The silent oil-free air compressor demonstrates remarkable advantages in multiple dimensions due to its unique technical design. The following is a detailed analysis from the aspects of core performance, application adaptability, and usage cost:

- Adopting oil-free lubrication designs (such as self-lubricating materials, special coatings, or dry sealing technologies), it completely prevents lubricating oil from participating in the compression process, avoiding oil mist and oil vapor from mixing into the compressed air.

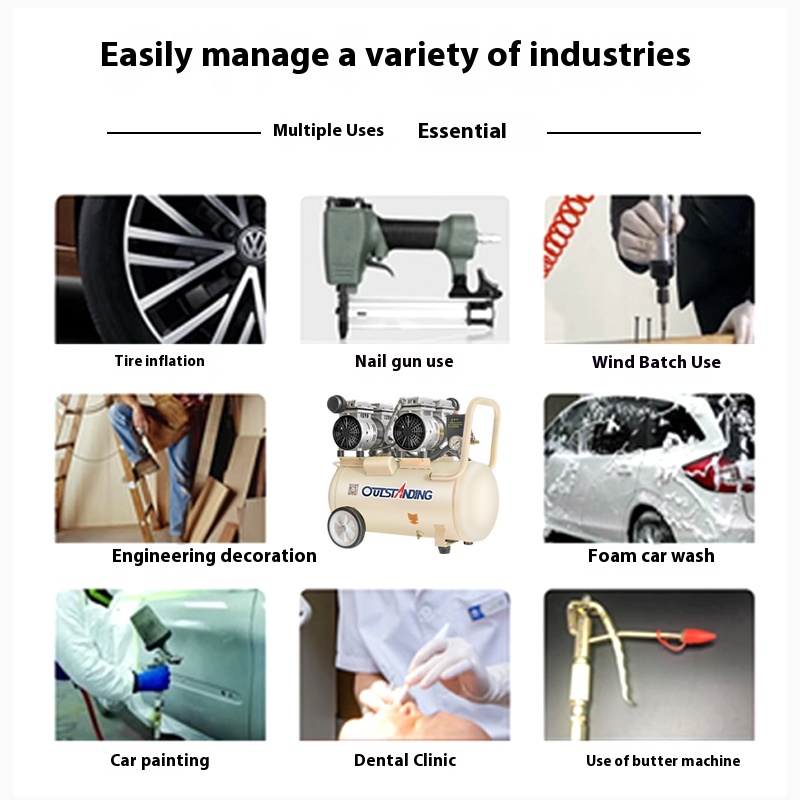

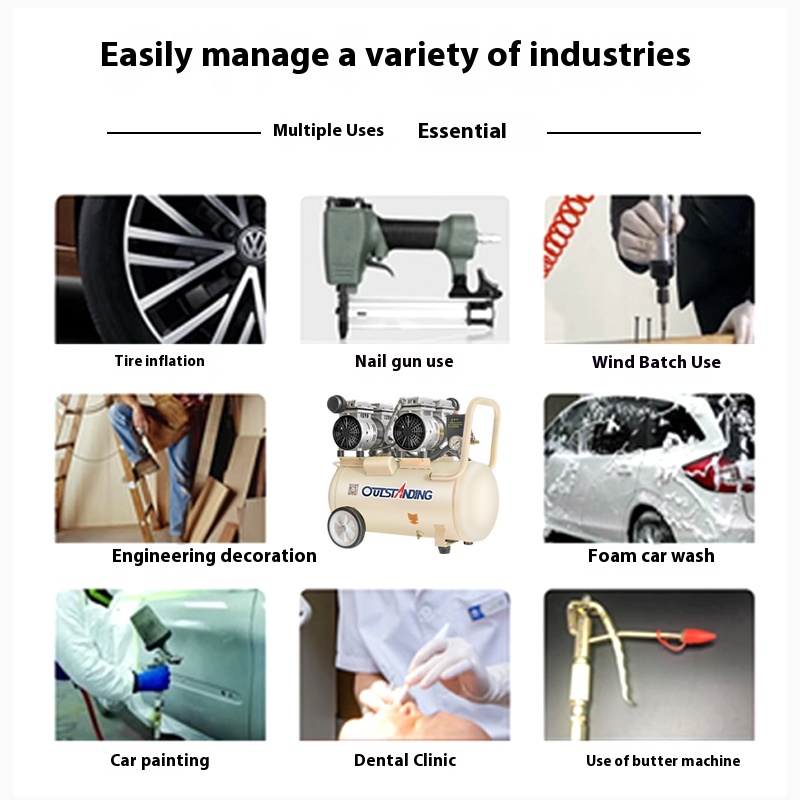

- Typical application scenarios: Food and beverage industry (e.g., filling and packaging links to prevent oil pollution from affecting food safety), pharmaceutical production (sterile gas source for pharmaceutical equipment), and electronics/semiconductors (avoiding oil molecules from contaminating precision components during chip manufacturing).

- Compressed air can directly meet the ISO 8573-1 Class 0 (oil-free) standard, eliminating the need for additional complex oil-removing filtration devices and reducing equipment investment and maintenance costs.

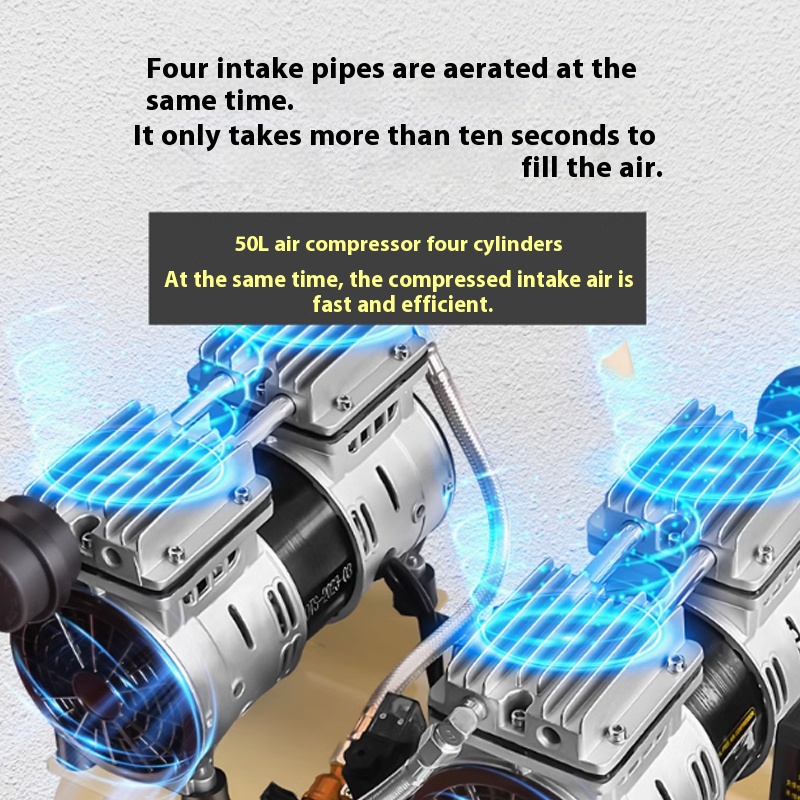

- Structural noise reduction: Using low-vibration compression principles (such as scroll or screw types), combined with soundproof covers (multi-layer sound-absorbing cotton + damping materials) and shock-absorbing bases (rubber pads/spring shock absorbers) to reduce mechanical noise propagation.

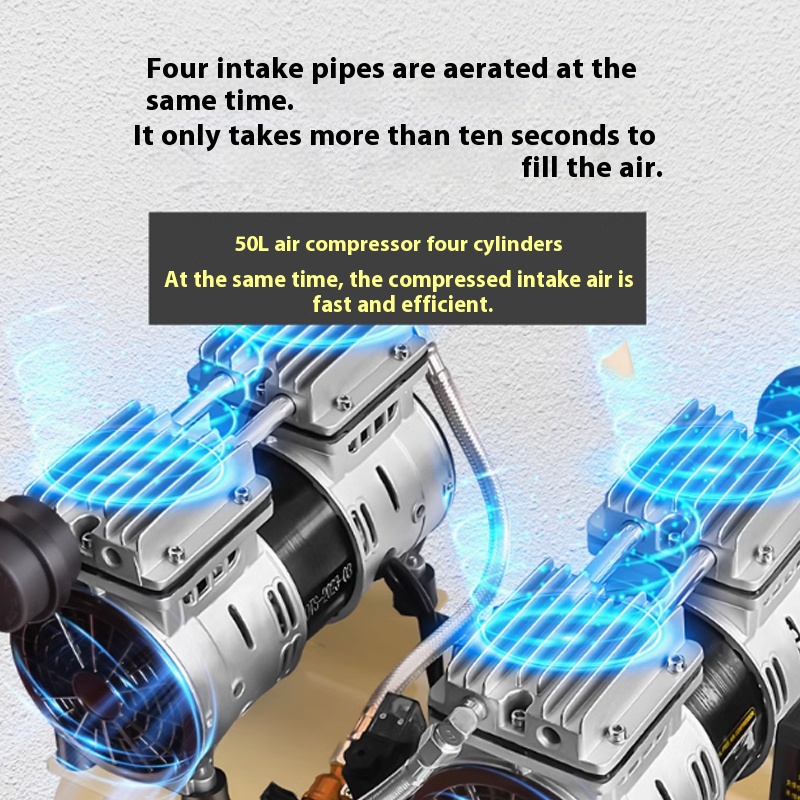

- Airflow noise reduction: Optimizing the design of intake/exhaust channels (such as mufflers and flow guides) to reduce noise generated by gas turbulence. Typical models can control noise levels between 40-60 dB(A), approaching the noise level of an office environment.

- Medical places (hospital wards, dental clinics to avoid noise disturbing patients), laboratories (not affecting the detection accuracy of precision instruments), and office areas (can be directly used indoors without separate machine room isolation).

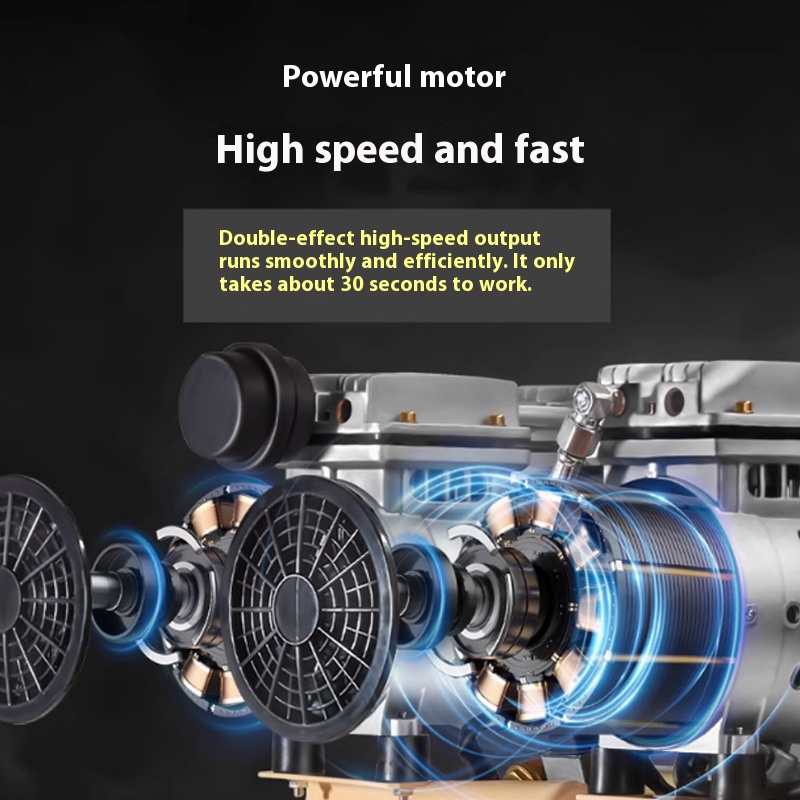

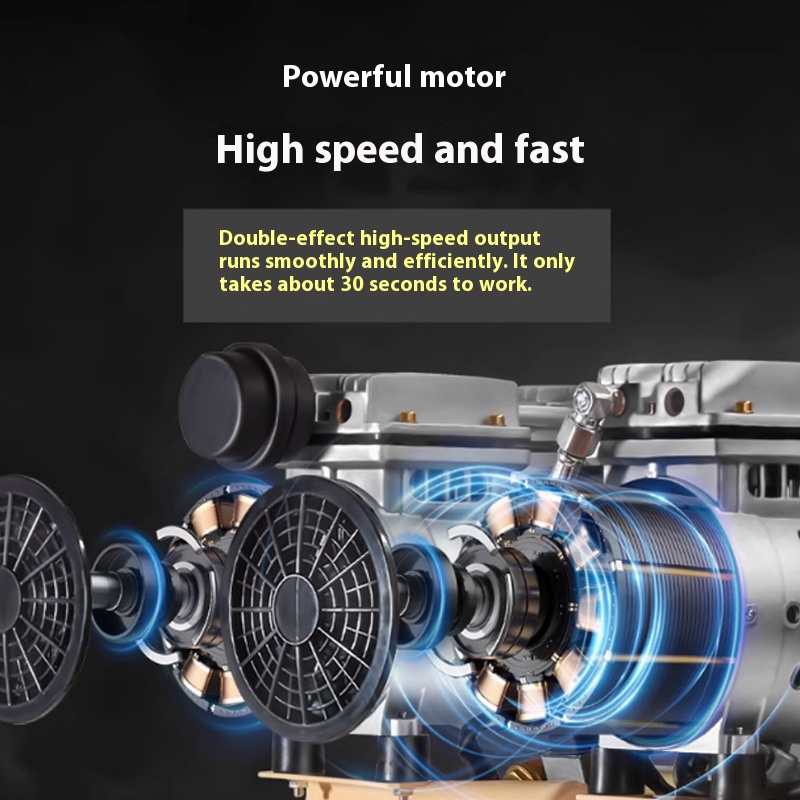

- Equipped with permanent magnet synchronous motors (IPM) or variable frequency motors (VFD), combined with pressure sensors and PLC control systems, it can automatically adjust the rotation speed according to real-time air consumption, avoiding energy waste from the "full-load start-stop" of traditional air compressors, with an energy-saving rate of 15%-30%.

- The volumetric efficiency of screw-type models can reach 85%-90%, and scroll-type models have no clearance volume during compression, making their efficiency closer to the theoretical value. Especially in small and medium air displacement scenarios (such as 1-10 m³/min), the energy consumption performance is better than that of oil-injected air compressors.

- Eliminates periodic tasks such as oil replacement, oil filter cleaning, and oil-gas separator replacement in traditional air compressors, reducing maintenance costs by more than 50%, and extending the maintenance cycle to 1-2 years (only requiring regular cleaning of air filters).

- The oil-free environment reduces wear and tear on components (such as piston rings and screw rotors). Combined with corrosion-resistant materials (aluminum alloy cylinders, ceramic coatings), the equipment life can reach 10-15 years, and the failure downtime rate is reduced by 80%.

- Under the same air displacement, the volume of oil-free air compressors is 30%-50% smaller than that of oil-injected models (e.g., small scroll-type models can be directly wall-mounted), suitable for narrow spaces such as workshop corners and laboratories.

- No need for external auxiliary equipment such as oil coolers and oil storage tanks, nor to consider waste oil treatment. During installation, only power supply and air pipes need to be connected for plug-and-play use.

- Avoids soil and water pollution caused by lubricating oil leakage, meets compliance requirements such as HACCP in the food industry and GMP in the pharmaceutical industry, and reduces environmental protection approval processes.

- The energy-saving design complies with the national "Double Carbon" goal. In some regions, it can enjoy subsidies for energy-saving equipment, and the low noise feature meets urban regional environmental protection regulations (such as factory boundary noise limits).