Dual-chamber vacuum packaging machines, leveraging their unique structural design and functional configuration, demonstrate significant advantages in packaging efficiency, application scenarios, freshness preservation, and more. They are particularly well-suited for medium and large-scale production enterprises and scenarios requiring batch packaging. Their core advantages can be categorized into the following four major types, with specific details as follows:

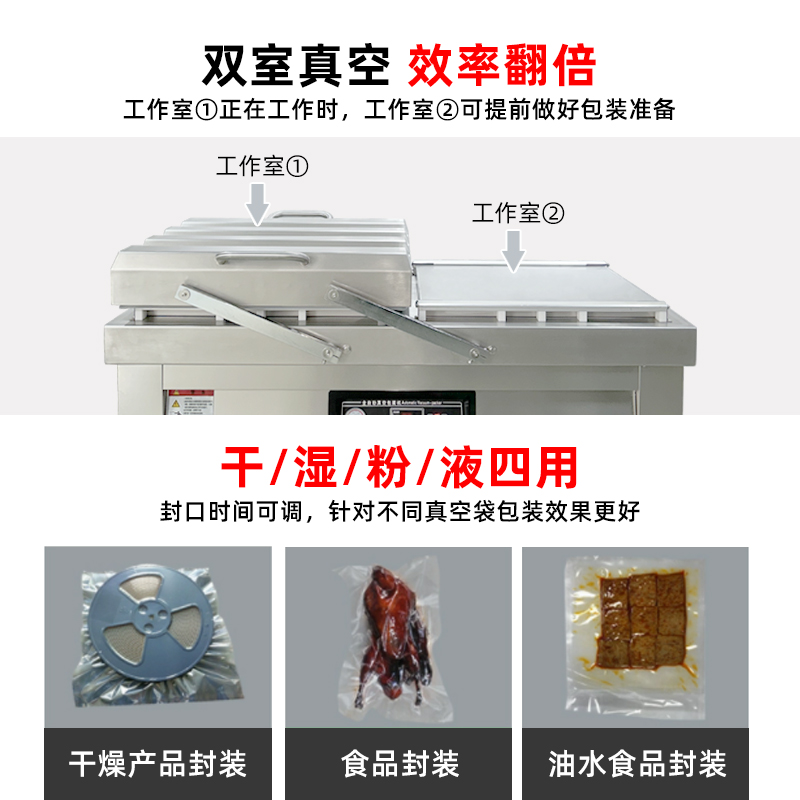

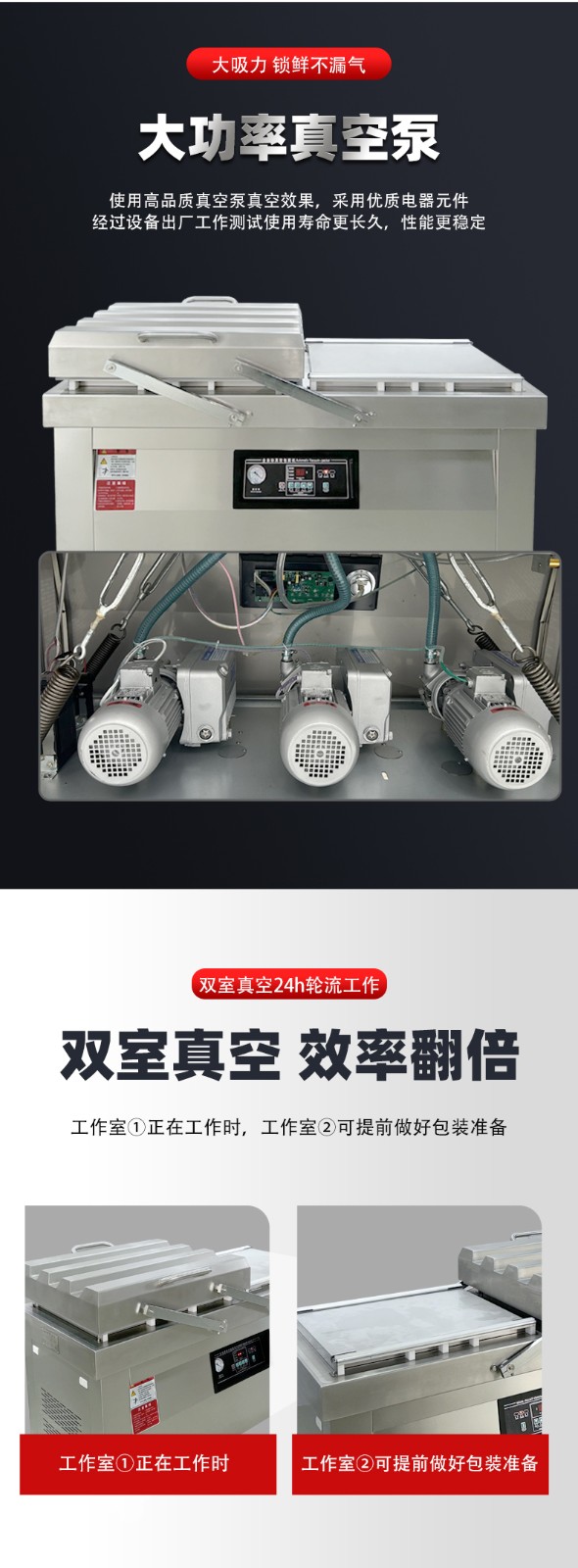

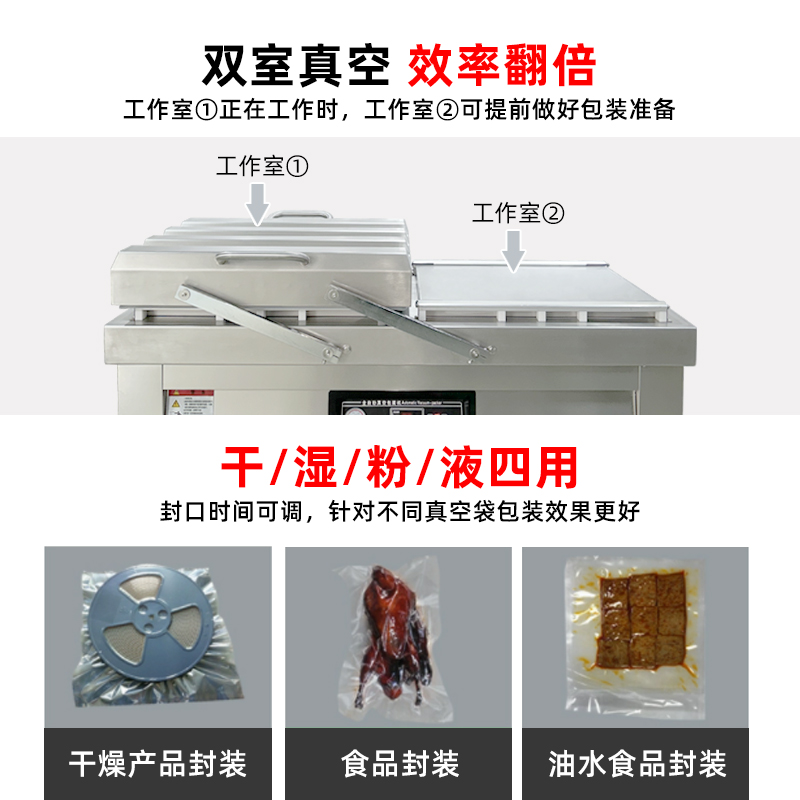

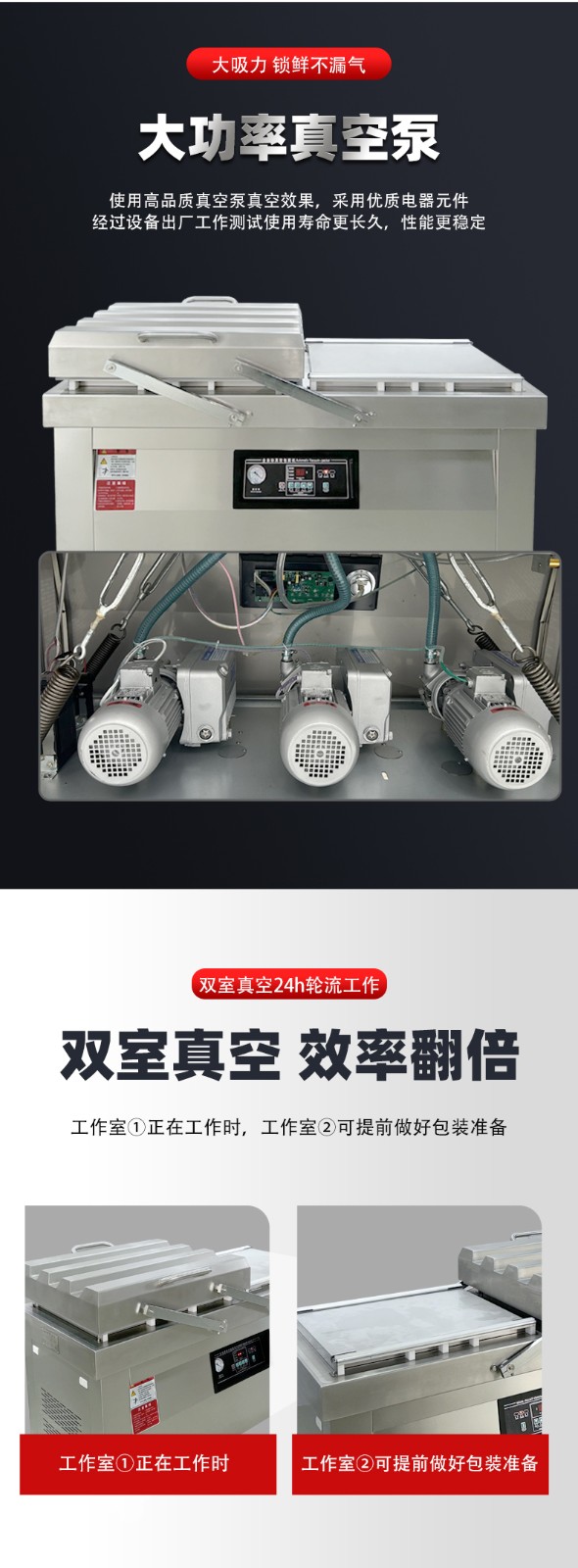

This is the most core advantage of dual-chamber models compared to single-chamber ones, rooted in the design logic of "alternating operation of dual chambers," which completely eliminates the time waste of "operators waiting while the single-chamber machine performs vacuum extraction and sealing."

Alternating Operation Mode: When the left vacuum chamber is conducting core processes such as vacuum extraction and heat sealing, the operator can simultaneously complete the preparation work (placing products → putting them into packaging bags → arranging bag openings) in the right vacuum chamber. After the processes in the left chamber are finished, the operation switches to the right chamber directly, while the left chamber enters the manual preparation stage. This forms a continuous workflow where "the machine never stops and the operator is always busy."

Significant Efficiency Improvement: The packaging speed can reach 20-50 bags per minute, with efficiency increased by more than 1.5 times compared to single-chamber models. Taking a meat processing enterprise as an example, if a single-chamber machine can package 8,000 bags per day, a dual-chamber machine can easily exceed 12,000 bags, greatly reducing the time cost per unit product.

Adaptation to Batch Requirements: It is especially suitable for high-intensity production scenarios such as morning peak hours and order peak seasons, avoiding production bottlenecks caused by insufficient equipment efficiency.

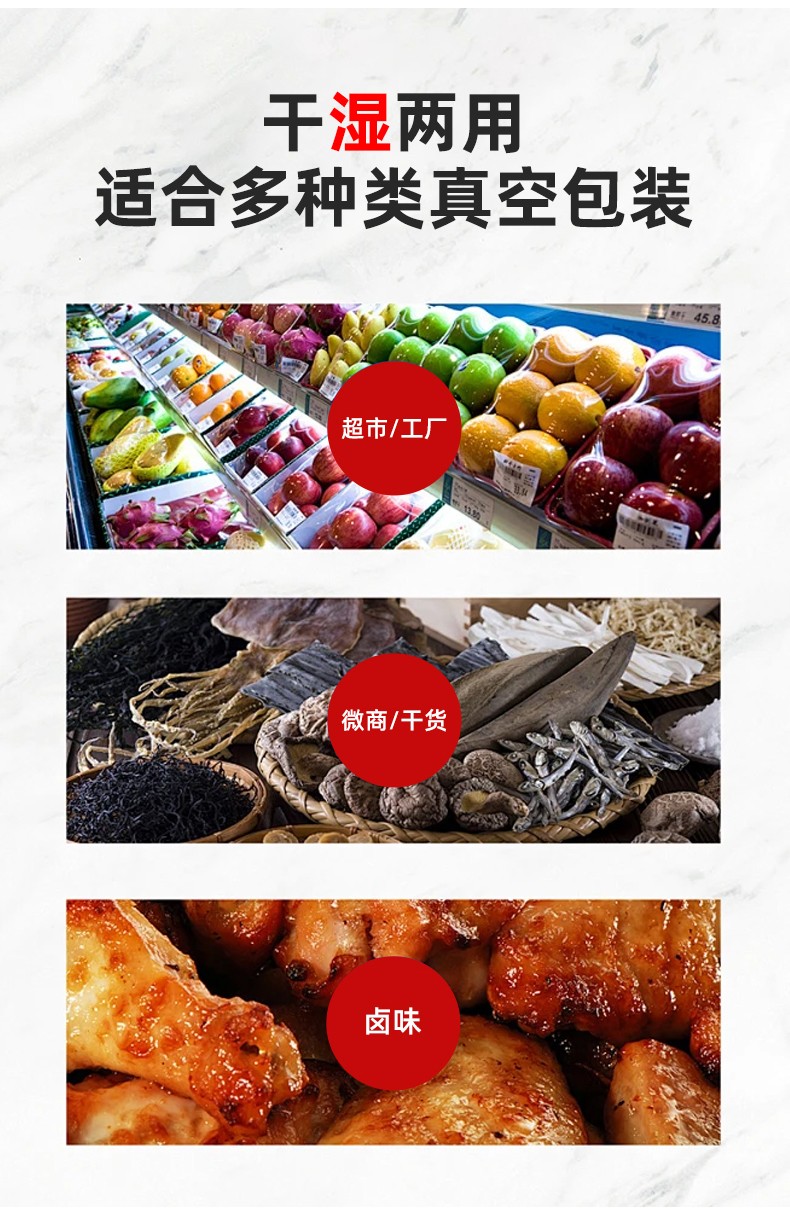

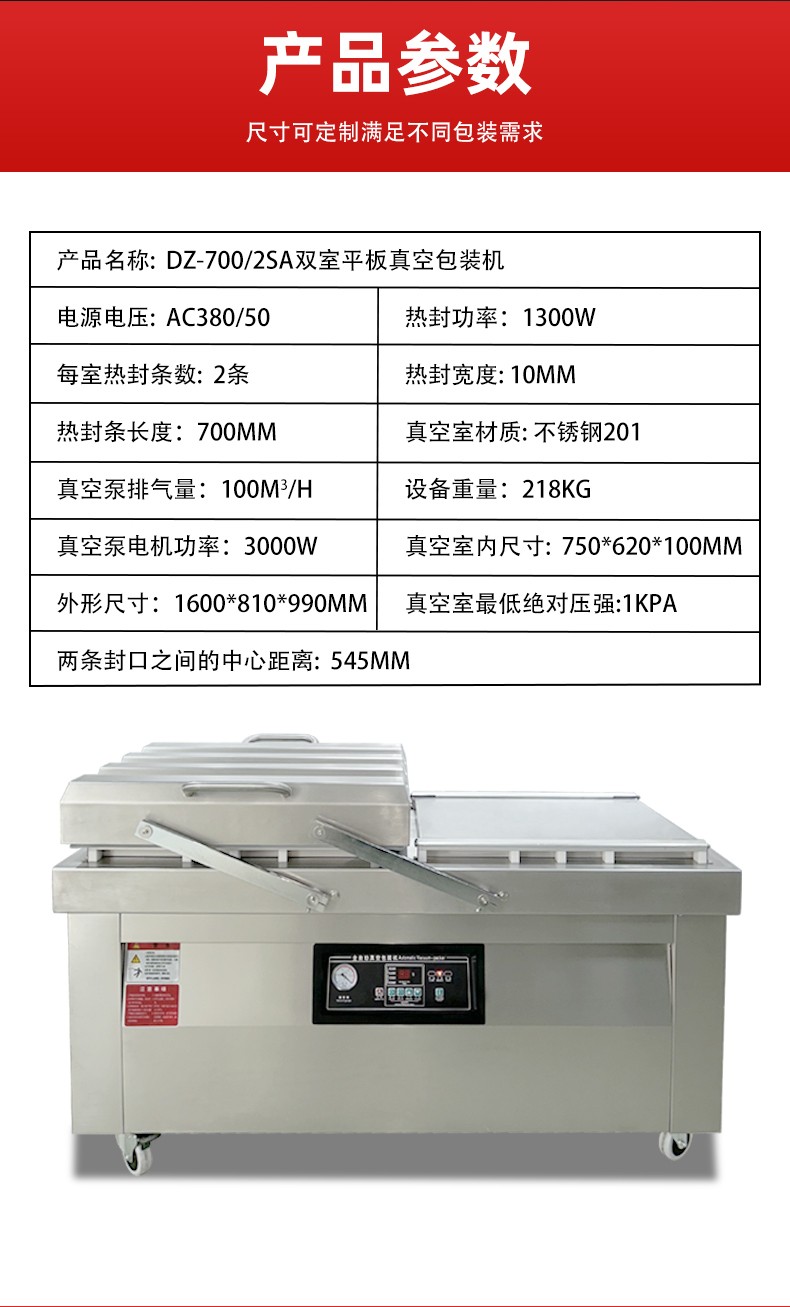

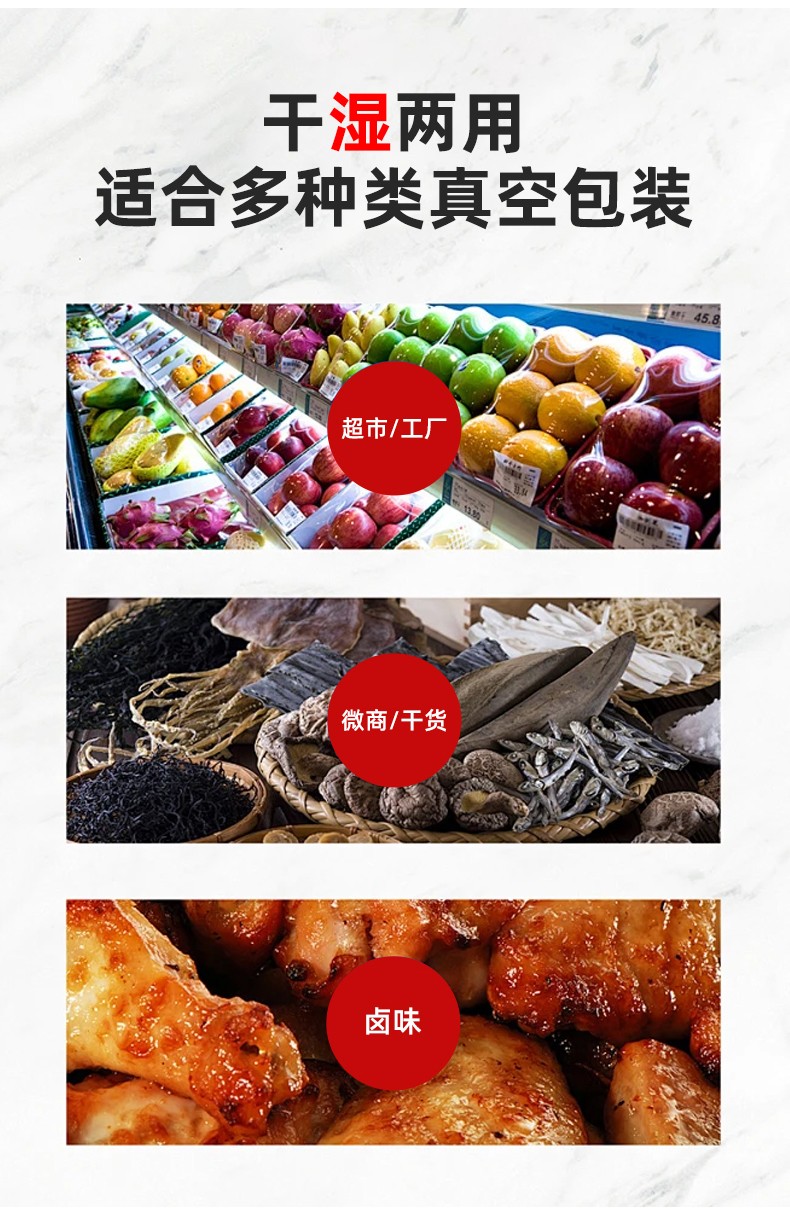

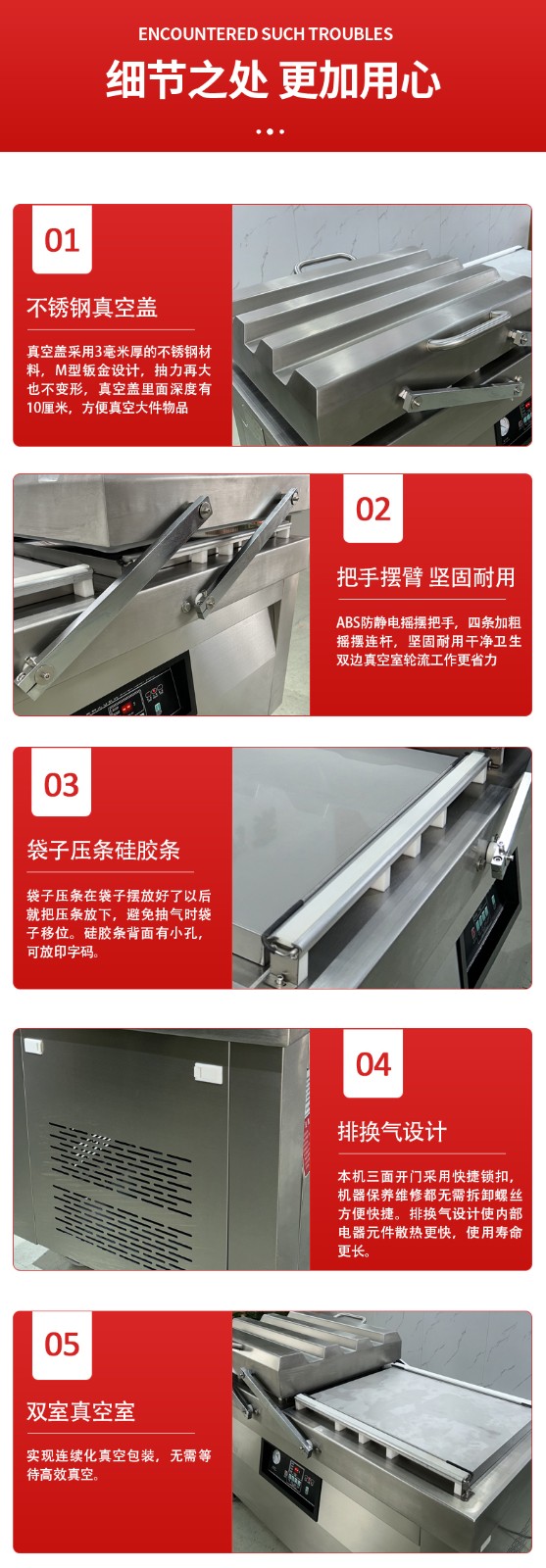

Dual-chamber vacuum packaging machines have strong "compatibility," which can not only adapt to various product forms but also adjust packaging parameters according to needs, without the need for frequent equipment or accessory replacement.

Compatibility with All-Form Products: Whether it is solids (meat, hardware parts, electronic components), liquids (seasonings, soups, oral liquids), powders (flour, coffee powder, traditional Chinese medicine powder), or pastes (jam, meat fillings, skin care creams), stable packaging can be achieved by adjusting parameters such as vacuum degree and sealing temperature. This solves the problem that some single-chamber machines are prone to leakage when packaging liquids and powders.

Adaptation to Multiple Packaging Materials: It supports various packaging materials such as composite films, aluminum foil bags, and nylon bags, which are compatible from food-grade fresh-keeping bags to industrial-grade anti-static bags, without the need for additional equipment modification.

Precise Adjustable Parameters: Through a microcomputer control system (some high-end models are equipped with touch screens), parameters such as vacuum extraction time (0-99 seconds), sealing temperature (50-250℃), sealing time (0-5 seconds), and gas filling volume (if equipped with a gas filling function) can be set accurately. For example, when packaging crispy vegetables, the vacuum degree can be reduced to avoid crushing; when packaging meat, the vacuum extraction time can be extended to ensure deep oxygen removal.

Optional Value-Added Functions: Some models are equipped with a built-in gas filling system. After vacuum extraction, inert gases such as nitrogen and carbon dioxide can be filled. This not only prevents fragile products (such as biscuits and potato chips) from being crushed but also further extends the fresh-keeping period, meeting the dual needs of "freshness preservation" and "shape protection."

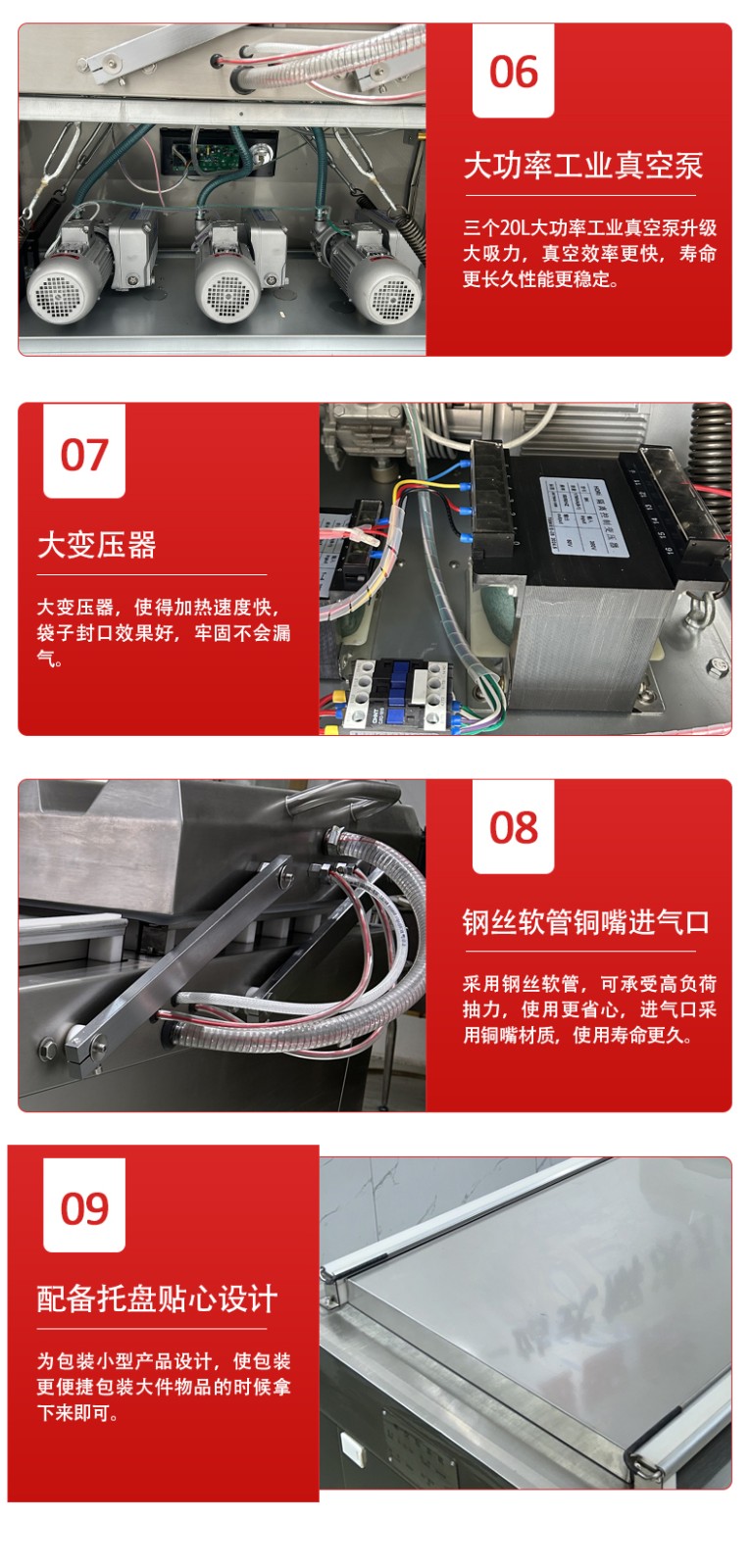

The core logic lies in solving the problems of product deterioration and damage from the root through "vacuum environment + sealed protection," which is of great significance especially for industries sensitive to storage environments such as food, medicine, and electronics.

The low-oxygen environment formed after vacuum extraction can inhibit the growth of microorganisms such as bacteria and molds (most microorganisms require oxygen to reproduce), while slowing down fat oxidation (preventing "rancidity" of meat and nuts) and vitamin loss. For example, the shelf life of fresh meat packaged in vacuum can be extended from 1-2 days to 7-15 days, and that of fresh-cut vegetables can be extended from 2-3 days to 5-7 days, while maintaining the original color, aroma, taste, and nutritional components.

For pharmaceutical products (traditional Chinese medicinal materials, sterile medical devices), it can achieve moisture-proof, anti-oxidation, and mildew-proof effects to avoid the loss of medicinal efficacy; for electronic components (circuit boards, IC chips), it can isolate moisture (preventing short circuits), dust (avoiding poor contact), and static electricity (protecting precision components), which is particularly suitable for long-term storage or long-distance transportation.

Hardware tools, bearings, etc., can avoid rust through vacuum packaging; clothing and textiles can be compressed in volume (reducing storage space) while preventing moth damage and peculiar smells.