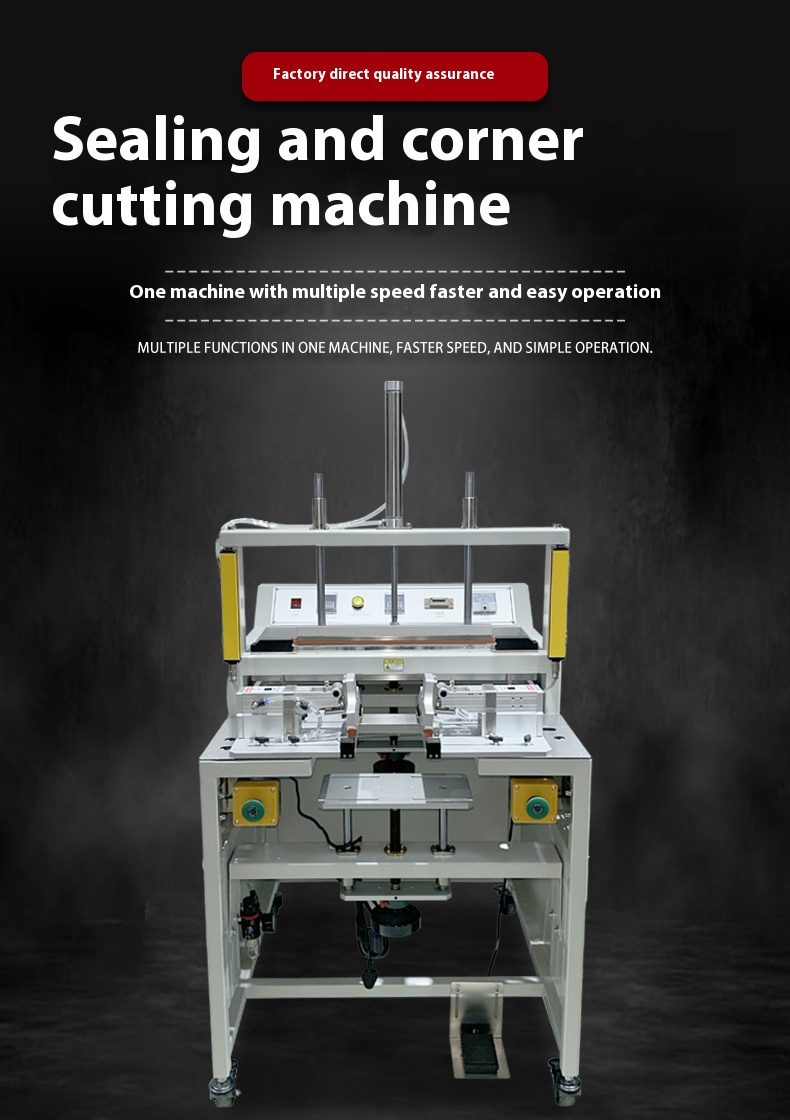

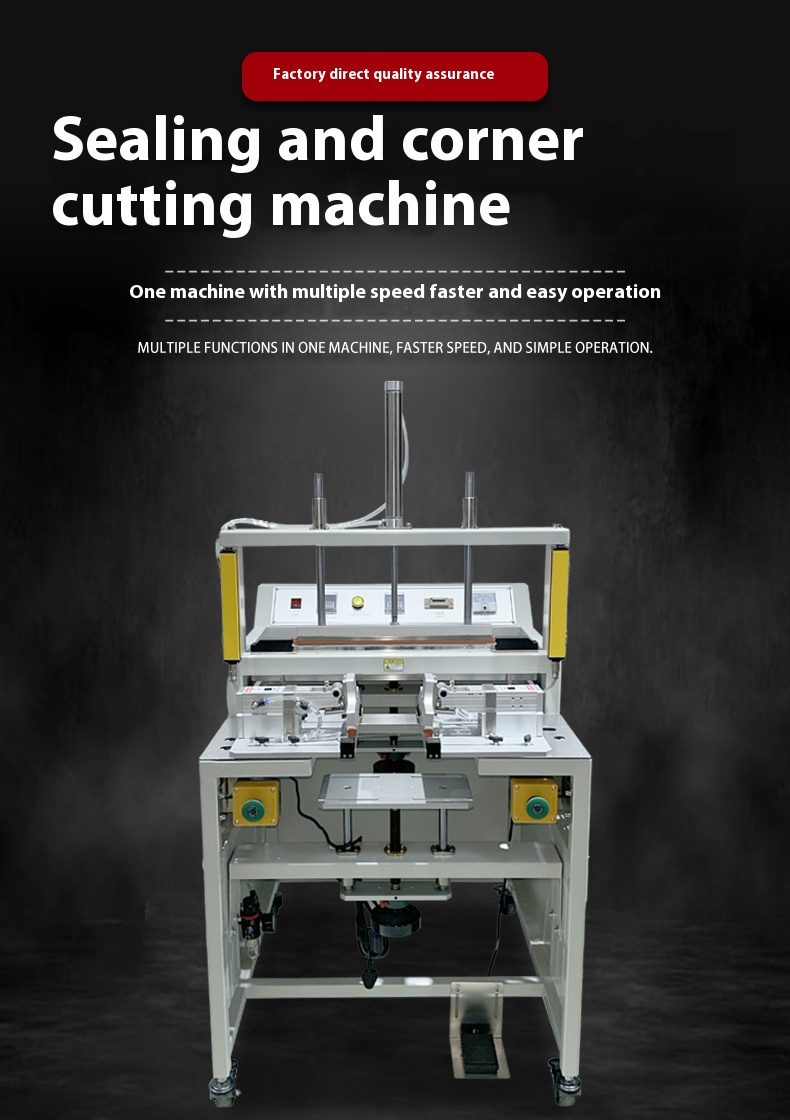

The core efficiency of the pneumatic sealing and corner-cutting all-in-one machine is reflected in the number of sealing-cutting cycles per minute and the processing volume per unit time, with significant differences between machines of different automation levels:

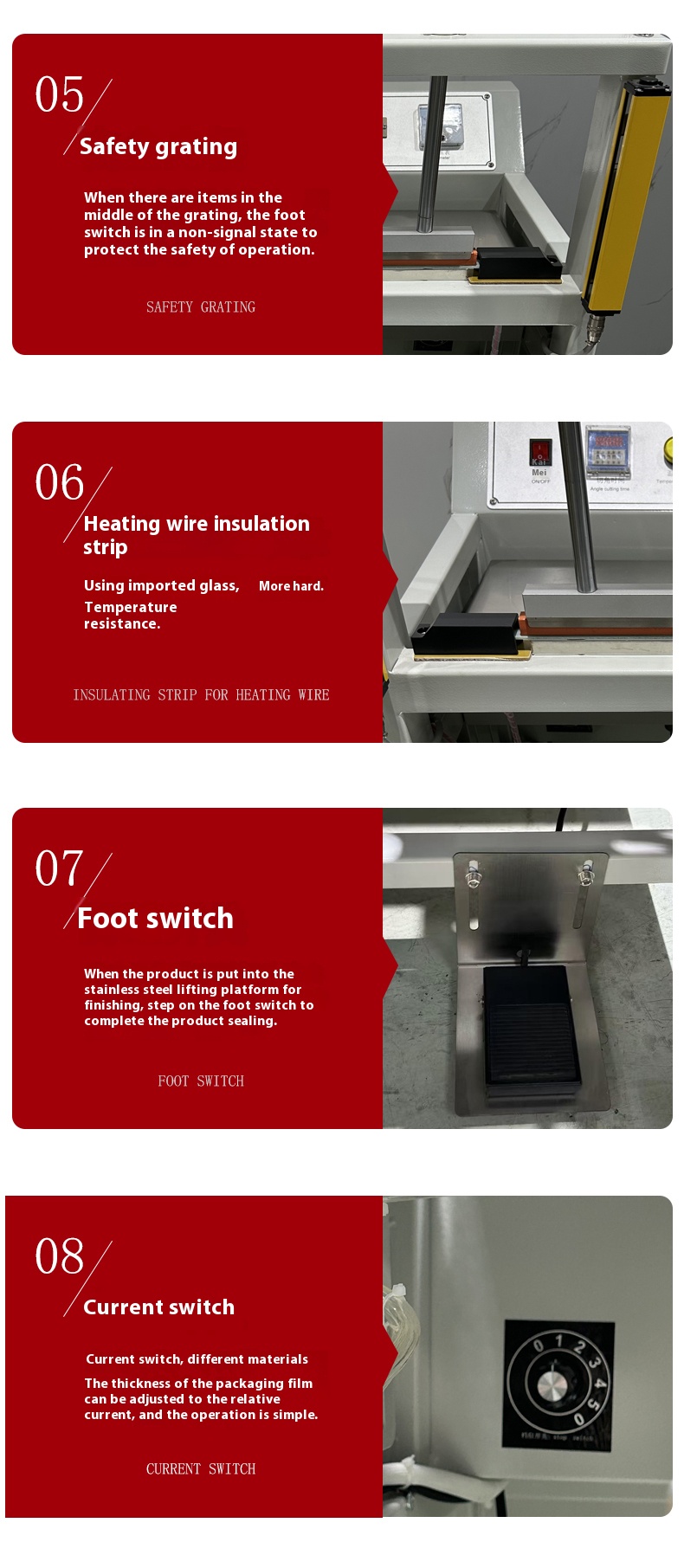

Semi-automatic models (mainstream type)These models require manual assistance for feeding and positioning (some are equipped with a foot switch for activation), while the sealing and cutting actions are automatically completed by the pneumatic system. They can achieve

15-50 sealing-cutting cycles per minute (specifically depending on the operator’s proficiency and the size of packaging materials).

Calculated based on a single 8-hour shift and an average of 20 cycles per minute, the daily production capacity can reach

9,600-12,000 pieces (assuming one packaging bag per sealing-cutting cycle).

They are suitable for

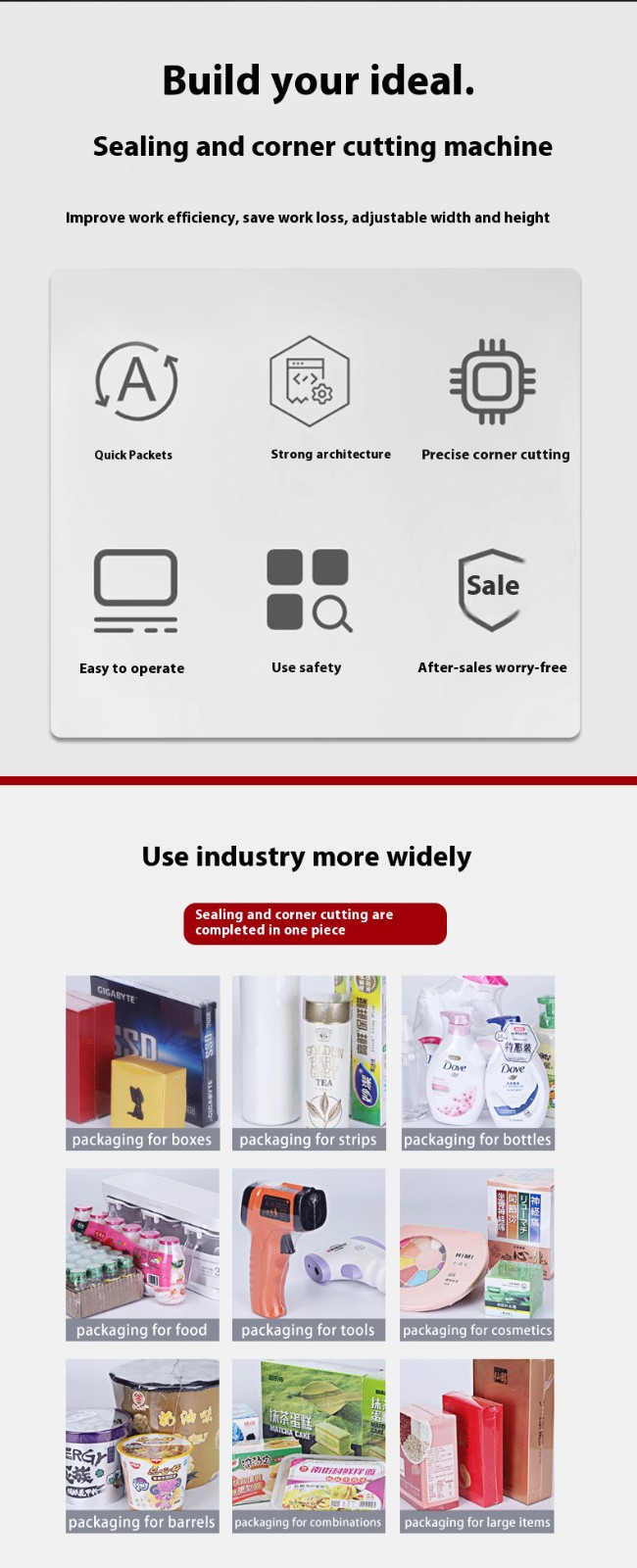

small-to-medium batch production (e.g., 10,000-50,000 pieces per day) and ideal for small and medium-sized manufacturers in the food and daily chemical industries, balancing efficiency and labor costs.

Fully automatic models (high-end type)Equipped with an automatic feeding mechanism, conveyor belt, and positioning sensors, these models require no manual intervention and can realize the full-process automation of "feeding - sealing-cutting - discharging". The number of sealing-cutting cycles per minute can reach

30-80, and some high-speed models even exceed

100 cycles per minute (requiring matching with thin, small-sized packaging materials, such as small bags for electronic components).

Calculated based on 50 cycles per minute and a single 8-hour shift, the daily production capacity can reach

24,000-38,400 pieces, making them suitable for large-scale mass production scenarios (e.g., pharmaceutical capsule packaging, bulk snack packaging). Their efficiency is

1.5-3 times that of semi-automatic models.

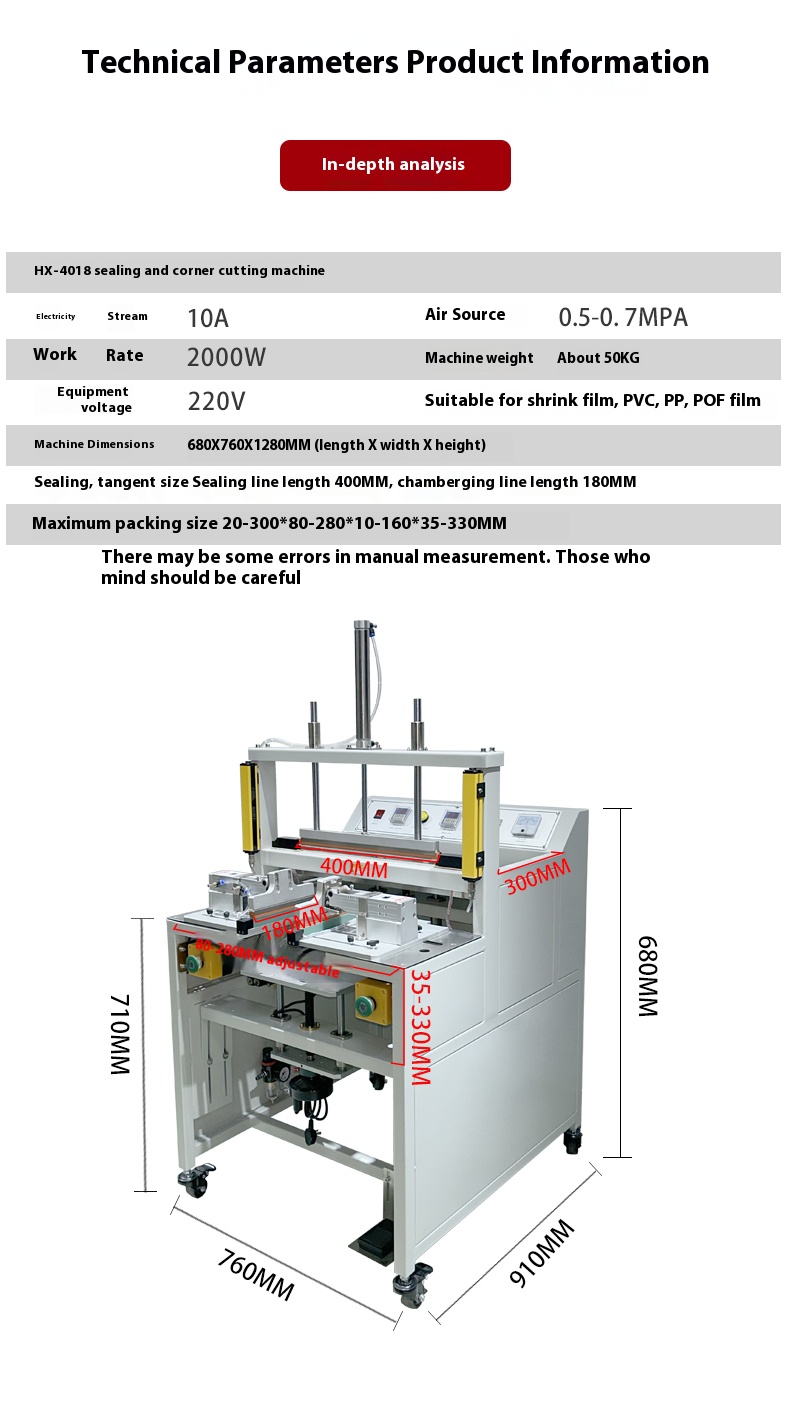

Compared with manual sealing machines and pure electric sealing machines, the pneumatic sealing and corner-cutting all-in-one machine gains its efficiency advantages from its technical characteristics:

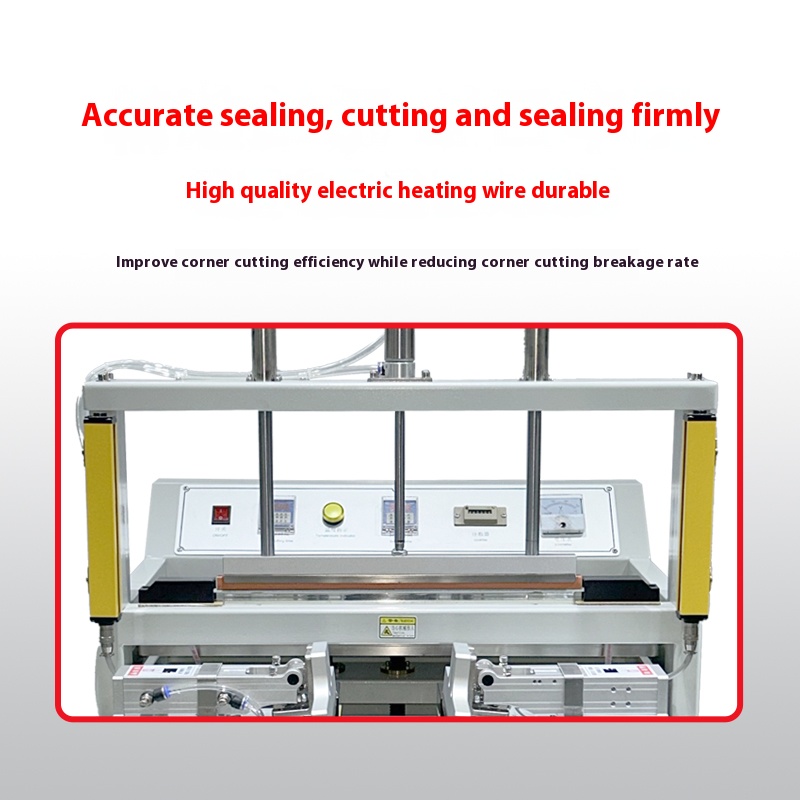

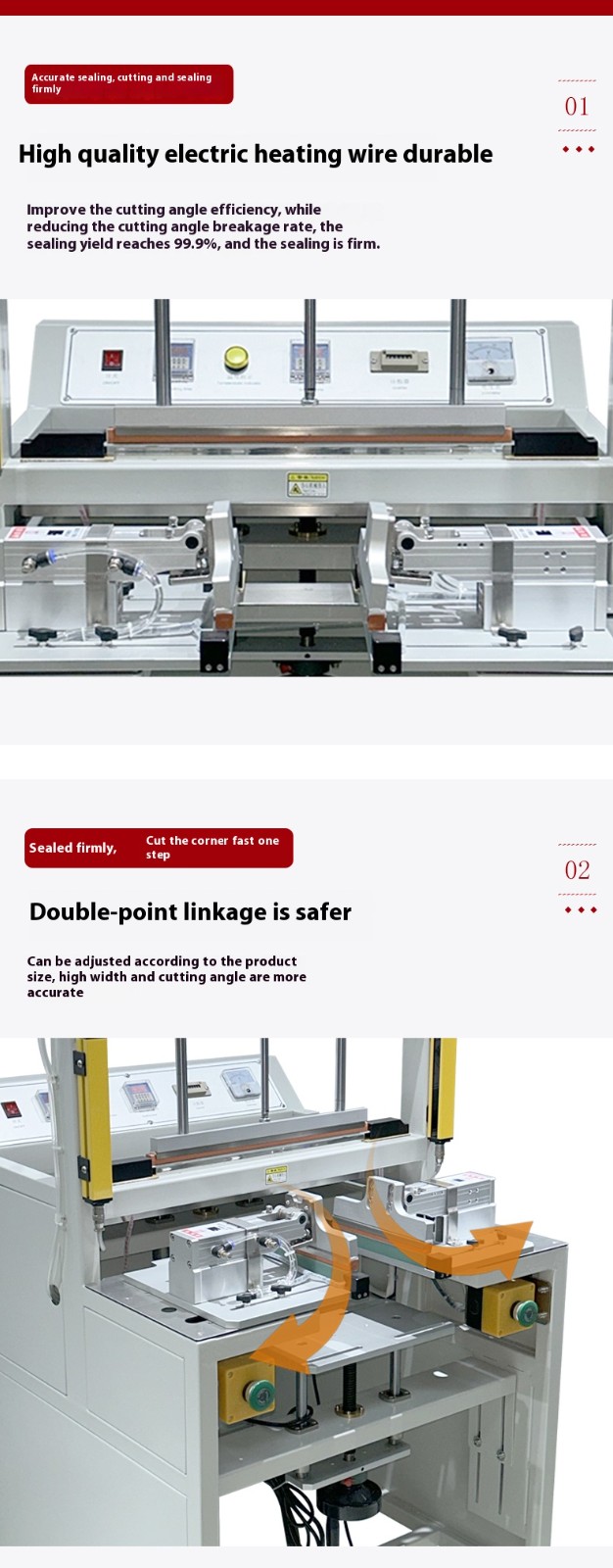

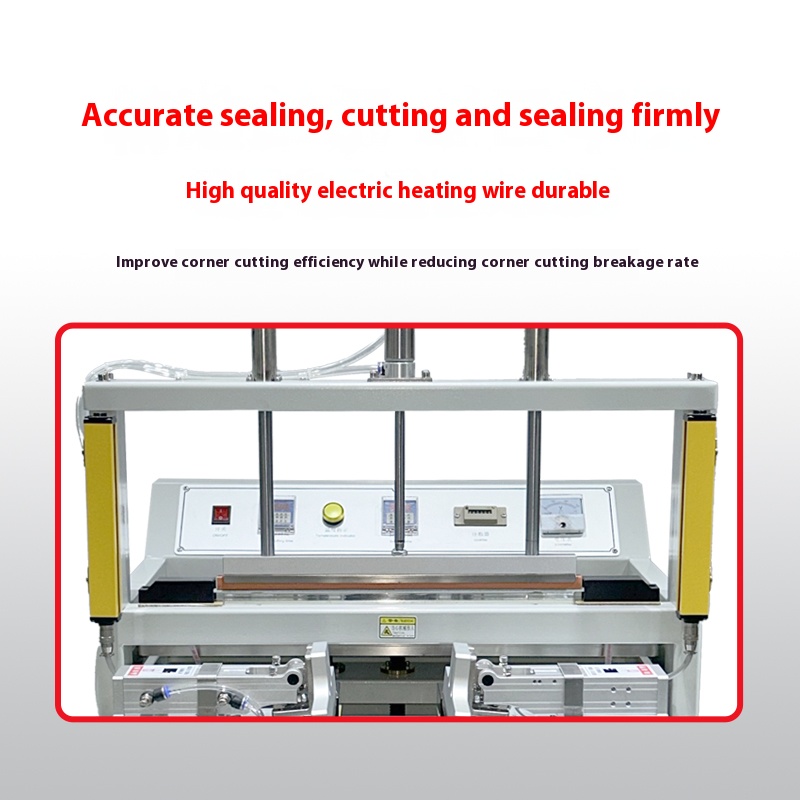

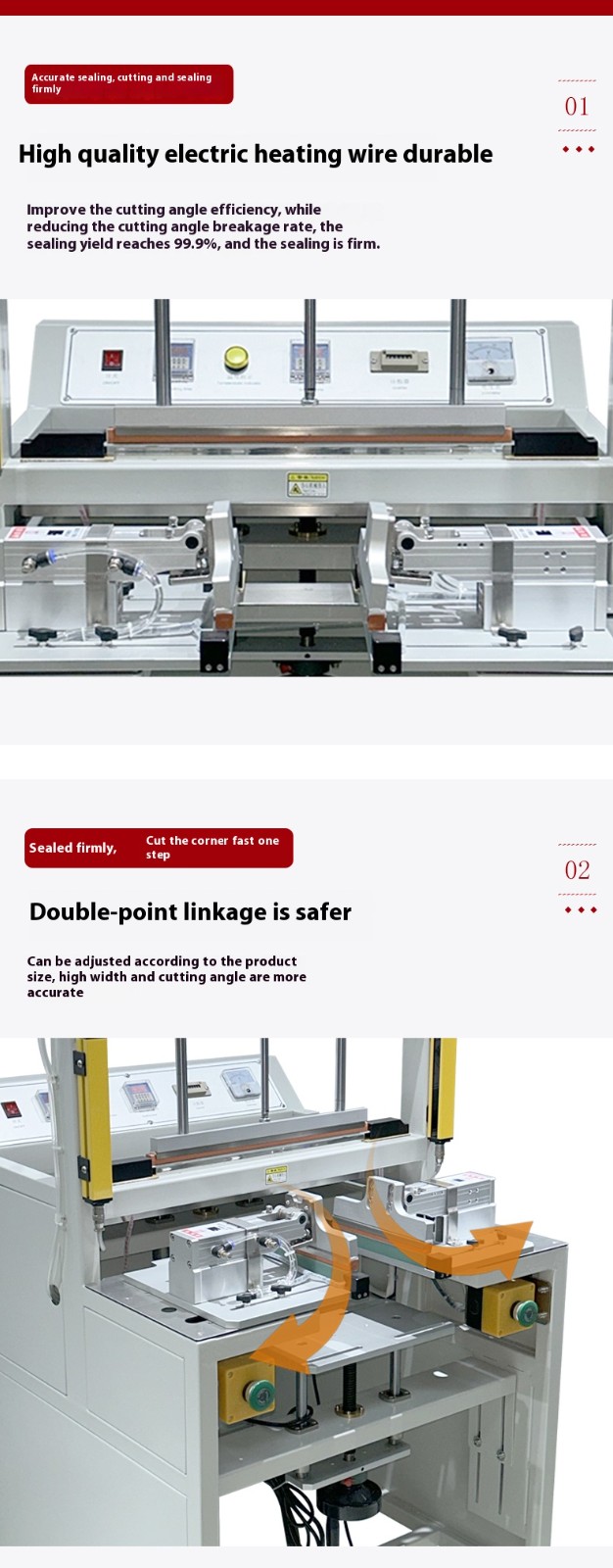

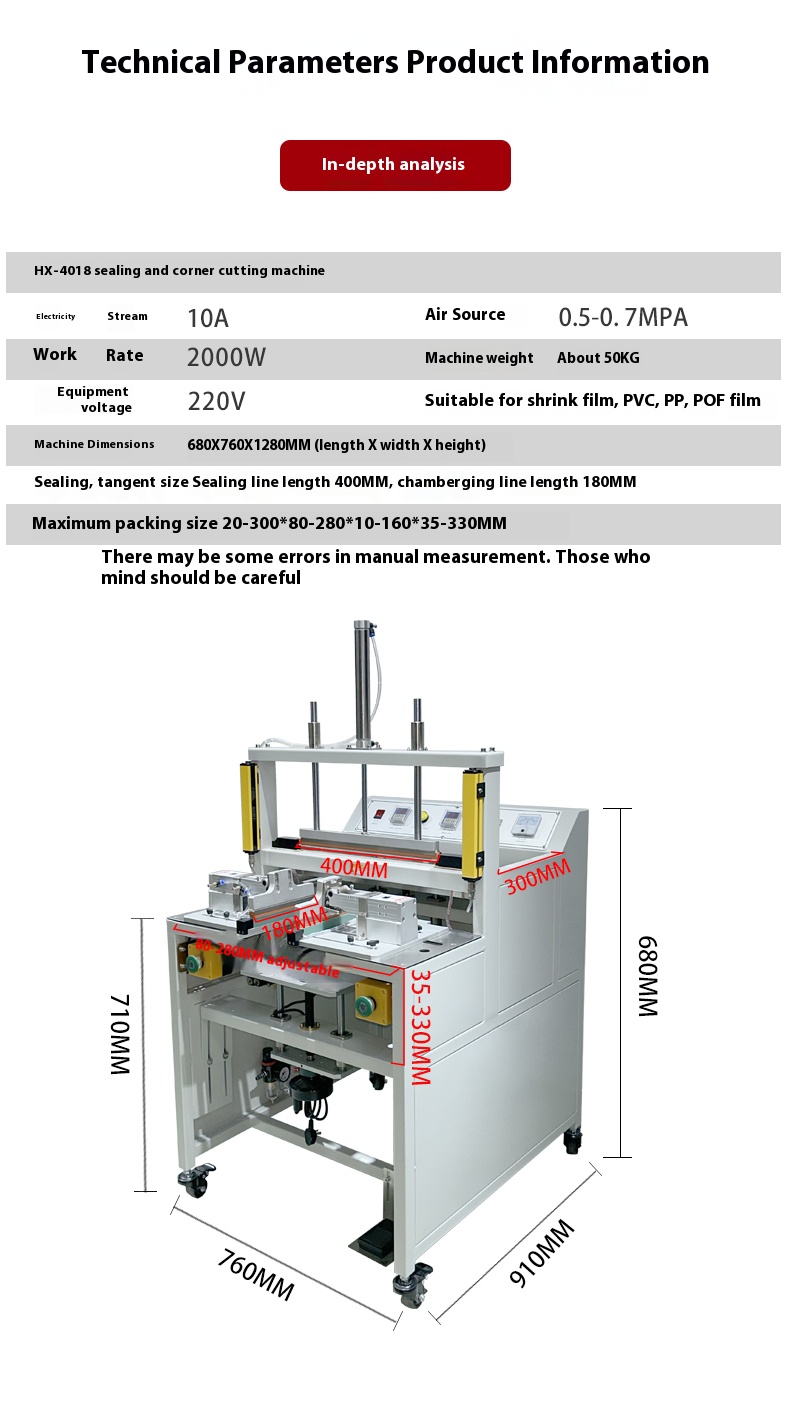

Pneumatic power: Fast response, reducing waiting timeThe core power comes from compressed air (air pressure: 0.5-0.7MPa). The action speed of the cylinder-driven sealing-cutting mechanism is much faster than that of electric motors (e.g., the mechanical transmission of traditional electric sealing machines). A single sealing-cutting cycle (heating - pressing - corner cutting - resetting) only takes

1-3 seconds, with stable actions and no mechanical jamming or delay.

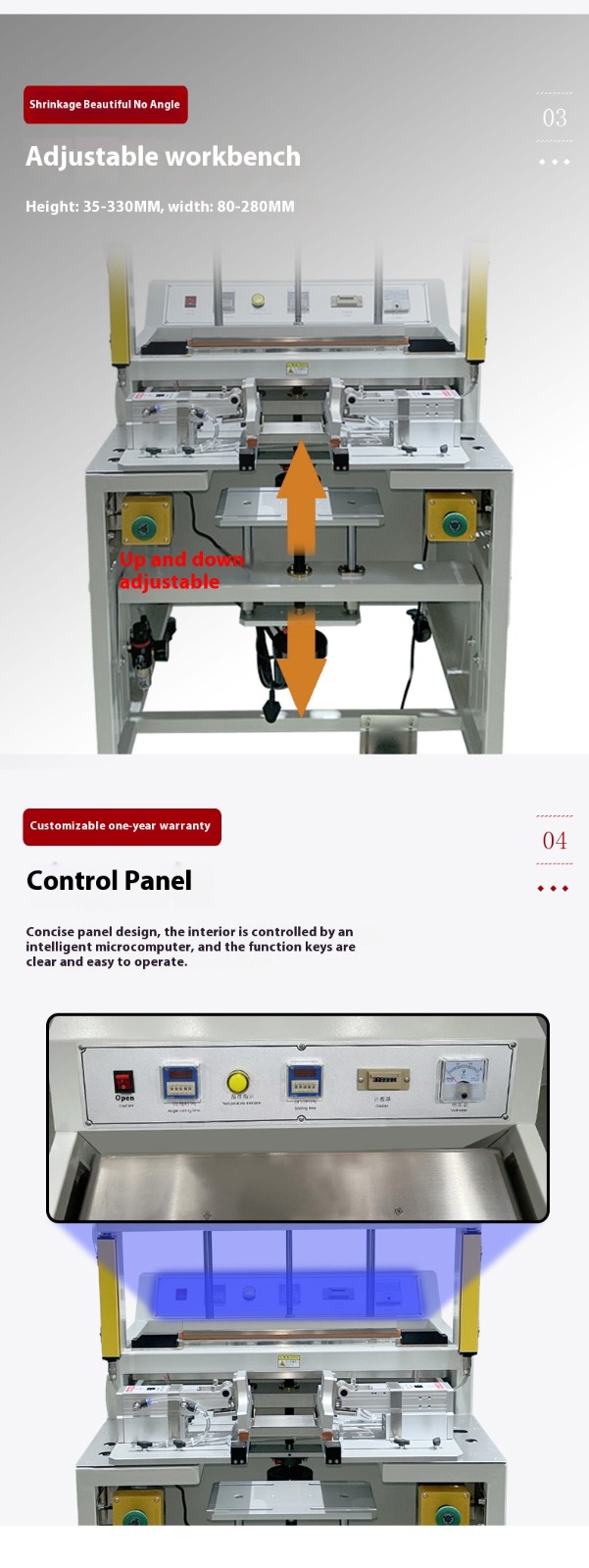

"Sealing + corner cutting" integration, eliminating secondary processesThe traditional process requires two steps at minimum: first manually sealing (e.g., using a sealing machine), then separately processing the corners with a corner-cutting machine or scissors. The all-in-one machine completes "melting sealing + precise corner cutting" simultaneously, reducing the operation time by more than 50% in a single process. This efficiency improvement is even more significant for scenarios requiring standardized corner cutting (e.g., avoiding sharp corners that may scratch hands and enhancing packaging aesthetics).

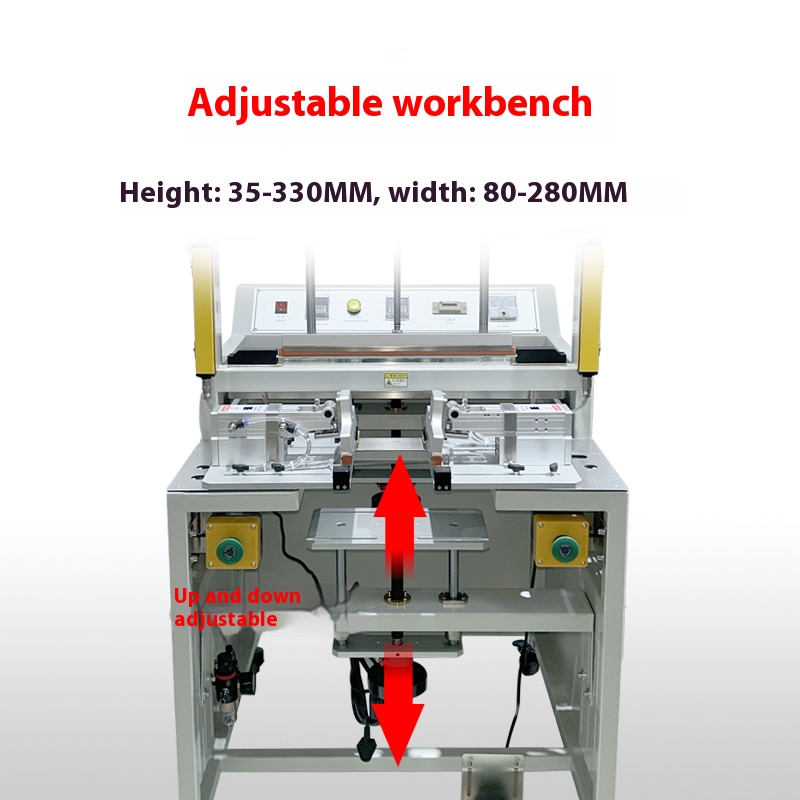

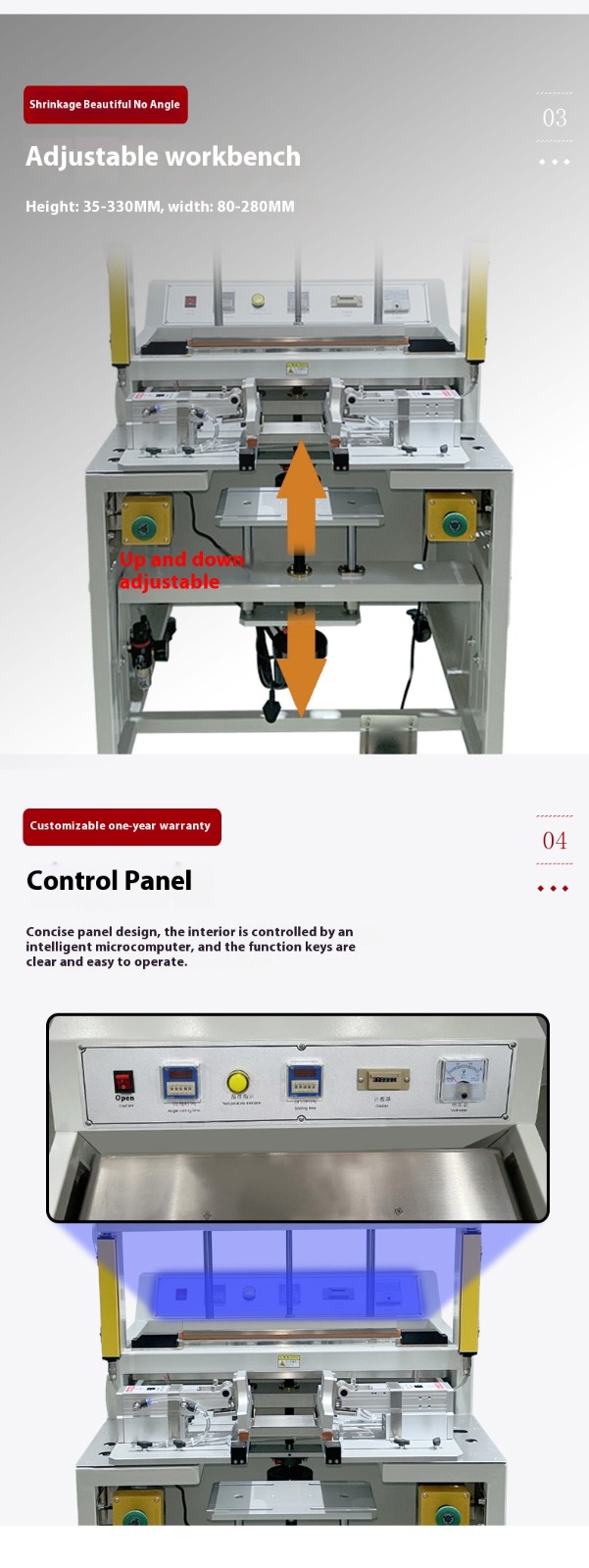

Adjustable parameters, adapting to multi-specification materials and reducing changeover timeThe machine can quickly adjust the sealing temperature (adapting to different materials such as PVC, PP, and POF), sealing length (usually 300-600mm), and corner-cutting angle (e.g., 45°, arc angle) via the control panel. The changeover time only takes

5-15 minutes (no need to disassemble complex components).

Compared with traditional equipment: To switch to packaging of different sizes, traditional equipment may require mechanical structure adjustments, taking more than 30 minutes. The all-in-one machine’s fast adaptability greatly reduces downtime and indirectly improves the total daily production capacity.

In practical use, some factors may reduce the machine’s efficiency, which should be focused on during model selection and operation:

Properties of packaging materials

- Thick materials (e.g., PE films with a thickness > 0.15mm) require higher heating temperatures and longer pressing times, which may extend a single cycle to 3-5 seconds and reduce efficiency by 20%-30%.

- Irregularly shaped packages (e.g., special-shaped bags, packaging bags with handles) require manual auxiliary positioning, which will reduce the speed of semi-automatic models (it is recommended to prioritize fully automatic models with customized positioning mechanisms).

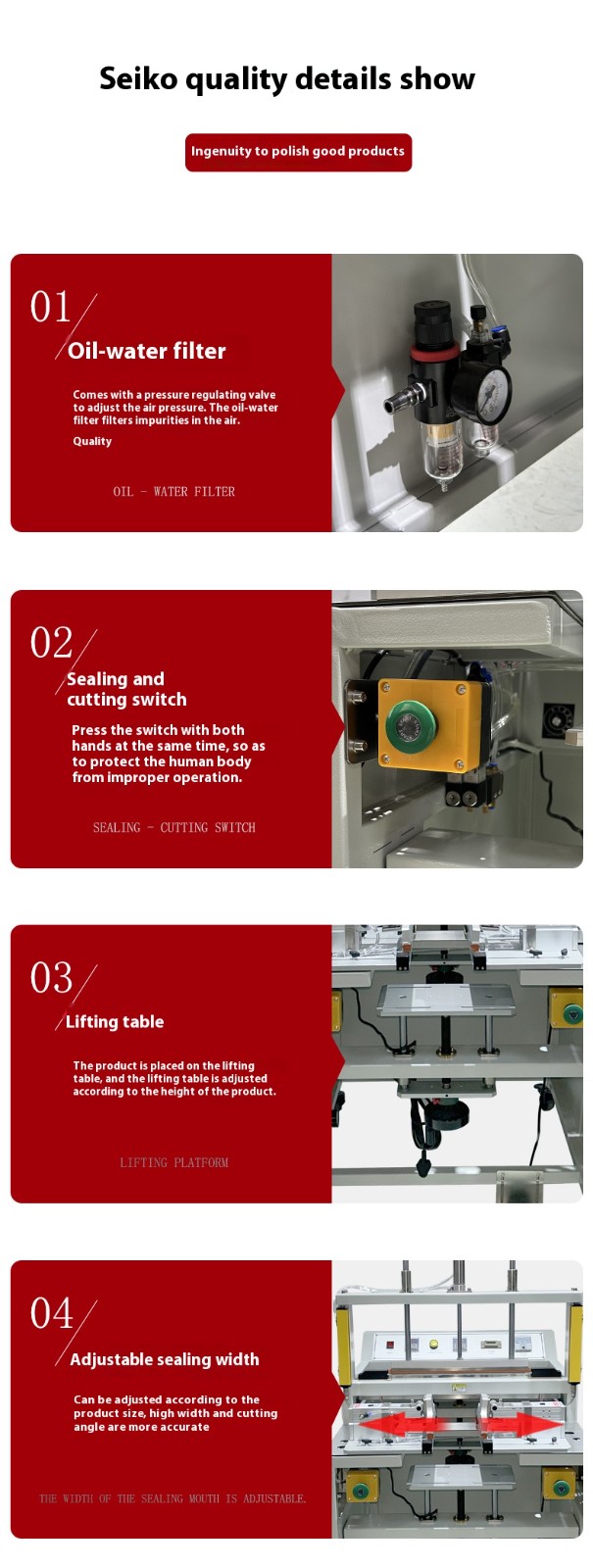

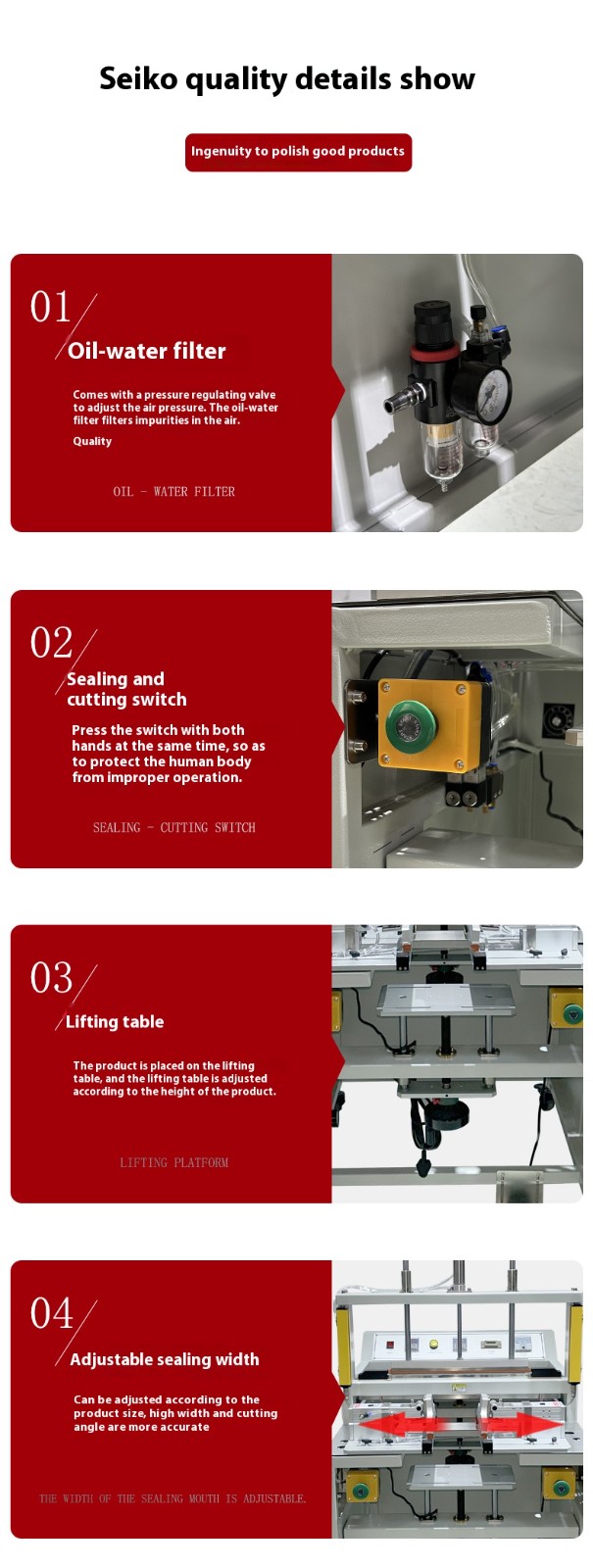

Air supply stabilityThe pneumatic system relies on stable compressed air. If the air pressure is insufficient (< 0.5MPa) or the air contains moisture/impurities, the sealing-cutting mechanism will act slowly and exert uneven pressure. This not only reduces efficiency but may also cause problems such as unstable seals and rough corner-cut edges. It is necessary to match the machine with an air source treatment unit (filter, dryer).