The core advantages of the intelligent inkjet coding and sealing integrated machine in terms of "adapting to different sizes" and "easy operation" are closely related to its equipment design, functional integration, and technical configuration. Specifically, they can be elaborated from the following two aspects:

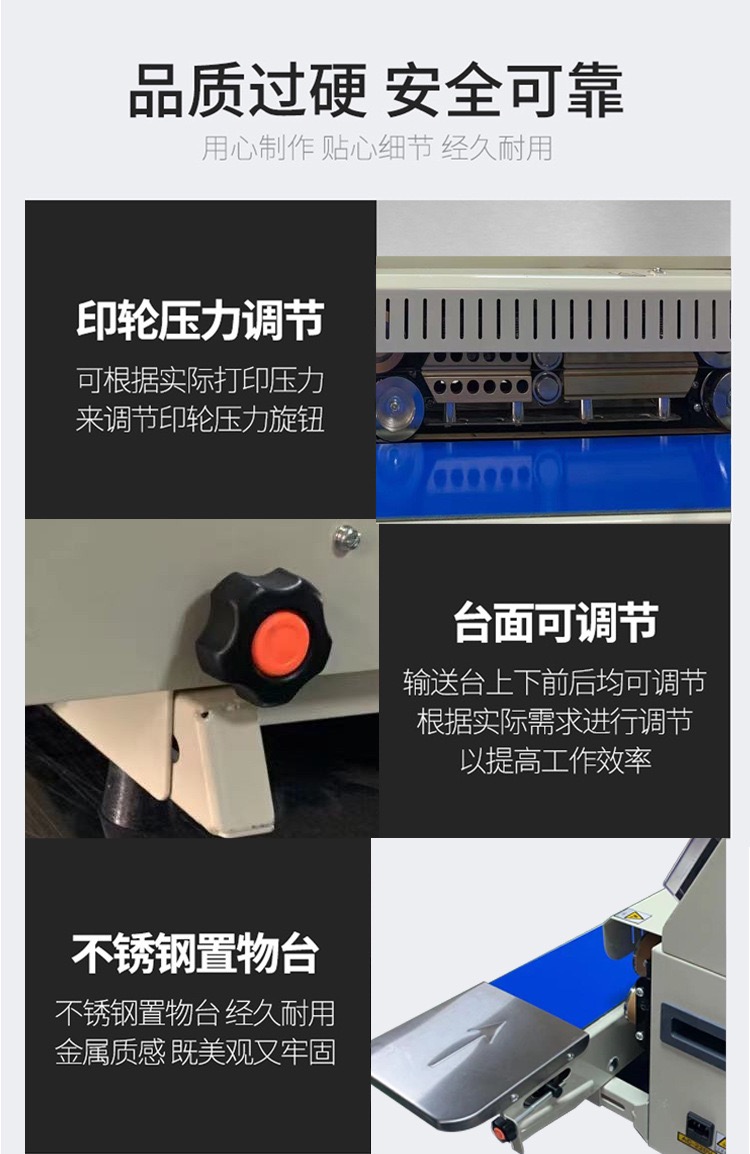

Through modular design and adjustable components, the equipment can easily handle packaging materials of different sizes (length, width, and height) without the need for frequent replacement of core parts, making it applicable to a wide range of scenarios:

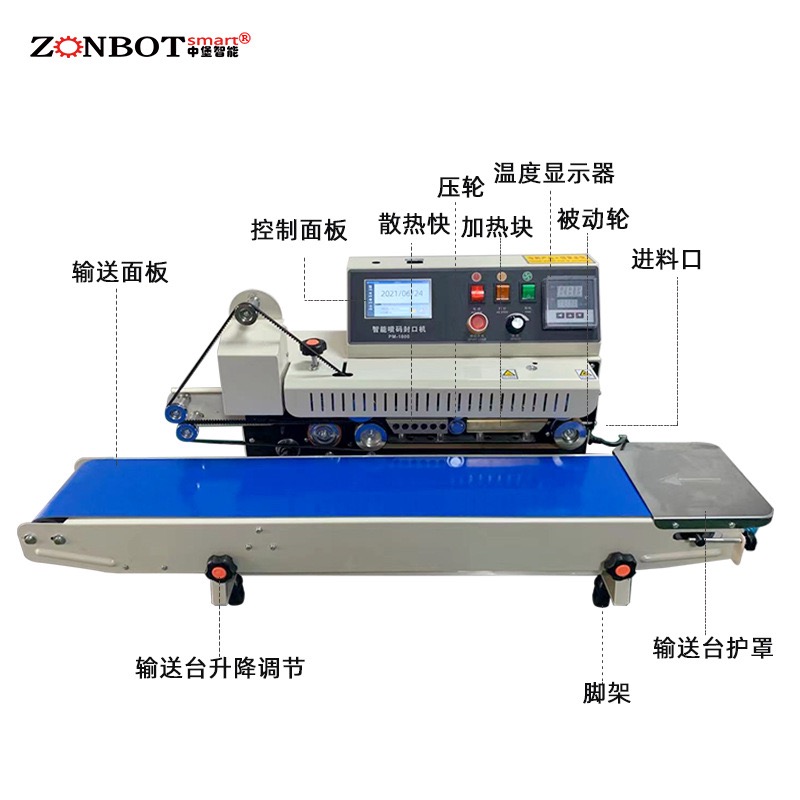

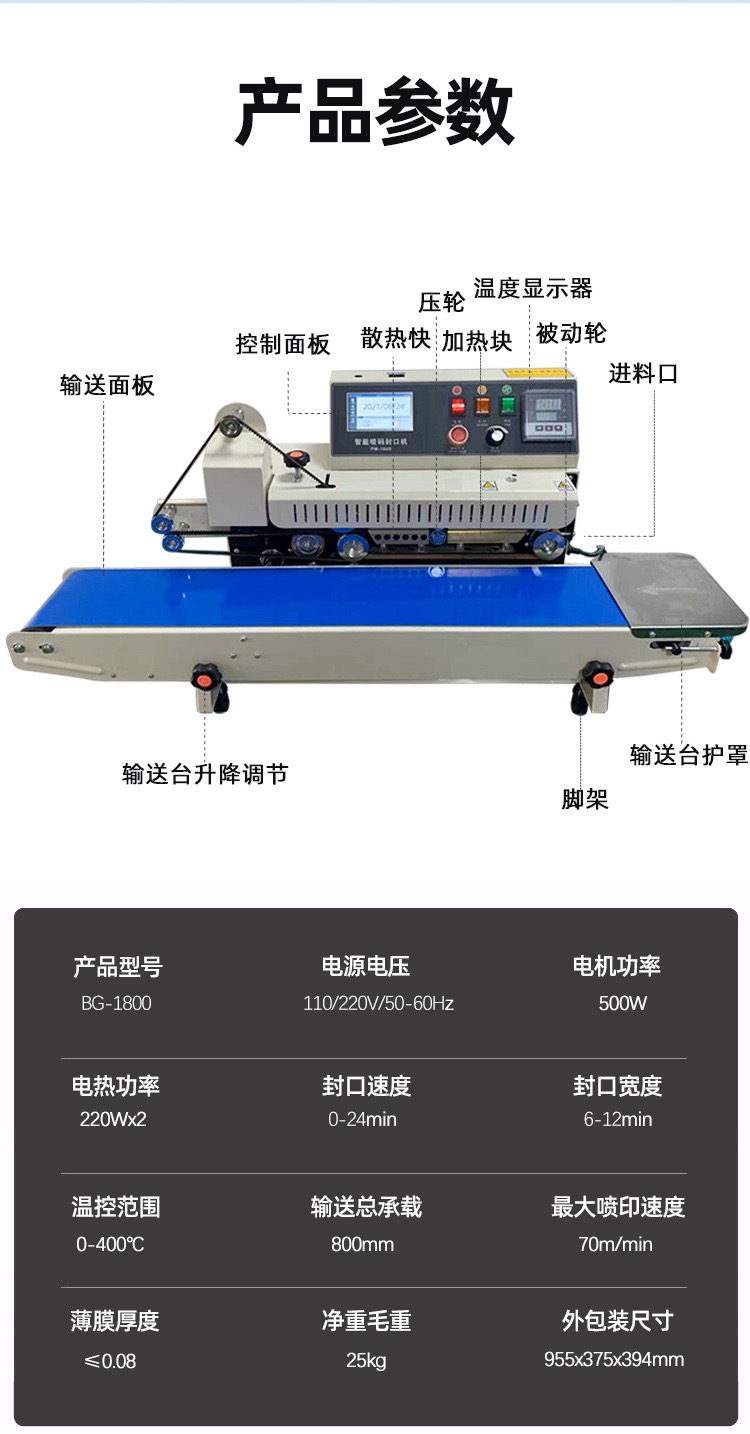

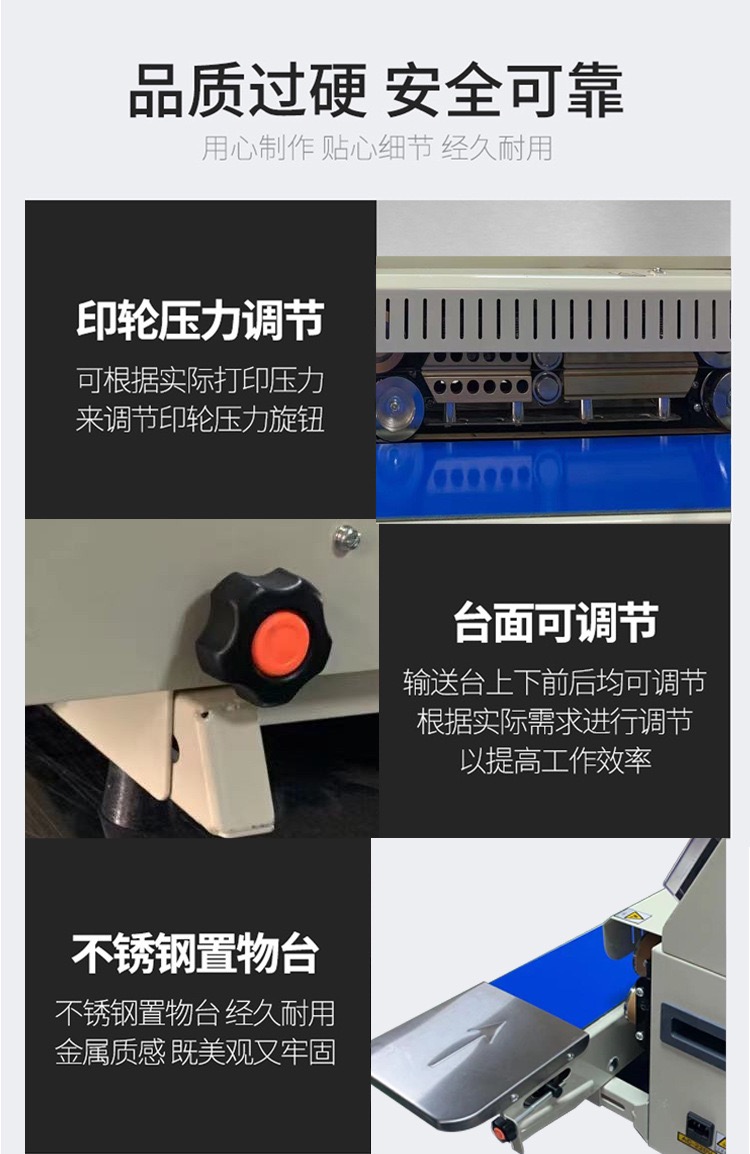

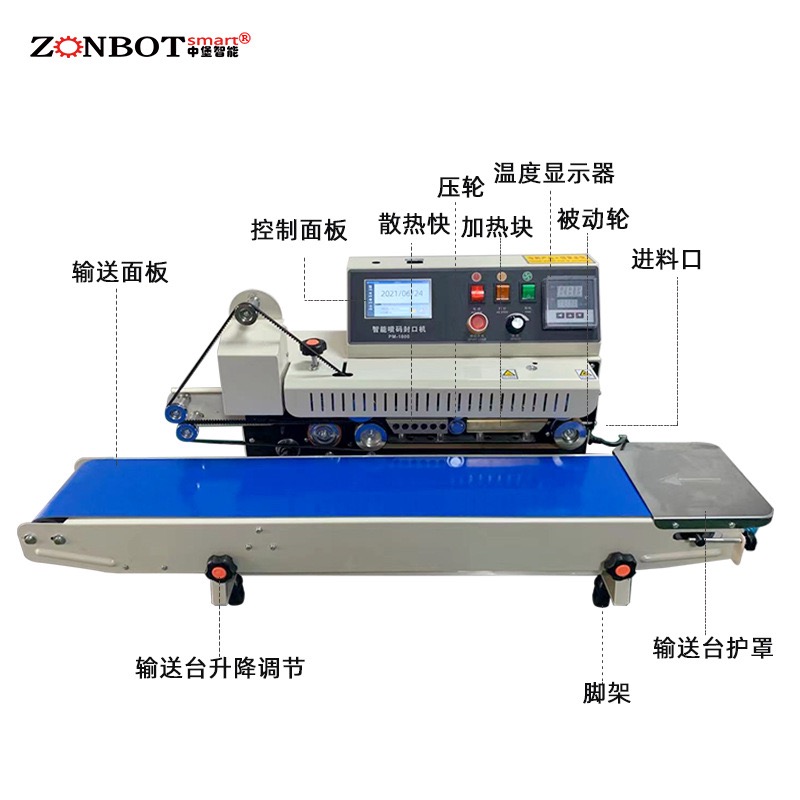

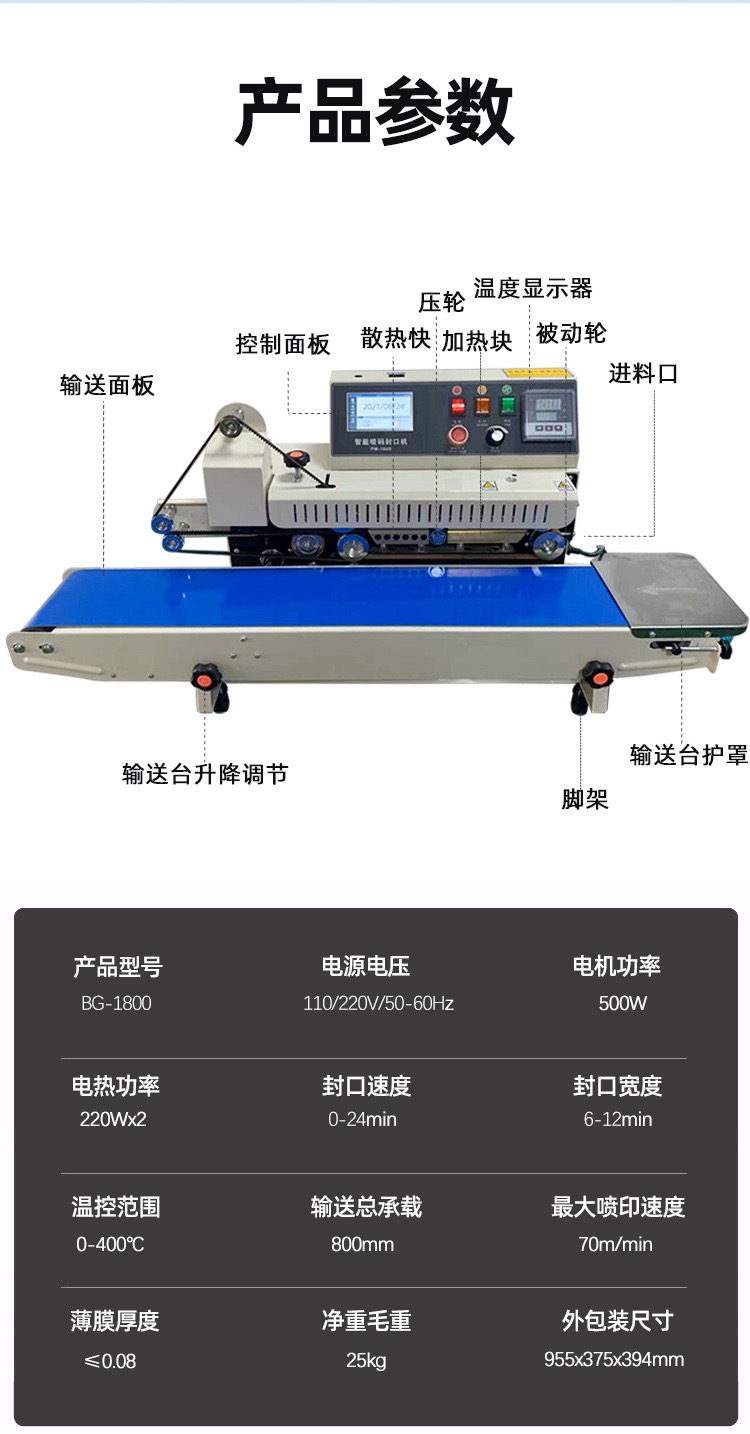

The equipment is equipped with flexibly adjustable conveying rails, sealing mechanisms, and inkjet head brackets. For example, when dealing with packaging bags (ranging from mini snack bags with a width of <10cm to large express bags with a width of >50cm), operators only need to set parameters via knobs or touch screens. The conveying rails will automatically adjust their width to stably transport the packages; the sealing heating blocks can move up and down according to the height of the packages; and the inkjet heads can be fine-tuned forward, backward, left, and right. This ensures that inkjet coding and sealing act accurately on the edges or designated areas of packages of different sizes.

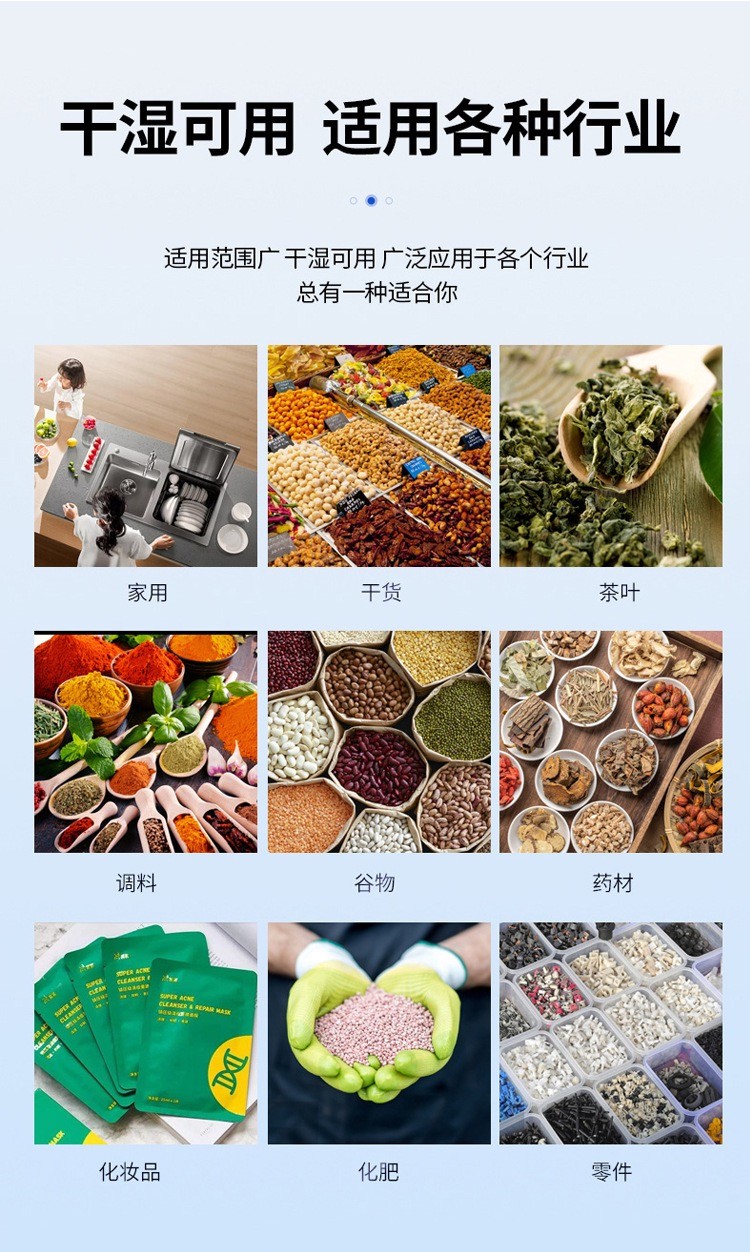

It is not only compatible with flat packaging materials such as plastic bags, aluminum foil bags, and cartons but also capable of handling packages of irregular sizes (e.g., special-shaped food bags, label areas on small medicine bottles, and irregular e-commerce cartons). Some high-end models even support automatic package size recognition via sensors, which directly matches the corresponding inkjet positions and sealing parameters without manual intervention, further improving adaptation efficiency.

With the core design concept of "user-friendly operation", the equipment reduces technical requirements for operators, enabling even novices to get started quickly:

It is equipped with a standard high-definition touch screen with a built-in visual operation menu. Key functions (such as "adjust package size", "set inkjet content", and "adjust sealing temperature/speed") are displayed in the form of icons or concise text. For instance, when it is necessary to switch to packages of different sizes, operators only need to select preset size templates (e.g., "15cm×20cm food bag", "30cm×40cm express carton") on the screen. The equipment will automatically complete parameter adaptation for the rails, inkjet heads, and sealing mechanisms. For custom sizes, operators can simply input the values without complex mechanical debugging.

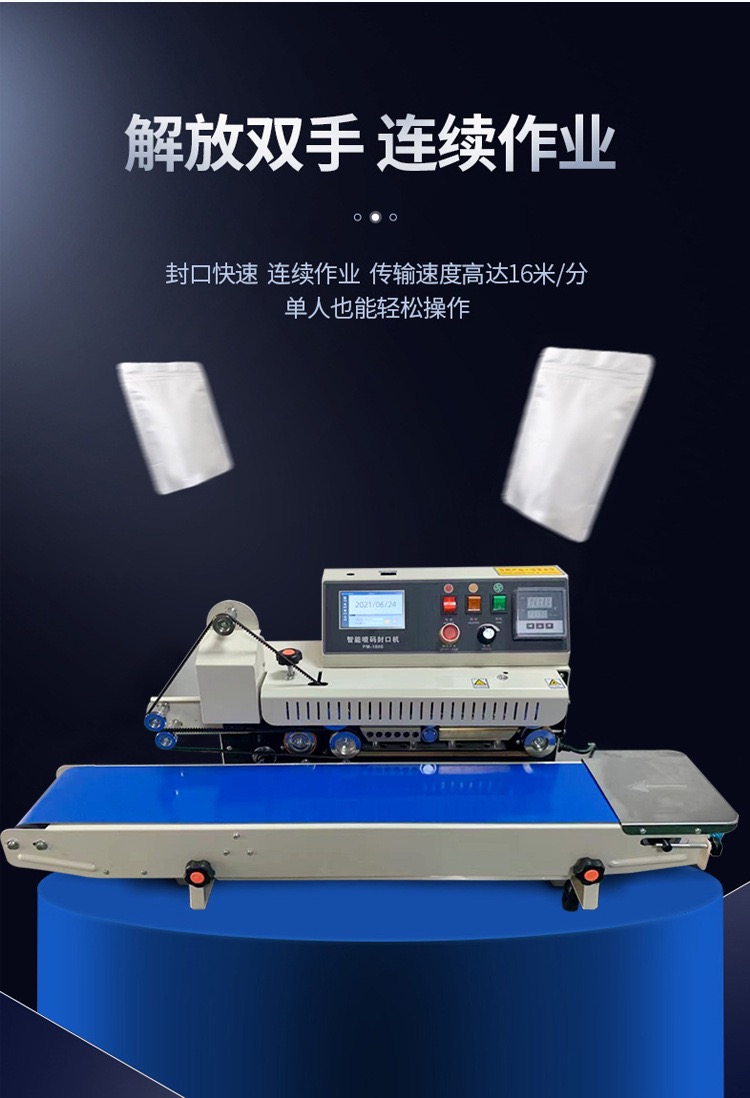

Daily operation only requires 3 steps:

① Place the materials to be packaged;

② Confirm or modify parameters on the touch screen (e.g., set the inkjet content as "production date + batch number", and select preset gears for sealing temperature based on packaging materials—120℃ for plastic films and 160℃ for aluminum foil bags);

③ Start the equipment, which will automatically complete the entire process of conveying, inkjet coding, and sealing.

Meanwhile, the equipment is equipped with a fault prompt function (e.g., "package size not adapted", "insufficient ink"). Problems are indicated via on-screen pop-ups or indicator lights, allowing operators to quickly resolve them according to the prompts without relying on professional technicians.

Wearable parts (such as inkjet heads and heating plates) adopt a quick-release design, enabling replacement without disassembling complex components. The equipment also has a built-in cleaning function—inkjet heads can be automatically cleaned by initiating the function via the touch screen. This reduces the complexity of manual maintenance and further lowers the operation threshold.