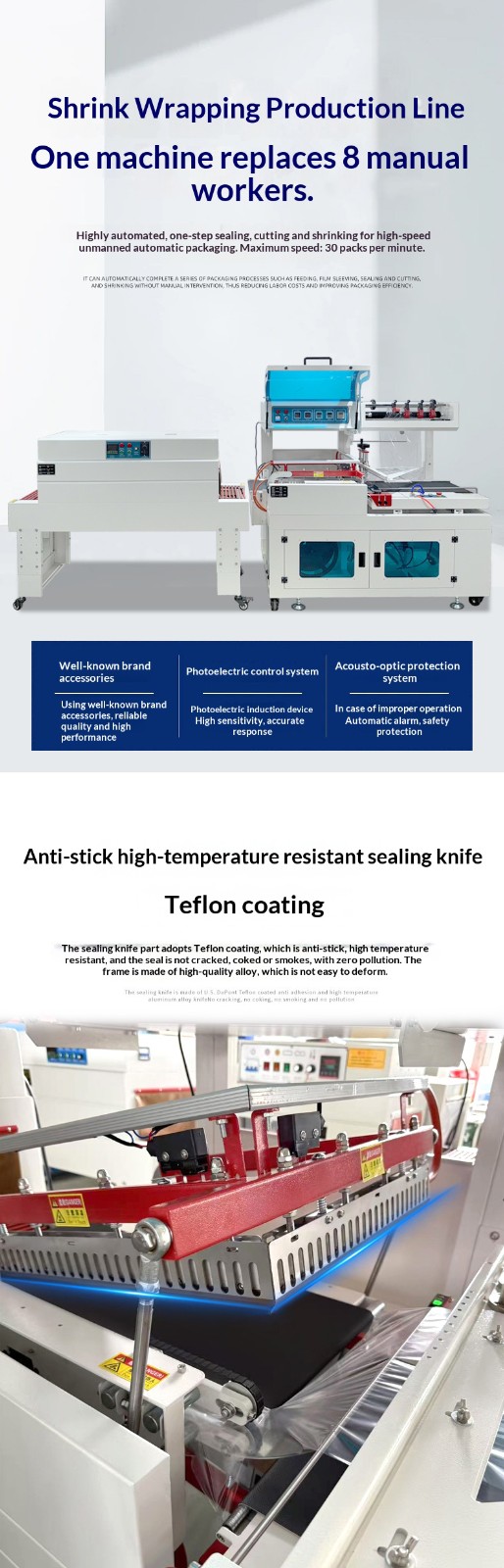

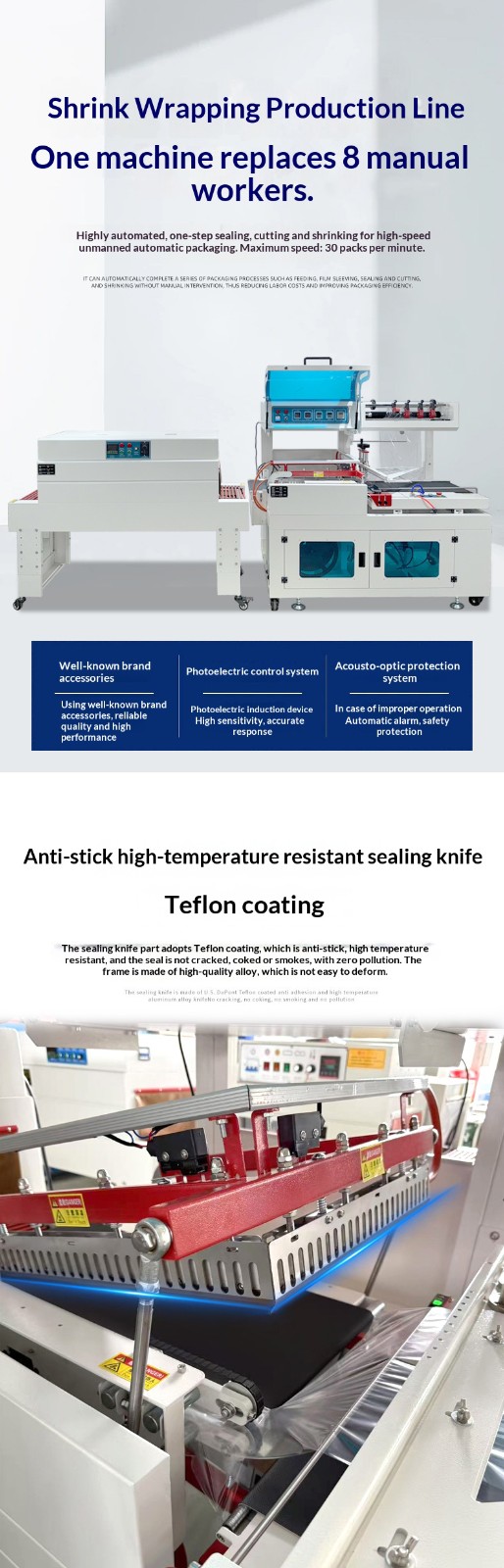

It can automatically complete the entire process of product feeding, film sleeving, sealing & cutting, heat shrinking, and discharging, enabling continuous assembly line operation without manual intervention.

- Precise Sealing & Cutting: The sealing and cutting blade is made of special alloy material coated with Teflon, ensuring non-stick film contact, firm seals, and thin sealing lines. Some high-end models are also equipped with a dual visual-mechanical positioning system, achieving a cutting accuracy of within ±0.1mm.

- High Automation Level: Adopting advanced PLC (Programmable Logic Controller) and photoelectric detection technology, it realizes fully automatic assembly line operation, replacing a large amount of manual work.

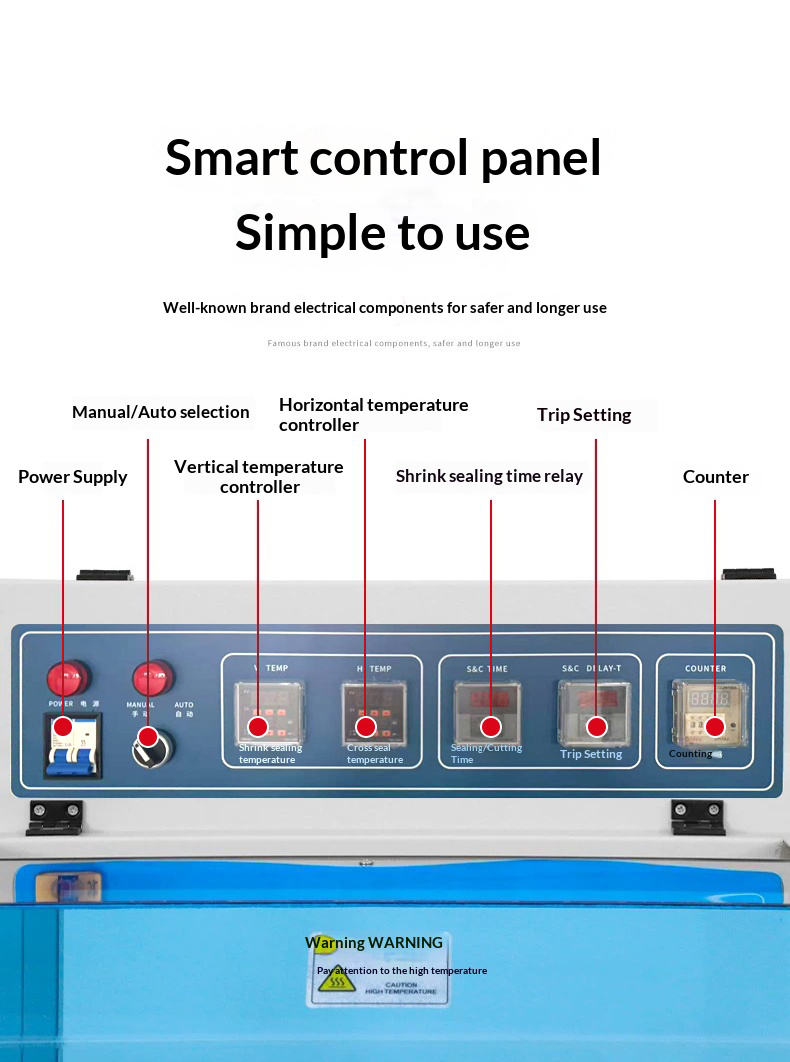

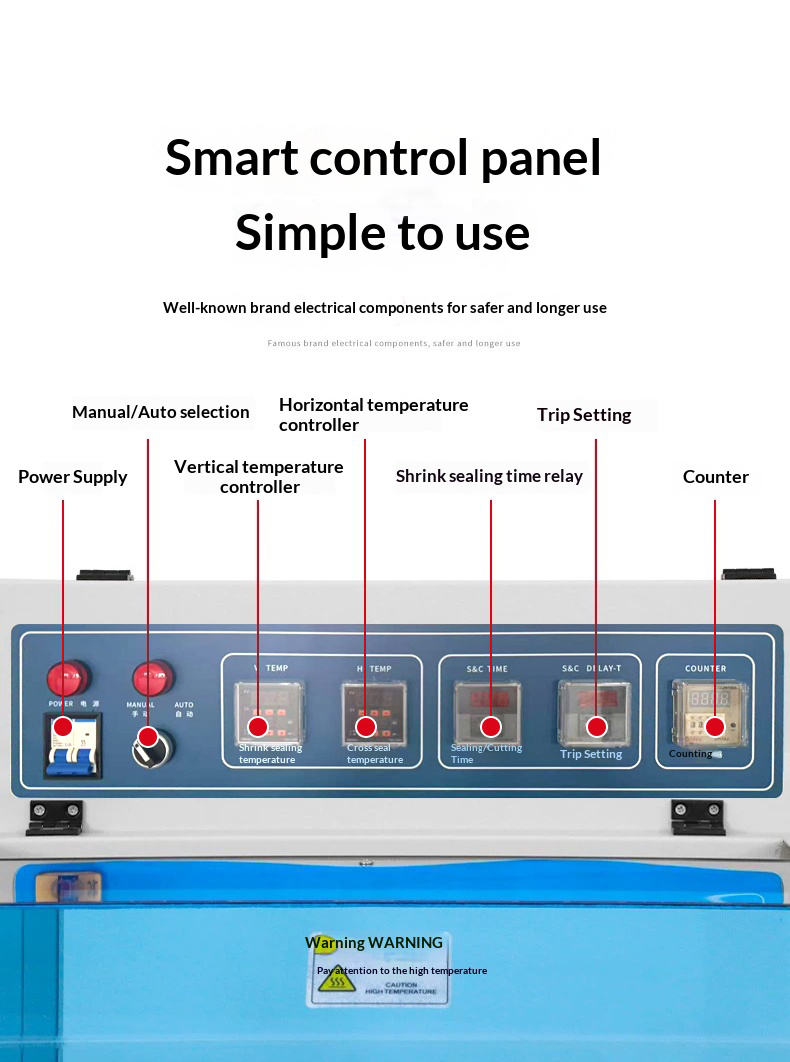

- Accurate Temperature Control: Typically equipped with a digital display temperature controller and imported thermal sensing control, the temperature can be adjusted within the range of 0-300℃ with a control accuracy of ±2℃, ensuring stable heat shrinking results.

- Easy Operation: The whole machine mostly adopts a touch screen control system, simplifying the operation process, reducing manual intervention, and enabling more convenient and precise parameter adjustment.

- Energy Efficiency & Environmental Friendliness: By optimizing the heating and transmission structures, the energy consumption of some models is lower than that of traditional models, complying with the concept of low-carbon energy conservation.

- Wide Application: Suitable for industries such as food, cosmetics, pharmaceuticals, printed matter, beverages, hardware, and plastics, compatible with various shrink packaging materials including POF, PE, and PVC.

The high automation feature directly translates into significant production advantages, completely overcoming the limitations of traditional manual packaging and replacing over 80% of manual operations (calculated based on 3-5 packers per single shift):

Traditional manual packaging requires multiple workers to perform repetitive tasks such as product placement, manual film sleeving, auxiliary sealing & cutting, and finished product sorting. It also faces issues like high staff turnover, high training costs, and heavy labor intensity. The fully automatic equipment can operate continuously 24/7, with a single unit replacing the workload of 3-5 workers. Calculated based on 300 operating days per year, it can save hundreds of thousands of yuan in labor costs annually.

It avoids work-related injury risks during manual operations (such as high-temperature burns and blade scratches) while reducing packaging errors caused by manual fatigue and negligence, lowering management and compensation costs.

Manual packaging efficiency is limited by proficiency and physical strength, with an hourly output typically only 500-800 pieces and prone to efficiency fluctuations. The fully automatic equipment can achieve a packaging speed of 20-60 pieces per minute (up to 80 pieces per minute for high-end models), with an hourly output exceeding 1200 pieces. It operates continuously without efficiency degradation, meeting the production needs of large batches and tight orders.

It supports uninterrupted multi-shift operation, especially suitable for continuous production scenarios in industries such as food and pharmaceuticals. It eliminates production line shutdowns caused by manual shift changes and breaks, enhancing the stability of overall production plans.

Manual operations are prone to problems such as skewed film sleeving, loose seals, uneven shrinking, and rough cutting edges, which affect product appearance and protection effects. Through precise mechanical positioning and electronic control, the fully automatic equipment achieves a sealing and cutting accuracy of ±0.1mm and a heat shrinkage temperature error of ±2℃, ensuring that each product's packaging is flat, sealed, and aesthetically pleasing with highly consistent quality.

Stable packaging effects can enhance the product's moisture, dust, and damage resistance, reducing losses during transportation. Meanwhile, it improves the product's appearance grade, helping to upgrade the brand image.

After replacing repetitive and low-value packaging labor, original workers can be transferred to higher-value positions such as quality inspection, equipment maintenance, and process optimization, improving the utilization rate of human resources.

The equipment supports rapid product specification switching (parameter adjustment takes only 3-5 minutes), adapting to the flexible production needs of small batches and multiple batches. Compared with the adaptation cycle of manual packaging (requiring retraining and process familiarization), it significantly improves production flexibility.