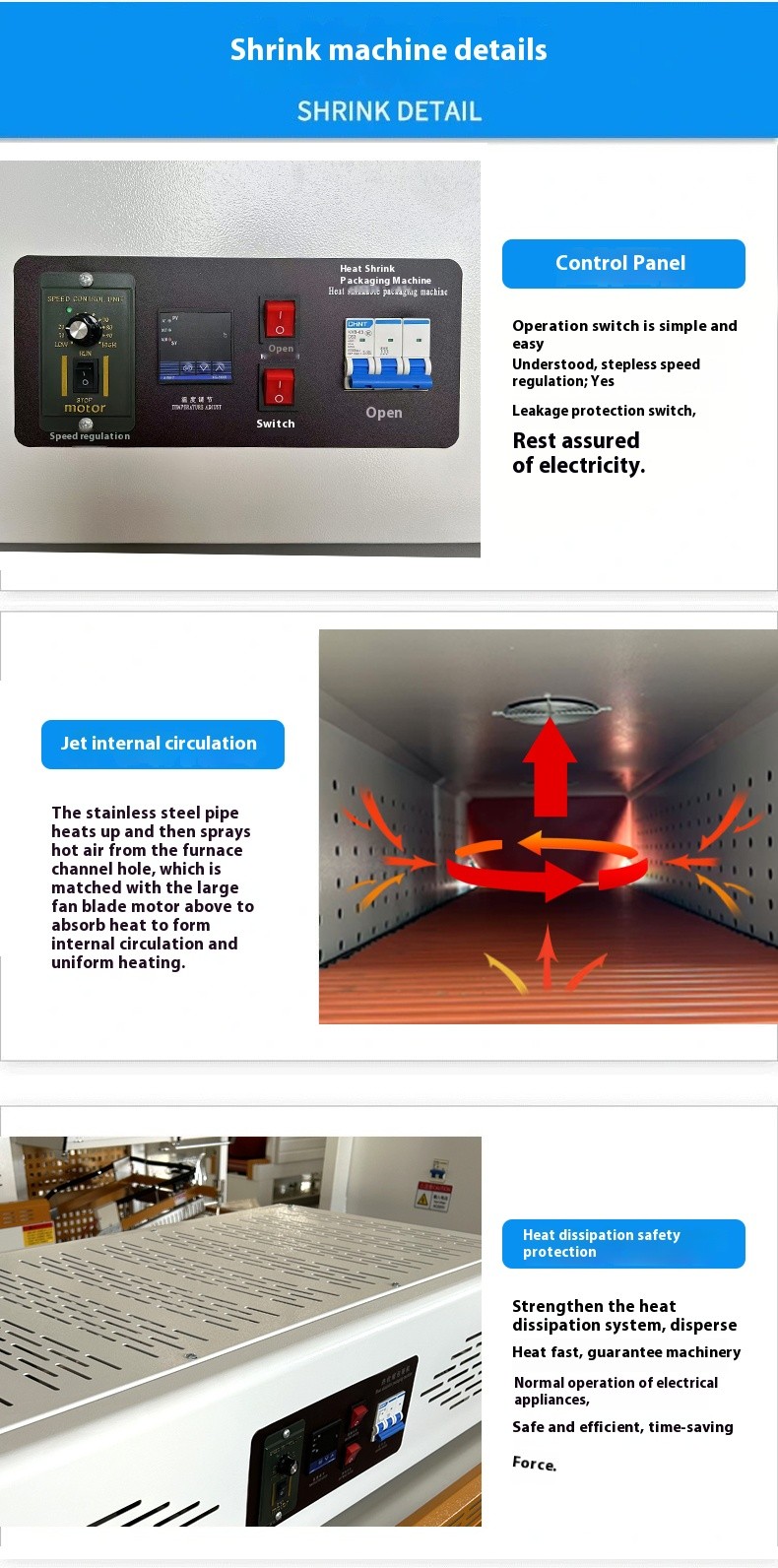

Equipment Inspection: Before starting the machine, carefully check whether all components of the equipment are in normal condition, including the pneumatic system, heating system, transmission device, etc., to ensure there are no problems such as looseness, wear, or leakage. At the same time, check whether the cutting knife is sharp and firmly installed to avoid the danger caused by the cutting knife falling off or jamming during operation.

Material Selection and Placement: Select appropriate packaging materials according to the packaging requirements to ensure that they meet the specifications and performance requirements of the equipment. When placing the packaging materials, be careful to avoid being scratched by the edges of the materials, and place the materials smoothly into the feeding port to prevent equipment failures or damage caused by the materials being skewed.

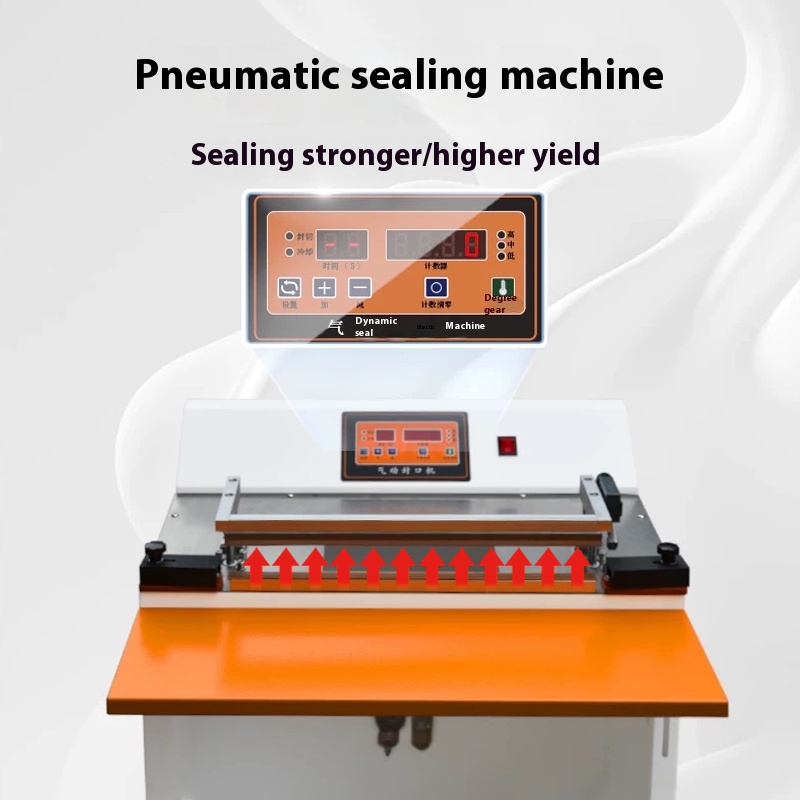

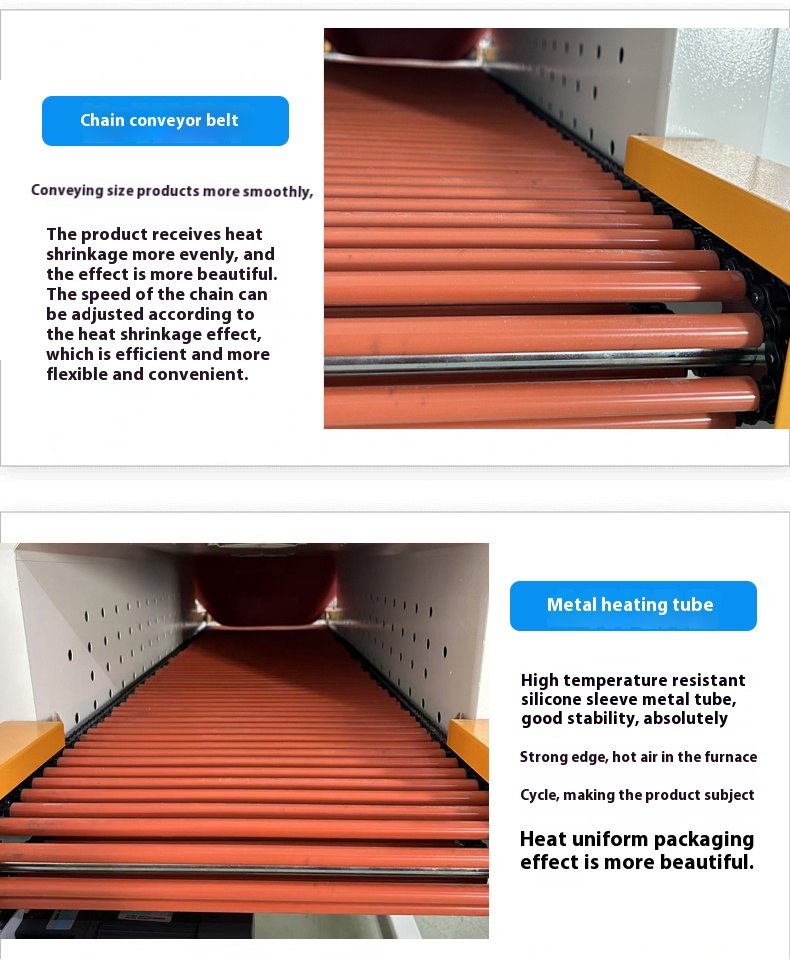

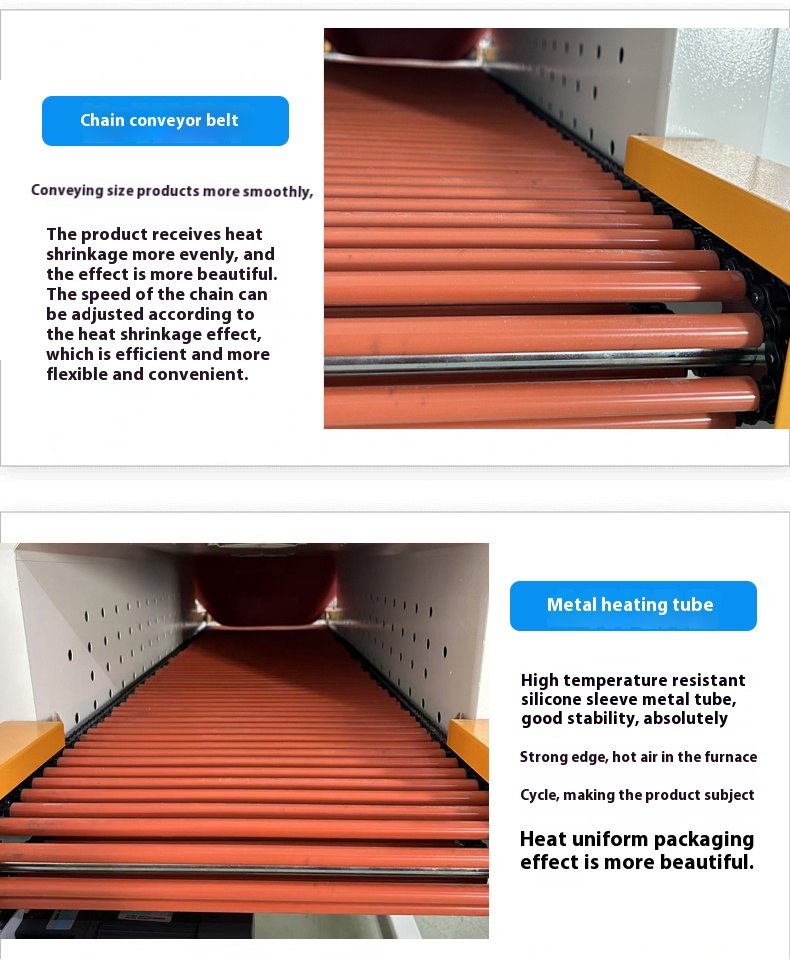

Operation During Running: When the equipment is running, it is strictly prohibited to put hands or other parts of the body into the sealing, corner-cutting, and heat shrinkage areas to avoid being scalded or pinched. If any abnormal operation of the equipment is found, such as strange noises, smoke, or peculiar smells, immediately press the emergency stop button, cut off the power supply, and notify professional maintenance personnel for inspection and repair. Do not handle it without authorization.

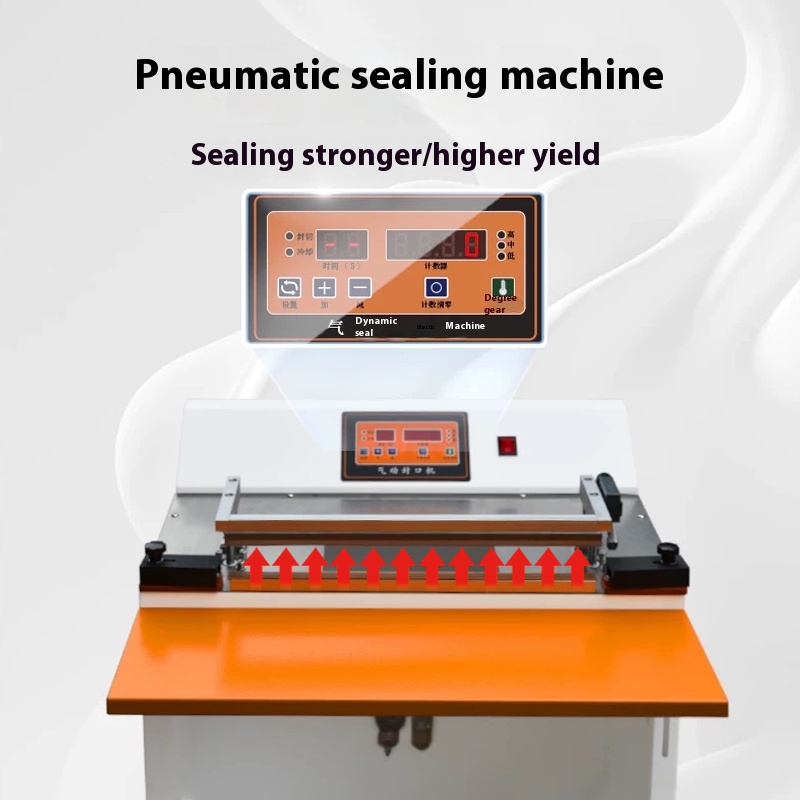

Maintenance of Heating Components: The heating components of the heat shrinkage packaging machine are at a very high temperature during operation. Do not touch the heating components during the operation of the equipment and for a period of time after shutdown to prevent scalding. Regularly clean the dust and debris on the heating components to ensure the heating effect and the normal operation of the equipment.

Maintenance of the Pneumatic System: Regularly check the pressure and sealing performance of the pneumatic system to ensure its normal operation. If insufficient air pressure or air leakage is found, deal with it in a timely manner. At the same time, do not adjust the pressure parameters of the pneumatic system casually to avoid affecting the normal operation of the equipment or causing potential safety hazards.

Shutdown and Cleaning: After the work is completed, first turn off the heating system, and then turn off the power supply and air source after the equipment has cooled down. Clean up the packaging waste and dust on the equipment in a timely manner to keep the equipment clean. Maintain key components such as the cutting knife, and apply an appropriate amount of lubricating oil to extend their service life.