After products enter the machine via the conveyor belt, the film is automatically wrapped around the exterior of the products. It then undergoes high-temperature sealing and cutting by electric heating wires to form a sleeve-shaped package. Subsequently, the package enters the heat-shrinking tunnel, where high temperature is used to make the film shrink evenly and adhere tightly to the product surface, completing the three-step packaging process of "film sleeving - sealing & cutting - heat shrinking".

- By automation level: It can be divided into semi-automatic sleeve-type heat-shrink packaging machines and fully automatic sleeve-type heat-shrink packaging machines. The semi-automatic type requires manual assistance for product placement or sealing operations, and is suitable for small and medium-scale production; the fully automatic type completes the entire process of conveying, sealing & cutting, and shrinking automatically, making it suitable for large-scale production.

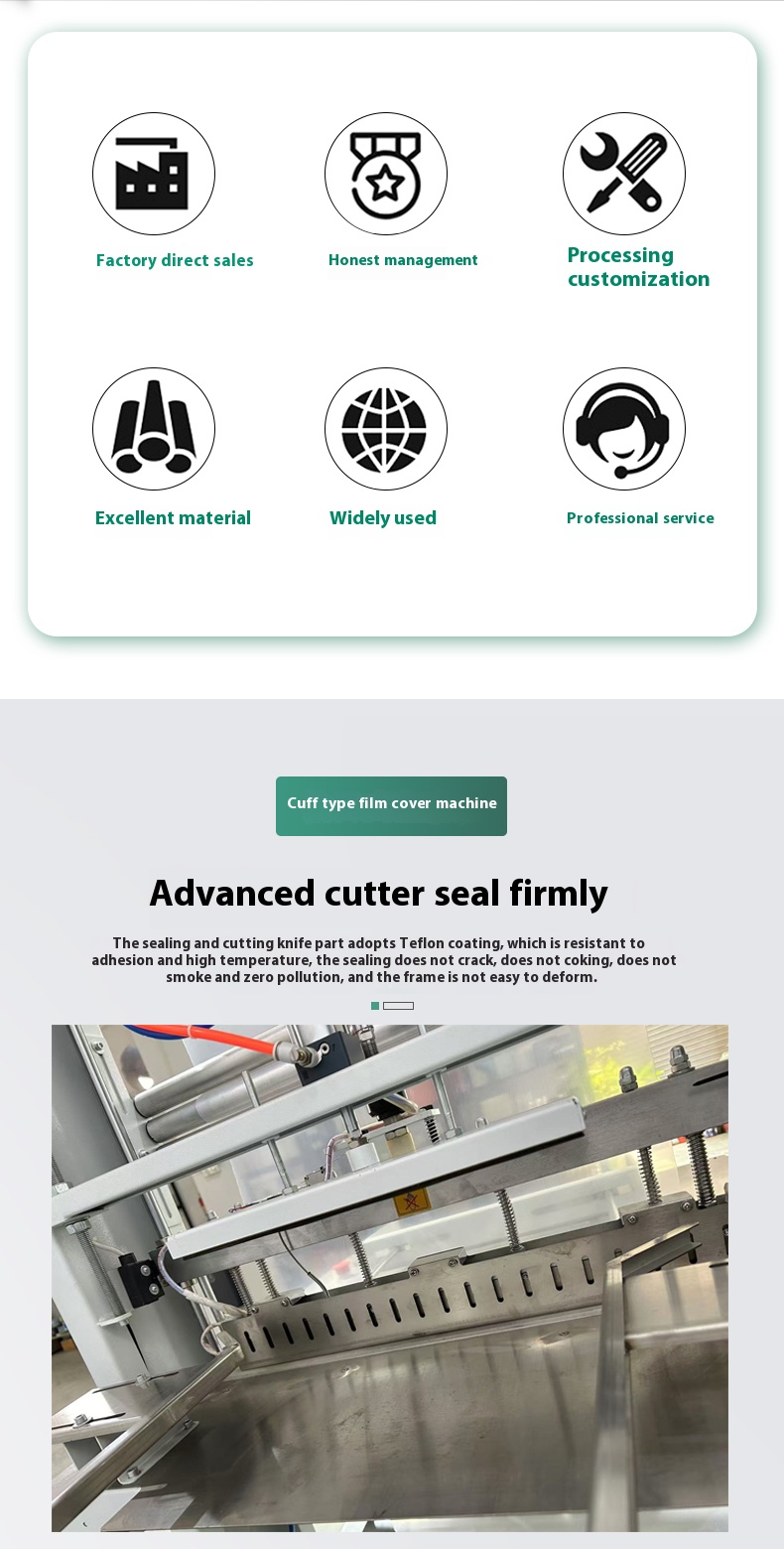

- By sealing technology: It includes heat-sealing sleeve-type packaging machines and cold-sealing sleeve-type packaging machines. Heat-sealing sleeve-type packaging machines achieve sealing by heating the sealing strip, and are applicable to heat-shrinkable films such as PE and POF; cold-sealing sleeve-type packaging machines use pressure to bond cold-sealing materials without the need for heating, and are suitable for temperature-sensitive products.

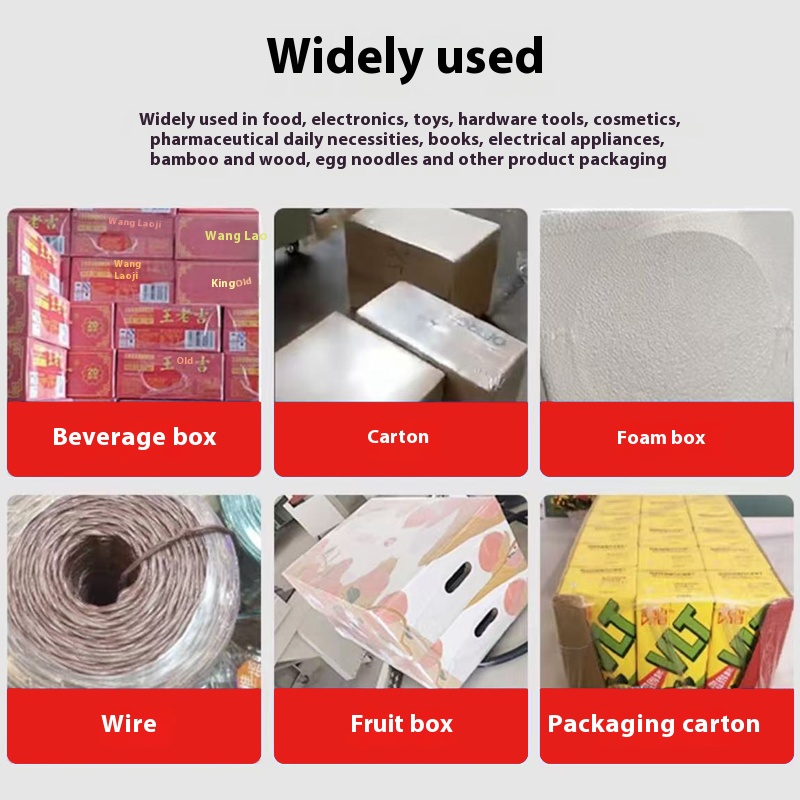

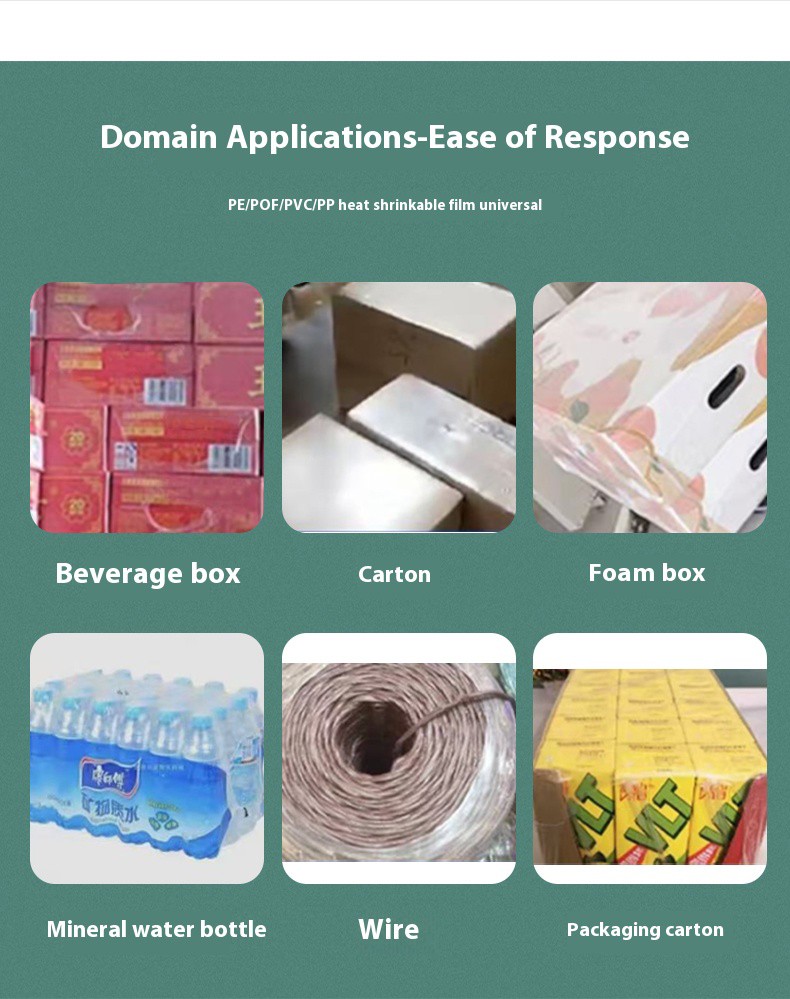

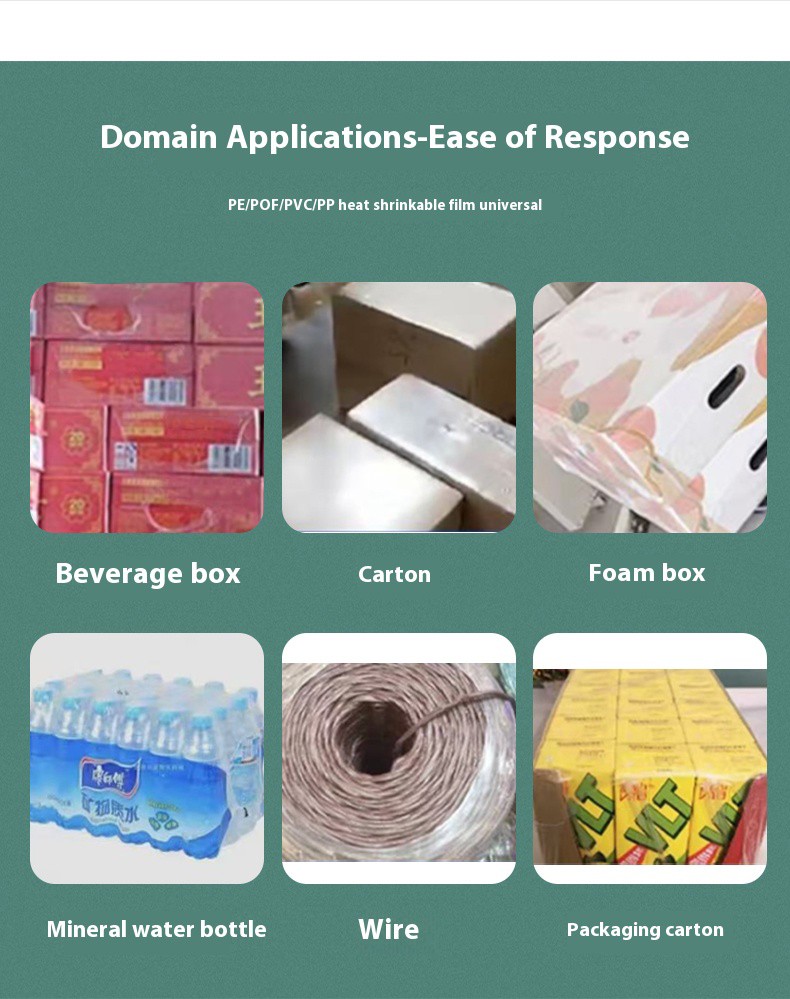

- By forming method: There are sleeve-type packaging machines and fully enclosed packaging machines. Sleeve-type packaging machines form a "sleeve" structure by wrapping the film, and are suitable for single-row/multi-row packaging of bottled beverages and other products; fully enclosed packaging machines allow the film material to completely wrap the products before shrinking, providing stronger sealing performance.

- By film material compatibility: The main types are machines compatible with PE films and machines compatible with POF films. PE films have strong puncture resistance and are suitable for heavy-duty packaging; POF films have high transparency and excellent shrinkage performance, and are mostly used in industries with high hygiene standards such as food and pharmaceuticals.

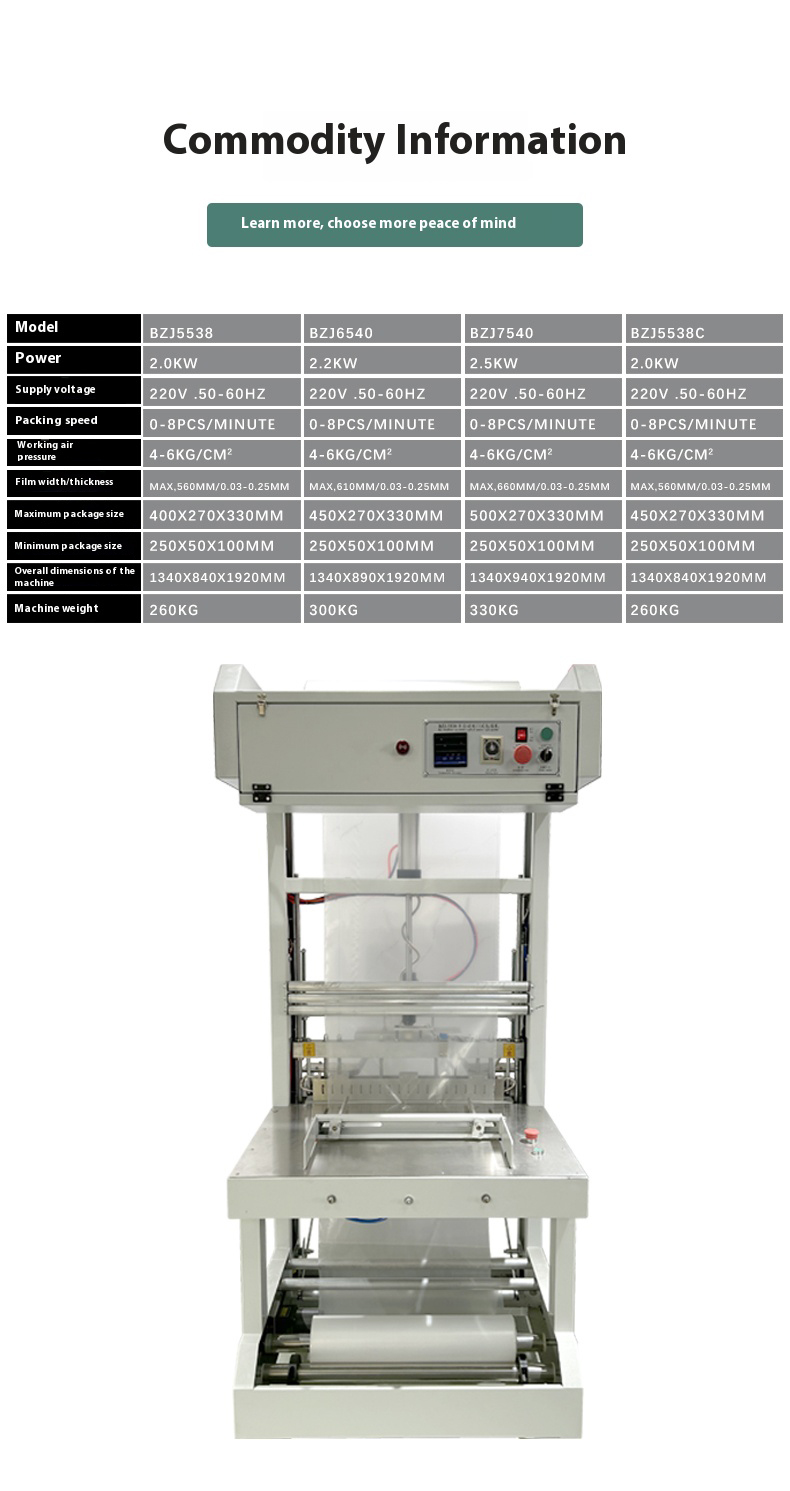

Fully automatic models can package 20-40 products per minute, support 24-hour continuous operation, and achieve a daily production capacity of 15,000-30,000 pieces. The conveyor chain is made of wear-resistant materials (such as solid steel rods covered with silica gel), with an operation error of ≤1mm, ensuring consistency in batch packaging.

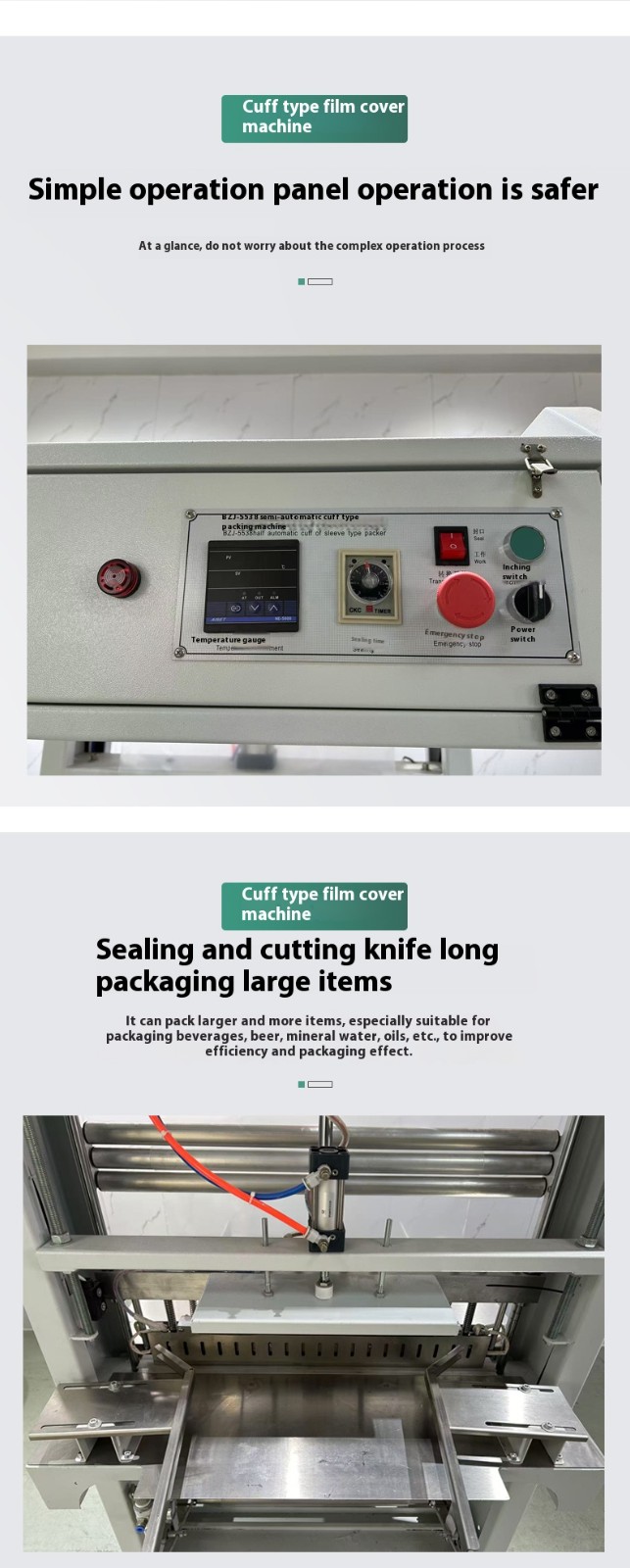

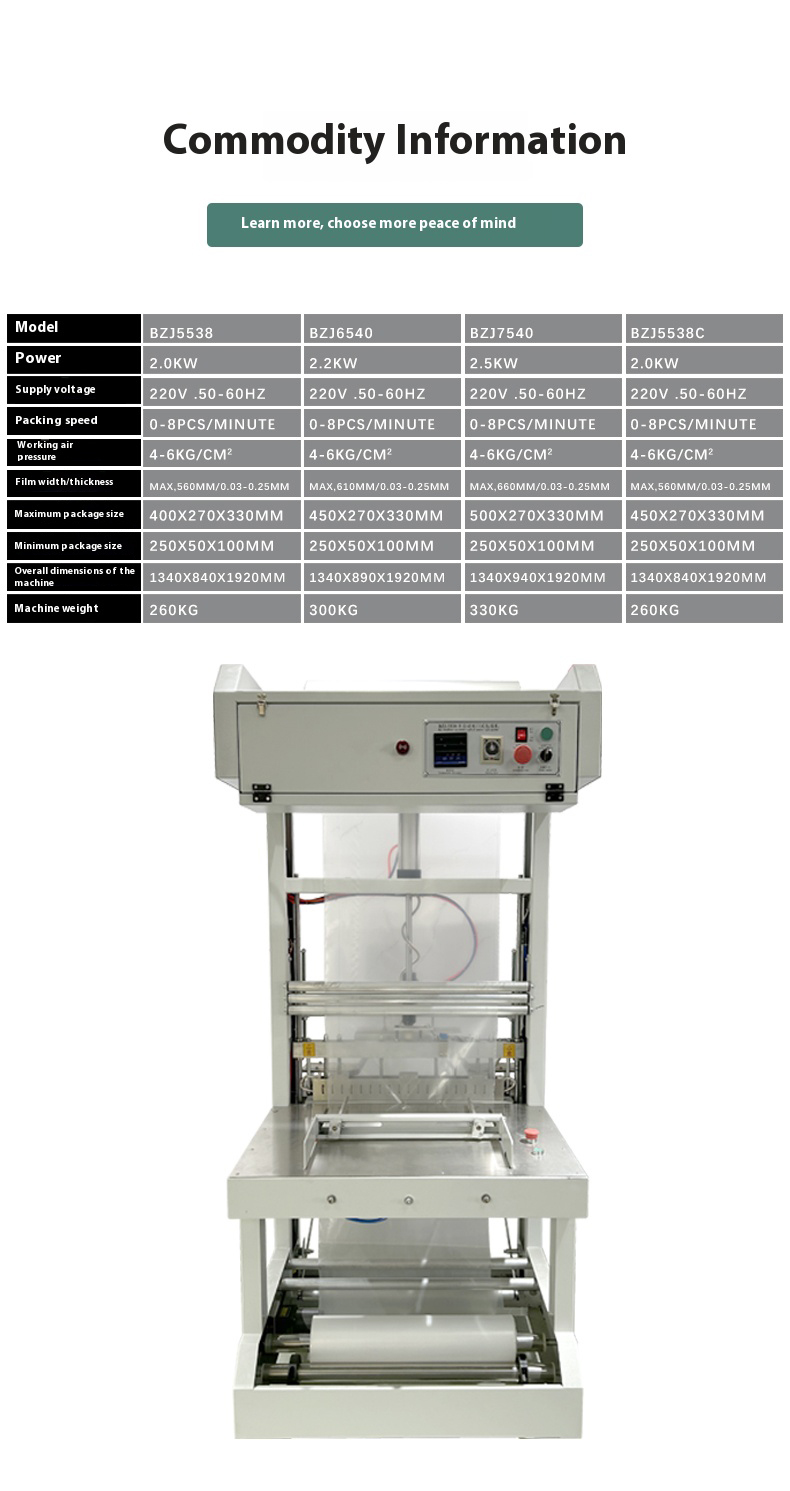

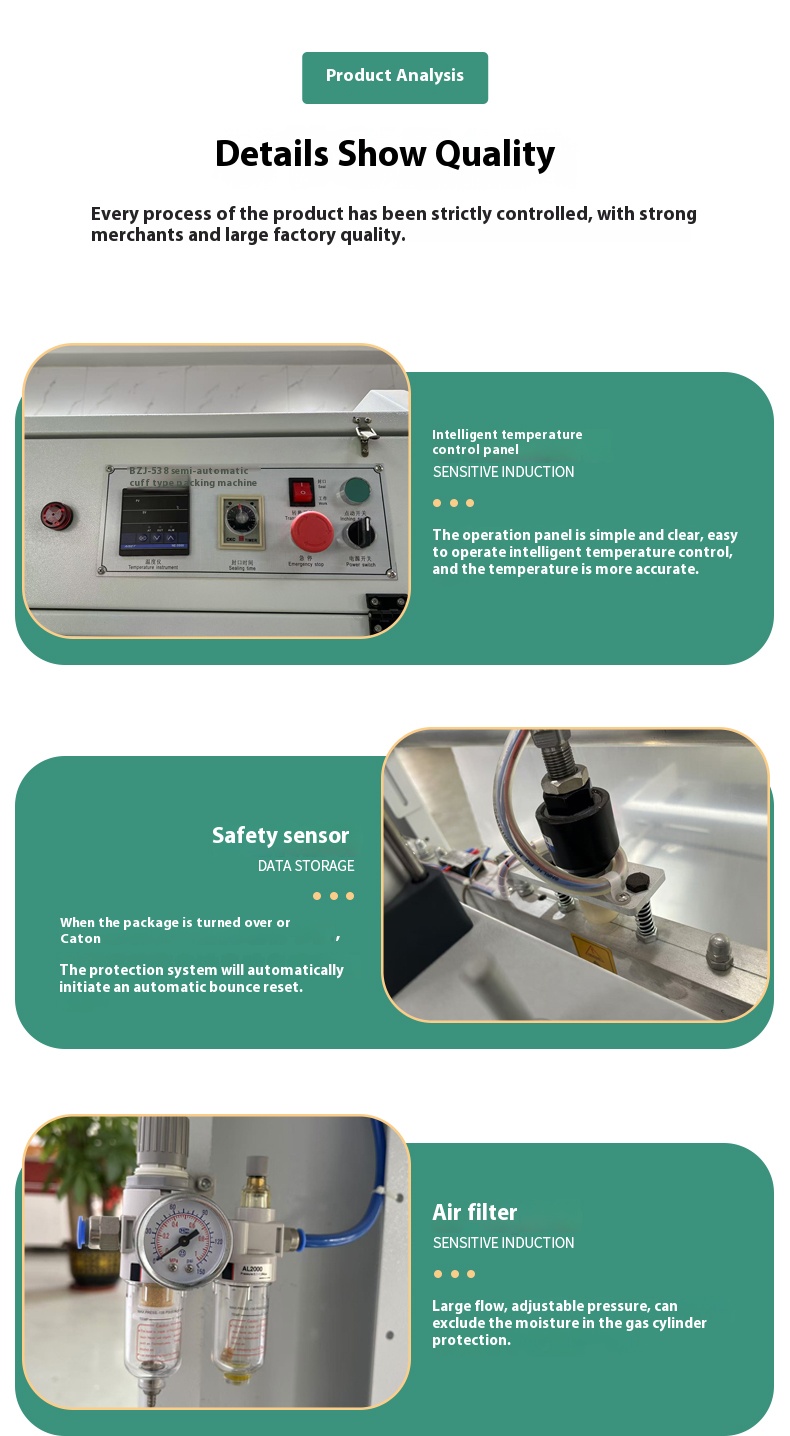

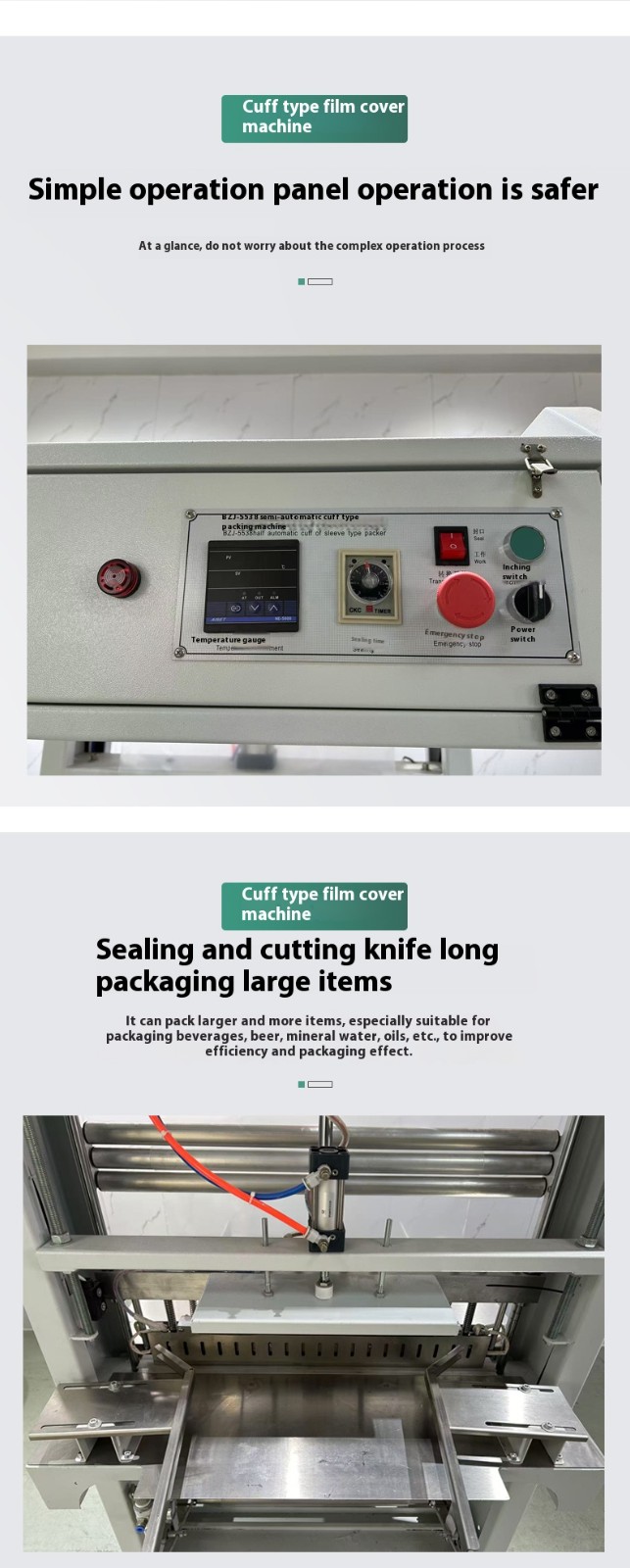

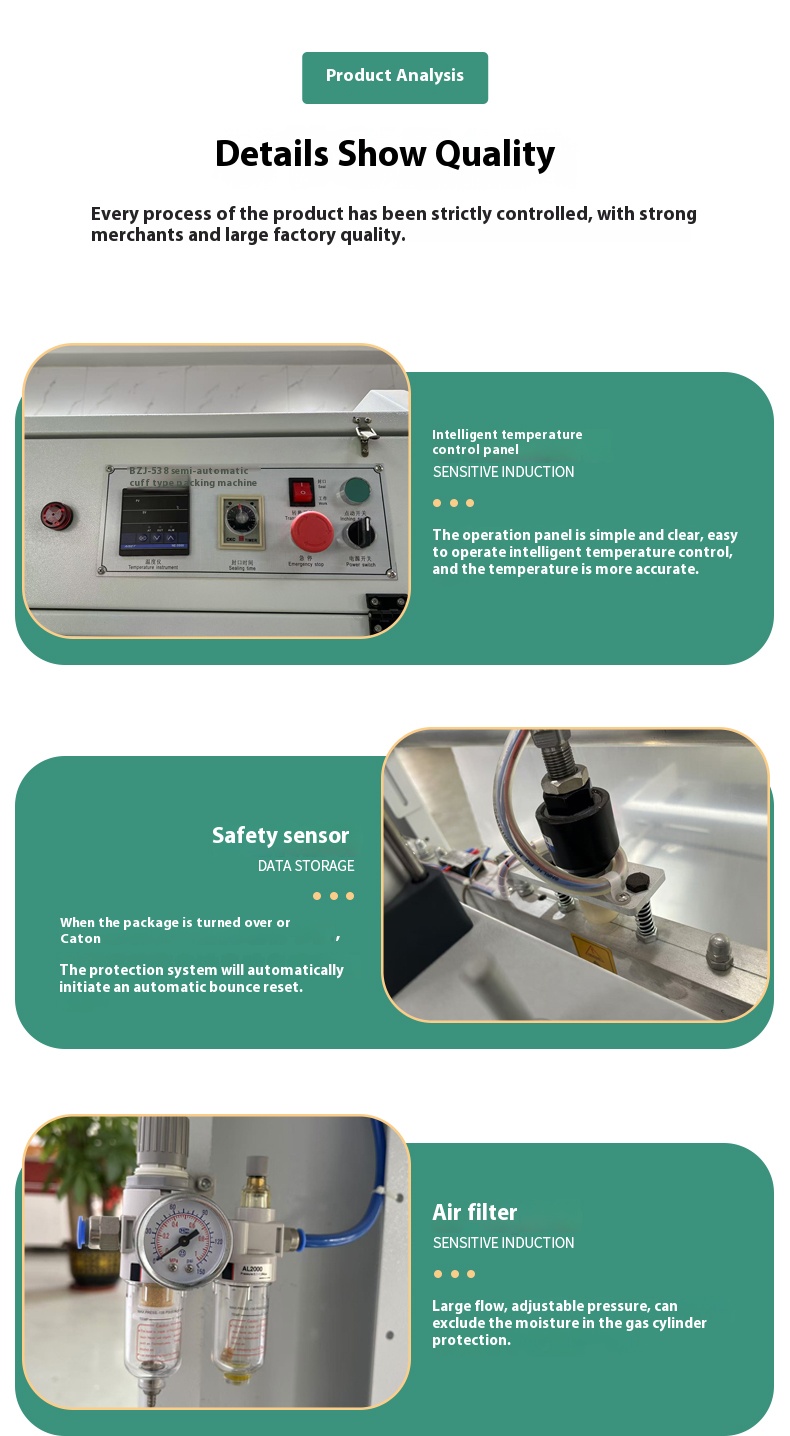

Through the PLC control system and touch screen, the sealing and cutting temperature (adjustable from 50-300℃), shrinkage time (adjustable from 0.5-5 seconds) and film tension can be precisely adjusted. It is compatible with PE/POF films of different thicknesses (0.02-0.2mm), avoiding problems such as film breakage and uneven shrinkage.

It can handle products with a wide size range (length 50-600mm, width 30-400mm, height 20-300mm), and supports square, circular, irregular-shaped products as well as multi-row combined packaging (such as 2-6 bottled beverages). It only takes 2-3 minutes to switch specifications without frequent equipment replacement.

Fully automatic models can replace 3-5 manual packaging positions, saving approximately 100,000-200,000 yuan in labor costs annually. They adopt infrared or quartz tube heating technology, which saves 30%-50% more energy than traditional electric heating wires. Moreover, the service life of the heating tube is 5-10 years, reducing the frequency of consumable replacement.

After heat shrinkage, the film adheres tightly to the product without wrinkles or bubbles. The transparent film can clearly display the product's appearance, improving the shelf display effect. It has excellent sealing performance, which can prevent moisture, pollution and transportation wear, and extend the product's shelf life (especially suitable for the food and pharmaceutical industries).

It is equipped with multiple safety protections: automatic power-off when the temperature in the heating area is overloaded, anti-misoperation protection for the sealing and cutting knife, and automatic alarm and fault code display by the PLC when the equipment is abnormal (e.g., "E01" indicates film feeding failure), allowing novices to quickly troubleshoot. The modular design facilitates the replacement of vulnerable parts (such as sealing and cutting knives, silica gel strips), reducing maintenance costs by 40%.