Here is a detailed comparison of the functional principles, application scenarios, and technical characteristics between compression sealing machines and ordinary sealing machines:

- Functional Combination: First compresses items through vacuum pumping, mechanical extrusion, or gas inflation, then seals the package, achieving dual effects of "volume reduction + sealing".

- Vacuum Compression: Suitable for fluffy items like clothes and quilts. It reduces volume by evacuating air (compression rate up to 50%-80%), such as the sealing machines used with household vacuum compression bags.

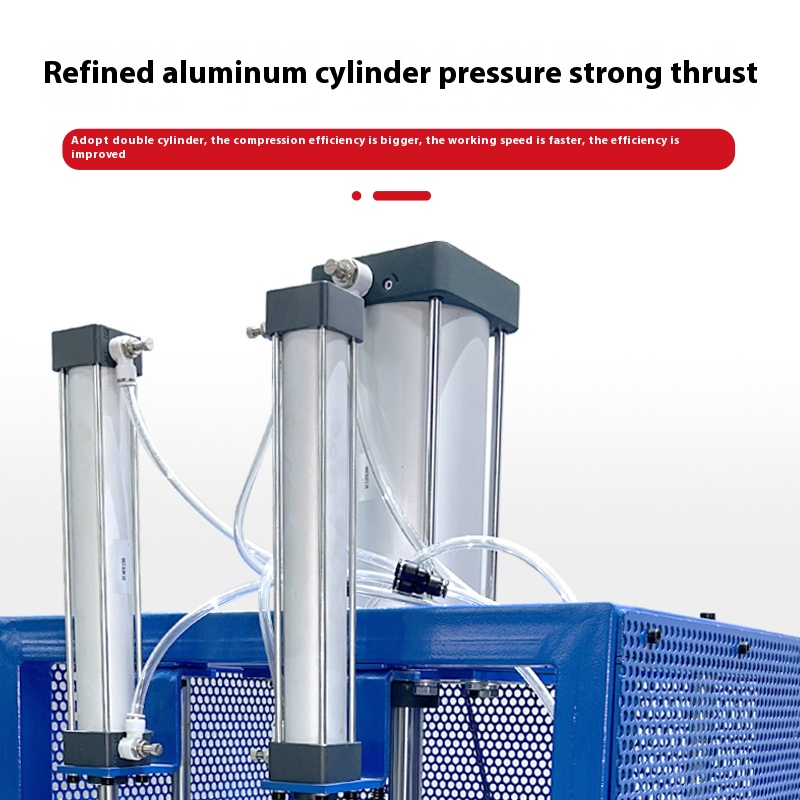

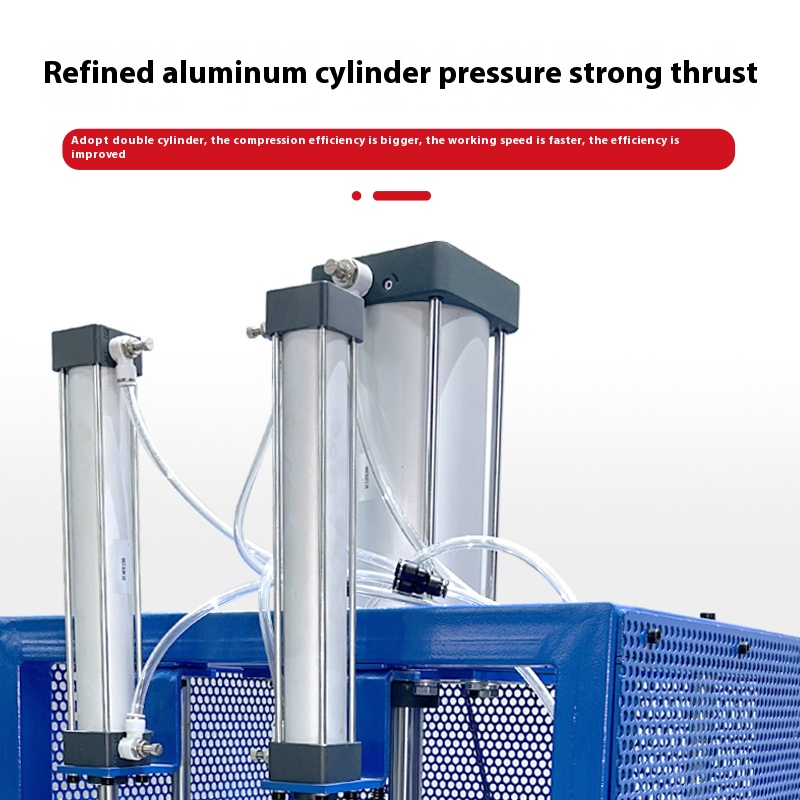

- Mechanical Extrusion Compression: Extrudes air between items via a pressing plate, commonly seen in vertical compression packing machines for the clothing and home textile industries.

- Inflation Compression (Reverse Logic): For fragile items, some models first inject inert gases (e.g., nitrogen) to fix the shape via air pressure, then seal the package (essentially "compressing" the space through gas pressure).

- Core Value: Saves storage and transportation space, reducing logistics costs (e.g., the transportation volume of down jackets can be reduced by 2/3 after compression).

- Single Function: Directly seals the package opening through heating or high-frequency welding without changing the original volume of items.

- Application Scenarios: Suitable for scenarios requiring only leak-proof or dust-proof effects, such as:

- Sealing snack bags and daily necessities packaging (e.g., sealing potato chip bags in supermarkets);

- Simple sealing of small packages for medicines and cosmetics (no need for space compression).

- Household/Individual Scenarios:

- Storing clothes, quilts, and blankets using vacuum compression bags to save wardrobe space;

- Compressing sleeping bags and camping mats for easy carrying during outdoor activities.

- Industrial/Commercial Scenarios:

- Textile Industry: Garment factories compress and pack clothes to reduce warehouse occupation;

- Food Industry: Vacuum-compressed packaging for meat and dried goods (e.g., mushrooms, fungus) to extend shelf life and save transportation costs;

- Logistics and Warehousing: E-commerce platforms compress fluffy goods (e.g., plush toys) to reduce the volume of express packages.

- Retail and FMCG:

- Sealing packaging for snacks, condiments, and tea (e.g., potato chip bags, soy sauce bags);

- Packaging for daily necessities (e.g., sample bags of shampoo, wet wipe bags).

- Light Industry and Laboratories:

- Sealing small samples of medicines and cosmetics;

- Simple sealing of laboratory sample bags (no need for a vacuum environment).

- Advantages:

- High compression rate, significant space saving;

- Some models have vacuum fresh-keeping functions (e.g., food packaging can extend shelf life by 3-5 times).

- Disadvantages:

- Higher price (household models cost 200-1,000 RMB, commercial models cost thousands to tens of thousands of RMB);

- Complex operation process (requires setting parameters like compression time and vacuum degree);

- High maintenance cost (needs regular replacement of vacuum pump oil and seals).

- Advantages:

- Low price (simple hand-press sealing machines cost only tens of RMB, commercial models cost hundreds of RMB);

- Simple operation (one-key sealing without complex debugging);

- Easy maintenance (no complex components, only needs cleaning the heating strip).

- Disadvantages:

- No compression function, unable to solve space occupation problems;

- Single sealing effect (only leak-proof, no moisture-proof or anti-oxidation capability).