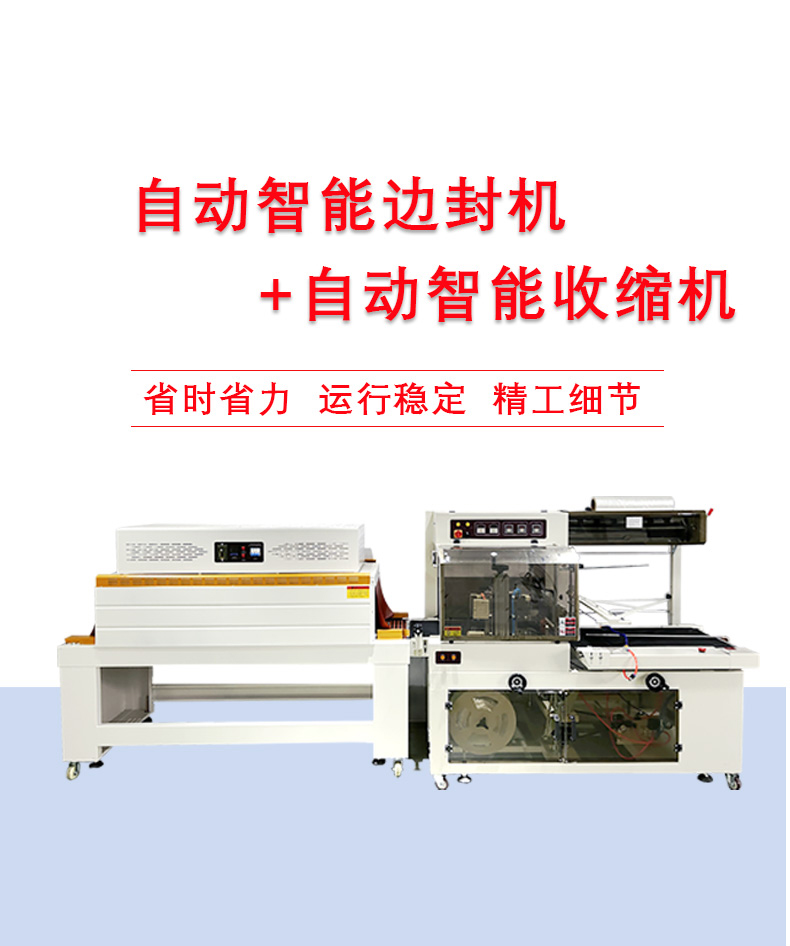

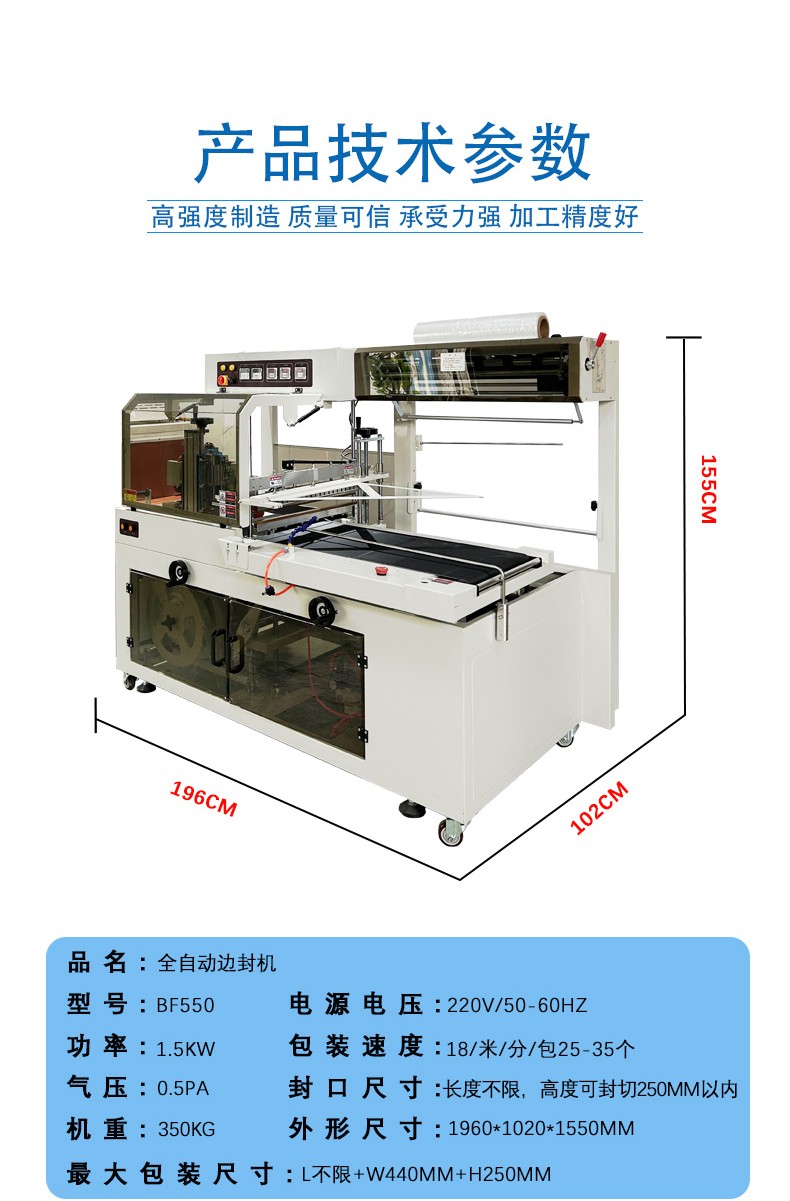

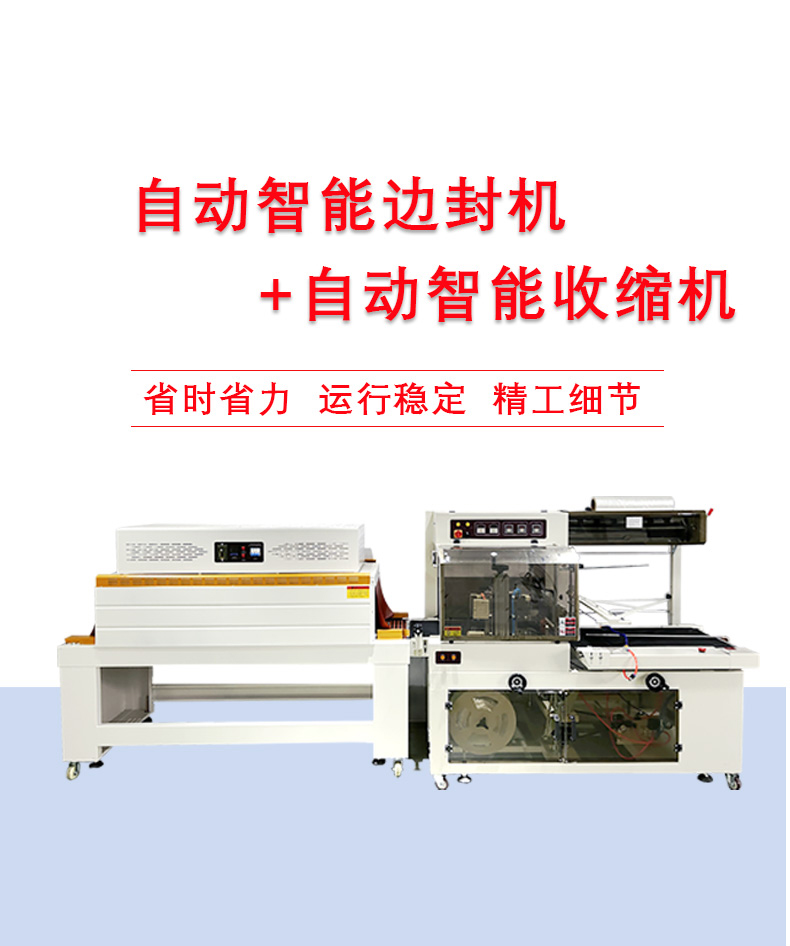

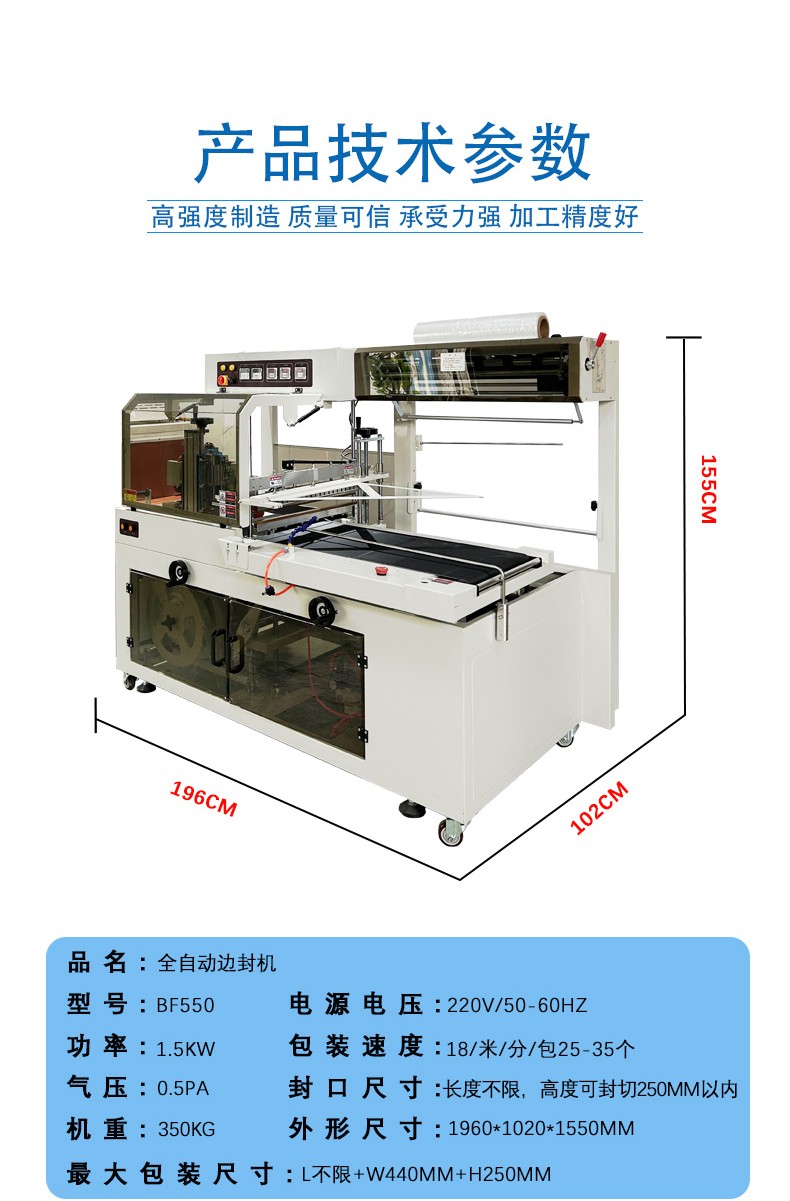

The fully automatic sealing, cutting, and heat-shrinking packaging machine requires no manual operation throughout the entire process, enabling continuous batch production. It significantly reduces labor costs and is suitable for large-scale mass production scenarios.

Release date:2025-08-19

Dual Assurance of Efficiency and Stability

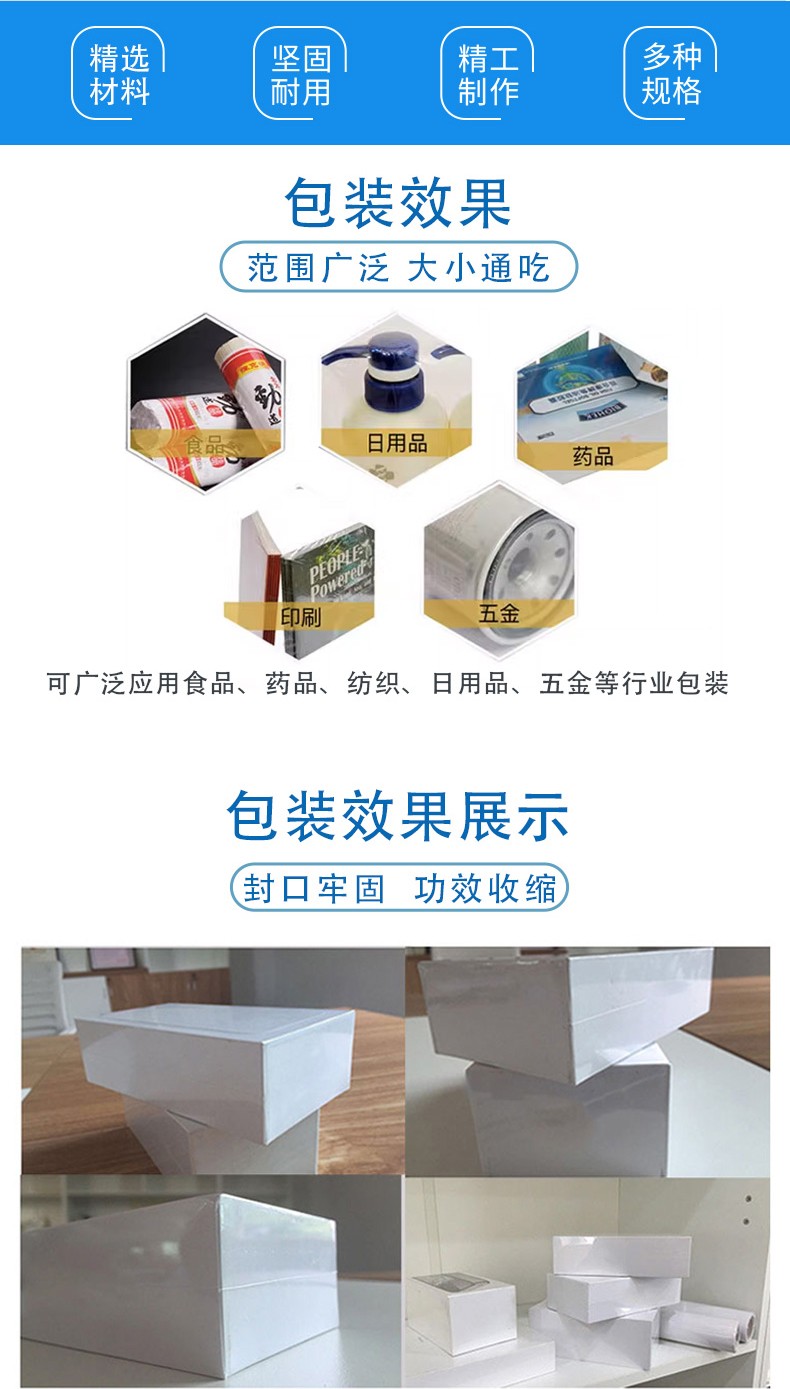

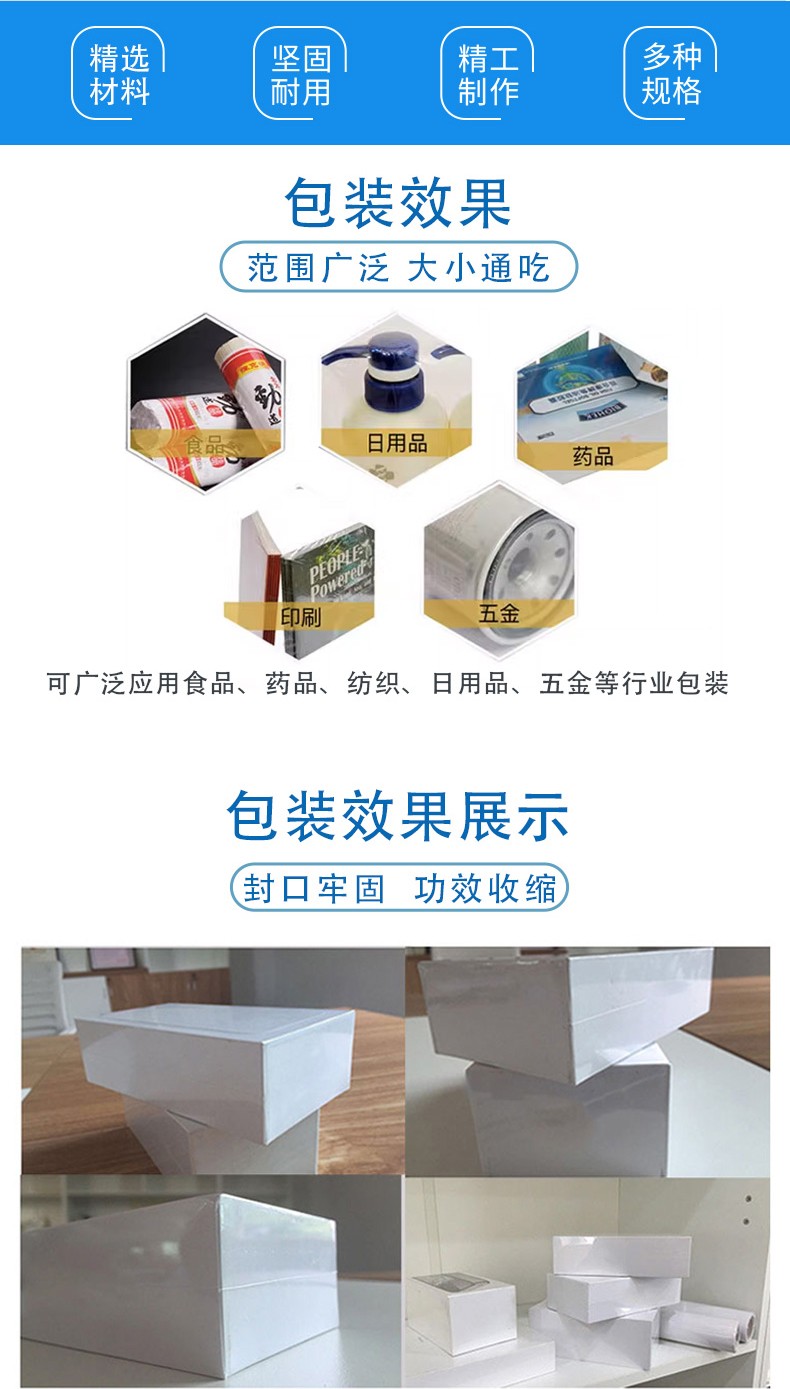

In large-scale mass production, manual packaging is prone to unstable quality due to fatigue and operational variations (such as skewed sealing edges or film wrinkles). In contrast, fully automatic equipment achieves standardized production through preset parameters (sealing temperature, shrinking time, film feeding speed, etc.), increasing product qualification rates to over 99%. For example, in the biscuit gift box production line in the food industry, thousands of boxes can be packaged per hour, with consistent sealing precision and shrink flatness for every box.

Adapting to Flexible Production Needs

Modern manufacturing often faces the need to switch between "multi-specification, small-batch" and "large-scale mass production" demands. High-end fully automatic models, equipped with quick changeover designs (such as replaceable sealing dies and parameter memory functions), can complete switches between different product specifications within 5-10 minutes. This not only meets the efficiency requirements of large-scale mass production but also maintains the flexibility of flexible manufacturing. For instance, cosmetics companies can quickly switch packaging parameters between lipstick gift boxes and face cream gift boxes on the same production line.

Reducing Comprehensive Costs

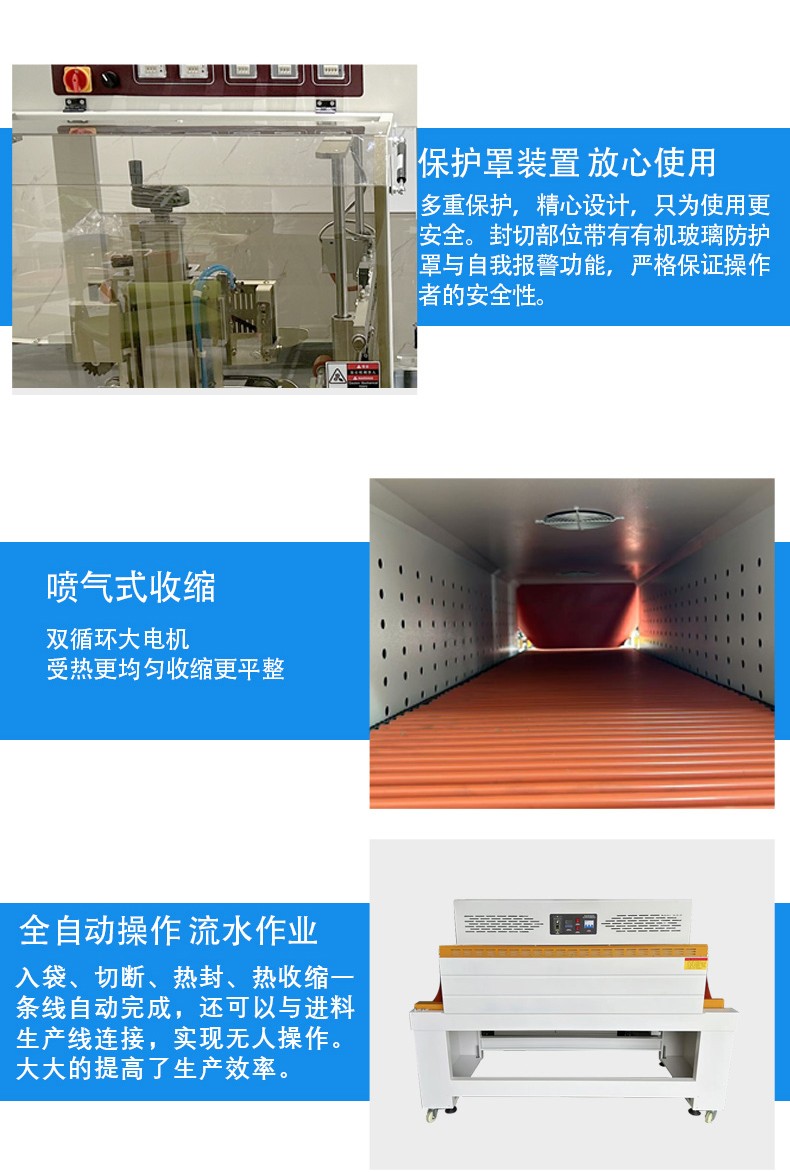

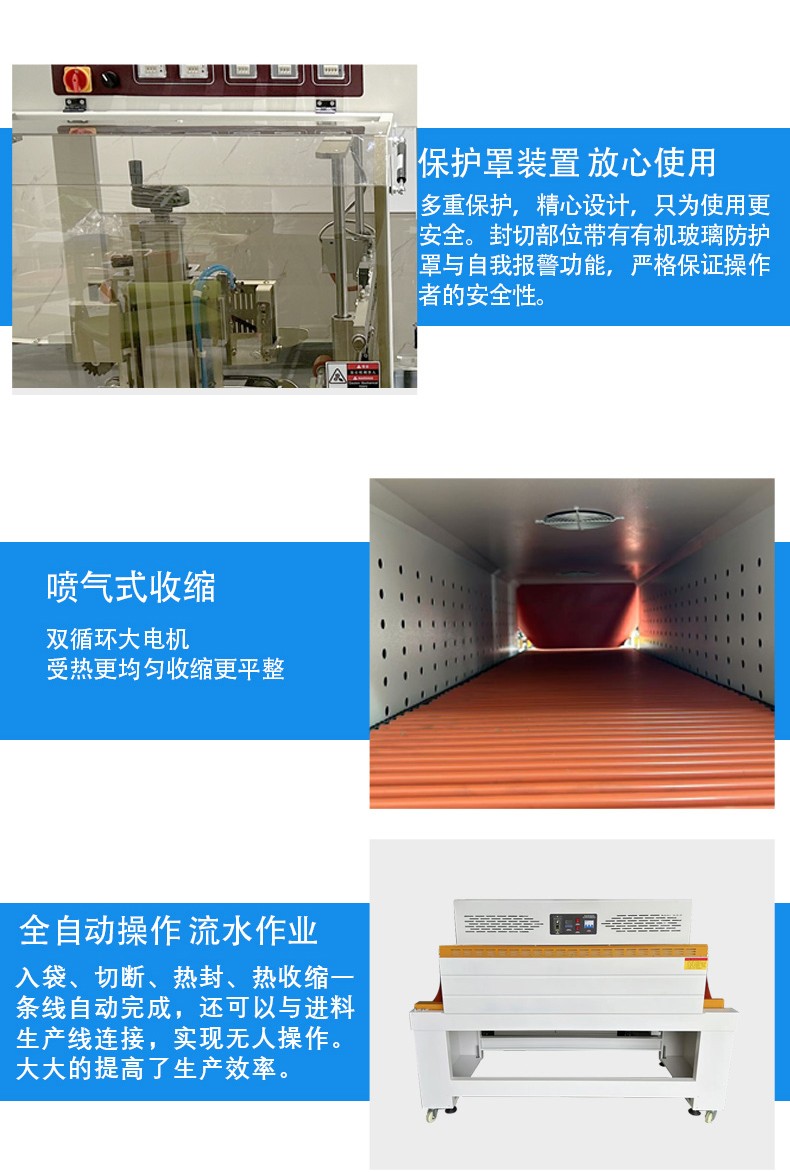

Beyond directly reducing the number of manual workers, full automation also lowers material waste: through photoelectric positioning and precise sealing, the equipment improves film utilization by 10%-15% compared to manual packaging. Meanwhile, stable packaging quality reduces rework costs caused by human errors (such as rework for damaged films or poorly sealed products). In the long run, the equipment investment can be recovered within 1-2 years through cost savings.

Meeting Industry Compliance Requirements

In industries with strict hygiene and traceability requirements such as food and pharmaceuticals, manual contact easily introduces contamination risks. Fully automatic equipment, however, adopts stainless steel bodies, closed conveying systems, and non-contact operations, complying with standards like GMP and HACCP. Additionally, it can record packaging parameters via IoT modules to achieve full-process production traceability, which is crucial for quality control in large-scale mass production.

Therefore, for industries with high production capacity demands and high product standardization (such as FMCG, electronics, and pharmaceuticals), fully automatic sealing, cutting, and heat-shrinking packaging machines are not only "cost-reduction tools" but also core equipment for ensuring product quality and enhancing production flexibility. They are particularly suitable for building unmanned packaging production lines