I. Stability: End-to-end Assurance from Machinery to Intelligence

Stability is a core performance indicator of labeling machines, directly affecting product qualification rates and production continuity. Fully automatic label separating and applying machines achieve high stability through a three-fold design of "mechanical structure + intelligent control + detection and correction":

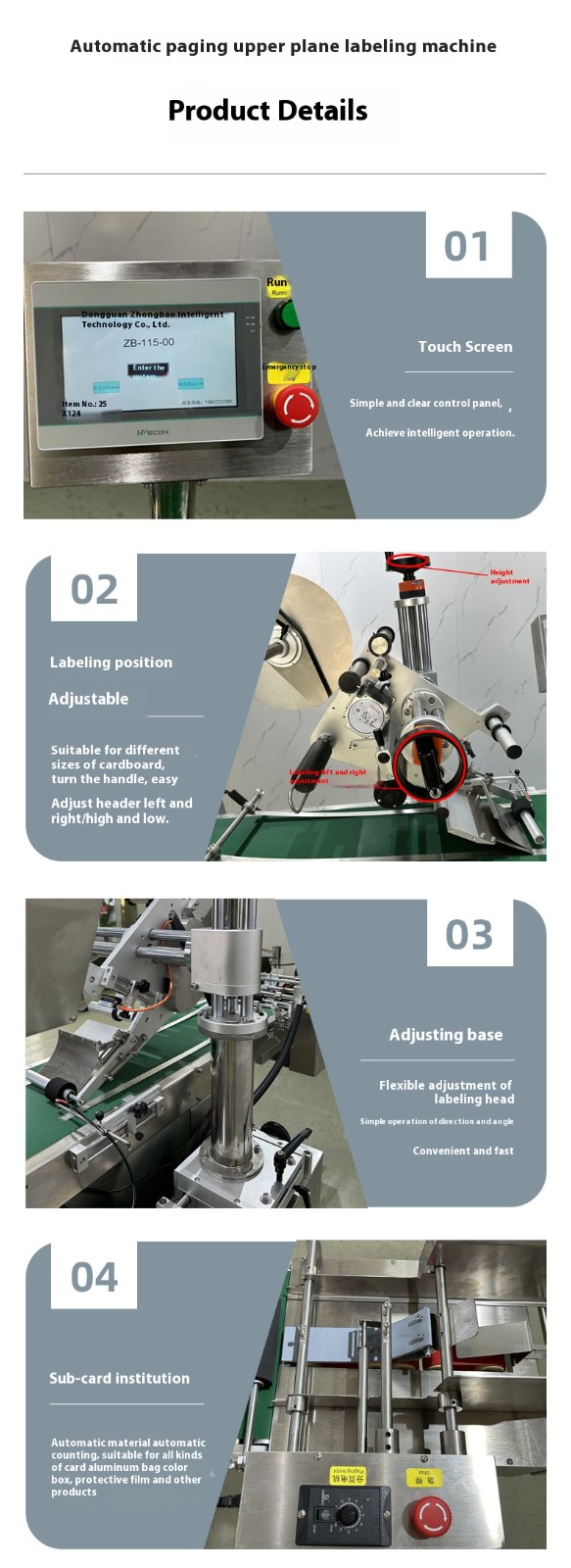

Anti-interference of Mechanical Structure

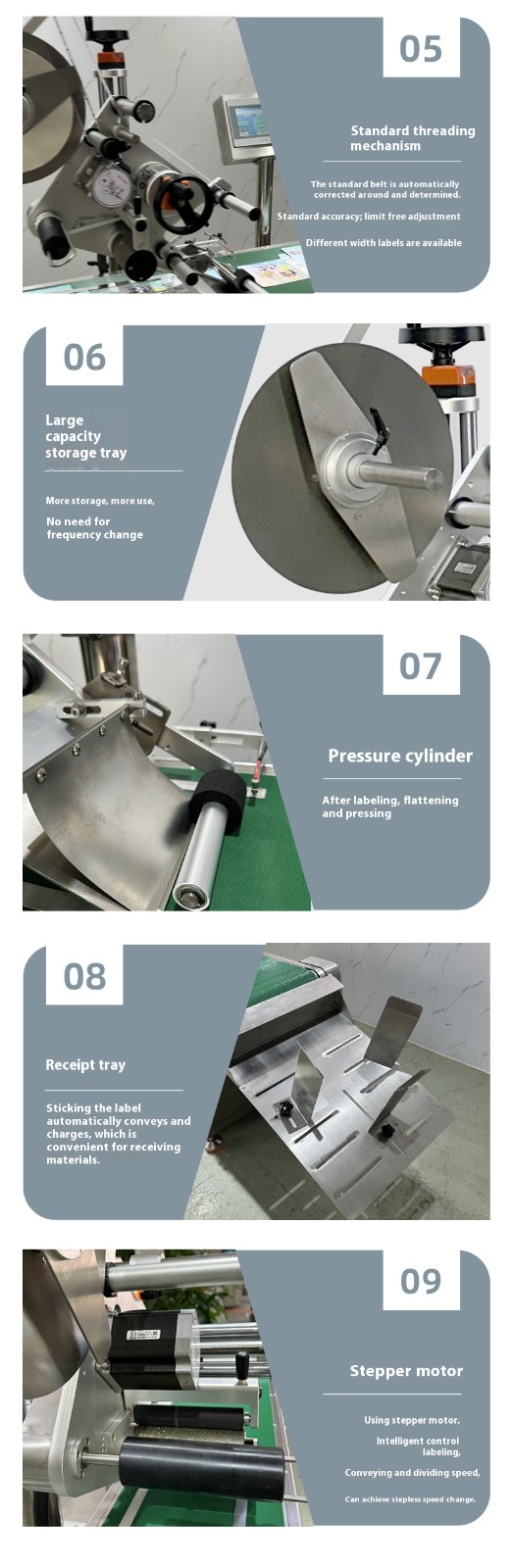

Adopting heavy-duty frames + precision guide rails (e.g., Taiwan's HIWIN linear guide rails) to reduce vibration during high-speed operation (amplitude ≤ 0.05mm), avoiding label offset caused by equipment shaking;

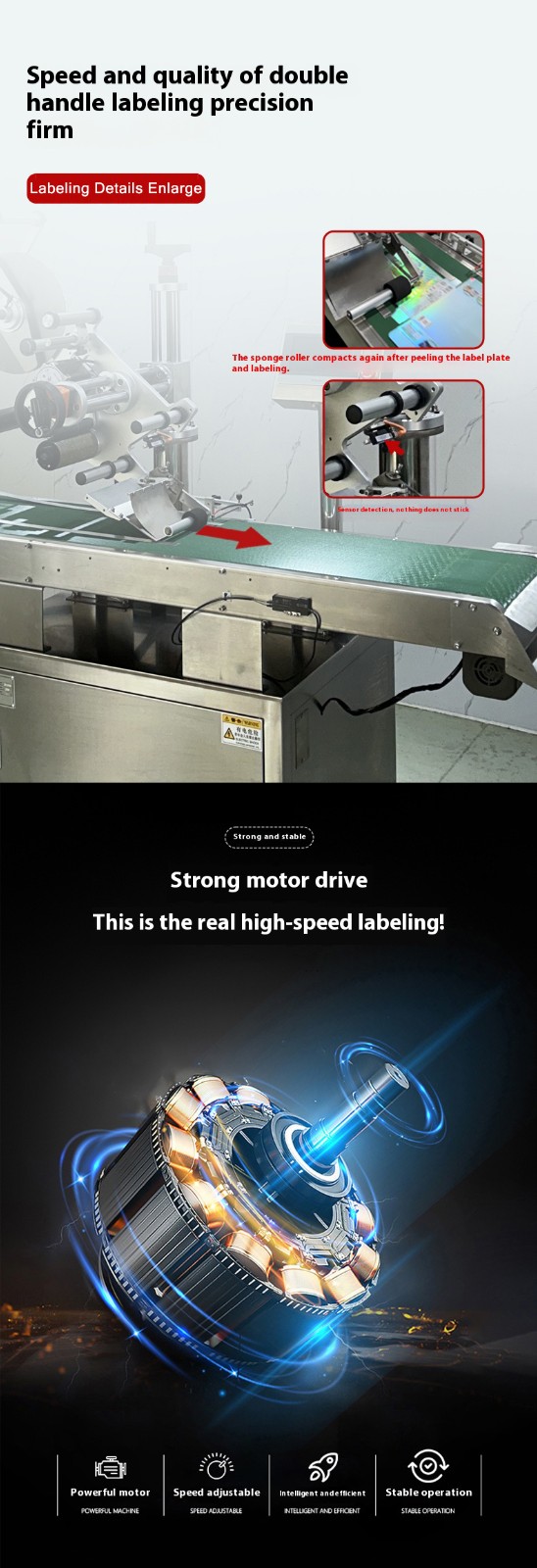

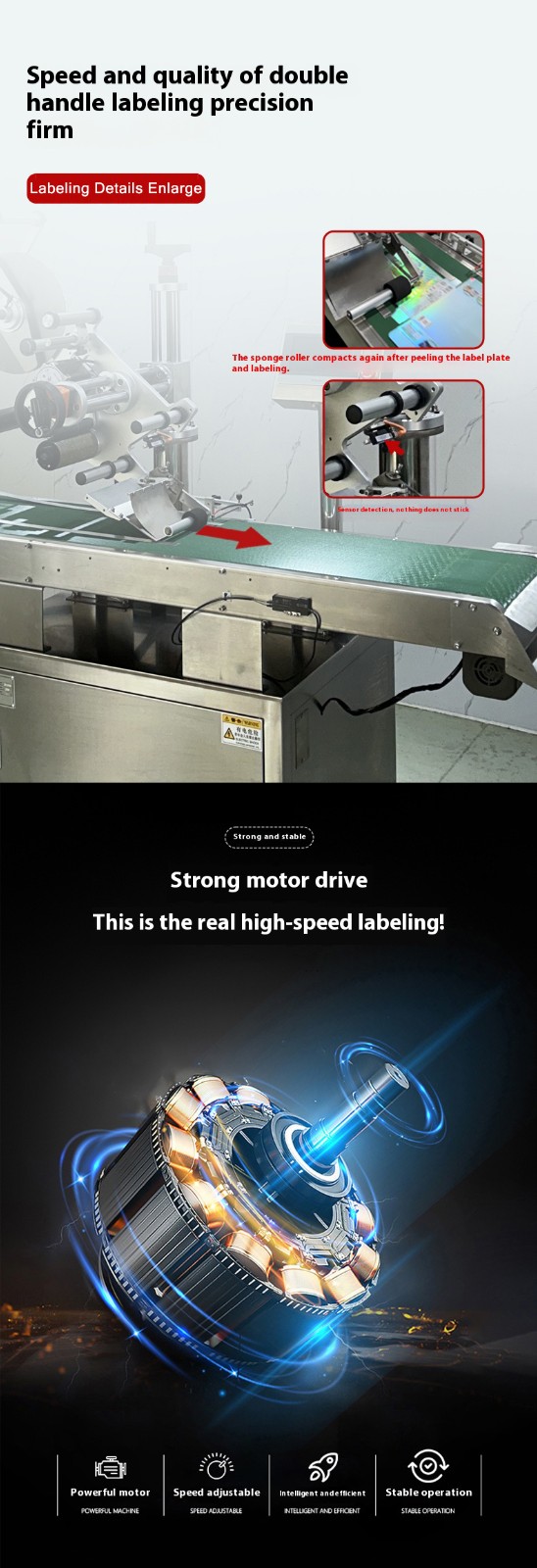

The labeling head is equipped with an elastic labeling mechanism (e.g., silicone rollers + buffer cylinders), which can adapt to products of different materials (such as hard surfaces of glass bottles and soft surfaces of hoses), ensuring uniform label 贴合 pressure and avoiding bubbles and wrinkles (labeling flatness ≥ 99.5%).

Precise Positioning with Intelligent Control

Equipped with servo motors + PLC closed-loop control systems (e.g., Siemens S7-1200 series) with a response time ≤ 0.1ms, which can real-time correct label position deviations caused by product tolerances (e.g., bottle height ±1mm);

Integrated multi-sensor linkage (fiber optic sensors detect product arrival, color mark sensors locate label reference lines) to ensure synchronization among "product, label, and labeling head". For example, during high-speed labeling of mineral water bottles, it can accurately lock the relative position of the label and the bottle seam.

Dynamic Detection and Correction

High-end models are equipped with AI visual inspection systems (e.g., Cognex In-Sight cameras) to perform 100% online inspection of label offset, wrinkles, missing labels, etc., after labeling. Unqualified products are automatically rejected (rejection response time ≤ 0.5s), controlling the defect rate within 0.1%;

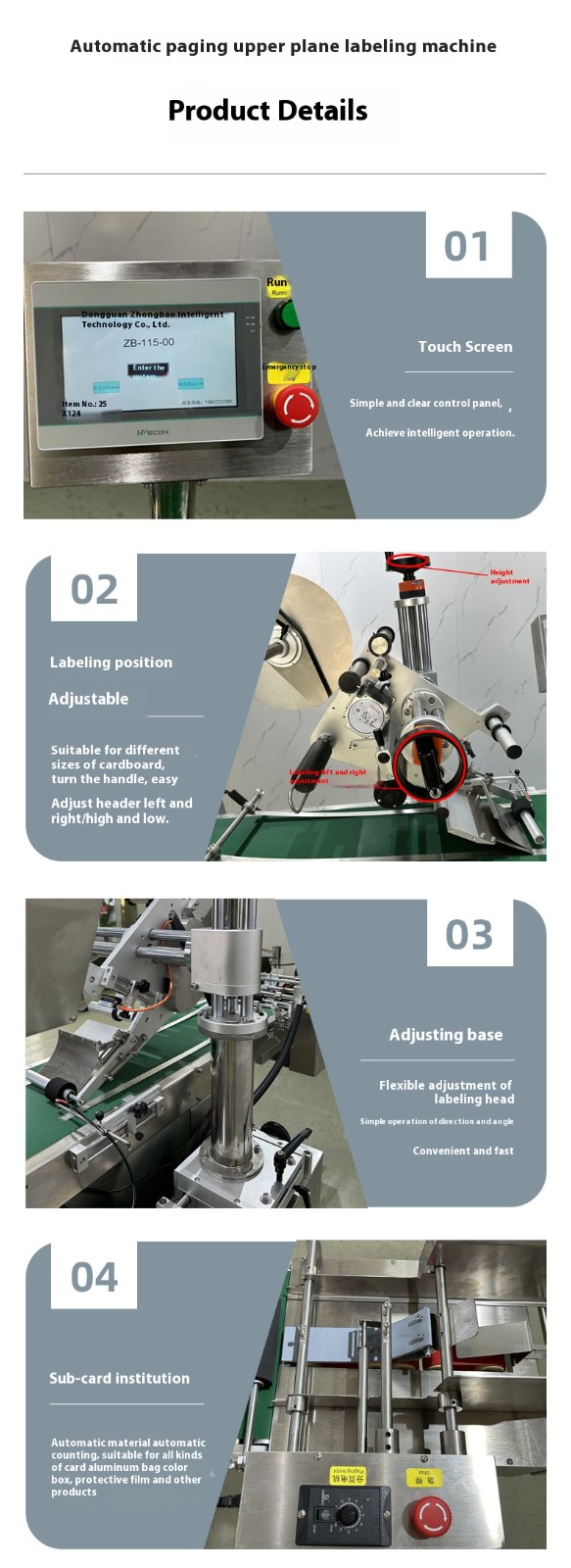

It has a fault self-diagnosis function (e.g., label shortage alarm, motor overload protection). After shutdown, the fault point can be displayed via the touch screen, reducing maintenance time to within 10 minutes and minimizing production line downtime losses.

II. Efficiency: Production Capacity Breakthrough from Single-machine Speed to Whole-line Collaboration

Efficiency is reflected in three dimensions: "high speed + quick changeover + low downtime", meeting the needs of mass production and flexible manufacturing:

High-speed Labeling to Adapt to Mass Production Rhythm

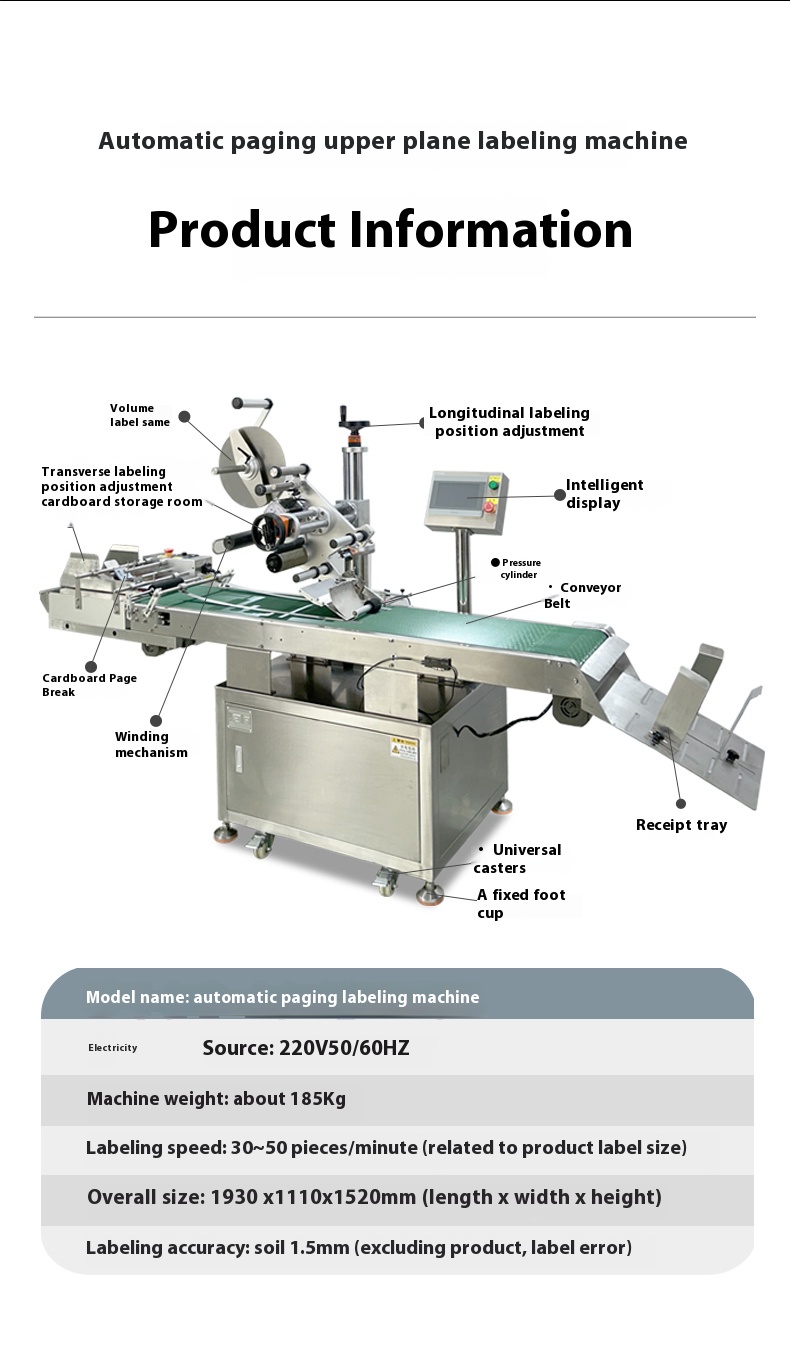

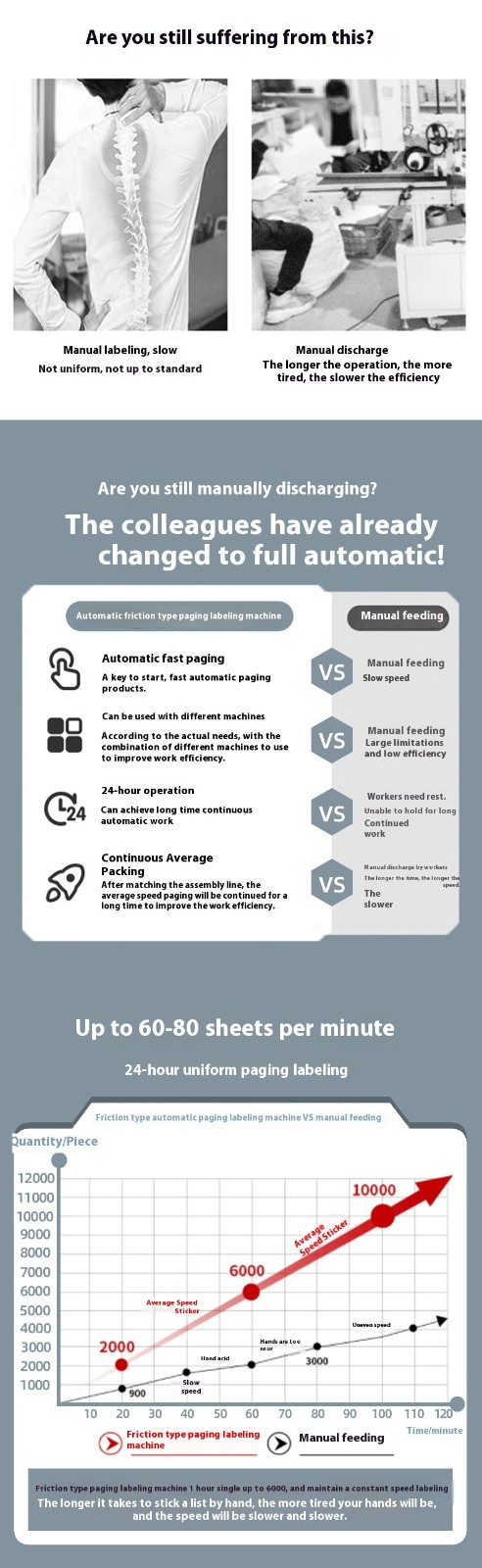

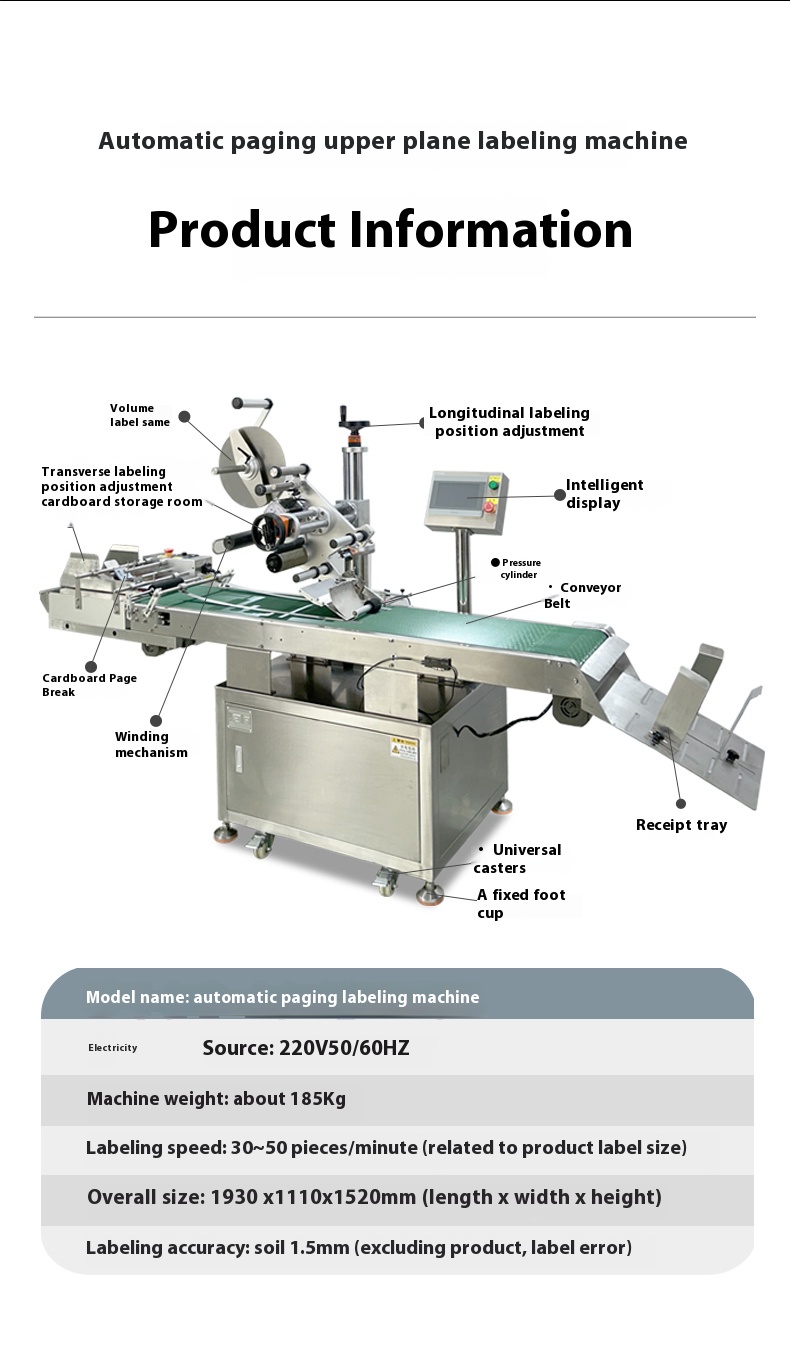

Regular models can achieve a labeling speed of 30-300 bottles/minute, with differentiated designs for different product types:

- Flat surface labeling (e.g., cartons): up to 300 pieces/minute (label size 50×30mm);

- Round bottle labeling (e.g., beverage bottles): up to 200 bottles/minute (bottle diameter 30-100mm);

- Special-shaped product labeling (e.g., cosmetic hoses): up to 100 pieces/minute (requiring adaptation to curved surface fitting).

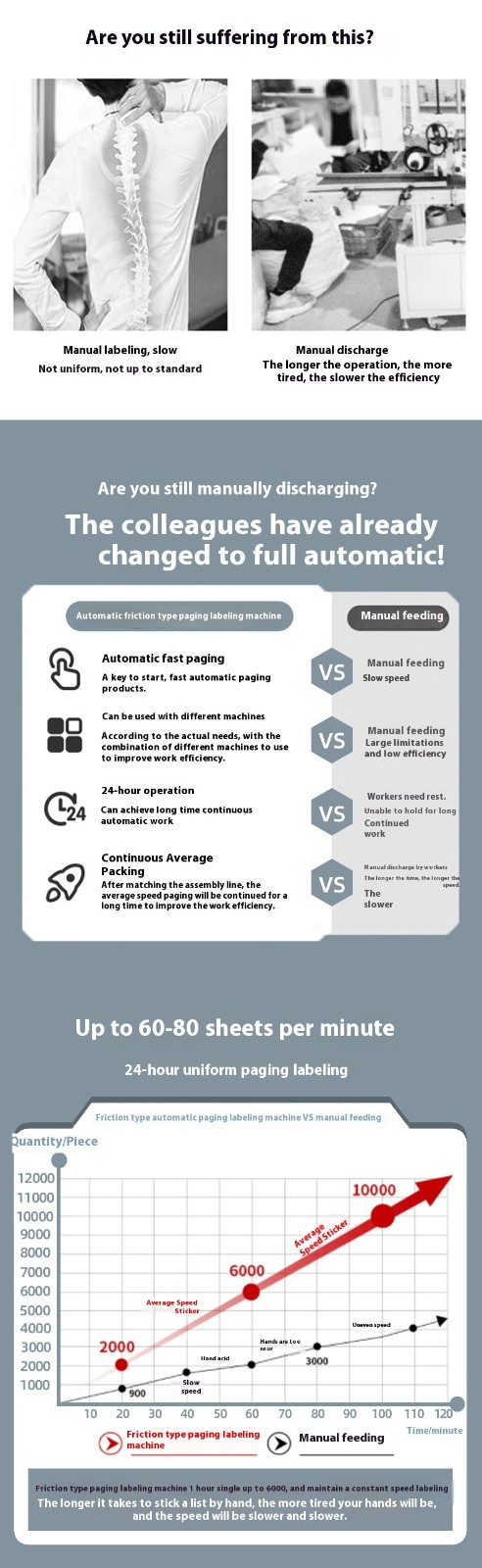

Compared with manual labeling (about 10-30 pieces/minute), the efficiency is increased by 10-30 times, and it can operate continuously for 24 hours, meeting the mass production needs of industries such as food and beverage, and pharmaceuticals (e.g., a mineral water factory achieves a daily output of 500,000 bottles on a single line).

Quick Changeover to Adapt to Multi-variety Production

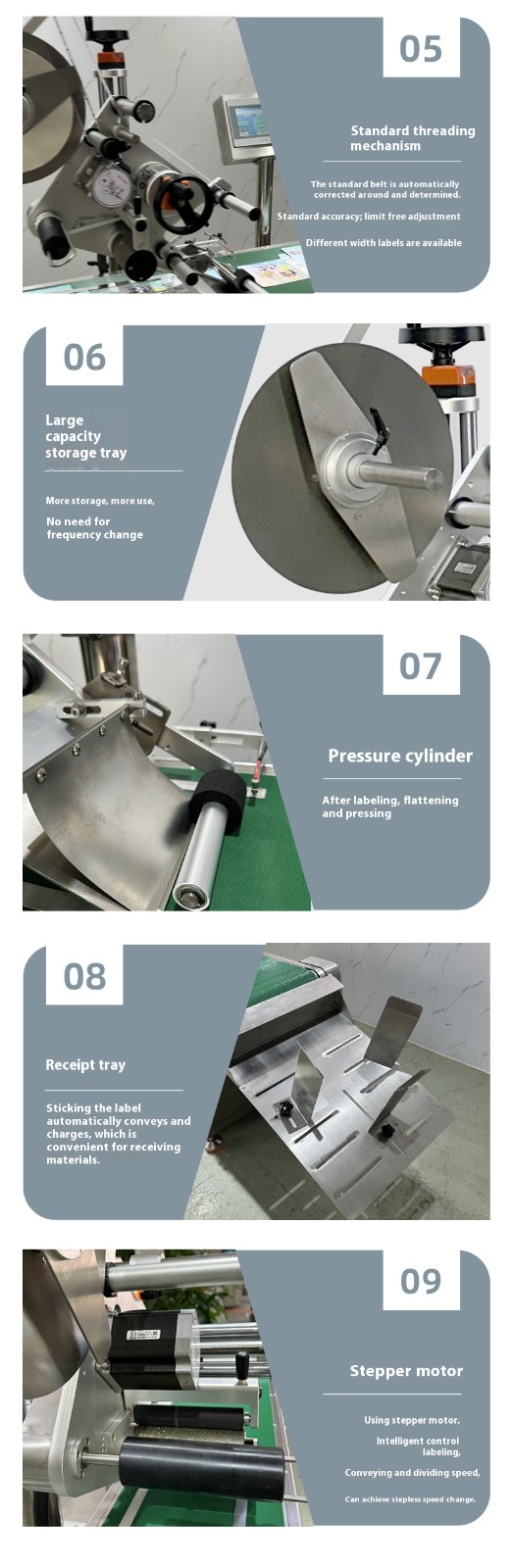

Adopting a modular design, adjustments to label width and product specifications can be achieved through "parameter memory + quick fixtures":

- Changing label sizes (e.g., from 30mm width to 80mm width): only need to adjust the distance between guide rods (with scale marks), taking ≤2 minutes;

- Switching product types (e.g., from round bottles to flat bottles): call preset parameters via the touch screen to automatically adjust the labeling head angle and labeling pressure, with changeover time ≤5 minutes (traditional equipment requires more than 30 minutes).

It adapts to the "small-batch, multi-variety" production mode. For example, a cosmetic factory can complete labeling switches for 5 different bottle types within 1 hour.

Whole-line Linkage to Reduce Process Breakpoints

It supports seamless connection with front-end filling machines and back-end cartoning machines (via conveyor belts + signal interaction), realizing full-process automation of "filling-labeling-cartonning" and eliminating waiting time for manual transfer;

Some models are equipped with a multi-head design (e.g., dual-head, triple-head), which can simultaneously apply "front main label + back instruction label + side traceability code" (e.g., pharmaceutical box labeling), saving time for multi-process transfer.

III. Wide Applicability: Covering Multi-form Products and Label Types

Fully automatic label separating and applying machines, through flexible structural design and functional expansion, can adapt to products and labels of different shapes and materials, covering most industrial scenarios:

Unlimited Product Forms

- Flat products: cartons, cardboard boxes, circuit boards, mobile phone cases, etc. (labeled via flat conveying + pressure labeling wheels);

- Curved products: round bottles (beverage bottles, medicine bottles), conical bottles (red wine bottles), curved boxes (cosmetic boxes), etc. (labeled via rolling labeling or rotating labeling mechanisms);

- Special-shaped products: hoses (toothpaste tubes), square bottles (milk cartons), irregular workpieces (automotive parts), etc. (positioned via customized fixtures + multi-axis linkage labeling).

Full Compatibility with Label Types

It supports self-adhesive labels (paper, transparent film, coated paper), shrink film labels (PVC, PET), RFID electronic labels (with chips), anti-counterfeiting labels (fragile paper, laser labels), etc.;

It can handle special label processes: such as rolled labels (diameter ≤ 300mm), folded labels (e.g., folded instruction stickers), and multi-connected labels (peeling multiple labels at once).

Comprehensive Industry Coverage

It is applicable to industries such as food and beverage (bottled water, cans), pharmaceuticals (medicine bottles, infusion bags), cosmetics (perfume bottles, mask boxes), electronics (batteries, circuit boards), automotive (parts traceability labels), and chemical industry (paint buckets, reagent bottles). It can even be used in special scenarios such as medical devices (surgical instrument packaging) and logistics (express waybills).

Summary: Core Value and Application Scenarios

The three major advantages of fully automatic label separating and applying machines—"stability, efficiency, and wide applicability"—essentially replace manual uncertainty through automation technology, improve precision and efficiency through intelligent control, and break scenario limitations through modular design. Ultimately, they help enterprises:

- Reduce labor costs (1 device can replace 3-5 workers);

- Improve product consistency (labeling qualification rate ≥ 99.8%);

- Flexibly adapt to multi-variety production (meeting C2M customization needs).

Whether in the mass-produced FMCG industry, the pharmaceutical and electronics industries with high precision requirements, or the cosmetics industry with multi-variety and small-batch production, such equipment can become the "flexible core" of the production line, supporting the upgrade from traditional production to intelligent manufacturing.