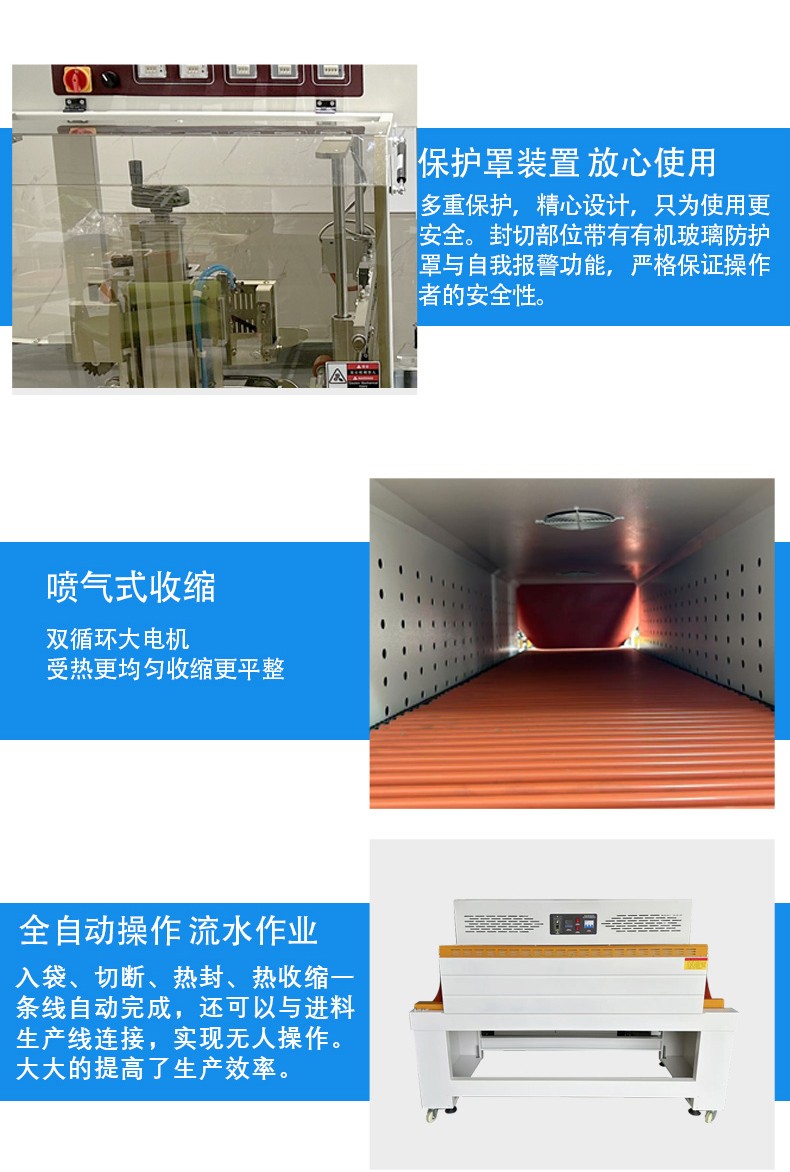

I. High-efficiency automation: Significantly improving production efficiency

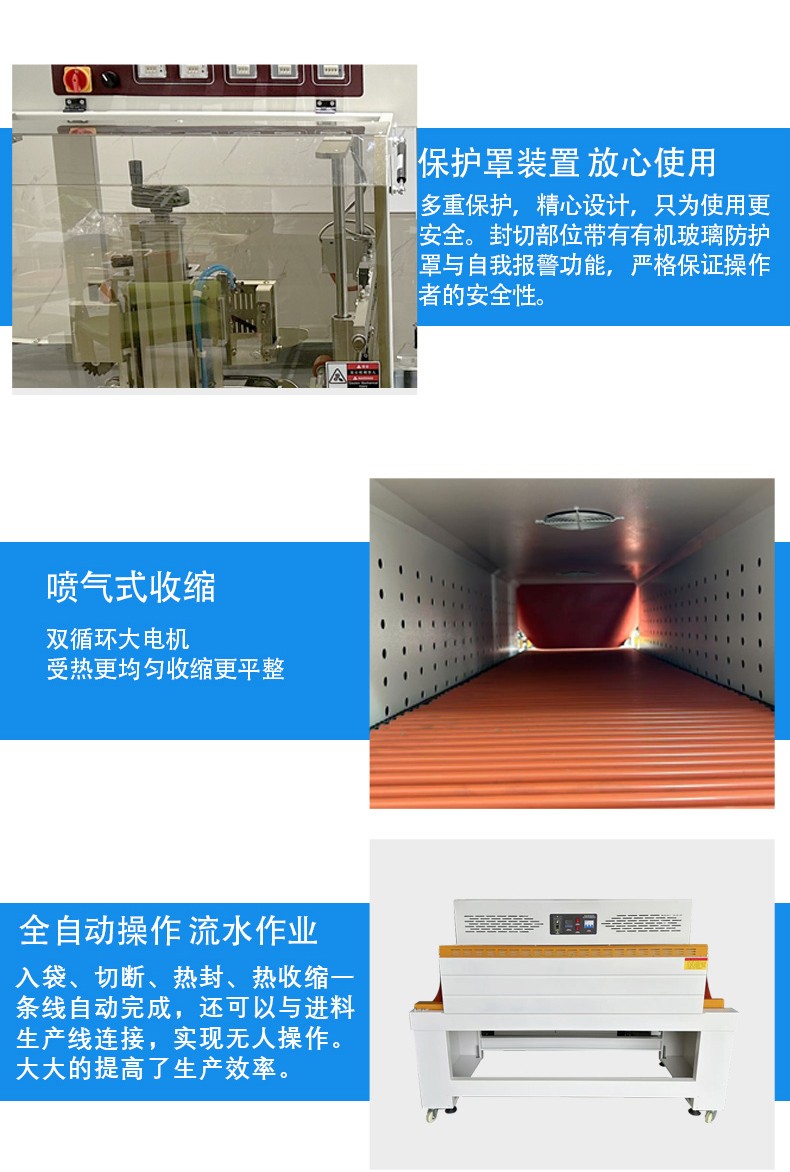

Full-process unmanned intervention

The entire process, from product loading, automatic film sleeving, precise sealing and cutting to heat shrink forming, is completed automatically by the equipment without frequent manual operations. For example, in the bottled beverage packaging line in the food industry, the equipment can achieve continuous packaging of 30-100 bottles per minute, with a daily output of tens of thousands of pieces, far exceeding the efficiency of manual packaging.

Equipped with an intelligent synchronous control system (such as PLC + touch screen), it can automatically match the product conveying speed, sealing and cutting frequency and heat shrinkage temperature, ensuring seamless connection of all links and avoiding jamming or shutdown.

Some high-end models support functions such as automatic deviation correction (for film material deviation) and material shortage alarm (automatic shutdown prompt when film material is insufficient), further reducing the cost of manual intervention.

Flexible adaptation to production lines

It can be seamlessly connected with front-end production lines (such as filling lines, boxing lines) or back-end warehousing systems (such as palletizers) to form a fully automated packaging line. For example, in the electronics industry, the equipment can directly receive motherboards and accessories output from the assembly line, and after packaging, directly send them to the warehousing conveyor belt, realizing the integration of "production - packaging - warehousing" and greatly shortening the production cycle.

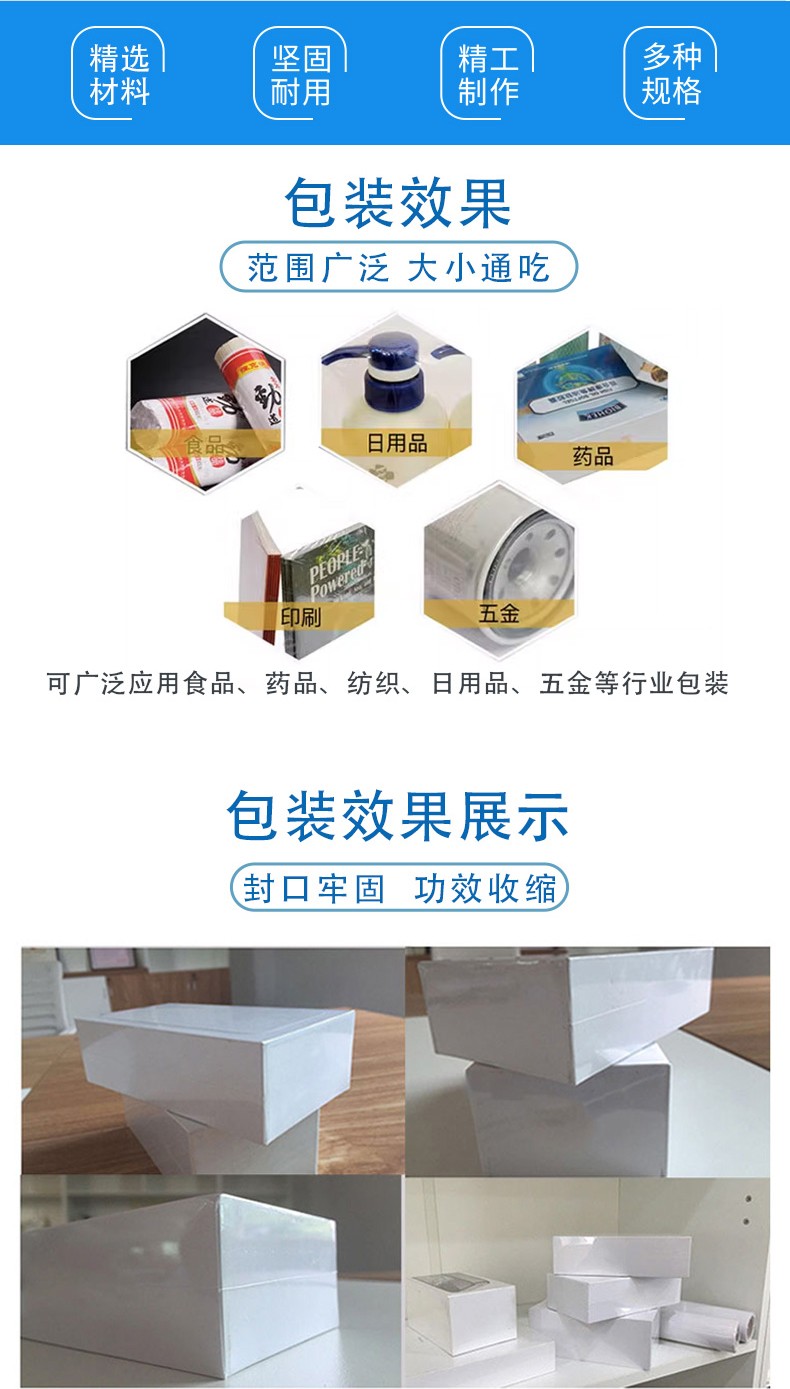

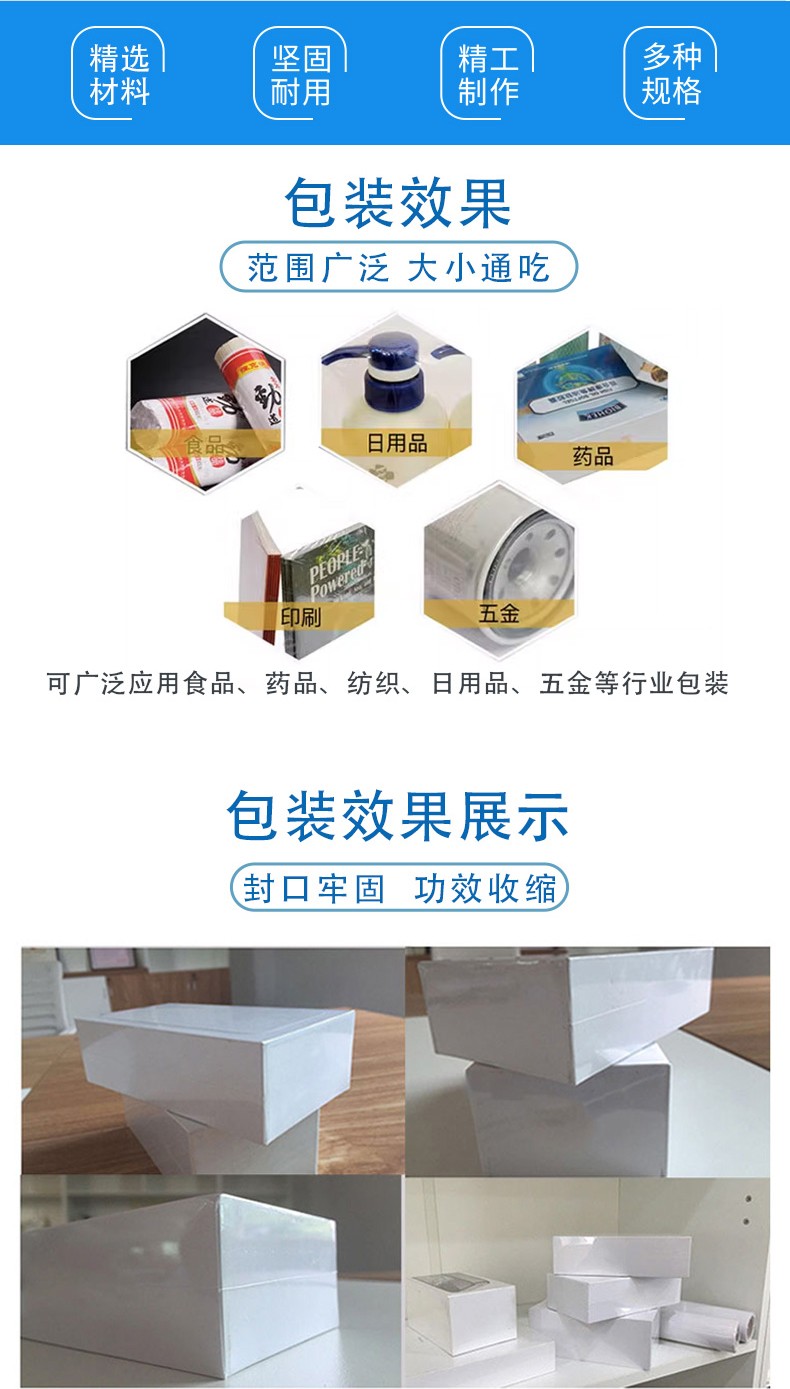

II. Wide scope of application: covering multiple industries and scenarios

Industry adaptability

It covers almost all major fields of the national economy, with typical applications including:

- Food industry: snacks (biscuits, candies), beverages (bottled water, fruit juice), fresh food (gift-boxed fruits), frozen food (dumplings, glutinous rice balls), etc. Packaging achieves moisture-proof, fresh-keeping and aesthetic effects.

- Daily necessities and cosmetics: shampoo, skin care product sets, paper towels, soap, etc. The characteristic of the shrink film closely fitting the product contour is used to highlight the packaging design and enhance shelf appeal.

- Industrial and electronic products: small hardware (screws, bearings), electronic products (mobile phone accessories, circuit boards), medical devices (syringes, test paper boxes), etc. Packaging achieves dust-proof, scratch-proof effects and facilitates storage and transportation.

- Building materials and home furnishing: pipes, plates, small furniture accessories, etc. Batch shrink packaging is used to fix assemblies and reduce shaking loss during transportation.

Product form compatibility

Whether the product is of regular shape (square, round, cylindrical) or irregular shape (special-shaped accessories, combined sets), whether it is single-piece packaging or multi-piece collective packaging (such as 6 bottles of beverage bundling, 10 boxes of facial mask sets), the equipment can be adapted by adjusting the film width, sealing and cutting size and shrinkage temperature:

- For fragile items (such as glass bottled sauces), low-temperature shrink film can be used and the temperature can be precisely controlled to avoid heat damage to the products;

- For large-size products (such as small household appliances), wide-width models (with film width up to 1.5 meters or more) can be selected to meet customized needs.