Semi-automatic wrapping machines are common packaging equipment that achieve a certain degree of automation in wrapping while requiring manual participation in some operational links. Below is a detailed introduction:

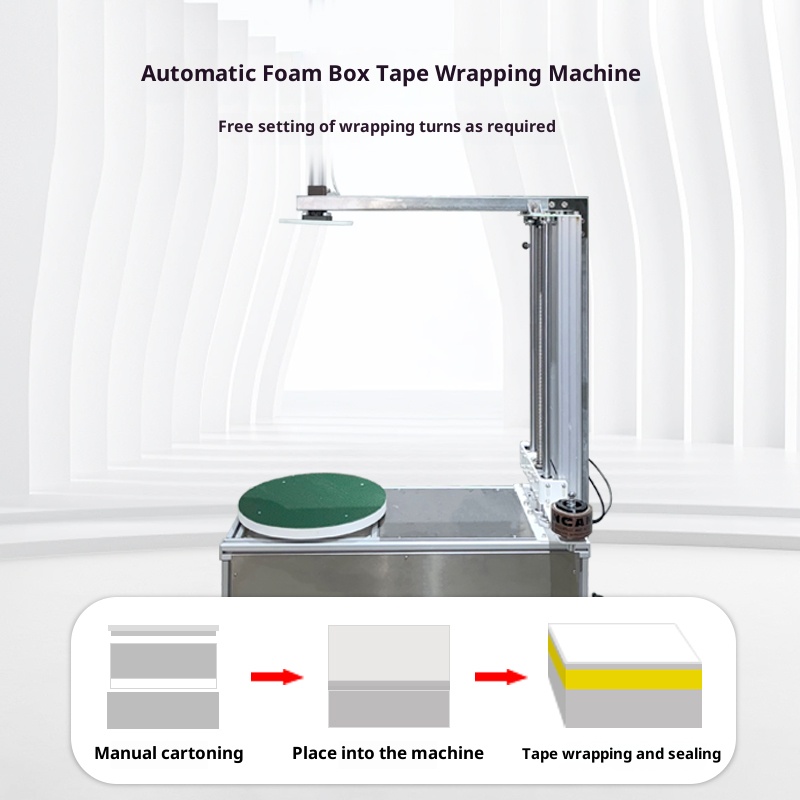

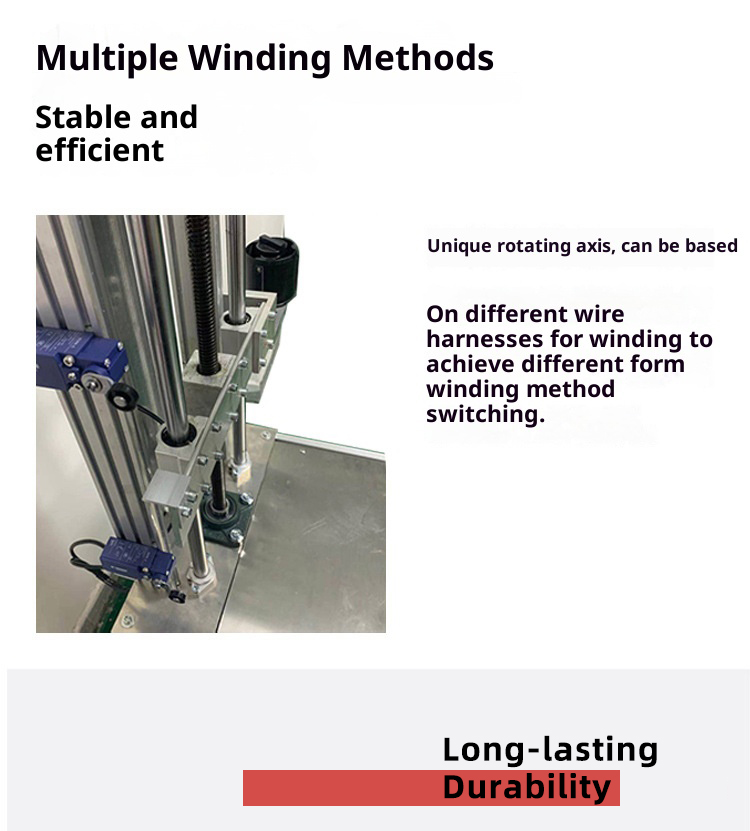

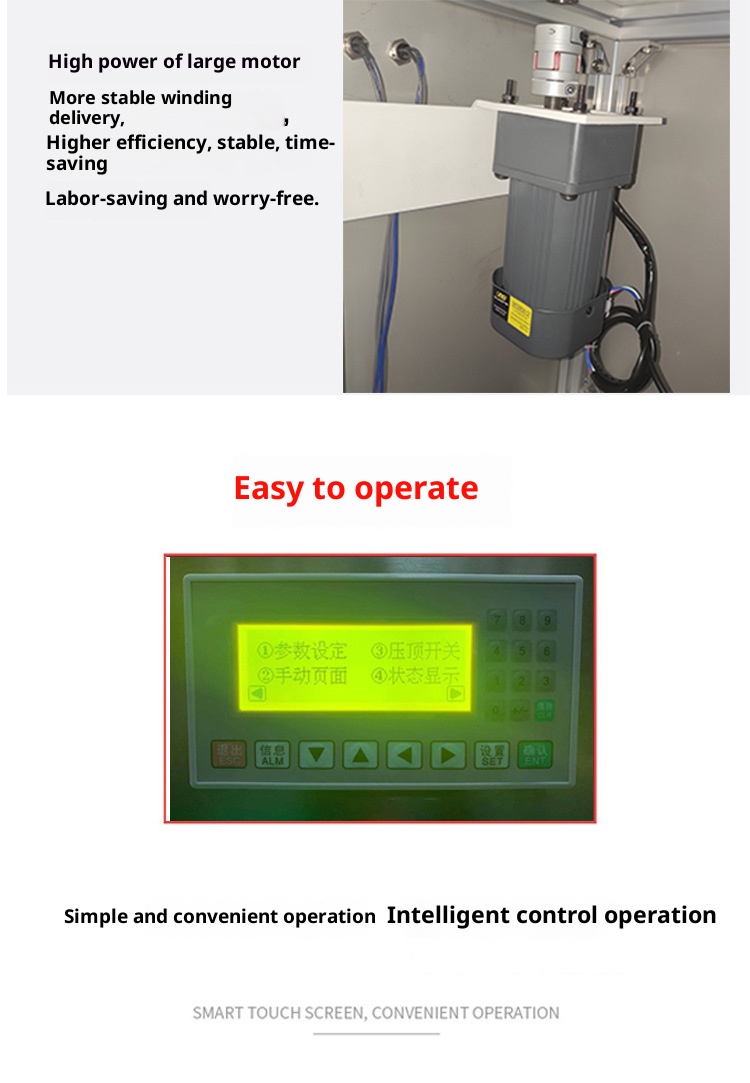

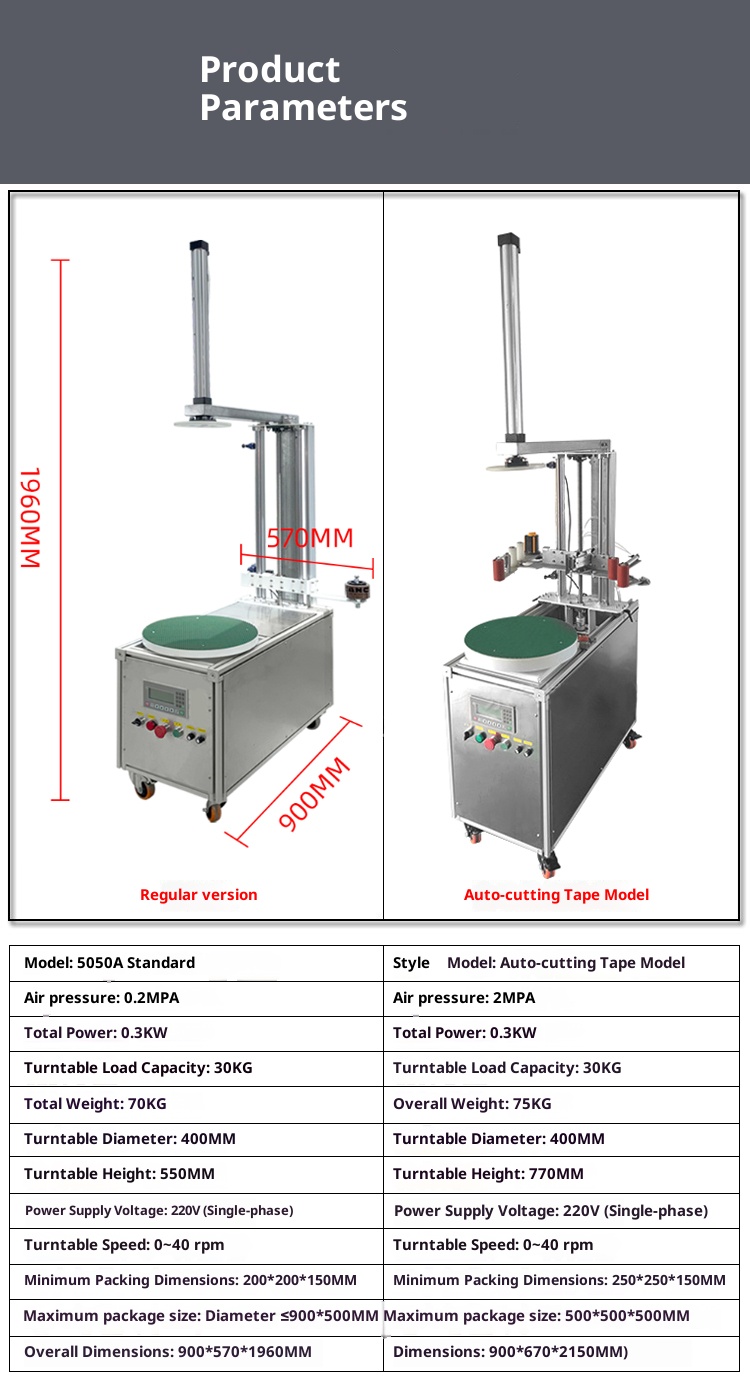

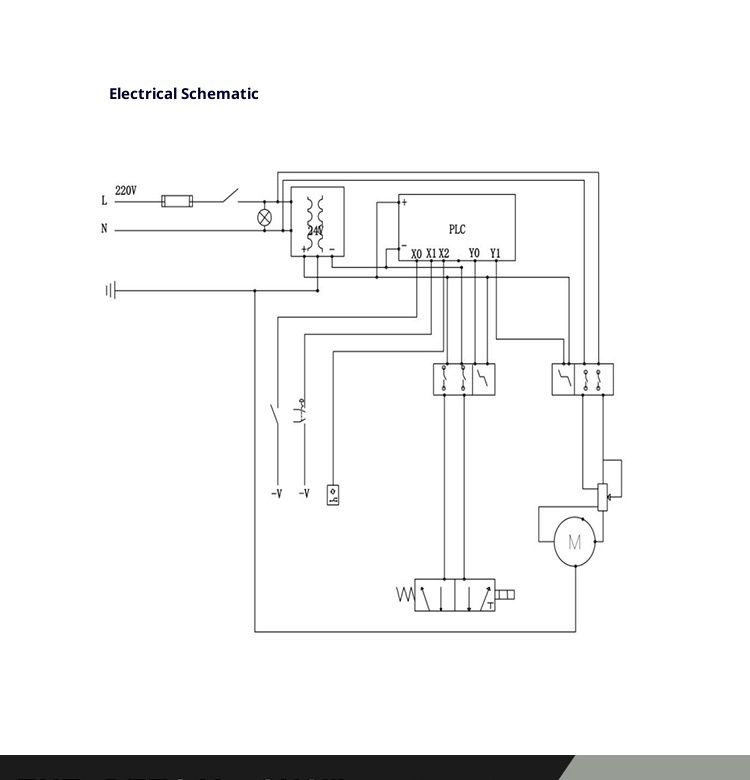

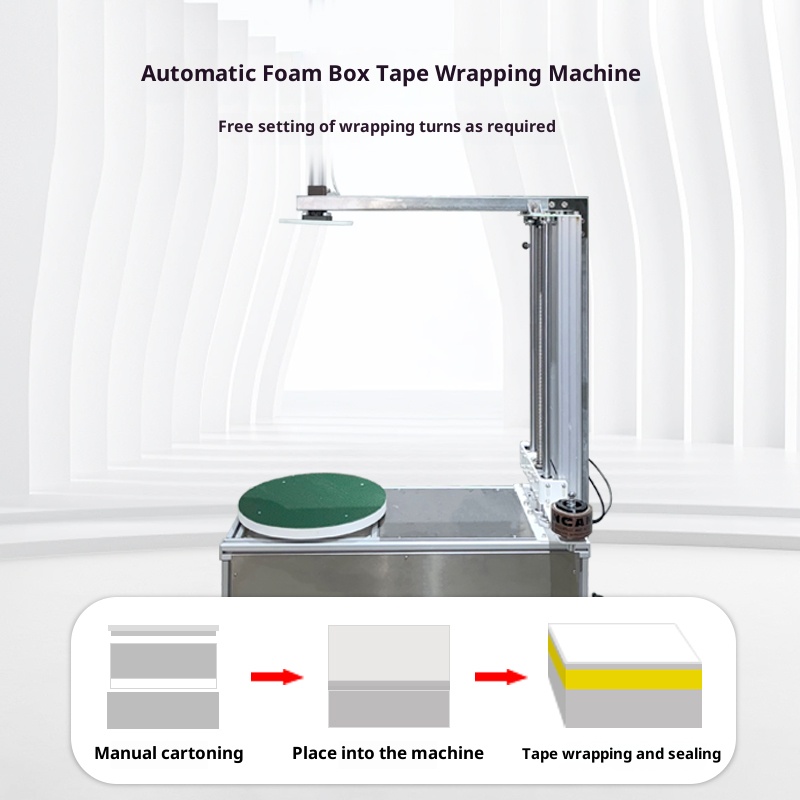

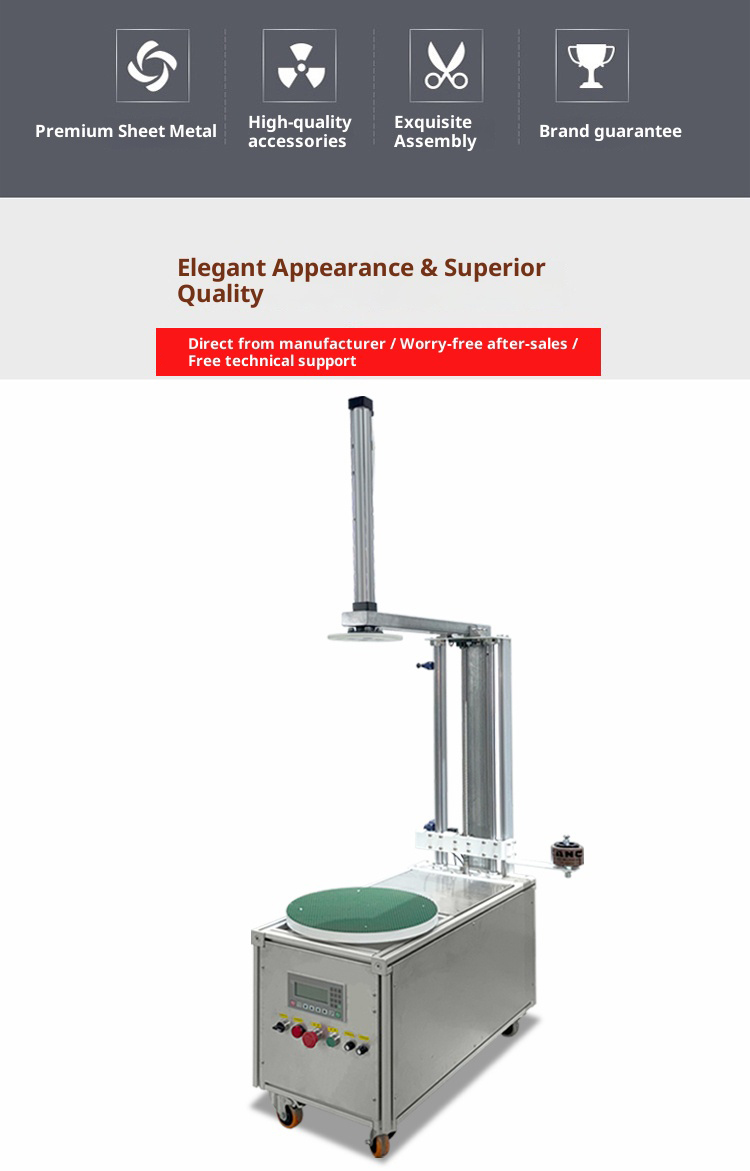

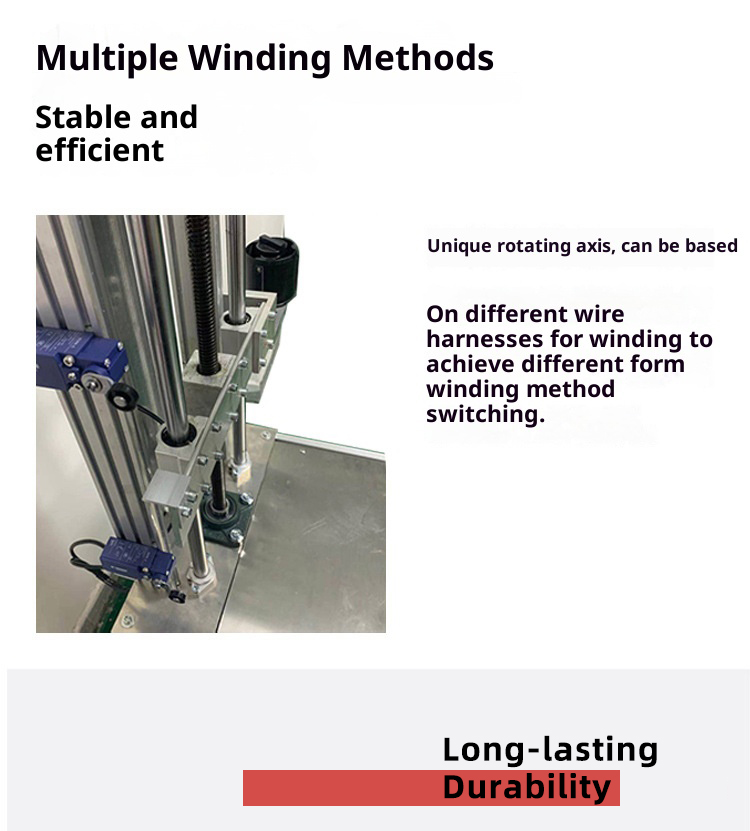

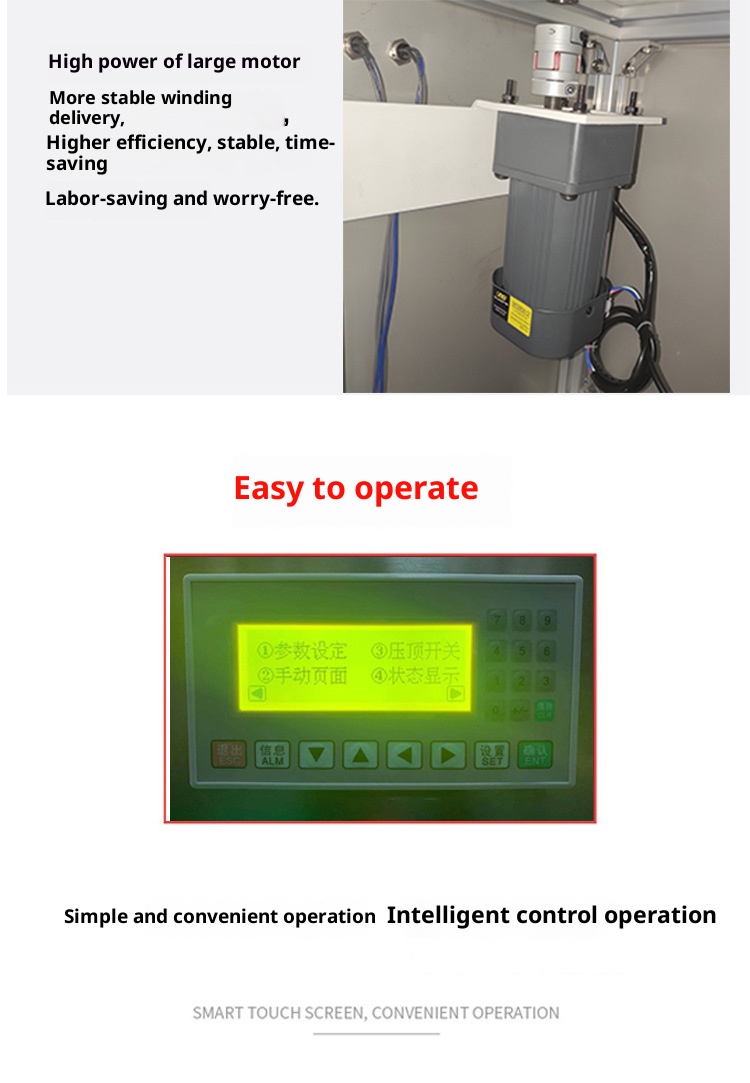

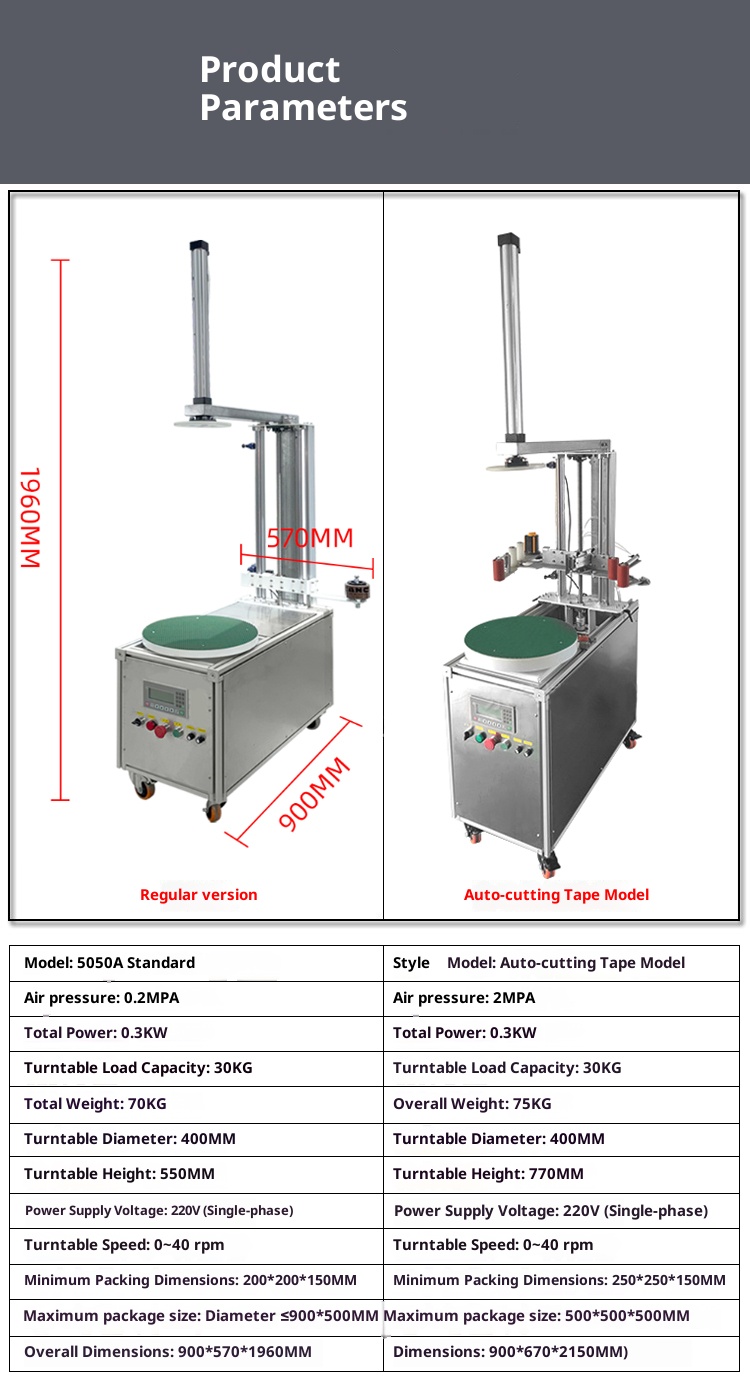

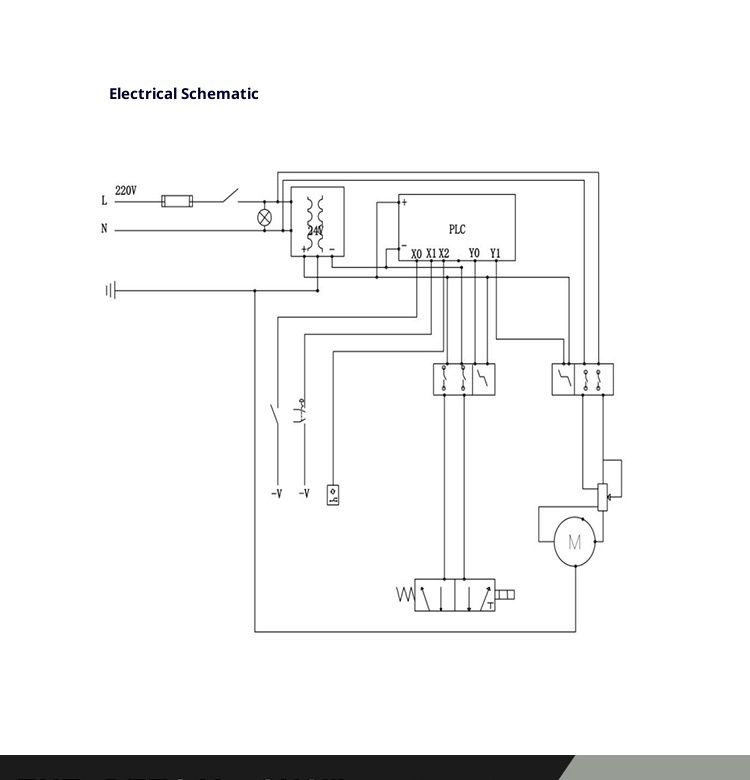

Semi-automatic wrapping machines usually require manual placement of goods on the rotating platform. The operator then fixes the starting end of the film at the bottom of the goods and sets parameters such as wrapping layers, top and bottom reinforcement layers, and film tension via the control panel. After that, the machine drives the rotating platform to rotate, while the film frame moves up and down along the height of the goods to complete the wrapping. Finally, the operator manually cuts the film.

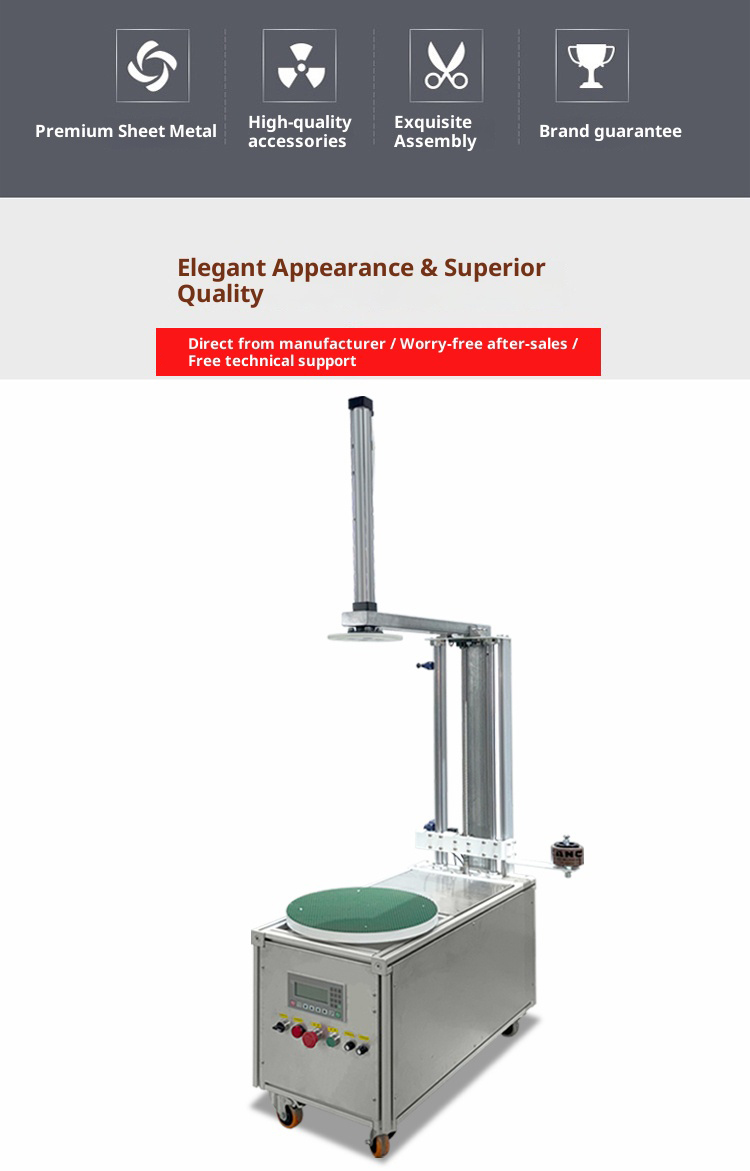

- High cost-performance ratio: Compared with fully automatic wrapping machines, semi-automatic models have a relatively lower price. They are suitable for small and medium-sized enterprises (SMEs) or businesses with small production scales, improving packaging efficiency to a certain extent without excessive investment.

- Easy operation: The equipment’s operation interface is usually simple. Operators can master the operation after brief training, facilitating daily use and maintenance.

- Excellent packaging effect: By setting parameters, it can perform relatively uniform and tight wrapping on goods of different sizes and shapes, ensuring packaging quality, stabilizing the goods, and providing waterproof and dustproof protection.

- Strong adjustability: It can flexibly adjust parameters such as wrapping layers and film tension according to the size, weight of the goods and packaging requirements, meeting various packaging needs.

- Small and medium-sized enterprises (SMEs): Due to their high cost-performance ratio, they are suitable for SMEs engaged in batch packaging of goods, such as small food factories and daily necessities factories.

- Enterprises with diverse types of goods: For enterprises that need to package goods of different sizes and shapes, semi-automatic wrapping machines can adapt to various goods through parameter adjustment, such as logistics and warehousing centers that often package various types of goods.

- Enterprises with small production scales: When an enterprise has a small production scale and the packaging volume is not particularly large, semi-automatic wrapping machines can meet its production needs and avoid waste of equipment resources.