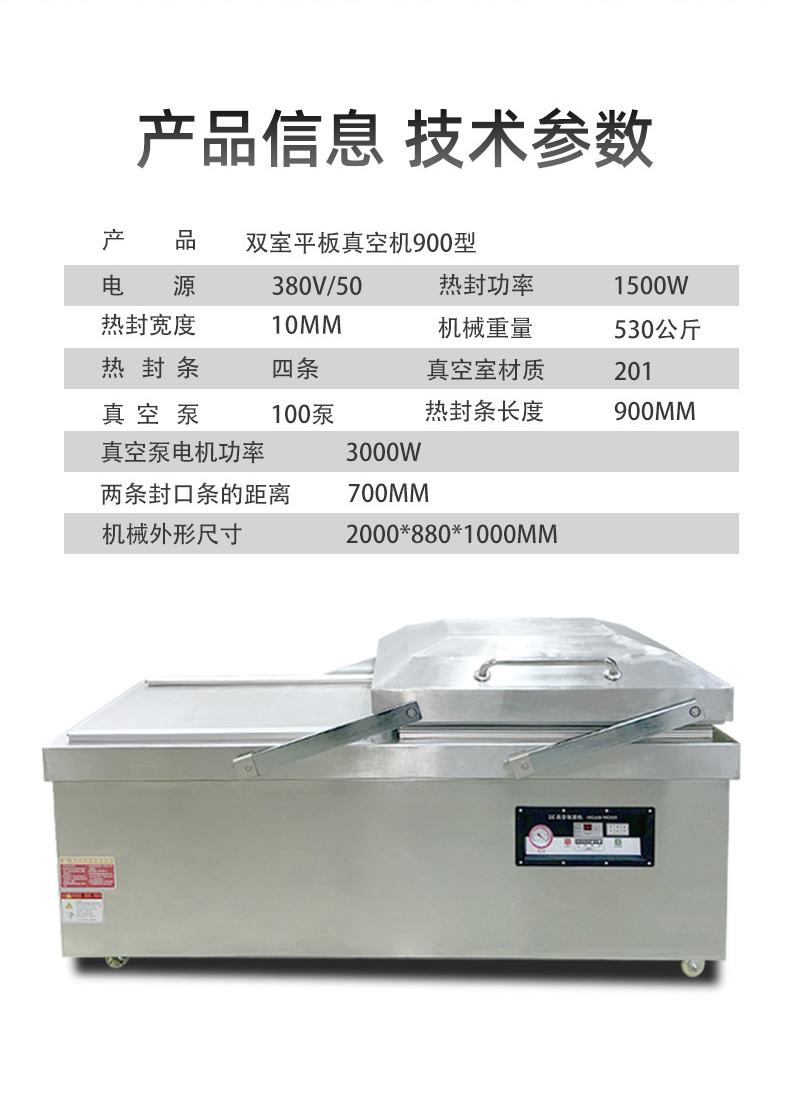

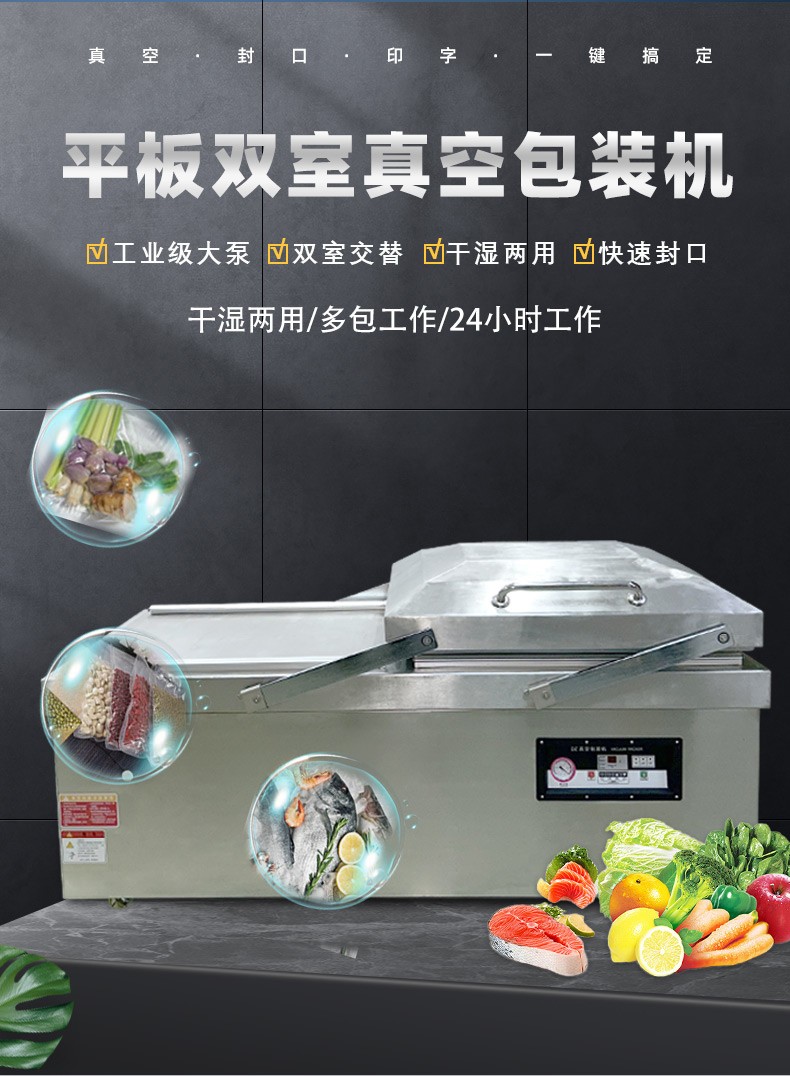

Core Logic of Alternating Operation: The two vacuum chambers of the equipment (commonly referred to as the "left chamber" and "right chamber") achieve process connection through a control system. After the left chamber completes vacuum pumping, heat sealing, and opens its door, the operator can immediately place items to be packaged in the left chamber and close the door. At this point, the right chamber has just finished the final steps of the previous packaging cycle (such as cooling and air return) and immediately starts its vacuum pumping process. When the right chamber enters the vacuum pumping stage, the left chamber has already completed material retrieval and a new round of material placement, entering a standby state. Throughout the process, the "vacuum pumping + heat sealing" actions of one chamber overlap with the "material placement + retrieval" actions of the other, almost eliminating the downtime of single-chamber machines caused by waiting for door opening/closing and manual operations.

Practical Benefits in Mass Production: In continuous mass production scenarios, this alternating mode can increase the "effective working time ratio" of the equipment to over 80% (single-chamber machines typically only reach 50%-60%). For example, packaging a standard-sized piece of meat takes about 15 seconds per cycle with a single-chamber machine, completing a maximum of 240 cycles per hour. In contrast, through alternating operations, a dual-chamber machine can reduce the "actual time per cycle" to 8-10 seconds (while one chamber is pumping vacuum, the other synchronously completes material placement and preparation), stably achieving 360-450 cycles per hour—an efficiency improvement of over 50%. For food processing plants, meat slaughterhouses, and other facilities requiring high-frequency packaging, this efficiency boost can directly reduce the number of equipment investments, lower labor costs, and minimize space occupation.

In addition, the alternating operation of dual chambers helps reduce operator fatigue. Since the operation rhythms of the two chambers are staggered, workers do not need to frequently wait for the equipment to complete a single cycle. Instead, they can form a smooth operational loop of "placing materials - retrieving materials - placing materials again," further ensuring the stability of mass production.