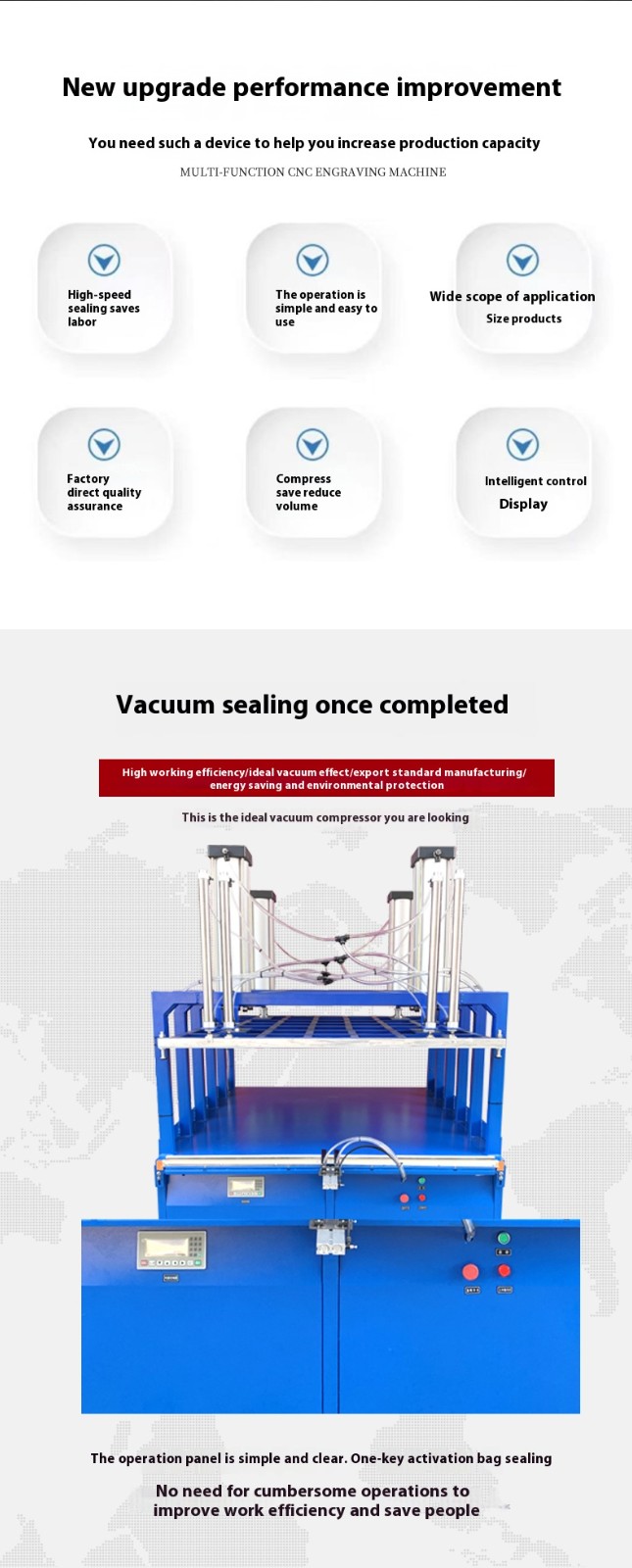

A vacuum compression sealer is a device that extracts air from the package to create a vacuum environment and seals the bag opening. It delivers the dual core values of "extending the shelf life of items" and "reducing packaging volume," and is widely used in household, commercial, and industrial scenarios.

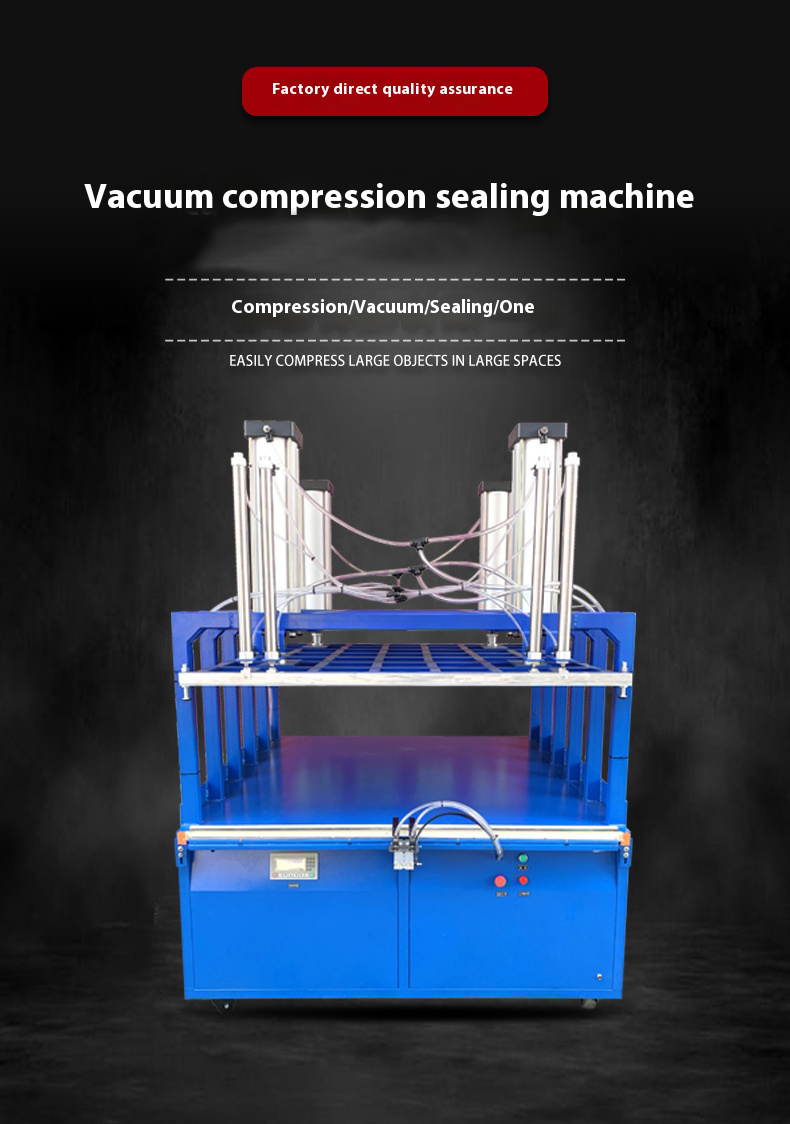

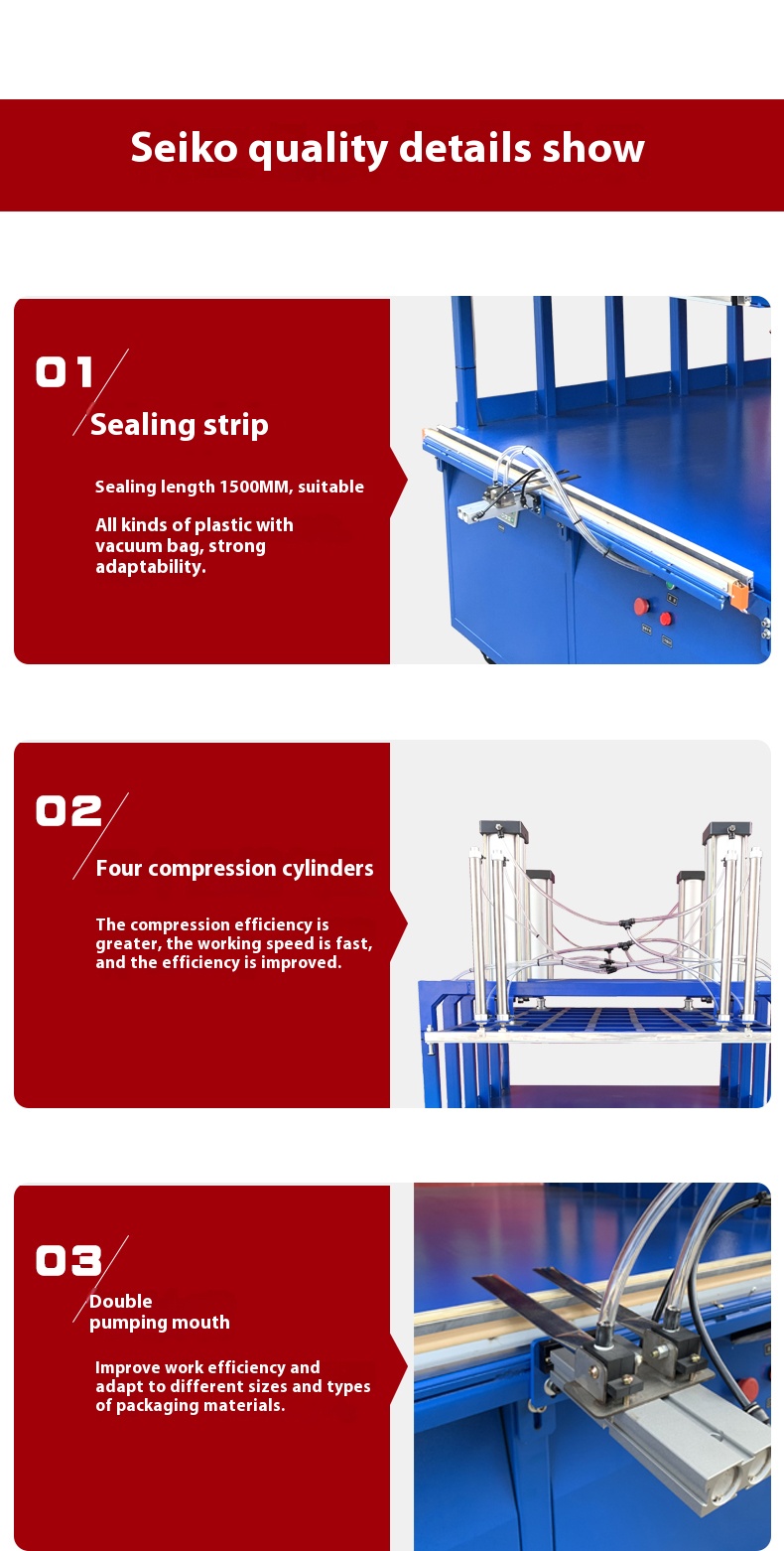

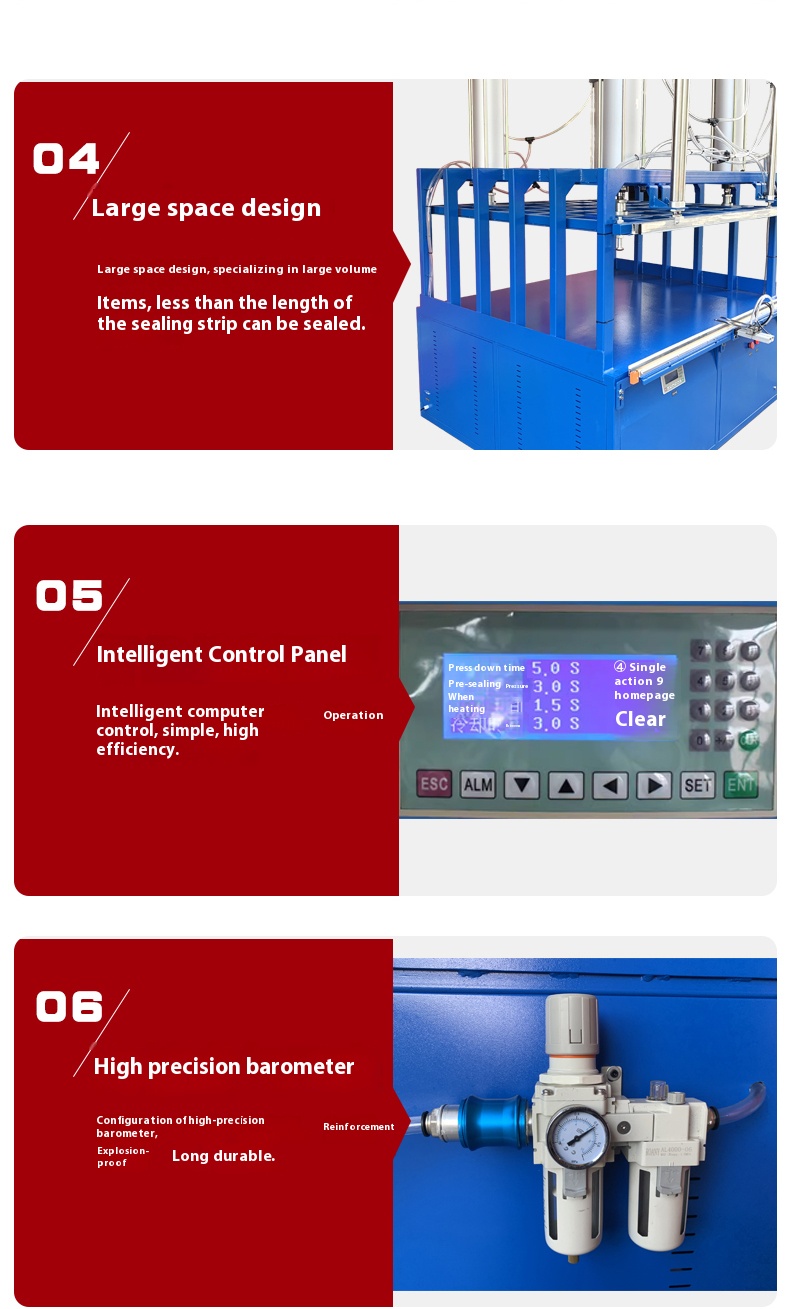

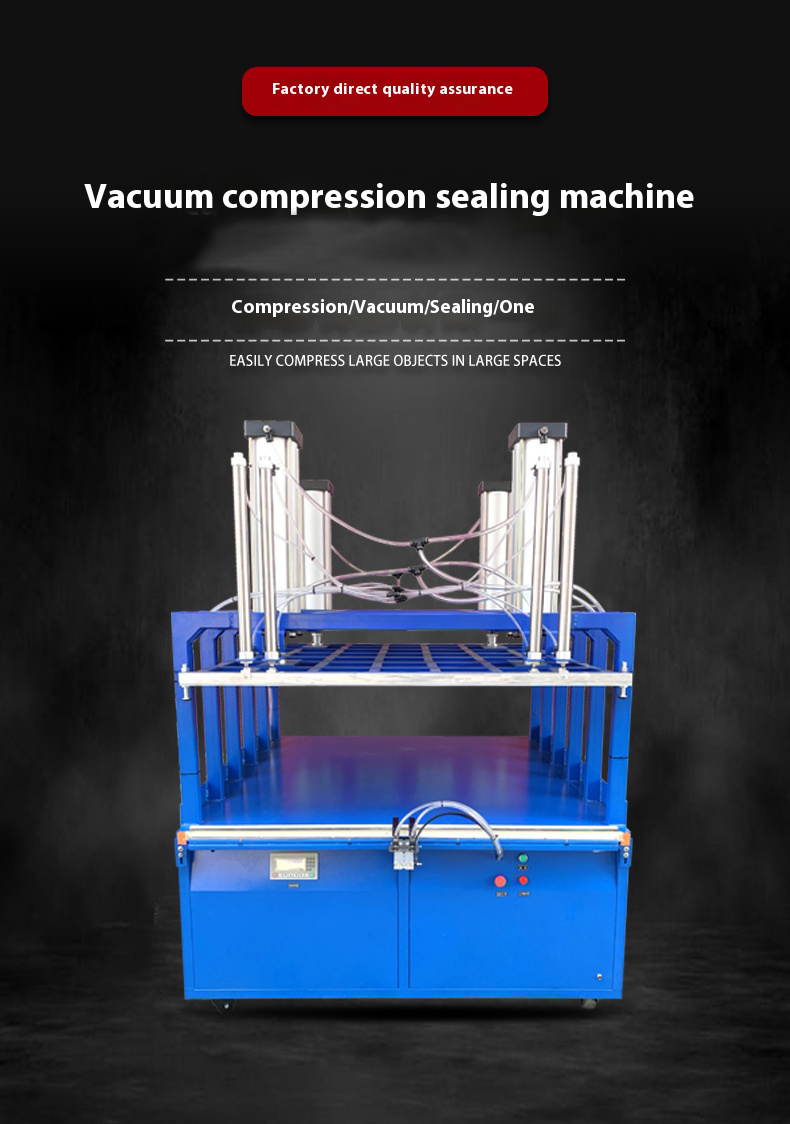

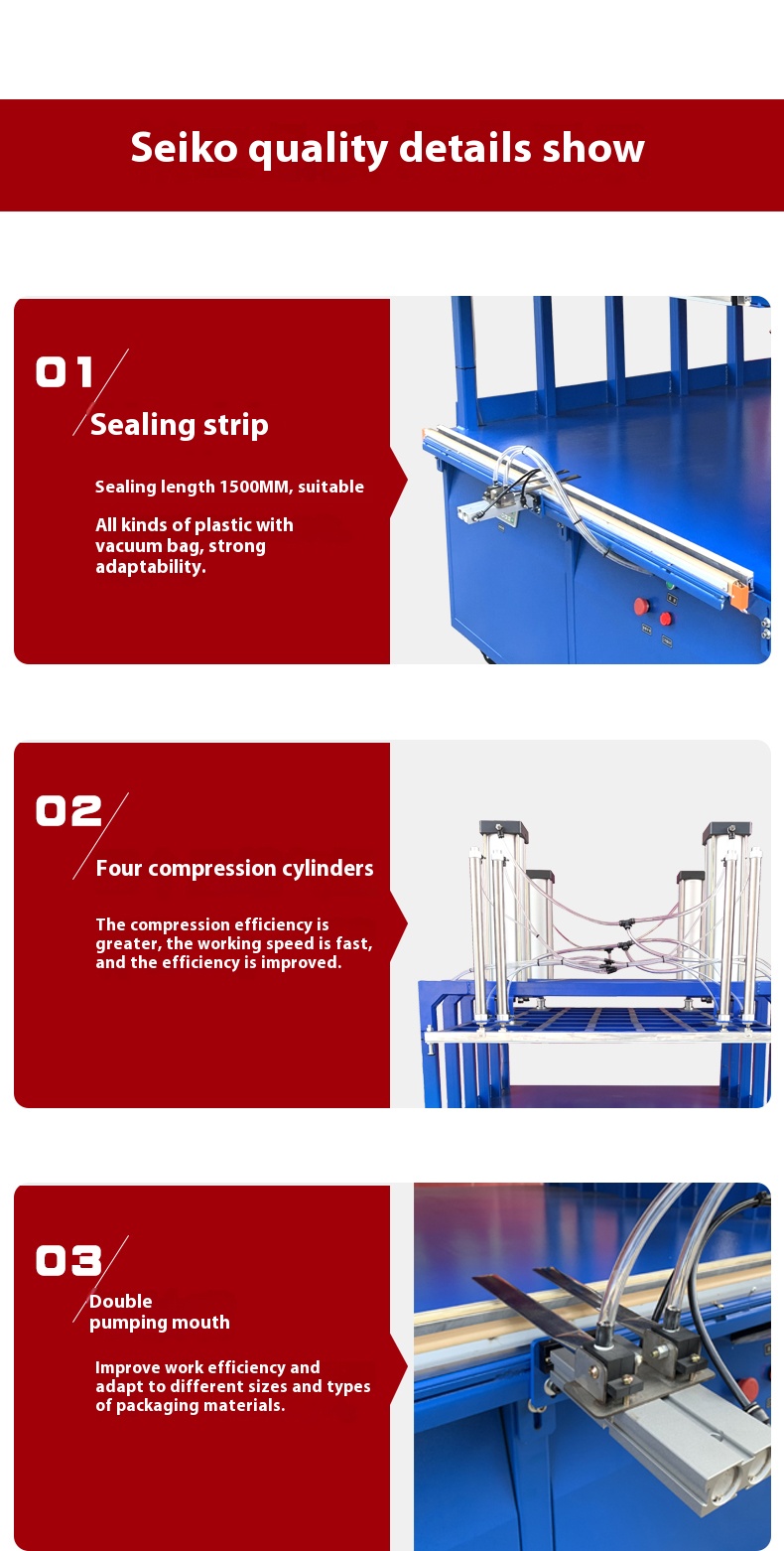

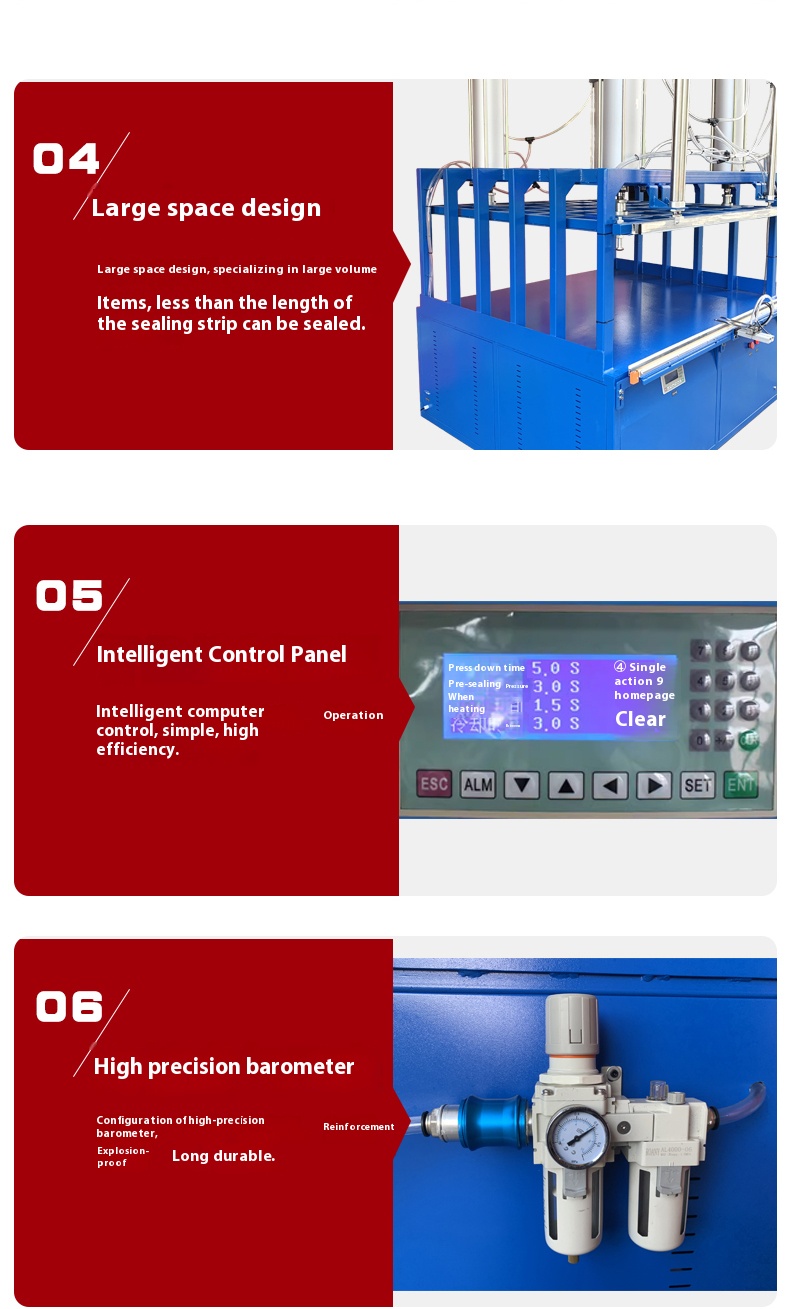

- Core Components: Mainly composed of a vacuum pump (responsible for air extraction), a control system (adjusts vacuum level and sealing time), and a sealing system (heat-sealing or cold-sealing components). Some industrial models are also equipped with conveying or positioning devices.

- Working Process: First, place the item into a dedicated packaging bag and tidy up the bag opening. Then, use the vacuum pump to extract air from the bag until the set vacuum level is reached. Finally, the sealing system heats and fuses or applies pressure to bond the bag opening, and the sealing is completed after cooling.

- Extend Storage Period: The vacuum environment isolates oxygen, which can inhibit the reproduction of bacteria and mold, reduce oxidative discoloration and nutrient loss of food, prevent rusting of metal parts, and also isolate external dust, insects, rodents, and odors to maintain the original quality of items.

- Optimize Space Utilization: For bulky items such as down jackets, quilts, and plush toys, the volume can be reduced by 50%-80% after air extraction. This not only saves space in household wardrobes and suitcases but also reduces the transportation load of enterprises and lowers logistics costs.