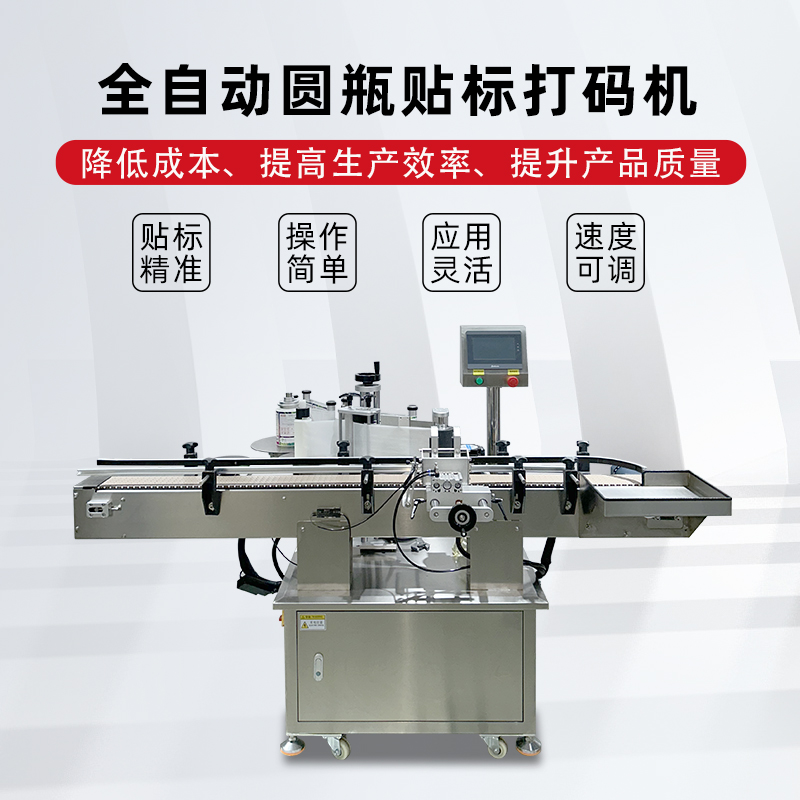

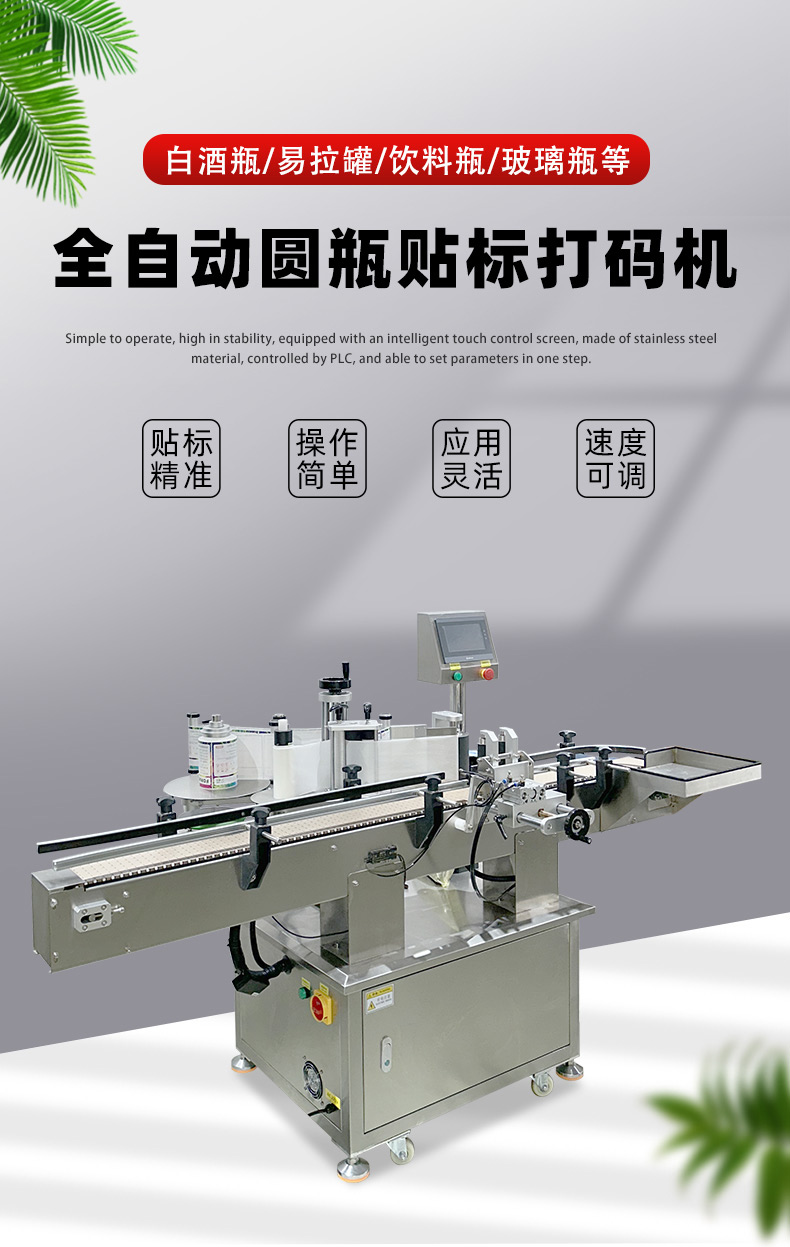

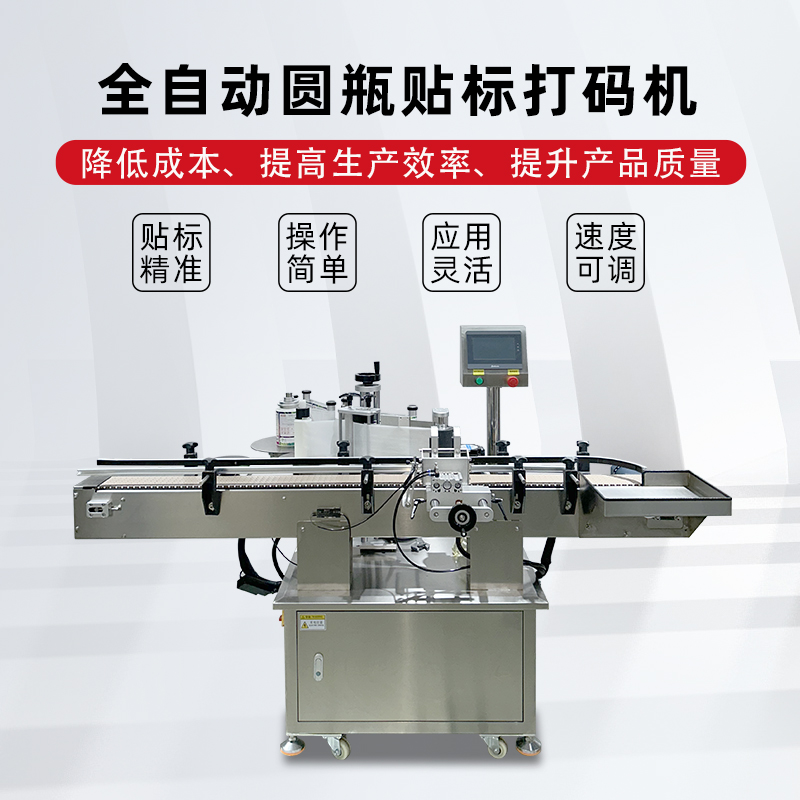

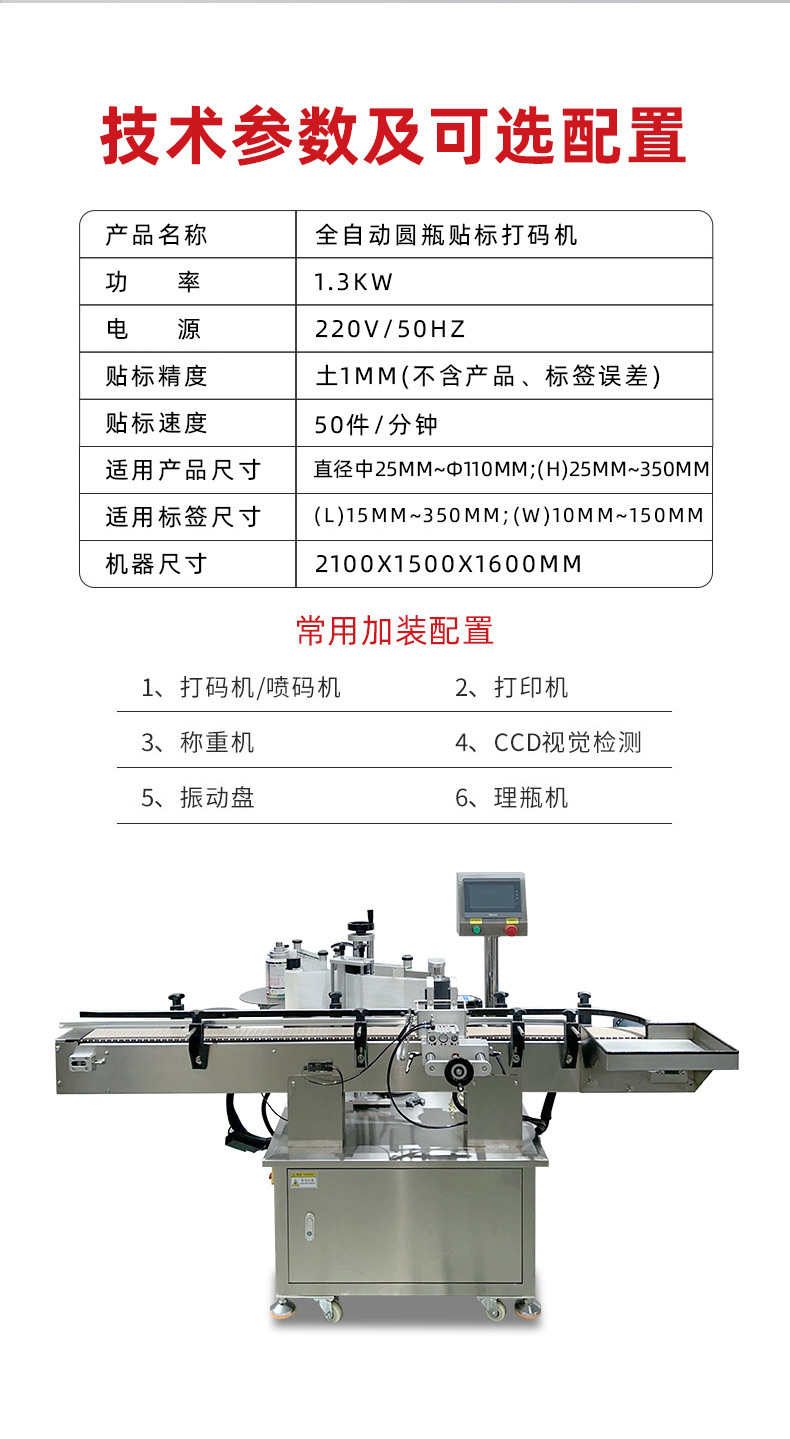

The core advantages of the round bottle positioning labeling machine lie in its high precision, strong adaptability, and high degree of automation. Its efficiency is reflected in stable labeling speed and low failure rate, which can significantly reduce labor costs and improve packaging consistency.

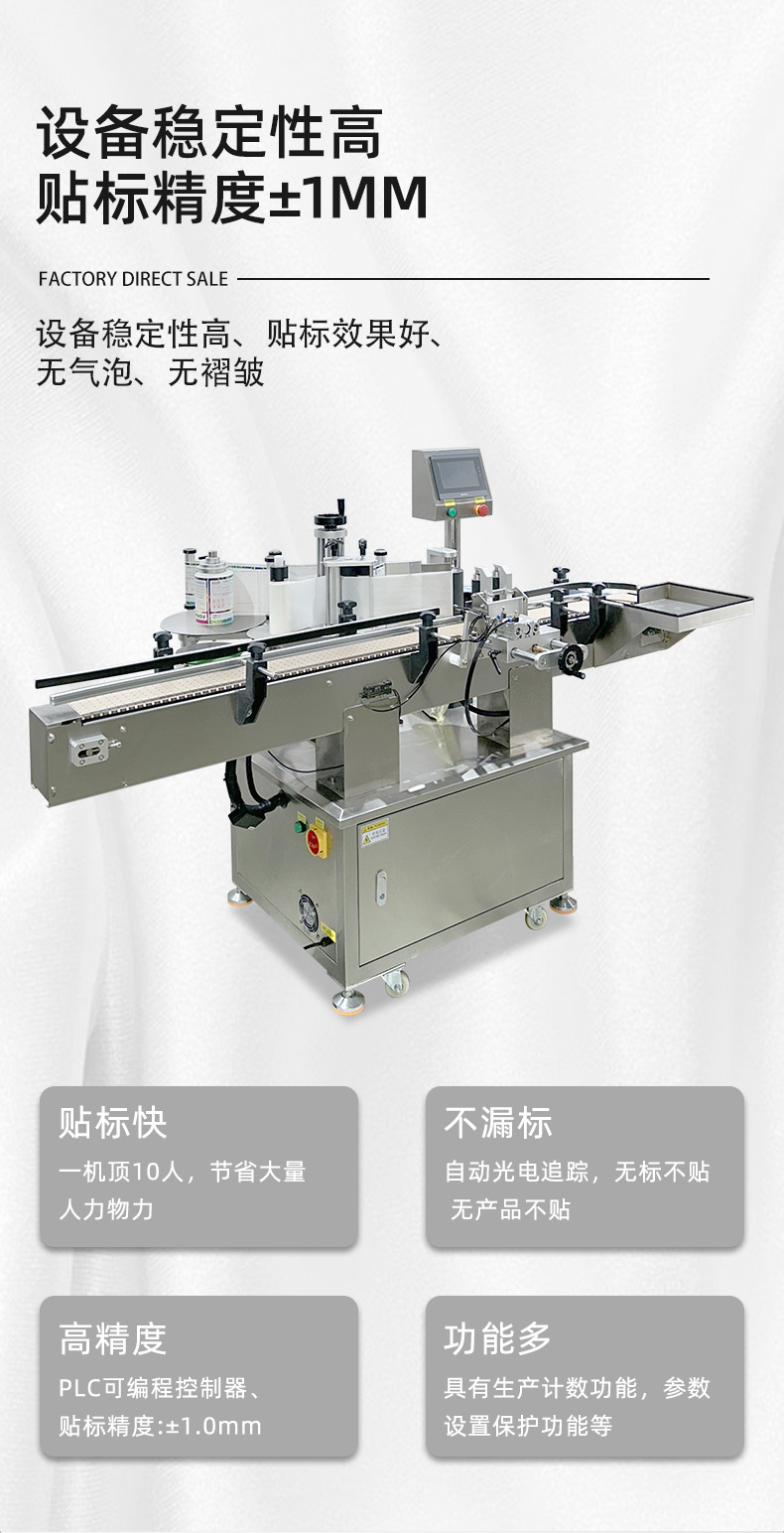

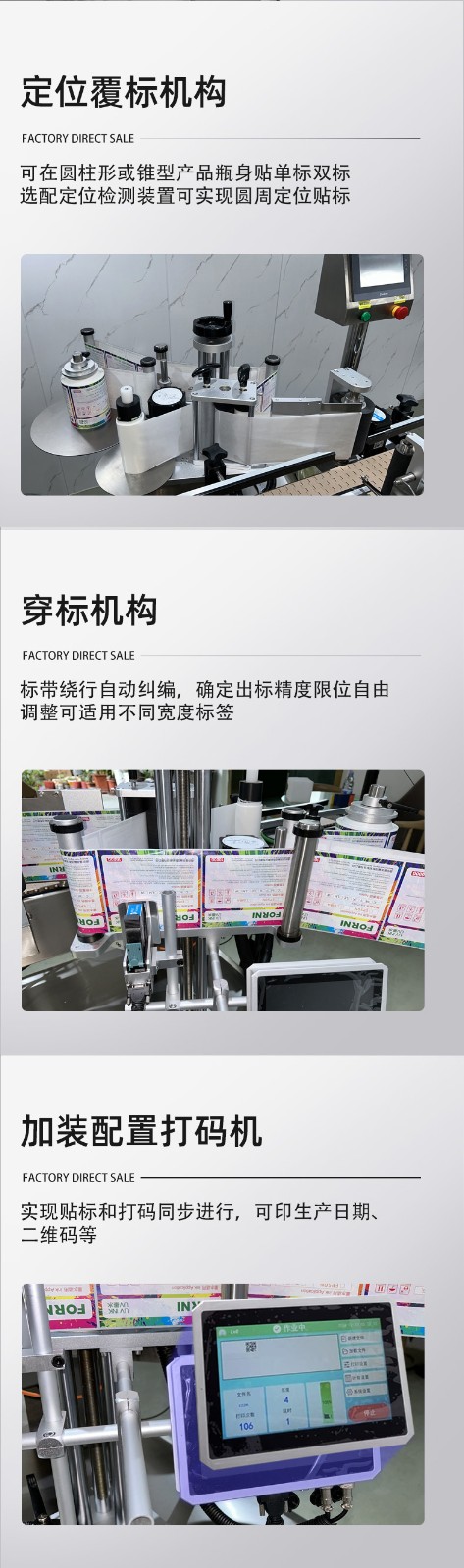

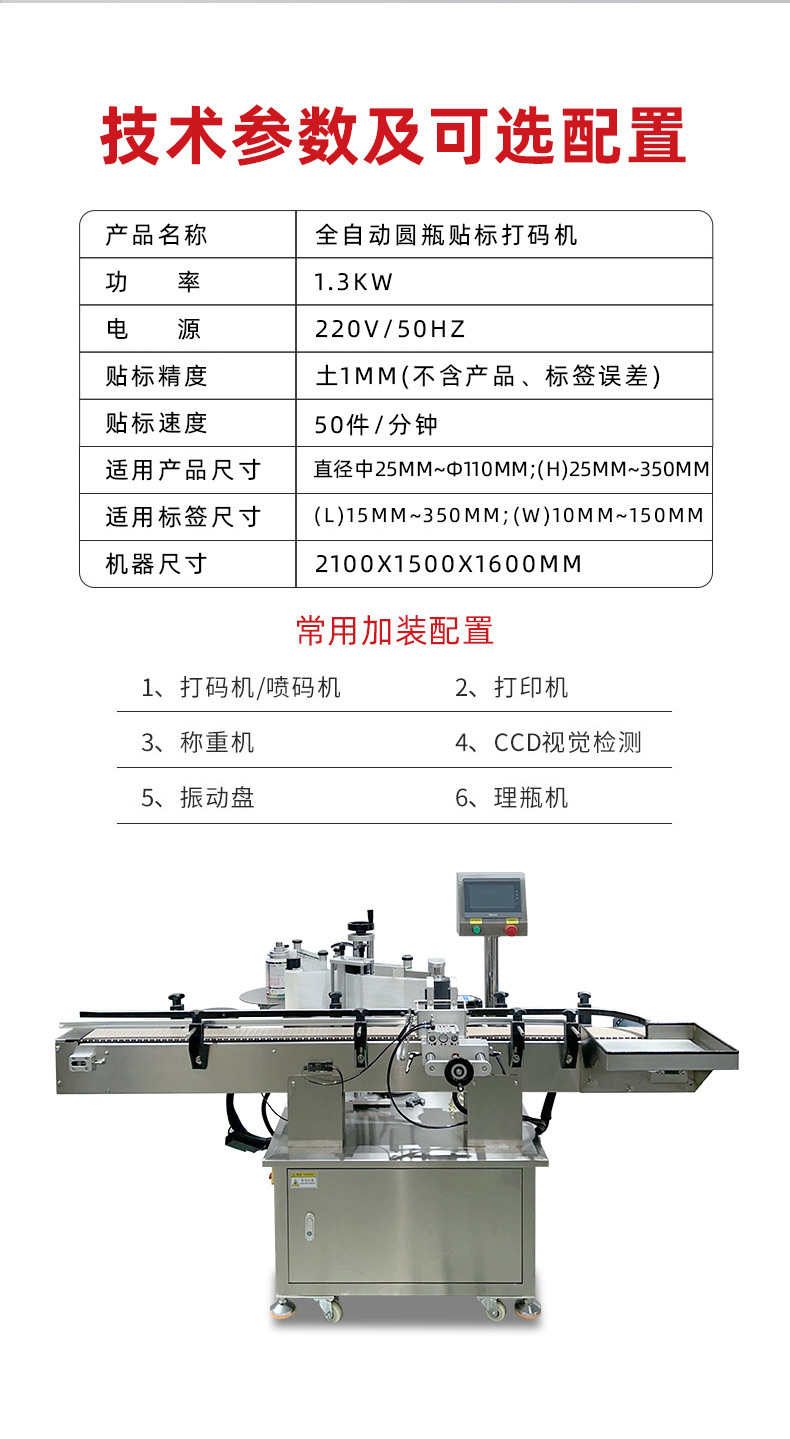

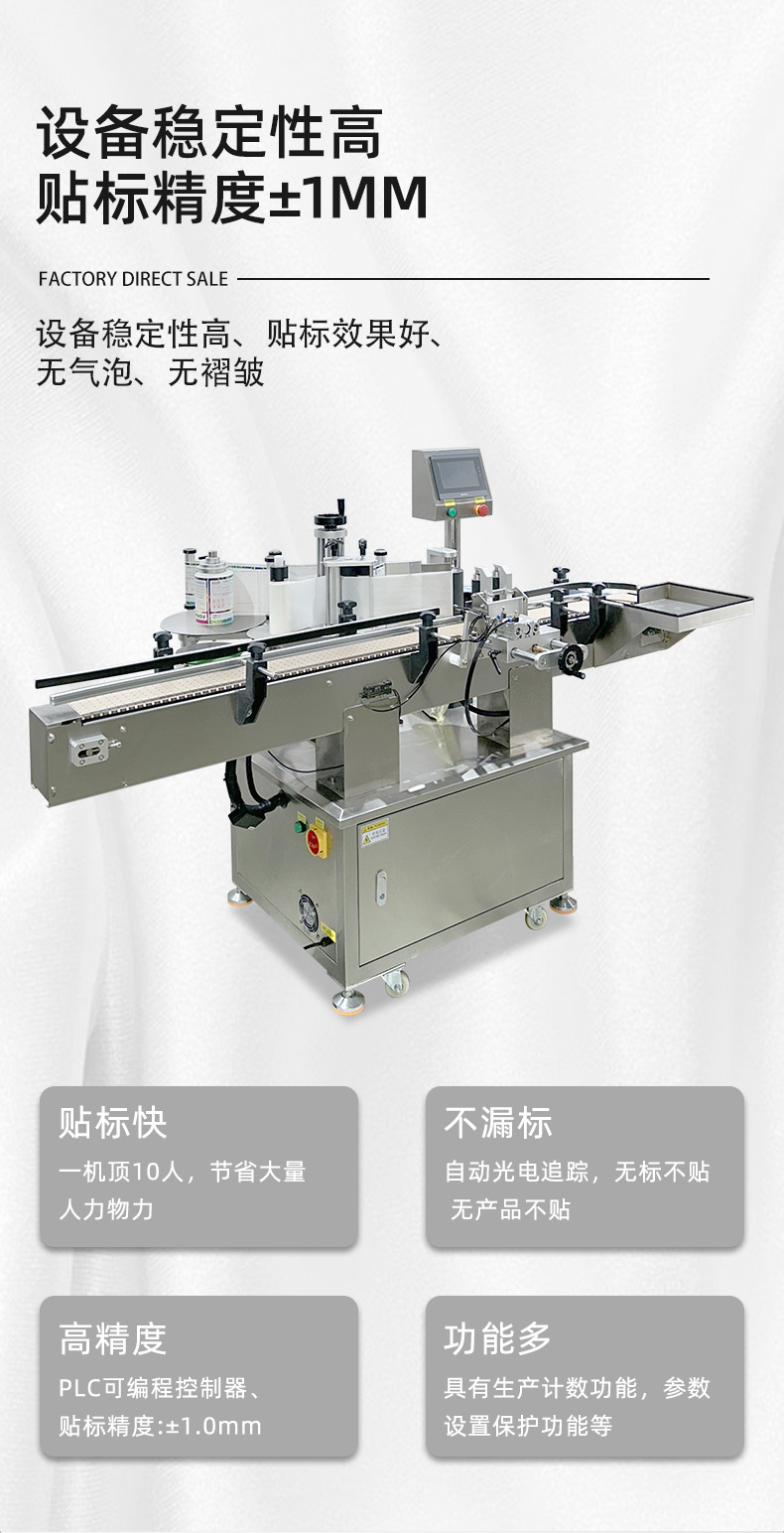

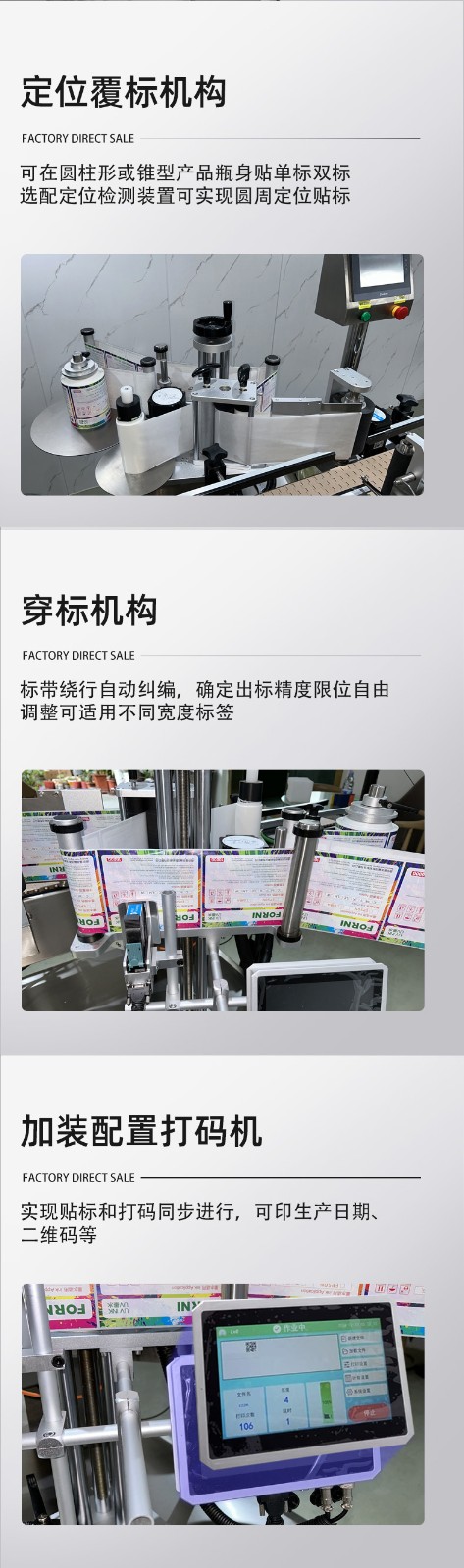

Relying on the combination of photoelectric/vision sensors and servo motors, the labeling precision can be stably maintained at ±0.5-1mm. It can realize the alignment of labels with patterns on the bottle body (such as centered logos and forward-facing text), and is especially suitable for industries with strict compliance requirements for label positions, such as pharmaceuticals and daily chemicals, avoiding problems like "crooked labels" and "slanted labels" in manual labeling.

It can be compatible with round bottles with a diameter of 30-100mm (some models can be customized) without replacing a large number of mechanical parts, and supports bottle bodies made of different materials such as glass, plastic, and metal. At the same time, it can handle various types of labels including self-adhesive labels, supervision codes, and anti-counterfeiting labels. When changing products, only parameter adjustment on the touch screen is needed, and the switch can be completed within 10 minutes.

It has built-in functions such as "automatic bottle separation, no labeling without bottles, and label shortage alarm", eliminating the need for manual bottle sorting or monitoring of label supply. Some models also support linkage with front and rear production lines (such as filling machines and cartoning machines) to form a fully automated packaging process, reducing the risks of manual handling and operational errors.

- Small desktop machines (for laboratories or small-batch production) have a speed of approximately 20-40 bottles per minute.

- Medium-sized fully automatic machines can reach 60-120 bottles per minute.

- Large high-speed machines (for pharmaceutical assembly lines) can exceed 150 bottles per minute.The machine can be flexibly selected according to production capacity, far exceeding the manual labeling speed of 5-10 bottles per minute.

The Mean Time Between Failures (MTBF) of mature models is usually more than 500 hours. With simple daily maintenance (such as cleaning sensors and lubricating bearings), the frequency of shutdown for maintenance can be reduced. Compared with the problems of manual work such as easy fatigue and fluctuating efficiency, the machine can maintain stable operation for 24 hours (regular label replenishment and maintenance are required), effectively increasing the total daily output.