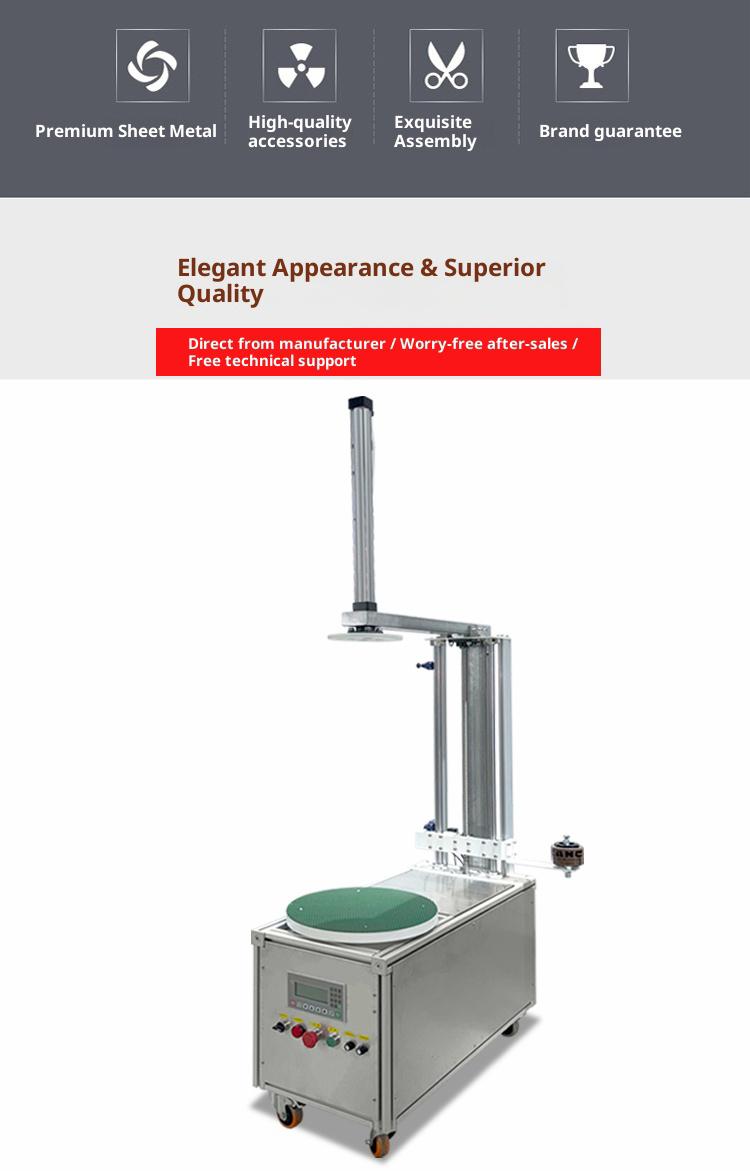

Automatic wrapping machines can adapt to goods of different sizes and shapes, achieving uniform and tight wrapping with stable, waterproof, and dustproof packaging effects. They feature high automation, significantly improving packaging efficiency.

Equipped with photoelectric sensors or dimension detection modules, the machine automatically identifies the length, width, and height of goods. It adjusts wrapping layers, film tension, and lifting speed in real time, enabling seamless and uniform wrapping of irregular goods with strong packaging consistency.

No manual film fixing, cutting, or finishing is required. From loading (fully automatic loading with assembly lines) to wrapping completion, each item takes only 30-90 seconds. A single device can handle 40-120 items per hour, 5-8 times the efficiency of manual wrapping.

Film elongation rate is controllable during wrapping (usually 10%-30%), ensuring tight and non-loose packaging while avoiding film waste. Some models support top/bottom reinforced wrapping and pre-stretching functions, further enhancing packaging stability and reducing consumable costs.

- Mass standardized goods: Such as cartons, turnover boxes, and regular palletized goods. Enables continuous wrapping to meet high-speed packaging needs at the end of production lines.

- Mixed-specification goods: Automatically switches packaging modes without frequent manual parameter adjustments. Suitable for mixed packaging scenarios in e-commerce warehouses and multi-category manufacturing industries.

- Heavy/large goods: Replaces labor-intensive wrapping operations that are difficult for humans to complete. Ensures packaging firmness, avoids safety risks of manual operation, and improves packaging efficiency for heavy goods.

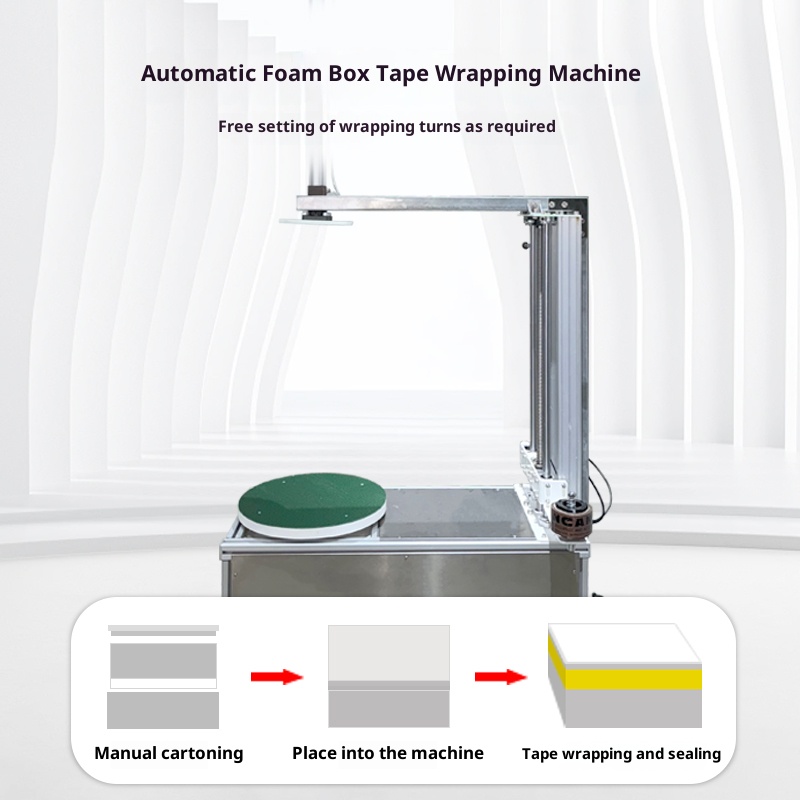

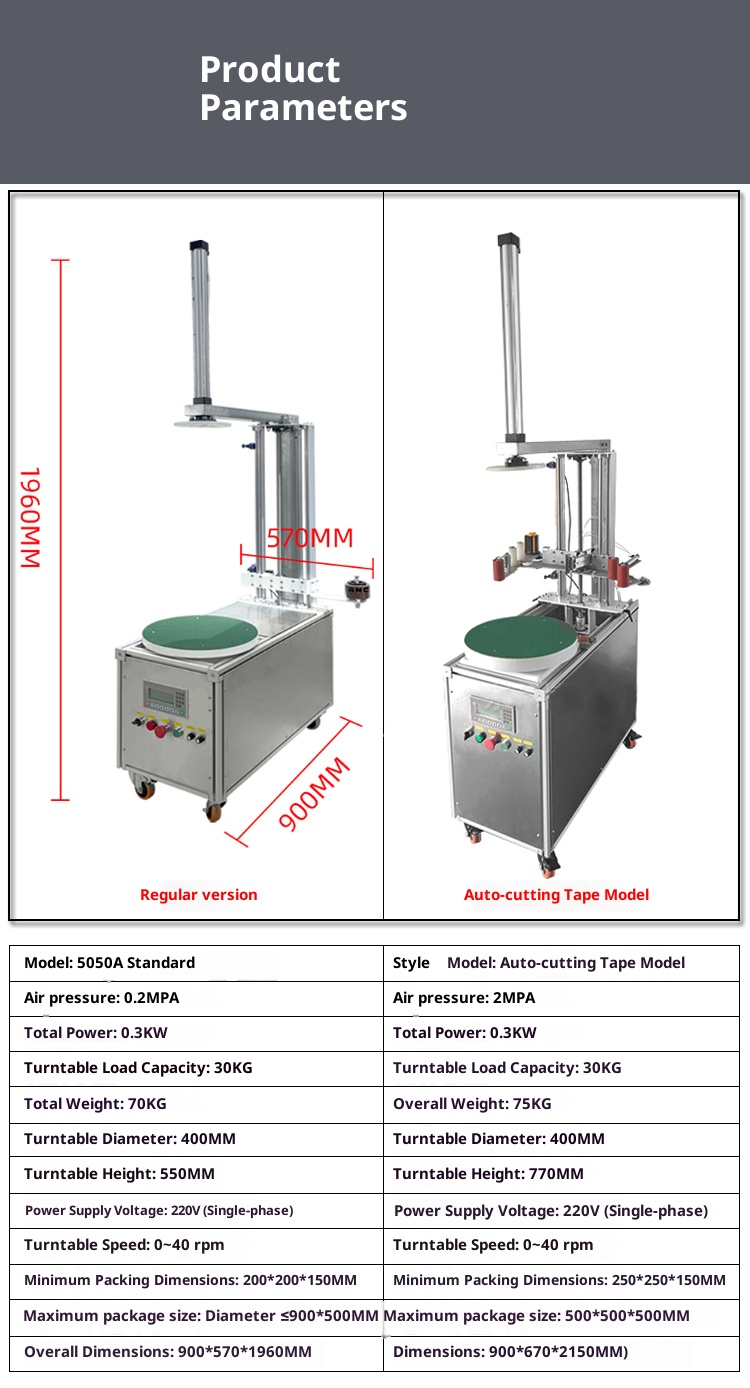

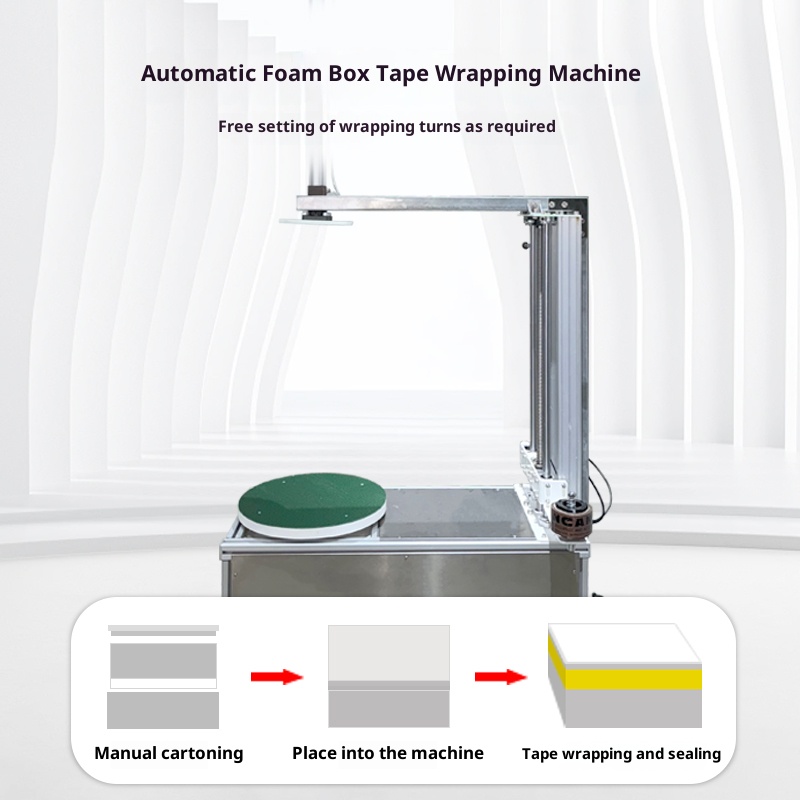

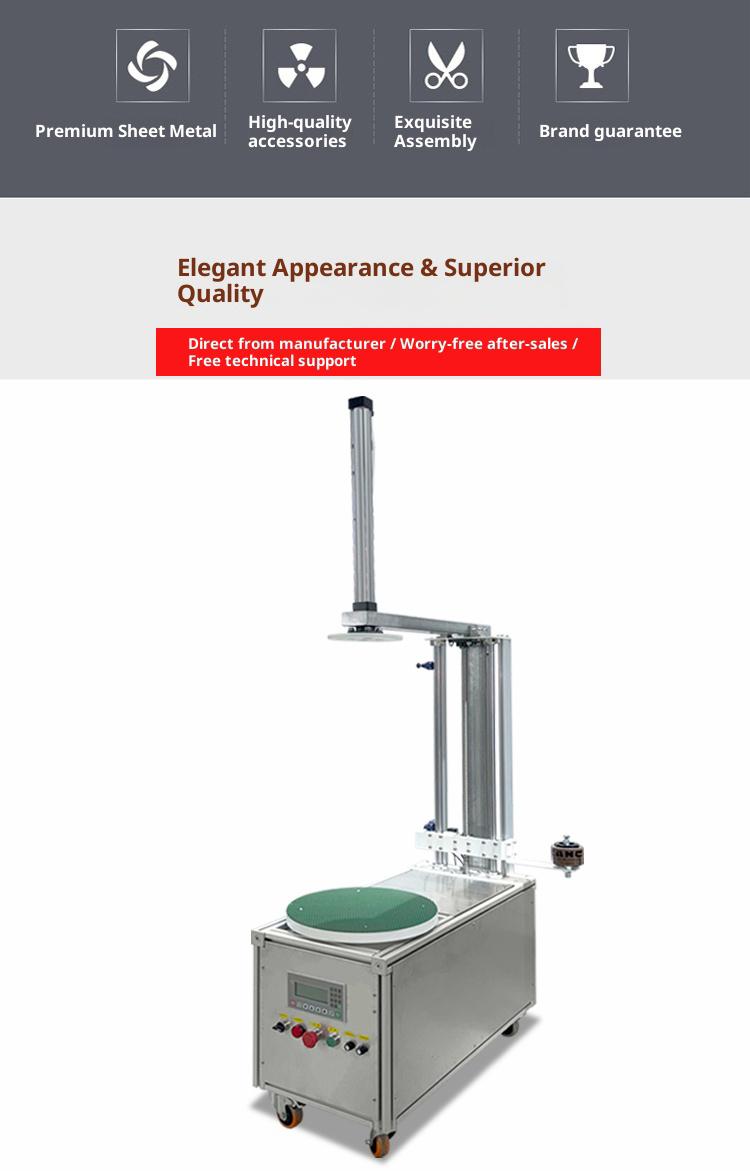

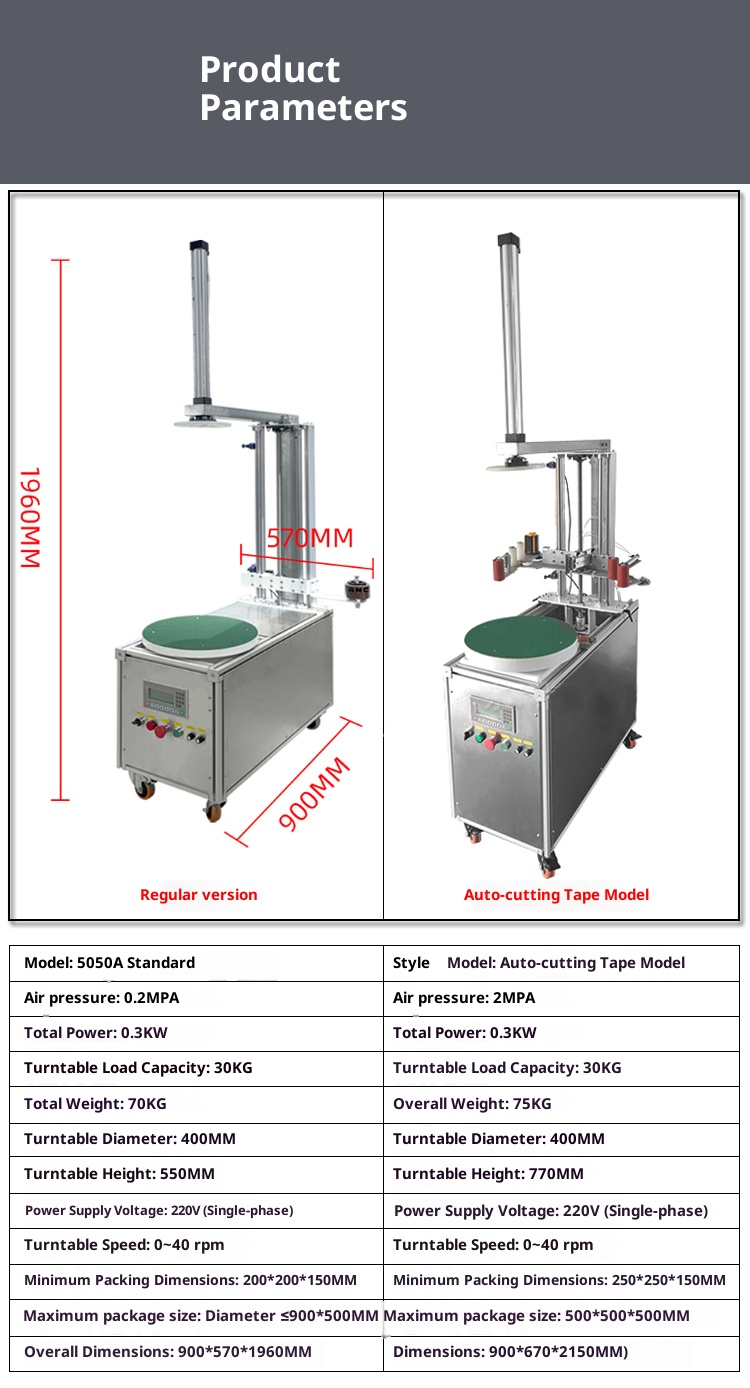

- Cargo wrapping machines: Mainly used for packaging palletized goods and large equipment. The rotating workbench drives the goods to rotate, while the film is wrapped from above or the side (e.g., common tape wrapping machines for logistics and warehousing).

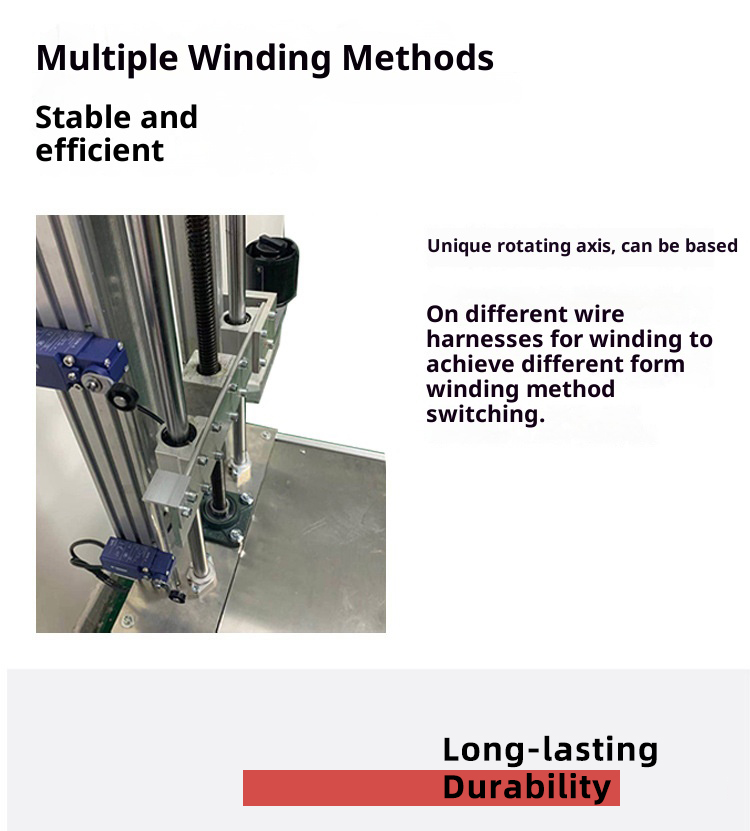

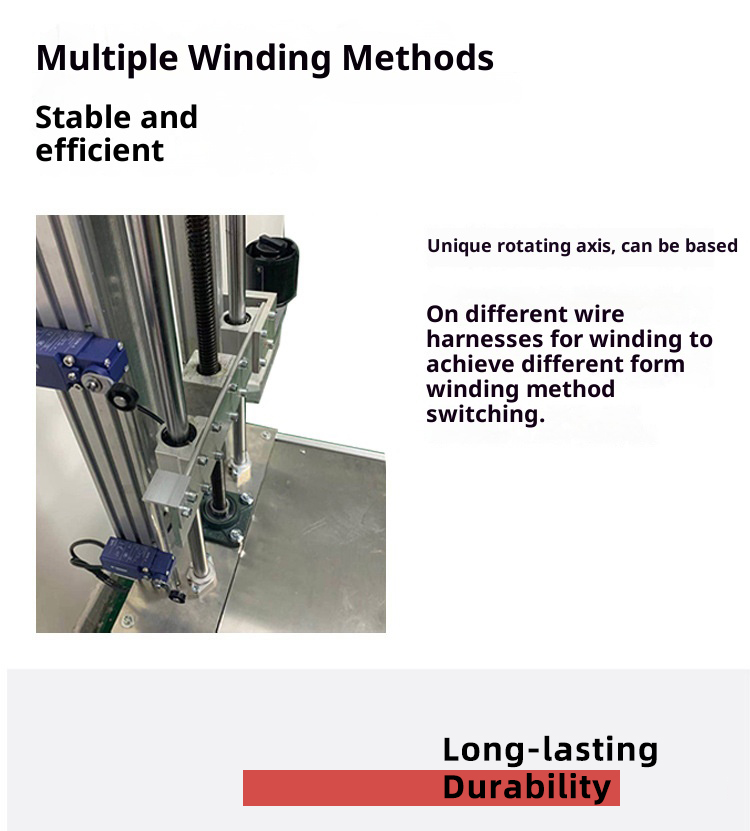

- Wire harness wrapping machines: Used for wrapping wires, cables, and other wire harnesses. The mechanical arm or traction device drives the wire harness to move while the film is wrapped, supporting full wrapping, spot wrapping, spiral wrapping, and other methods.

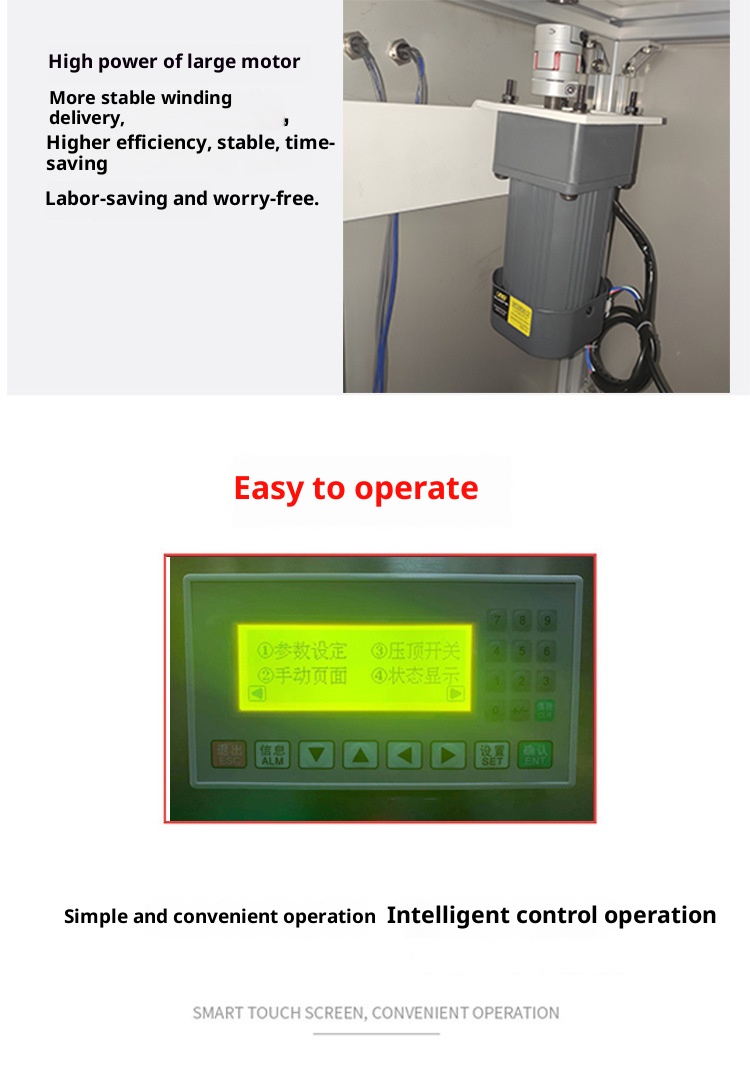

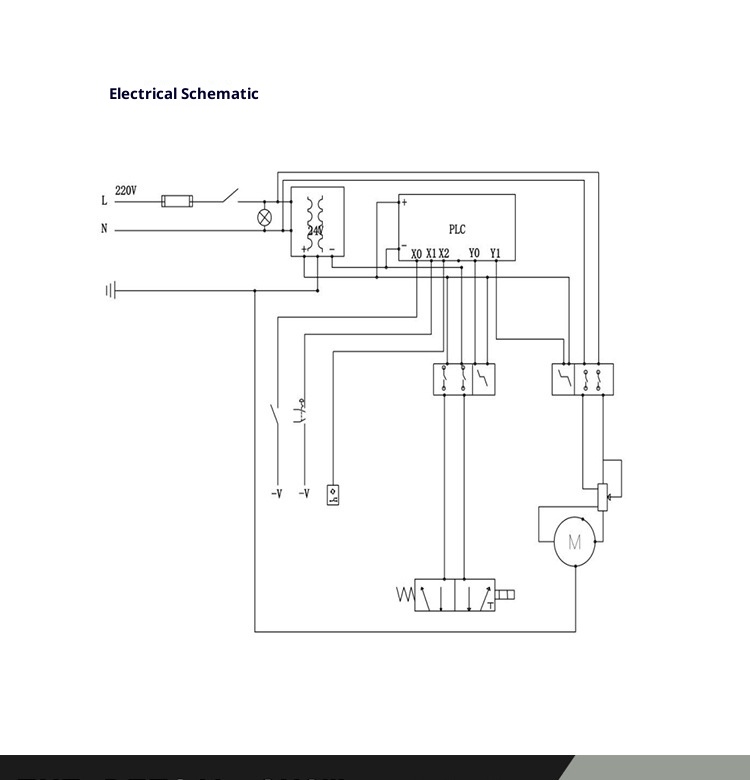

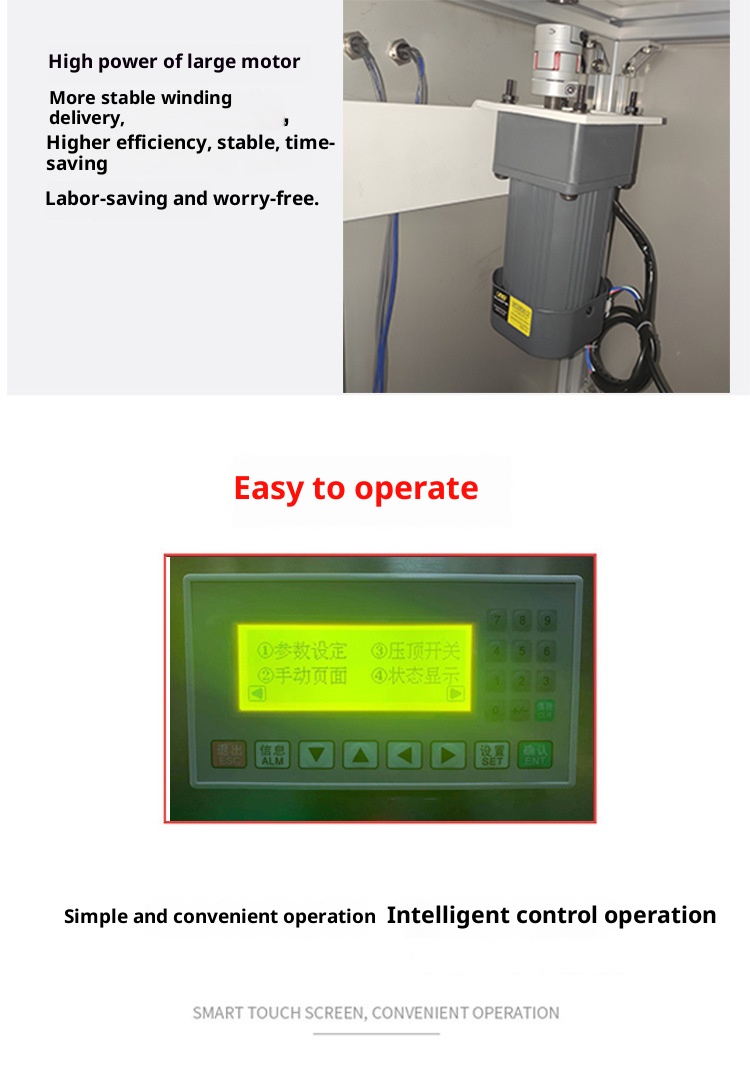

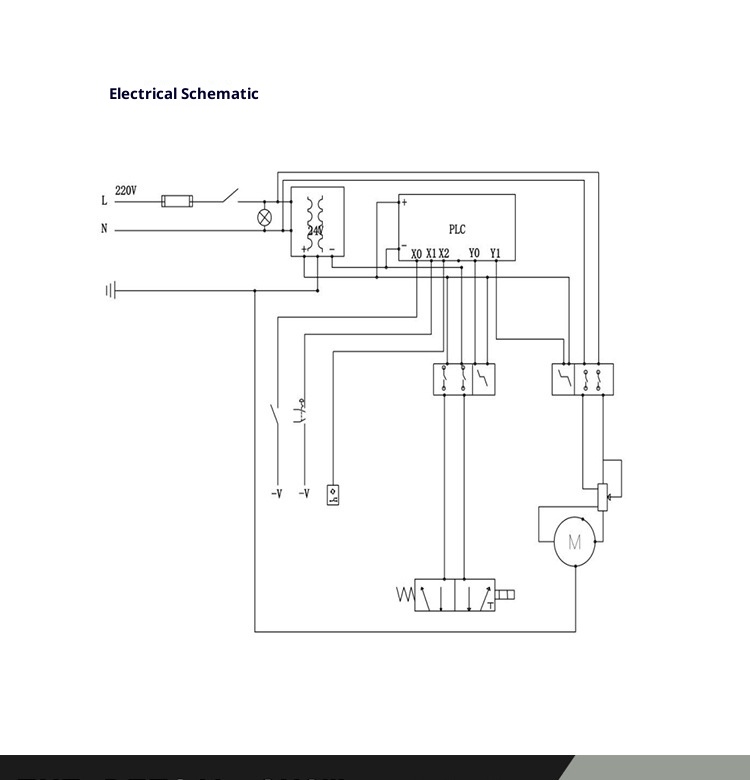

- Fully automatic wrapping machines: Equipped with automatic loading, wrapping, and film cutting functions. Achieves automated operation through PLC programming without manual intervention, featuring high production efficiency.

- Semi-automatic wrapping machines: Requires manual loading, and the equipment completes the wrapping action. Some links such as film cutting may need manual assistance.

- Handheld wrapping machines: Compact and portable, operated manually by workers. Suitable for small-batch, irregular objects or wrapping in space-constrained environments.

- High automation: Some high-end models are equipped with intelligent control systems, which can automatically identify the shape and size of items and adjust wrapping path, force, speed, and direction.

- High wrapping precision: The wrapping tightness error of some wire harness wrapping machines can be controlled within ±2mm, enabling precise film wrapping of items of various specifications.

- Easy operation: Usually equipped with a control panel or touch screen control system, allowing operators to easily set parameters and operate the equipment.

- Logistics and warehousing industry: Used for wrapping palletized goods to reinforce them and prevent scattering or displacement during transportation.

- Electronic and electrical industry: Used for wrapping wires, cables, and electronic wire harnesses to insulate, protect, and organize the wire harnesses.

- Manufacturing industry: Can package various parts and mechanical equipment to protect products from damage during transportation and storage.