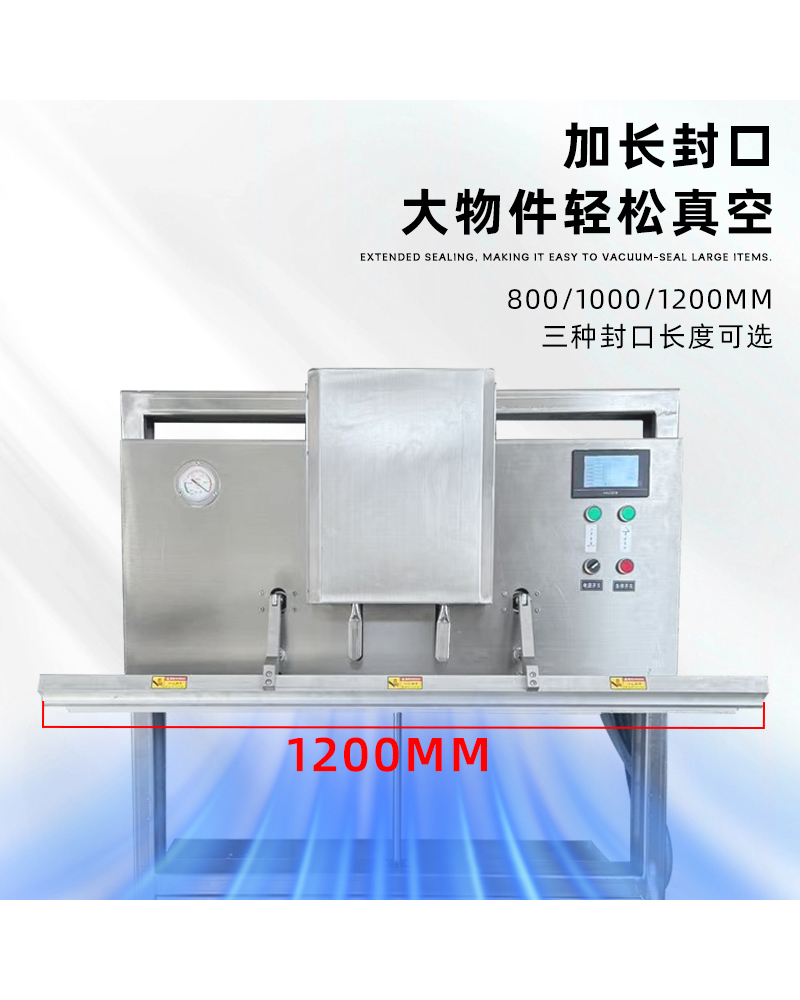

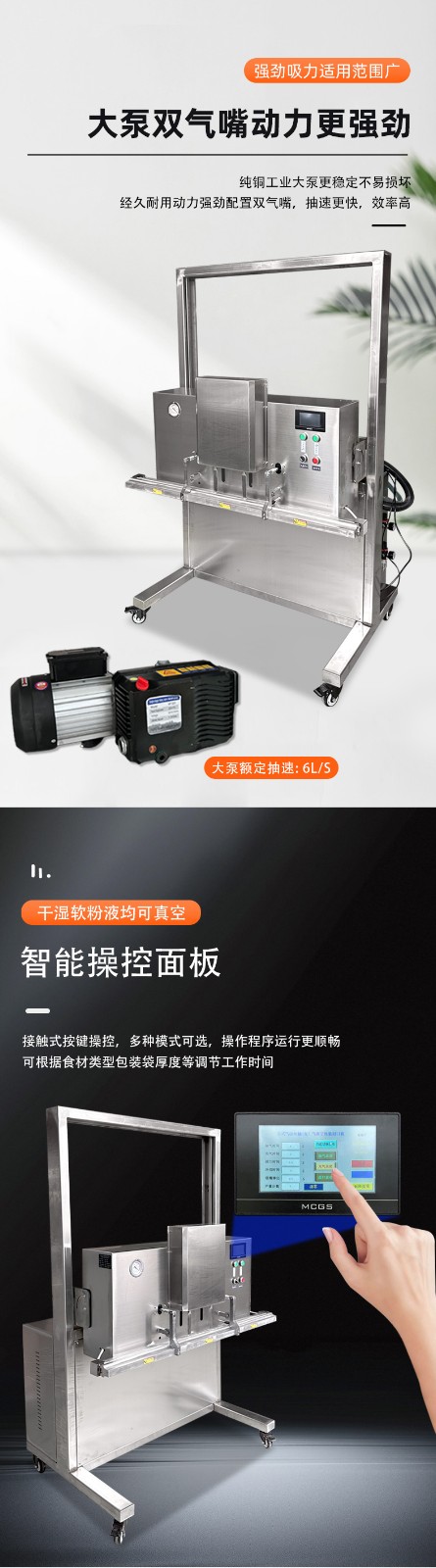

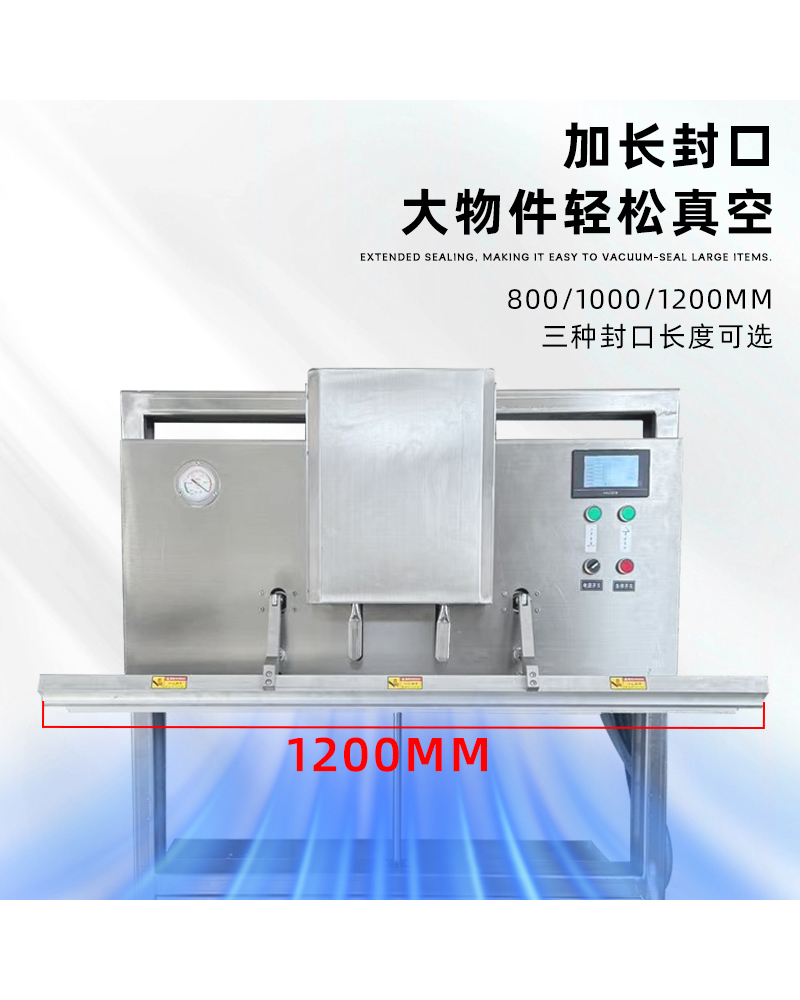

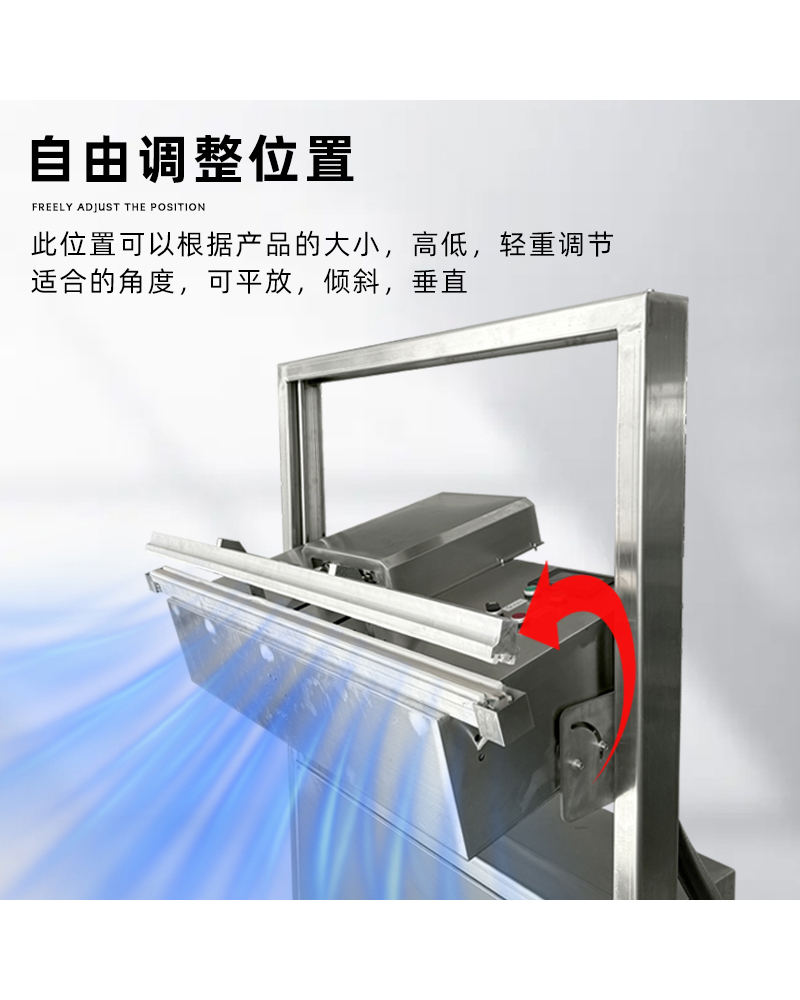

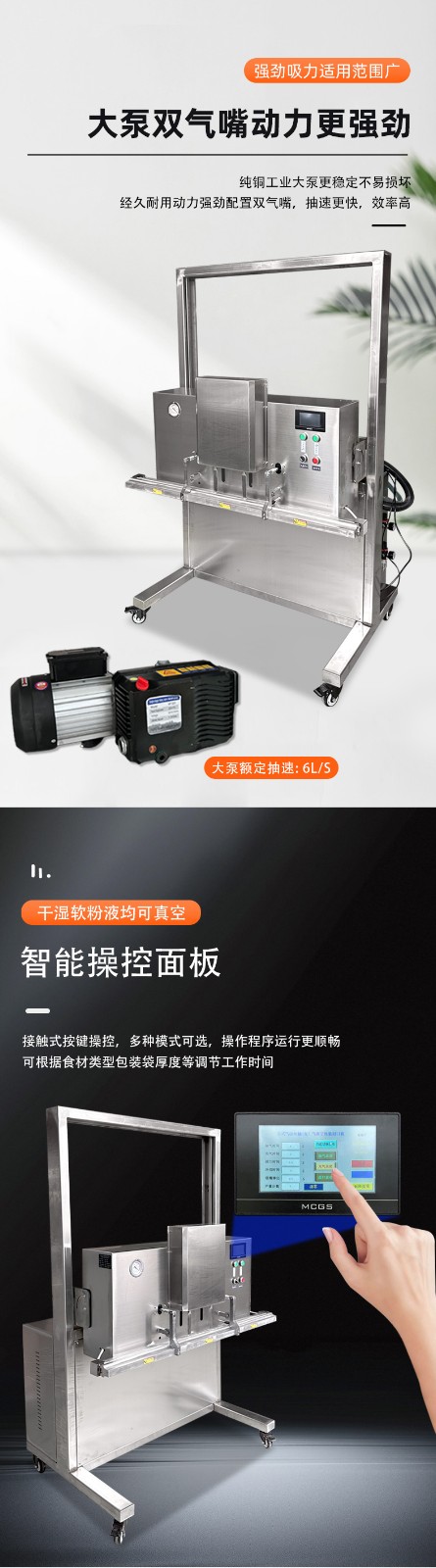

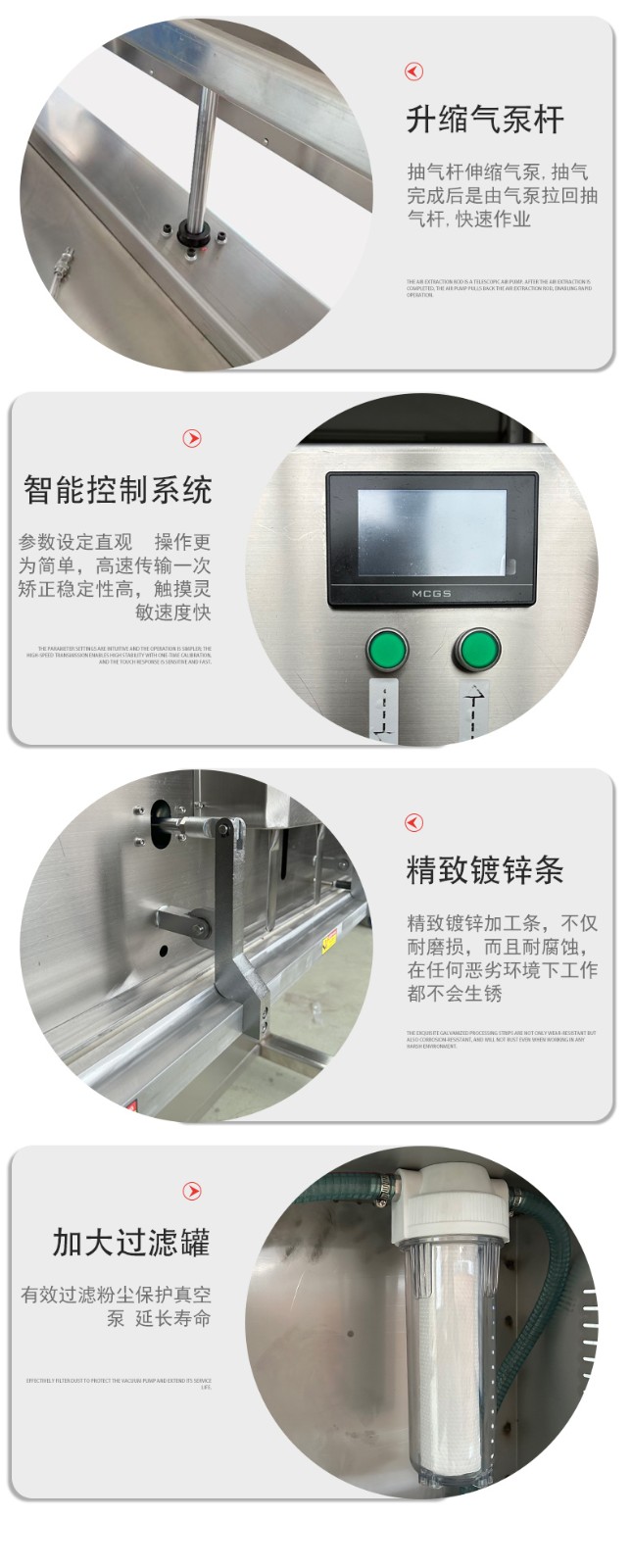

The vertical lifting vacuum packaging machine meets the vacuum packaging needs for large-sized, heavy-weight, irregular-shaped products, or multi-category small-batch production.

Release date:2025-10-29

Its core is to meet the vacuum packaging needs of large-sized, heavy-weight, irregular-shaped products or multi-category small-batch production. The following are specific scenario classifications.

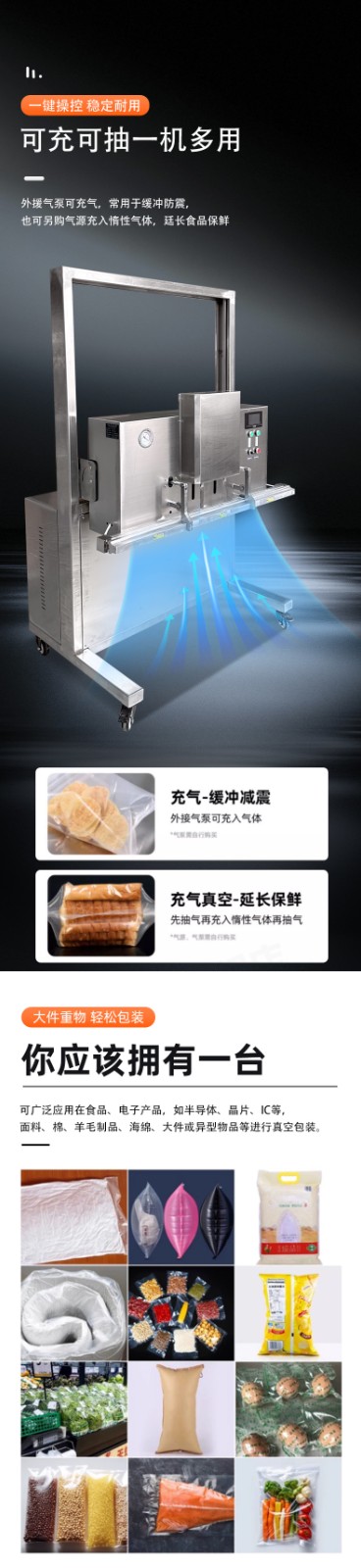

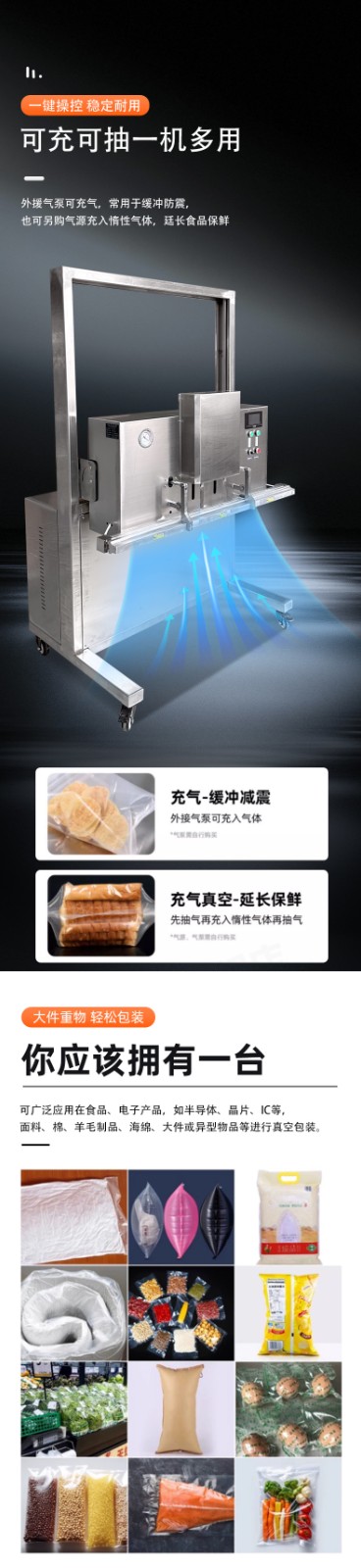

This is its most important application field, especially suitable for processing foods that are difficult to package with conventional horizontal machines.

- Meat Processing: Whole chickens, ducks, large pieces of beef, mutton, and pork ribs can be directly packaged with bones without cutting.

- Aquatic Seafood: Frozen sea fish, whole king crabs, and large-sized shrimps can avoid extrusion damage during packaging, while isolating air to prevent spoilage after thawing.

- Prepared Dishes and Semi-Finished Products: Large-capacity prepared dishes (such as 5-10kg packages for hotels) and whole portions of baking dough can further extend the fresh-keeping period through nitrogen-filled packaging.

- Specialty Foods: Whole cases of fruits (such as strawberries and blueberries), large pieces of cured meat/sausages, and barrel-packed dried foods (such as large bags of walnuts and wolfberries) are compatible with packaging containers of different heights.

It is used to protect precision components and avoid functional failure caused by moisture and oxidation.

- Large Components: Computer motherboards, industrial circuit boards, and large connectors can adapt to the irregular shapes and large sizes of the components.

- Finished Equipment: Small home appliance parts (such as air conditioner compressor components) and semi-finished headphones/speakers can avoid collision between components during packaging, while isolating moisture and dust in the air.

- Metal Parts: Stainless steel parts and hardware accessories can prevent oxidation and rust during long-term storage.

It meets the strict industry requirements for packaging tightness and hygiene.

- Chemical Raw Materials: Granular or powdered chemical reagents (such as plastic particles and pigment powders) can prevent leakage during transportation, while isolating air to avoid chemical reactions of components.

- Pharmaceutical Products: Chinese medicinal materials (such as whole ginseng and large pieces of deer antler) and large packages of medicinal capsules or tablets (such as 10kg packages for factories) comply with pharmaceutical-grade hygiene standards to ensure stable drug quality.

- Hazardous Materials: Small barrels of chemical additives with low corrosiveness can reduce volatilization and leakage risks through sealed packaging.

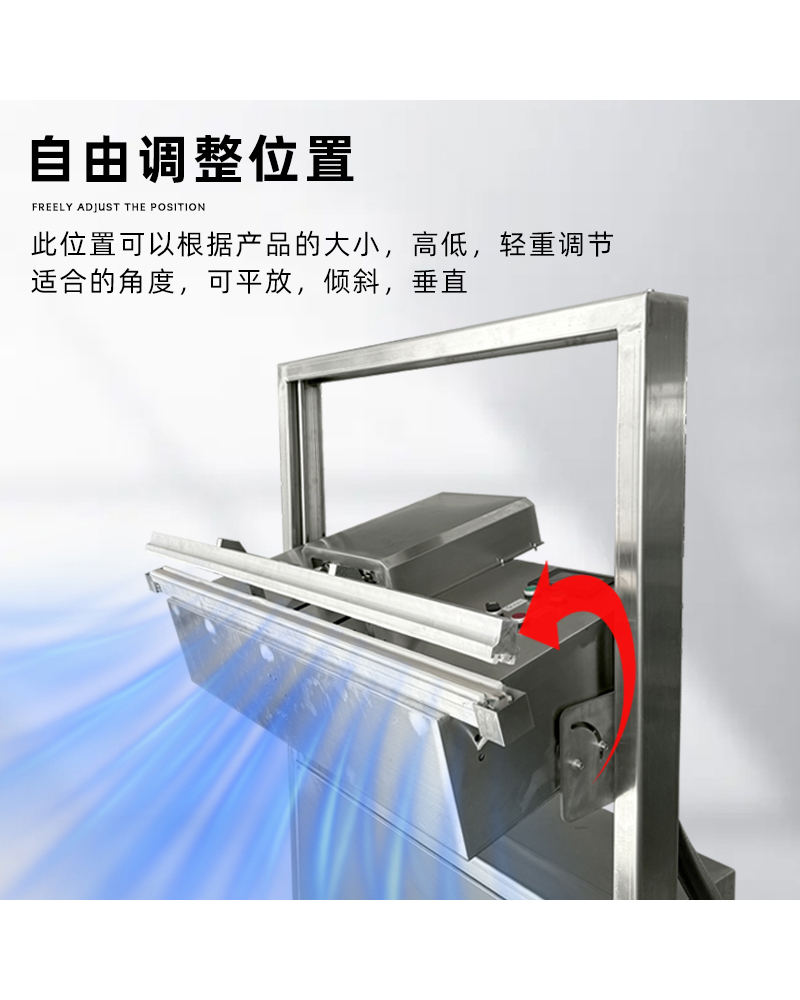

- Hardware and Machinery: Small mechanical parts (such as bearings and gear sets) and irregular-shaped metal tools allow the workbench to be adjusted according to the height of the parts to avoid deformation during packaging.

- Home Textiles: Large beddings (such as double-sized down comforters) and pillows are compression-packaged; vacuuming reduces their volume for easy storage and transportation.

- Gift Packaging: Large gift boxes (such as customized red wine gift boxes and specialty gift boxes) can be fully vacuum-packaged to prevent moisture or damage to internal items during transportation.