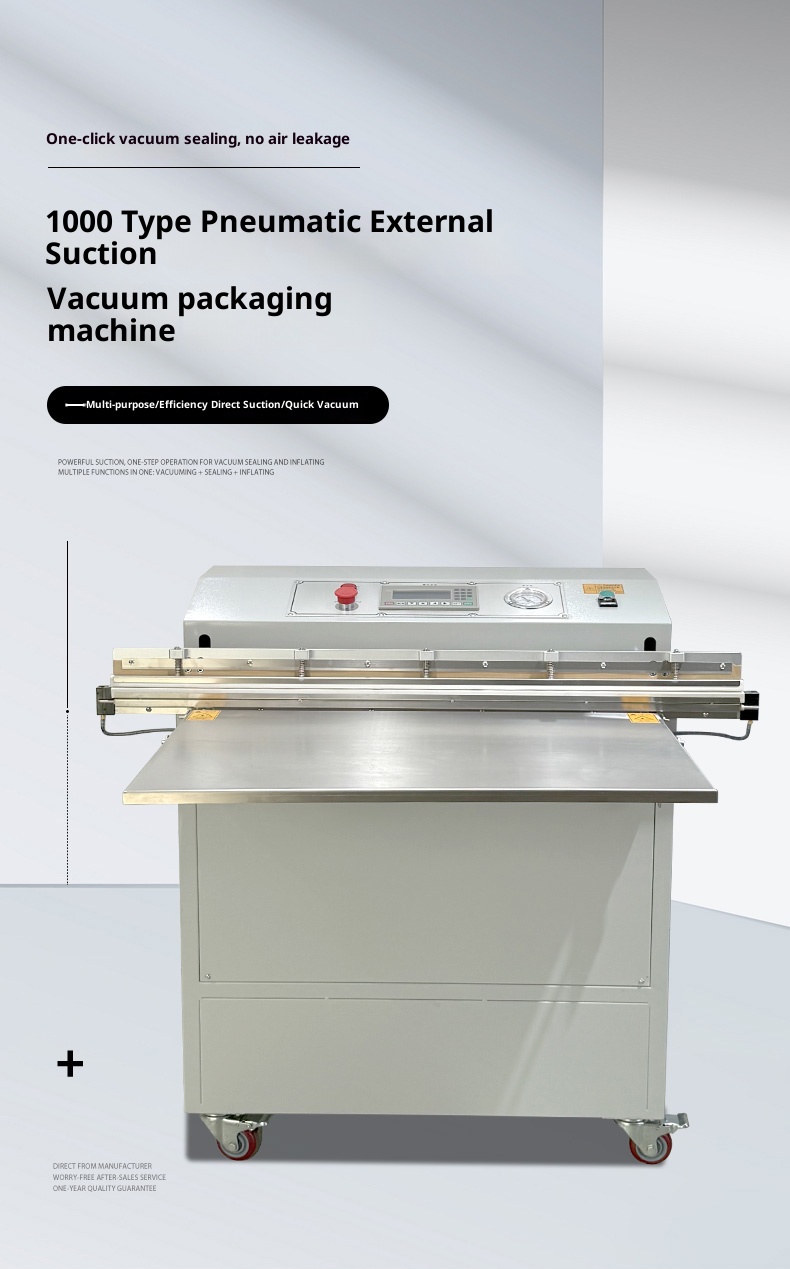

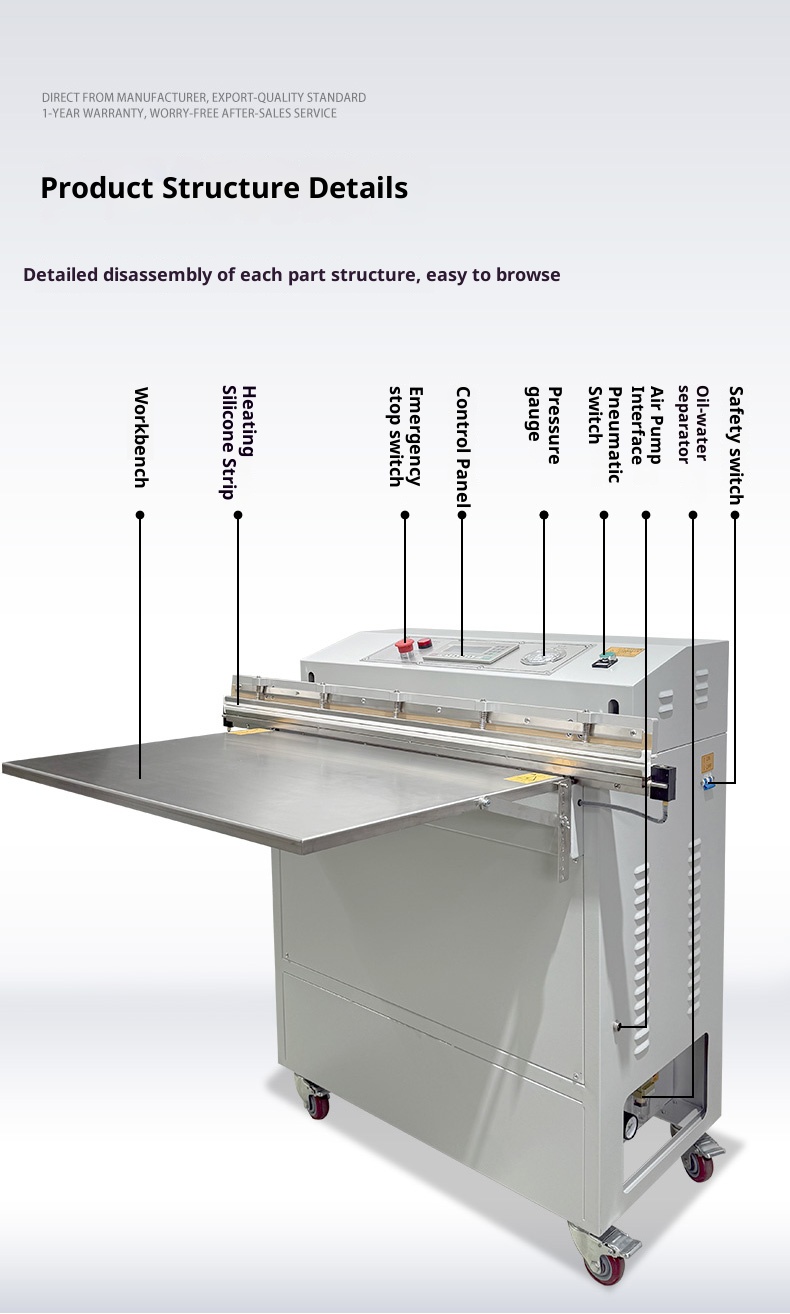

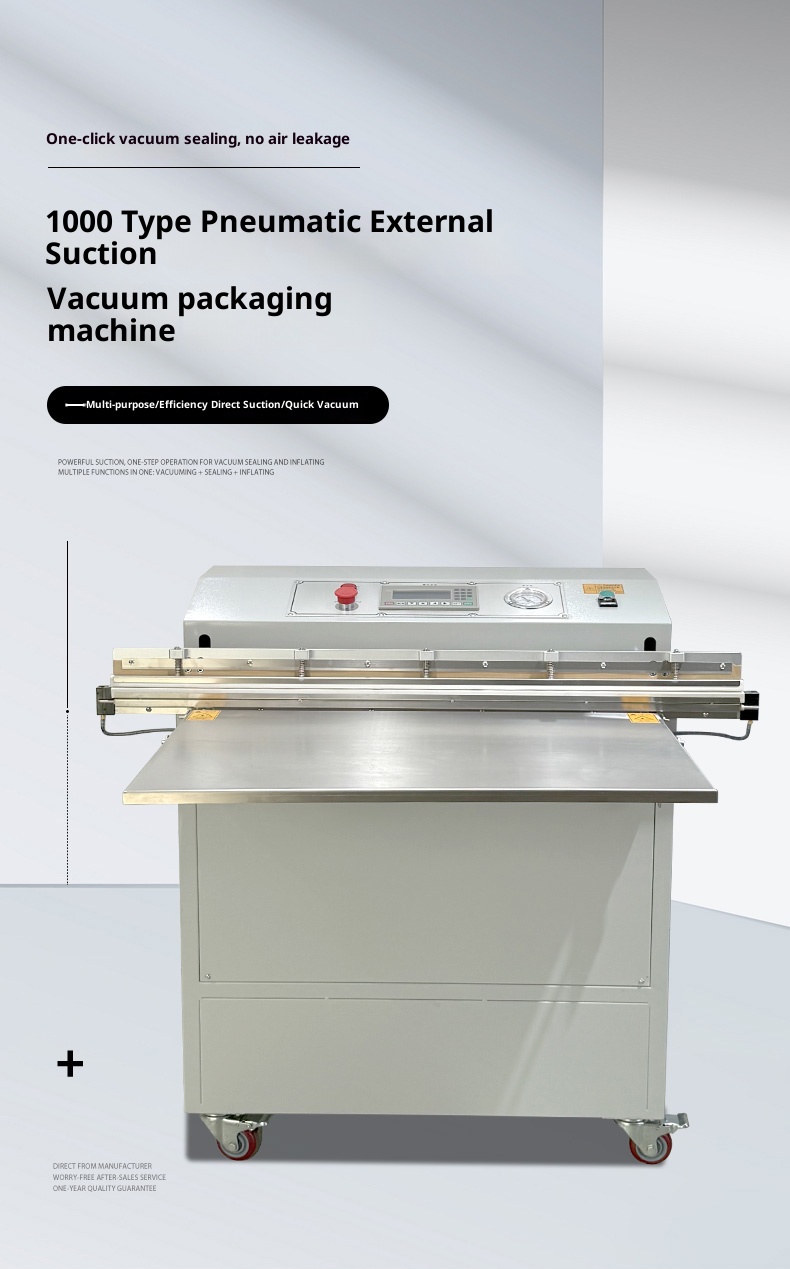

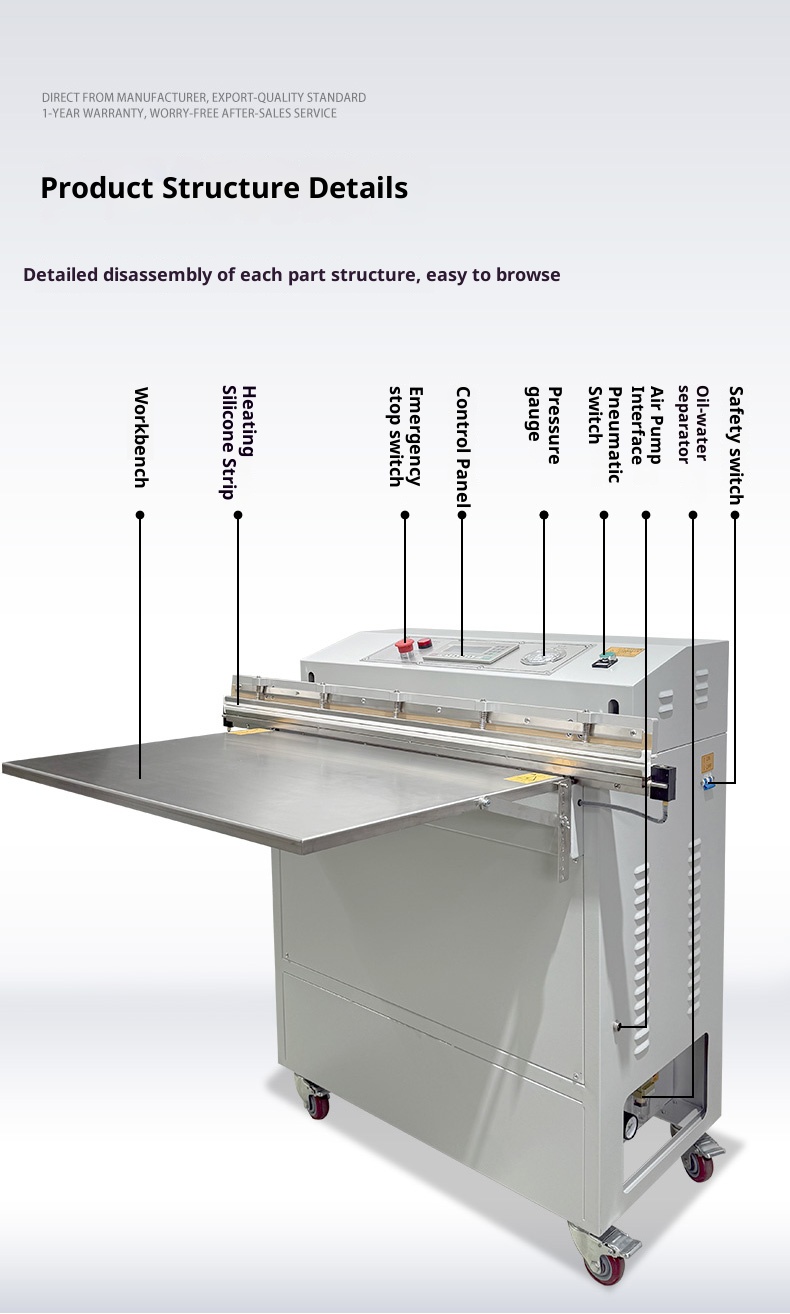

The external vacuum packaging machine is a device that extracts air from the packaging bag and seals it via an external air-extraction component. It achieves moisture-proof, fresh-keeping and dust-proof protection for items, with its core advantage being the ability to package items that exceed the chamber size, are pressure-sensitive or have irregular shapes.

The machine completes packaging in three steps, without the need to fully place the item into a closed chamber:

- Placement and sealing positioning: Put the item to be packaged into a vacuum bag, and place the bag opening on the machine’s sealing strip (no need to put the entire item into the machine).

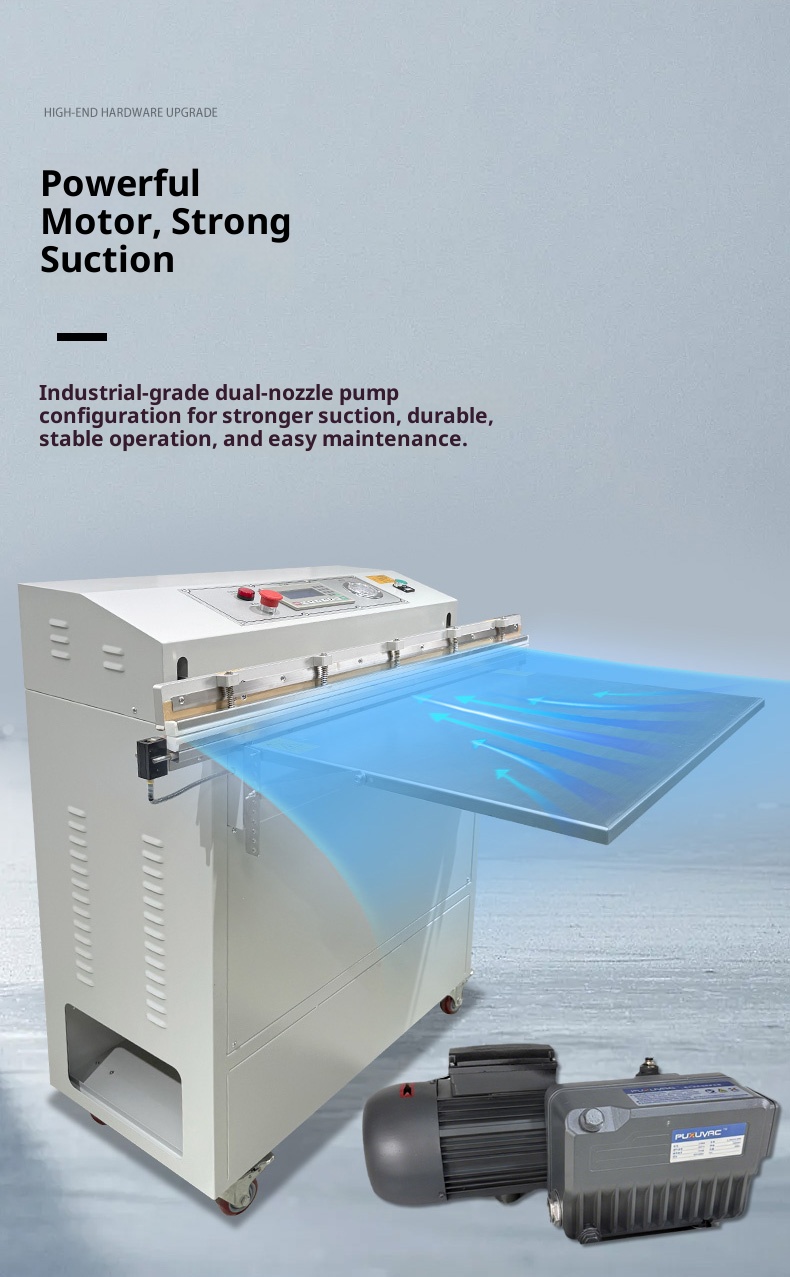

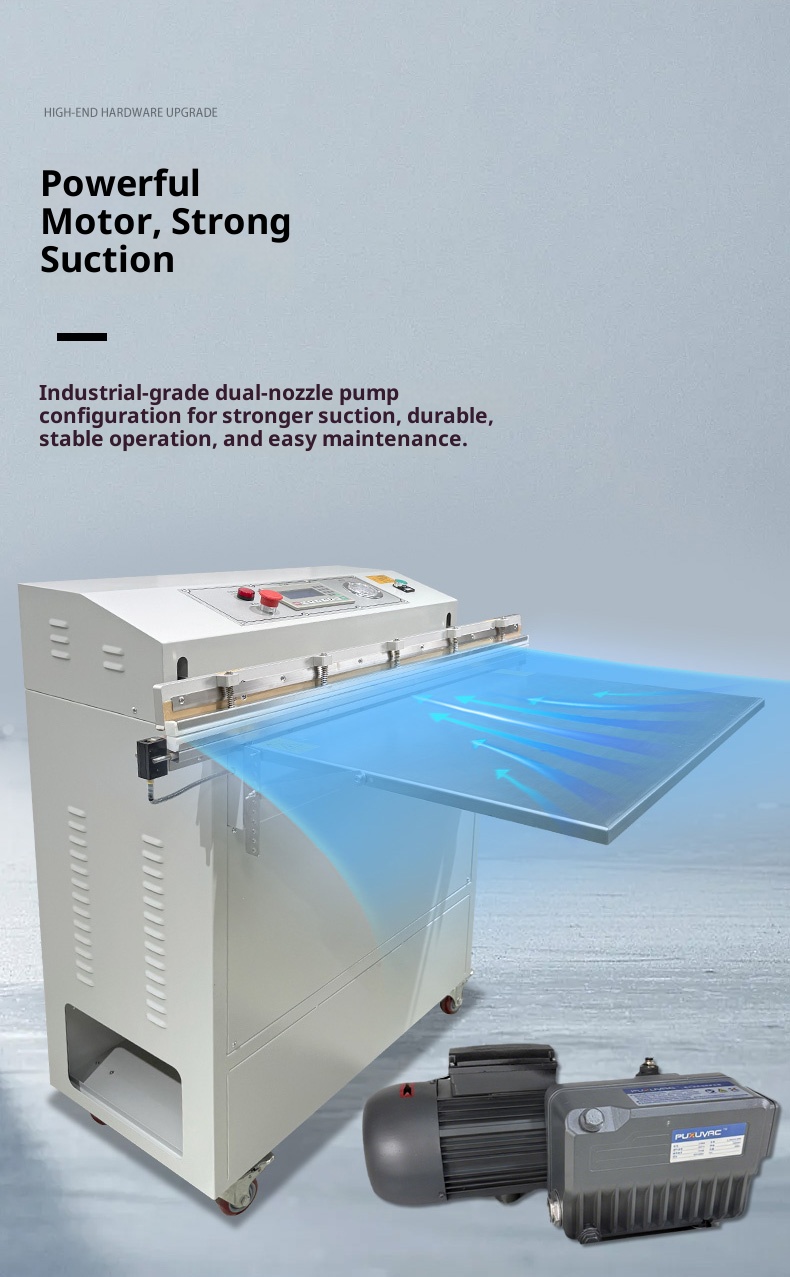

- External vacuum extraction: The machine’s air suction nozzle is close to the bag opening. After starting, it quickly extracts air from the bag until the set vacuum level is reached.

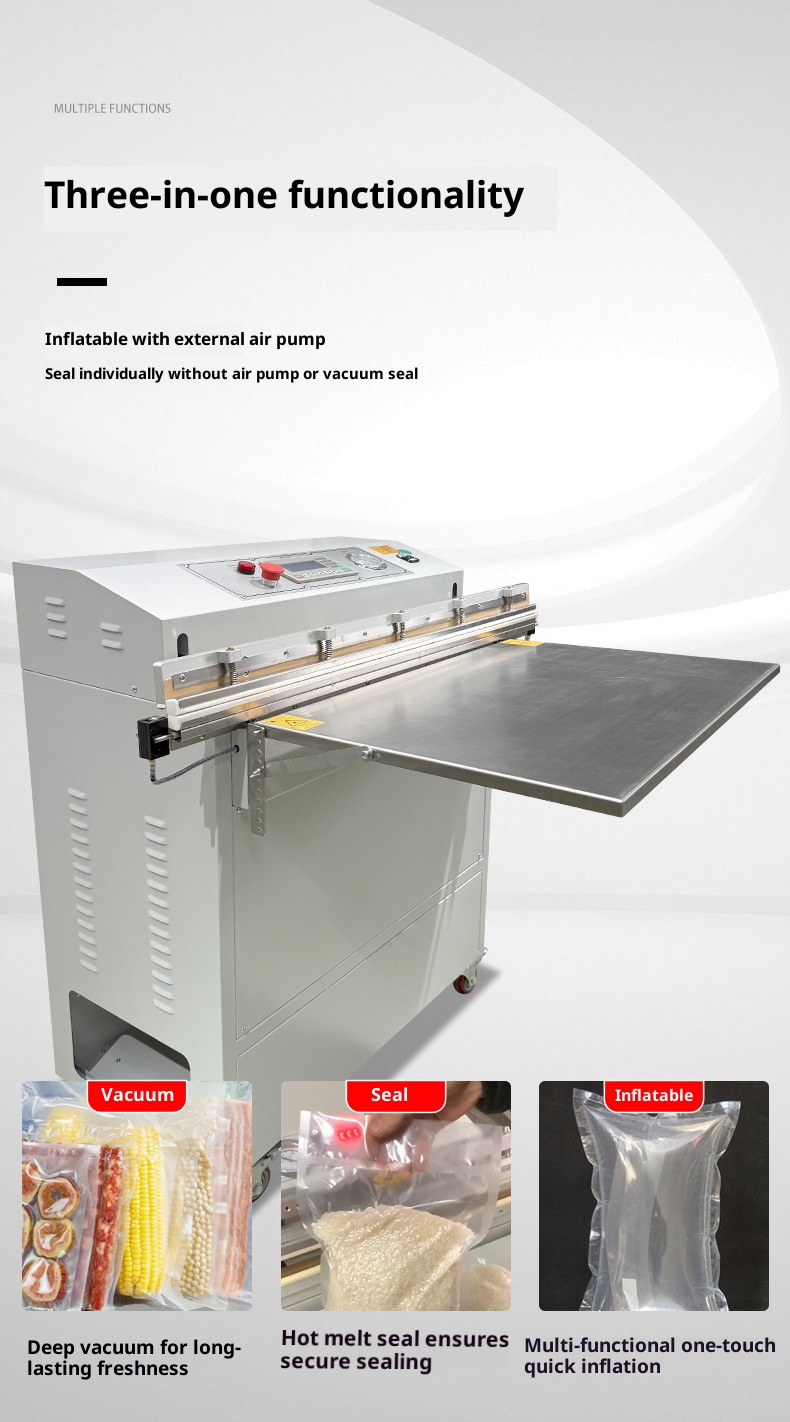

- Sealing and shaping: After vacuum extraction is completed, the sealing strip heats up instantly to seal the bag opening. Some machine models can also fill inert gas (such as nitrogen) as needed to complete the packaging.

Compared with internal vacuum packaging machines, it has significant differentiated advantages:

- Flexible packaging size: Not limited by the machine’s chamber, it can package items much larger than the machine itself, such as large furniture accessories, whole rolls of fabric, and long strip-shaped parts.

- Protection for fragile/pressure-sensitive items: The air extraction process does not rely on chamber extrusion, avoiding damage to fragile items (such as glass products) and soft items (such as plush toys) caused by extrusion from internal vacuum machines.

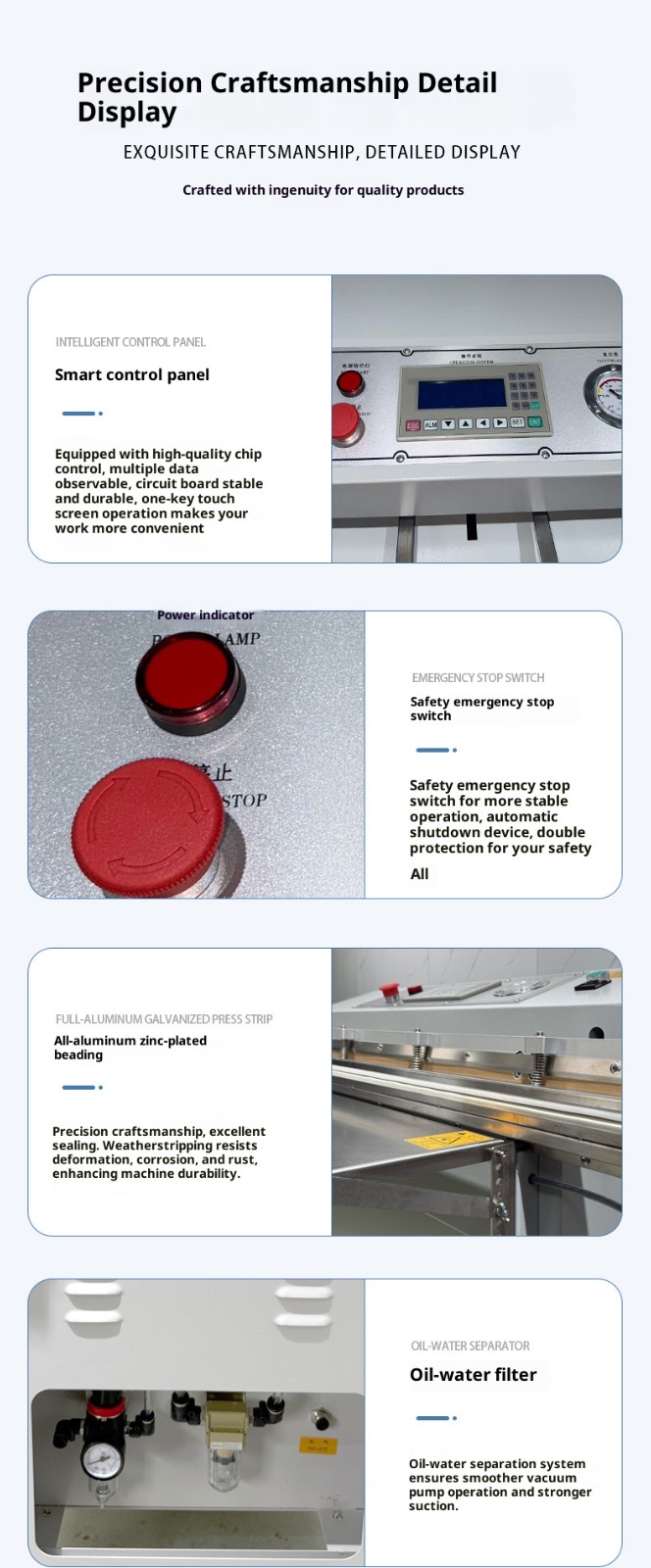

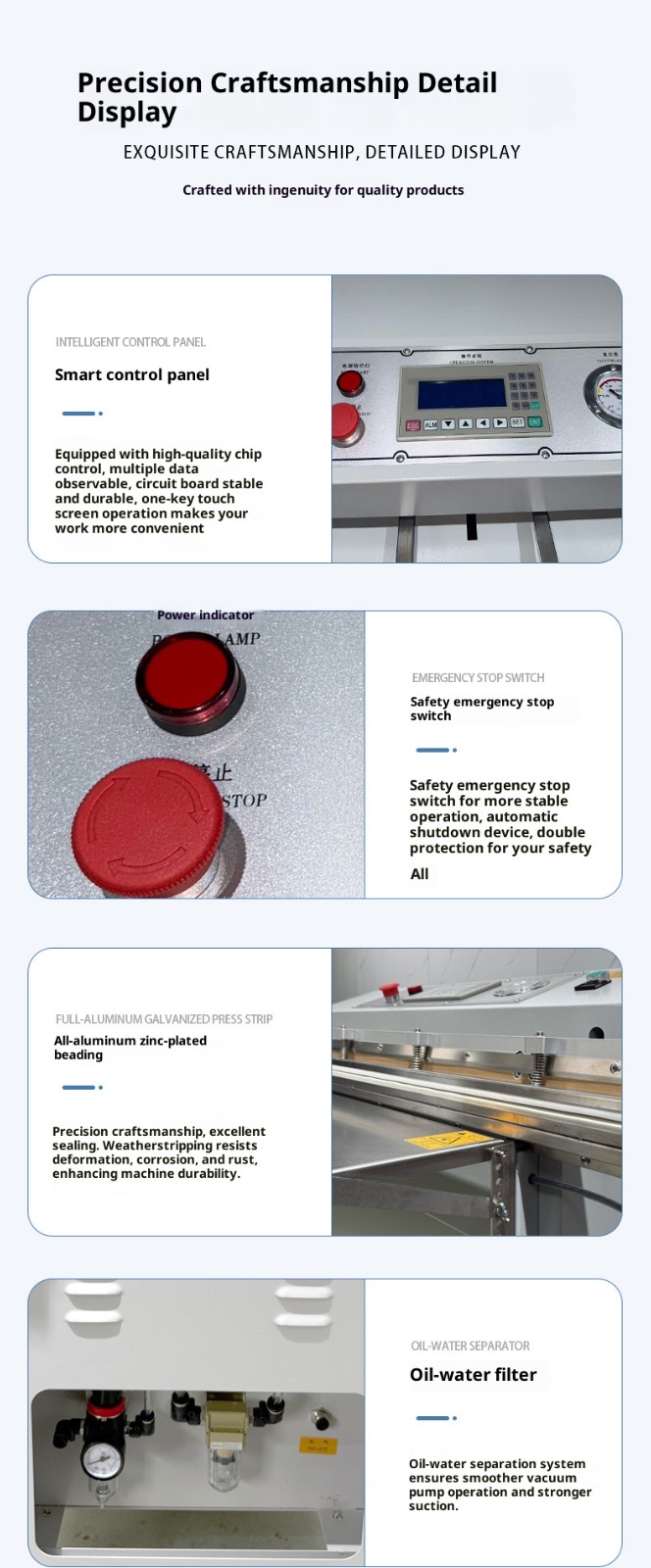

- Low operation threshold: No frequent adjustment of the chamber size is required; you only need to position the bag opening to start. Some models are equipped with foot switches, allowing efficient operation by a single person.

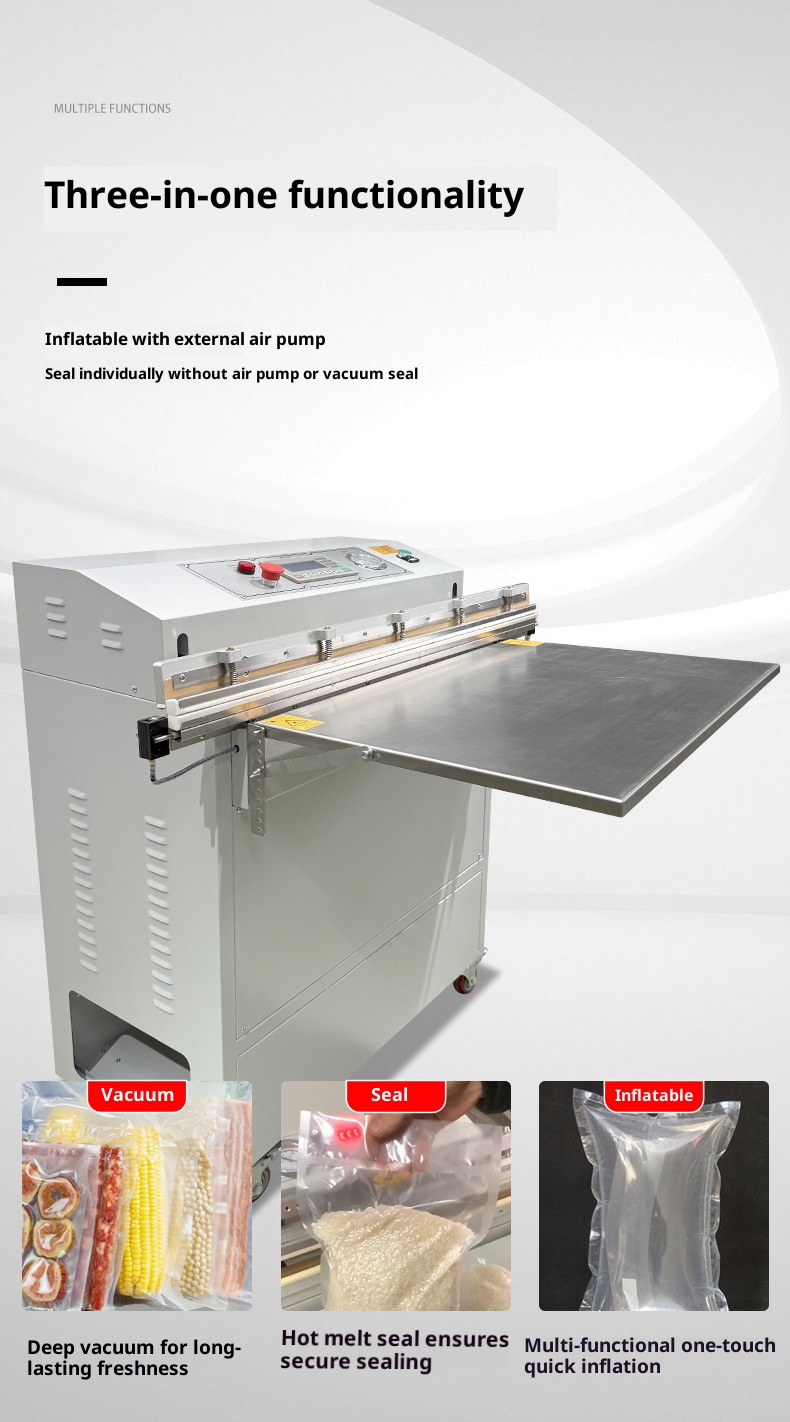

- Adaptability to multiple scenarios: Supports multiple packaging materials such as PE, PA and aluminum foil; it can switch between two modes: "vacuum sealing" and "gas-filled fresh-keeping", meeting both industrial rust-proof and food fresh-keeping needs.

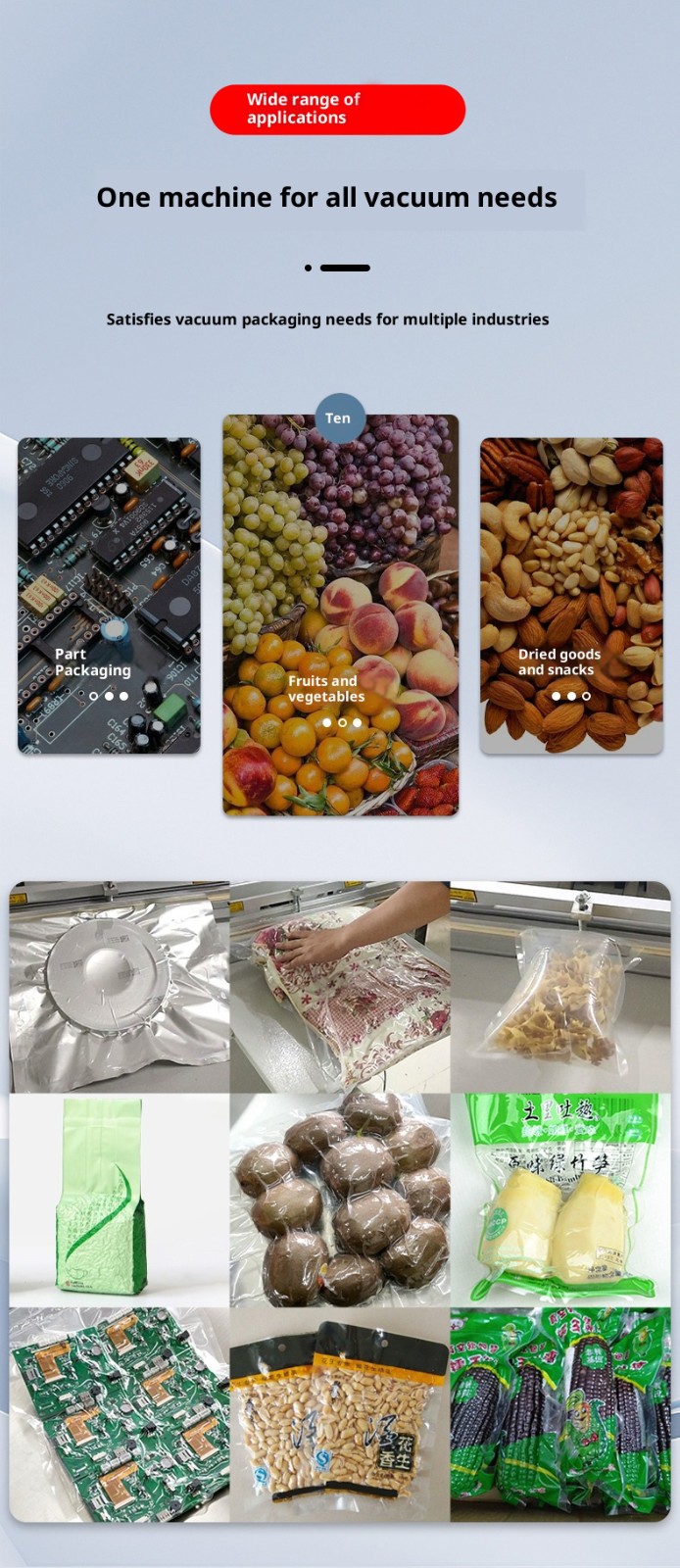

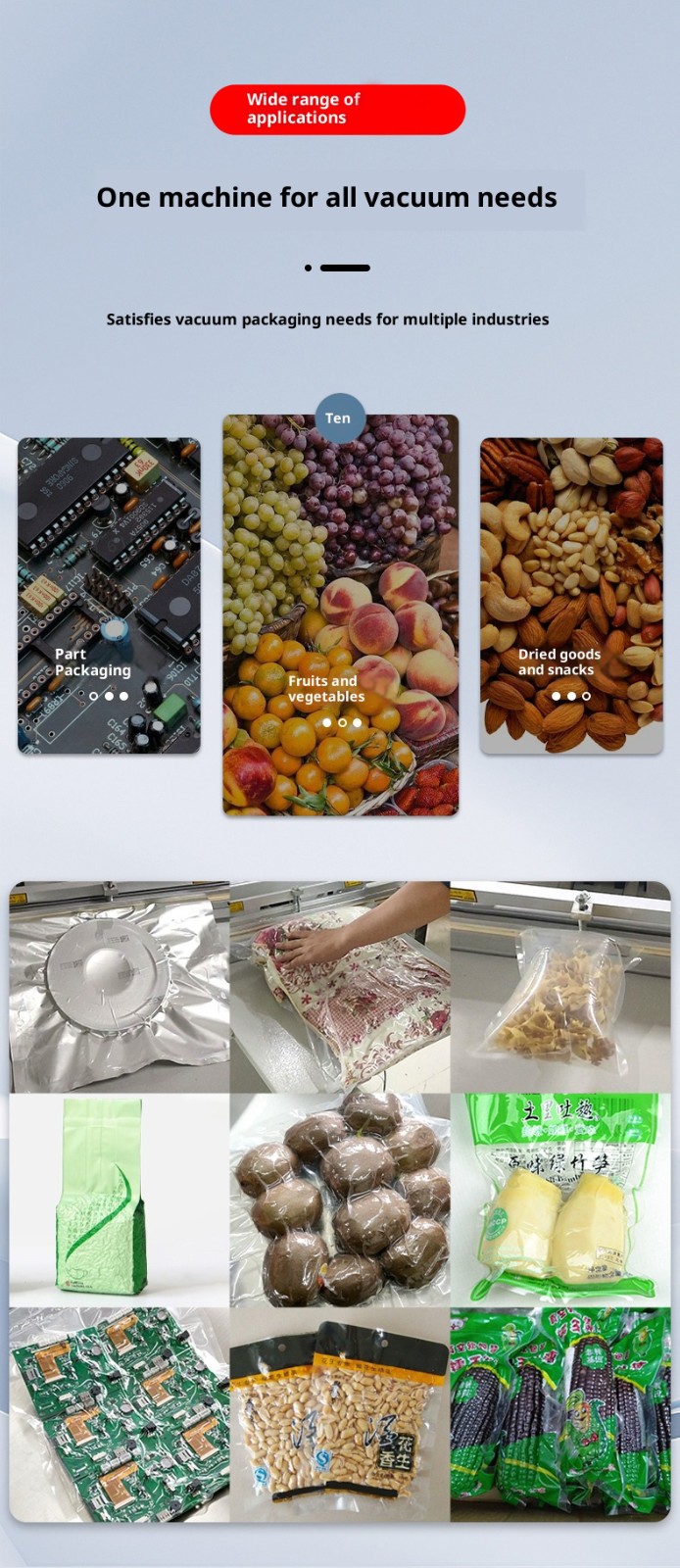

It widely covers industries such as industry, food, and home furnishing, and is especially suitable for items with special shapes:

- Industrial field: Vacuum packaging of large mechanical parts, metal components, and whole boxes of electronic components to prevent moisture and rust during transportation.

- Food field: Vacuum fresh-keeping of large quantities of meat, seafood and cooked food, or gas-filled pressure-proof packaging (filled with nitrogen) for bread and pastries.

- Home and textile field: Compressed packaging of curtains, quilts and large plush toys to reduce storage and transportation space.

- Pharmaceutical and daily chemical field: Vacuum moisture-proof packaging of Chinese medicinal materials and health products, or dust-proof sealed packaging of whole boxes of skin care products.