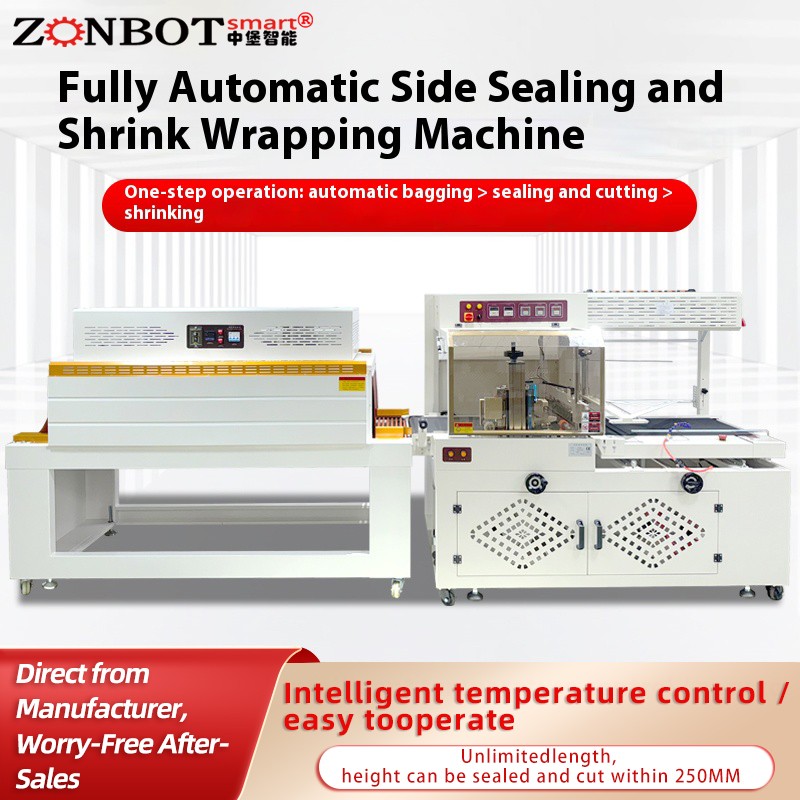

The "high degree of automation" and "wide range of applicability" of fully automatic side-seal heat shrink packaging machines are the core advantages behind their widespread application across various industries. These two features mutually support each other and synergistically enhance the practical value of the equipment. A detailed analysis from the following dimensions can further illustrate this:

The automation advantage of these machines runs through the entire packaging process, eliminating the need for frequent manual involvement. Its core is reflected in three aspects: process autonomy, precise parameter control, and user-friendly operation.

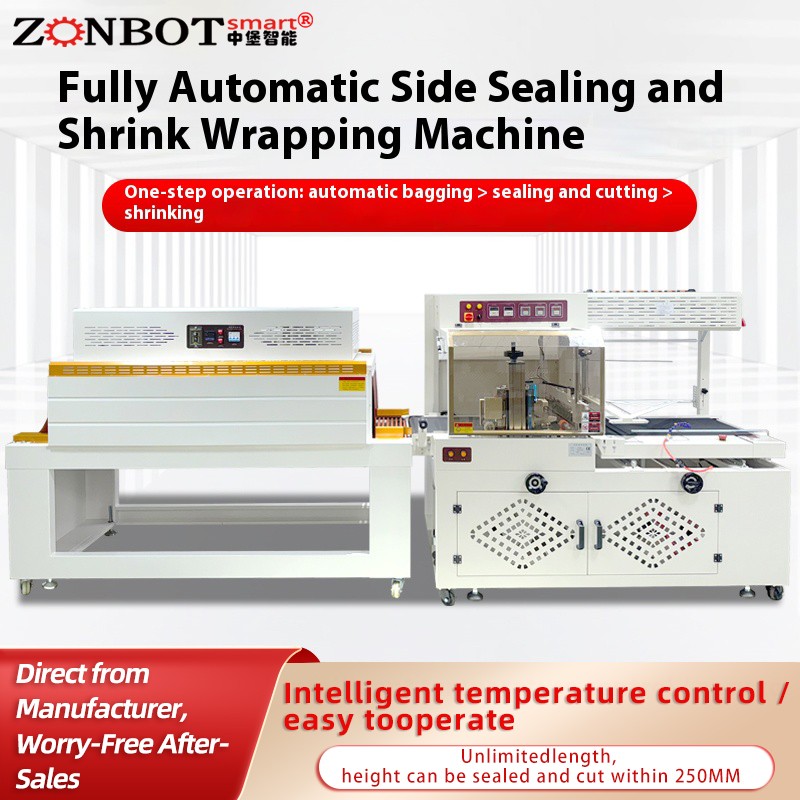

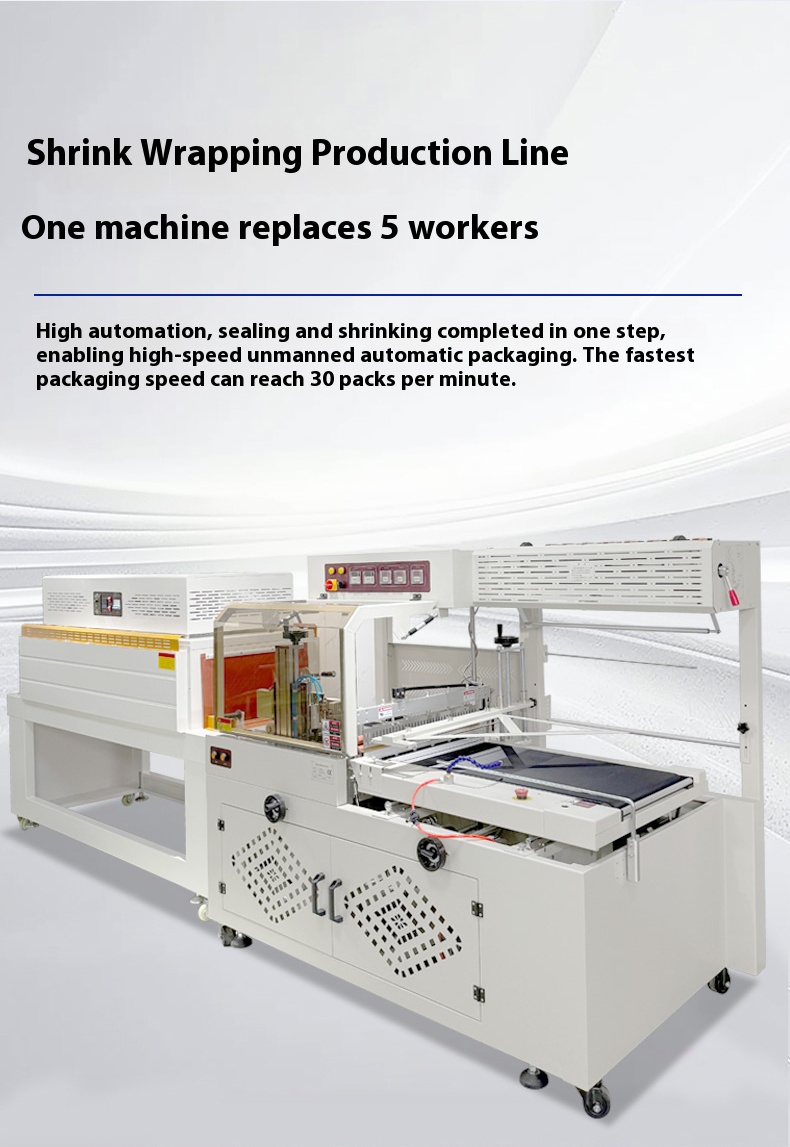

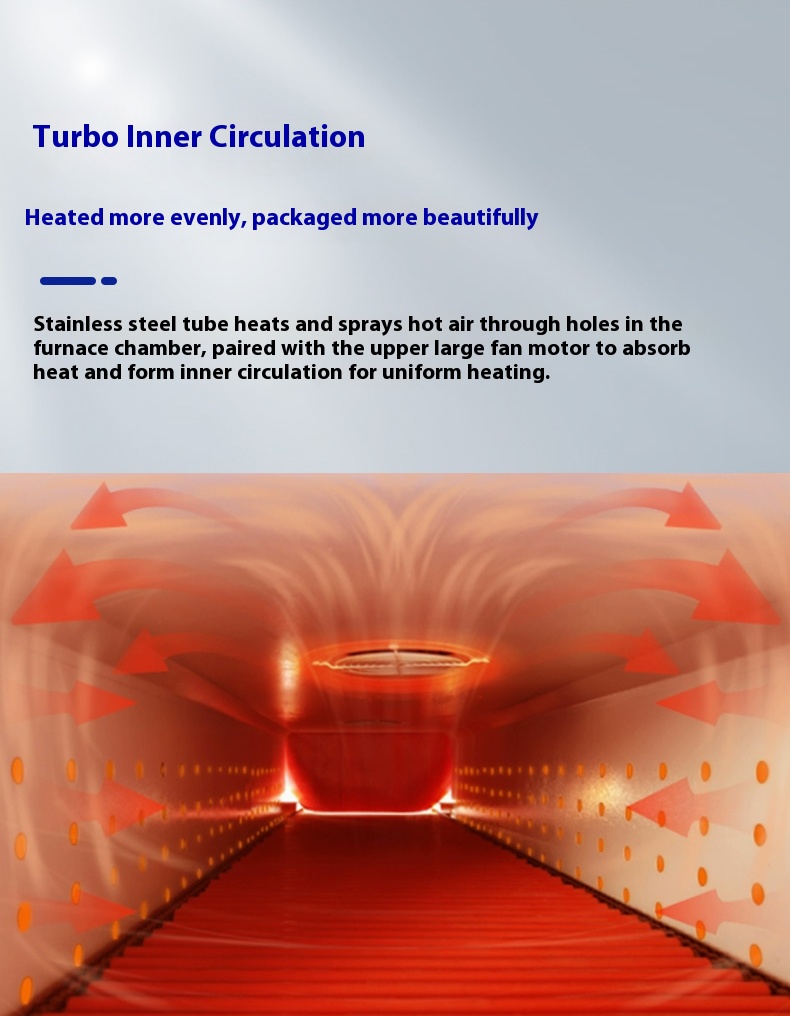

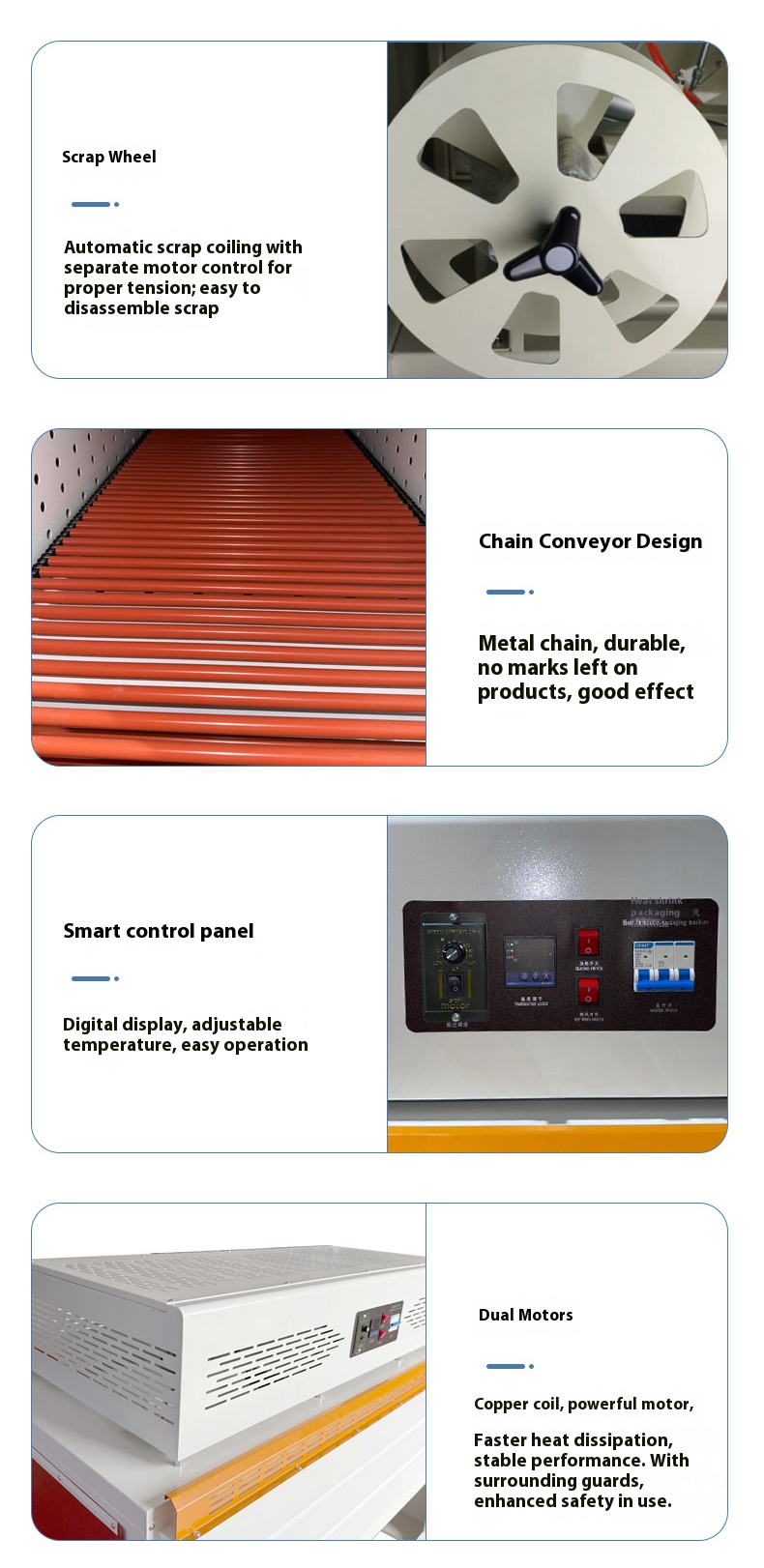

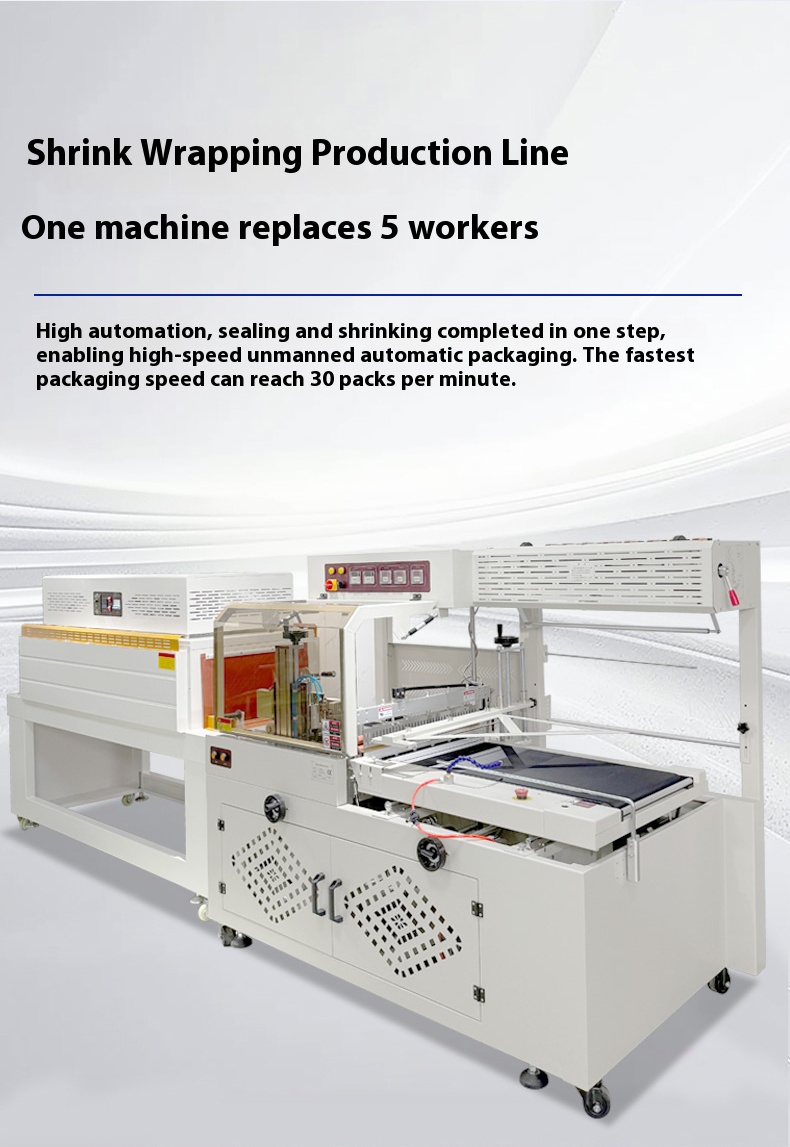

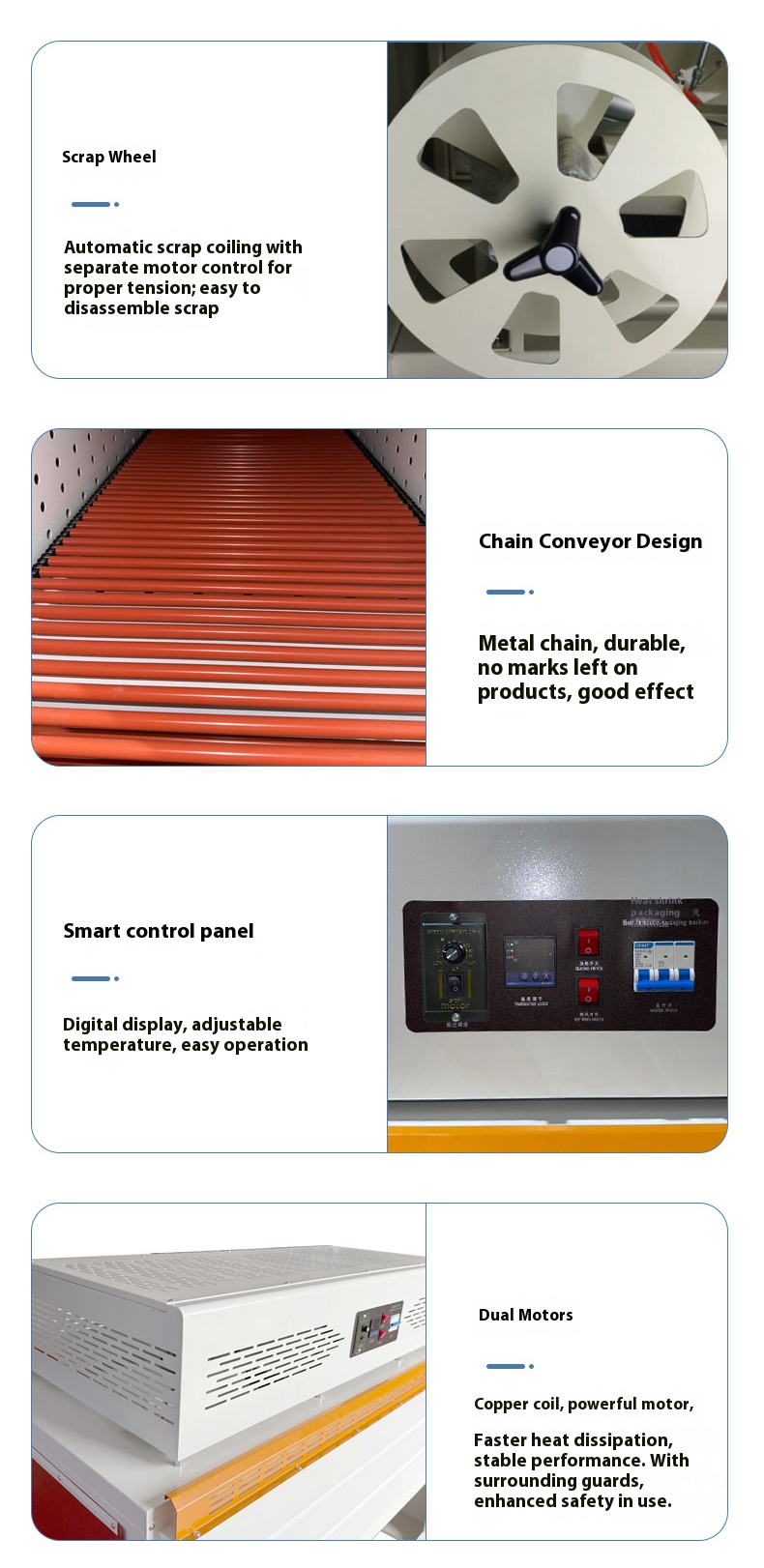

The equipment can independently complete the entire process, including "film feeding → product positioning → vertical/horizontal sealing and cutting → automatic waste film recycling → heat shrink tunnel heating → finished product conveying", without the need for manual film feeding, adjusting the sealing and cutting position, or handling semi-finished products. For example, when packaging multi-bottle beverage combinations, it is only necessary to place the products in batches on the feeding conveyor line. The machine will automatically align the products, match the film width, and complete the sealing, cutting, and shrinking processes—no dedicated personnel are required to monitor the entire process. A single machine can replace the packaging workload of 2-3 workers, significantly reducing labor costs and operational errors.

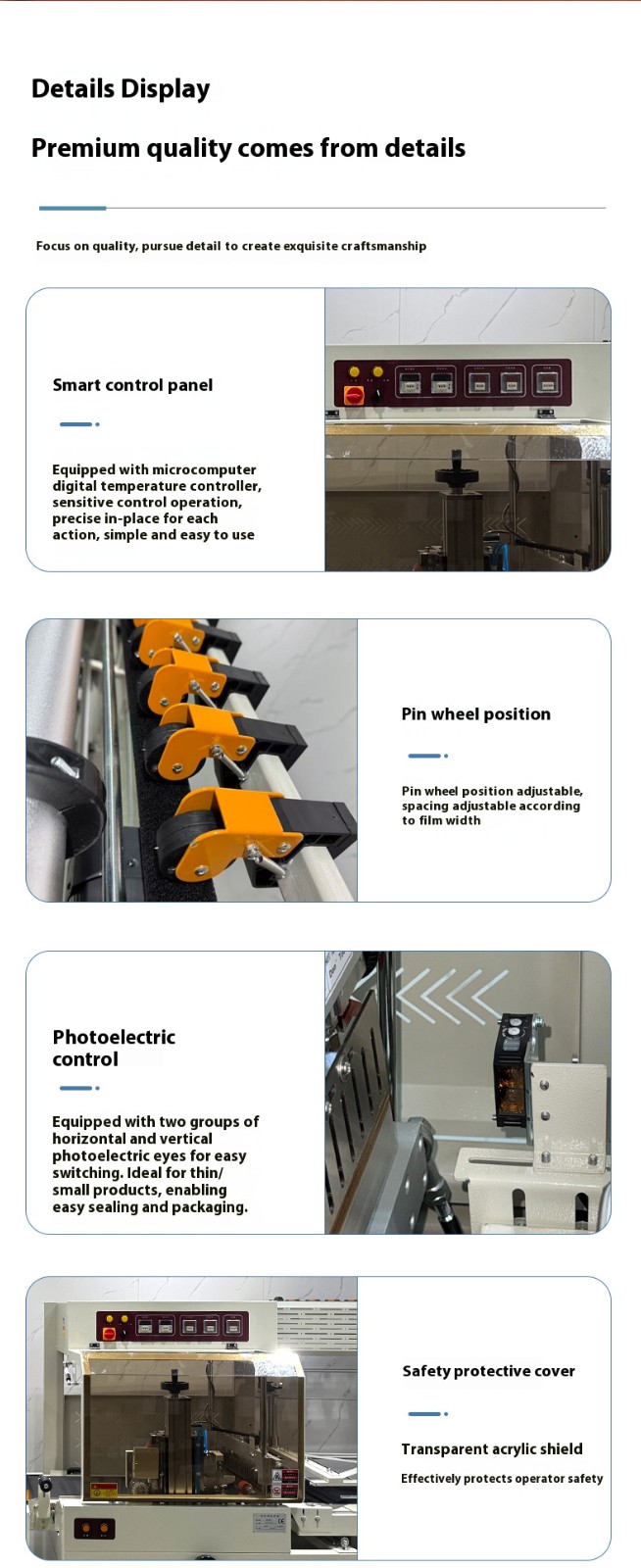

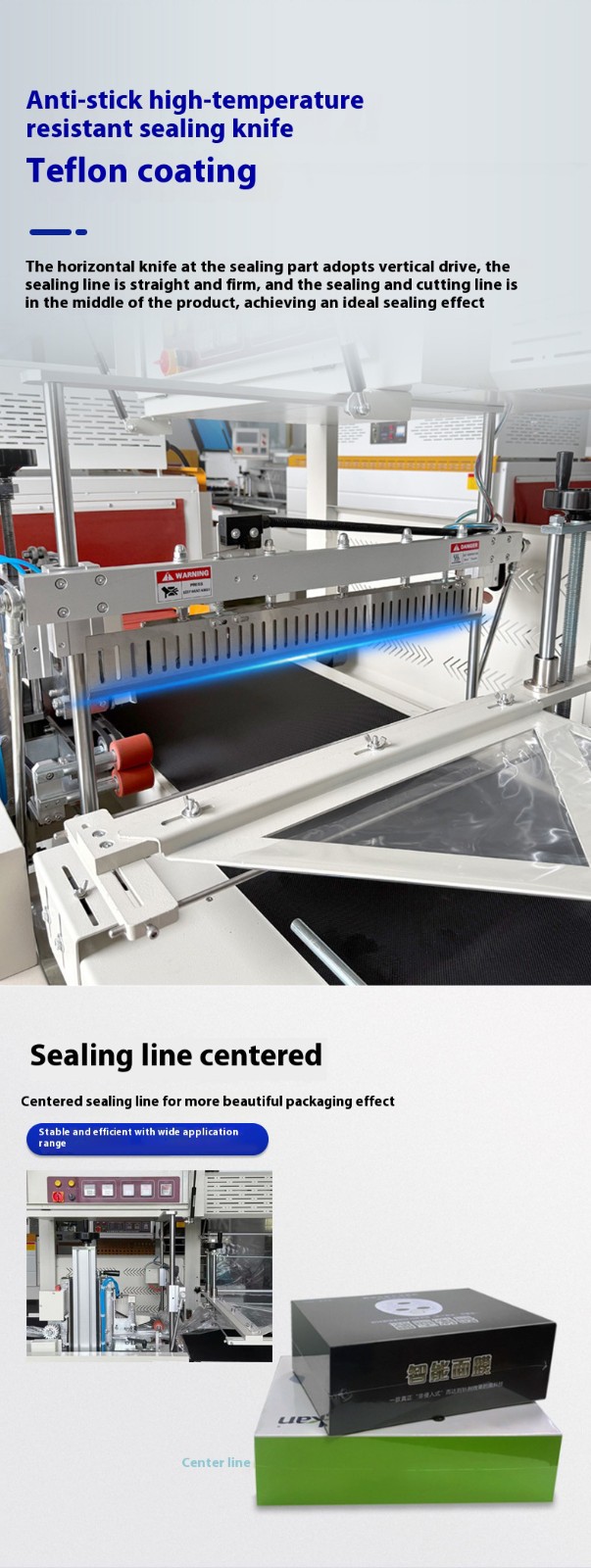

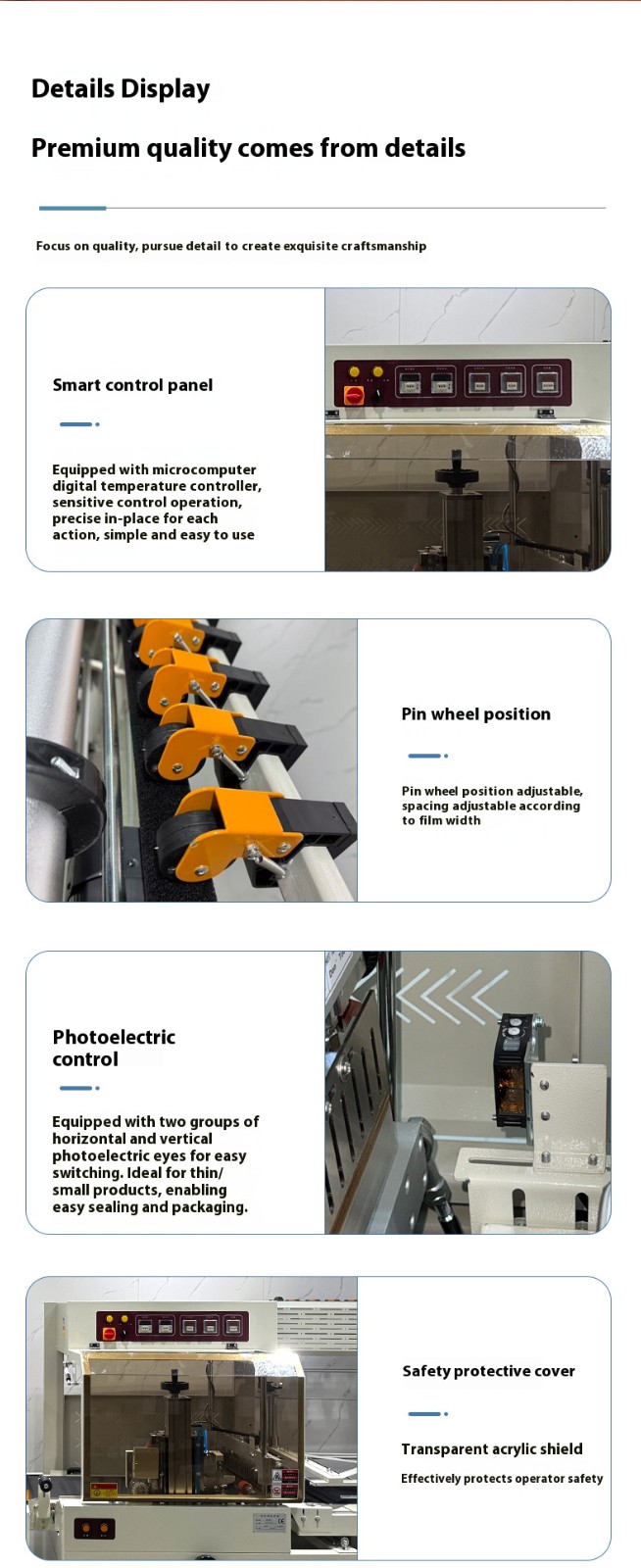

Relying on a PLC programmable control system and a touchscreen operation interface, parameters such as packaging speed (usually 10-60 pieces per minute, with some high-speed models reaching up to 80 pieces per minute), sealing and cutting temperature (80-200°C, adjusted according to film material), heat shrink time, and film feeding length can be set with one click. Moreover, these parameters can be stored and recalled—when changing products, there is no need for repeated re-adjustment; the preset program can be directly used. For instance, when switching from packaging cookie boxes to shampoo bottles, it is only necessary to select the corresponding product parameter template on the screen. The machine will automatically adjust the temperature of the sealing and cutting knife and the speed of the conveyor line, avoiding the time consumption and errors caused by manual adjustment.

The equipment is equipped with multiple intelligent protection functions: when the film is exhausted, the machine will automatically stop and sound an alarm; when the temperature of the sealing and cutting knife is abnormal (too high or too low), the system will monitor it in real time and trigger protection measures to prevent the film from being burnt or the seal from being insecure; when there are no products at the feeding port, the film feeding and sealing/cutting processes will pause simultaneously to avoid waste of empty film. These automatic protection functions not only reduce the risk of equipment failure but also decrease the frequency of manual inspections, improving the reliability of the equipment's continuous operation.

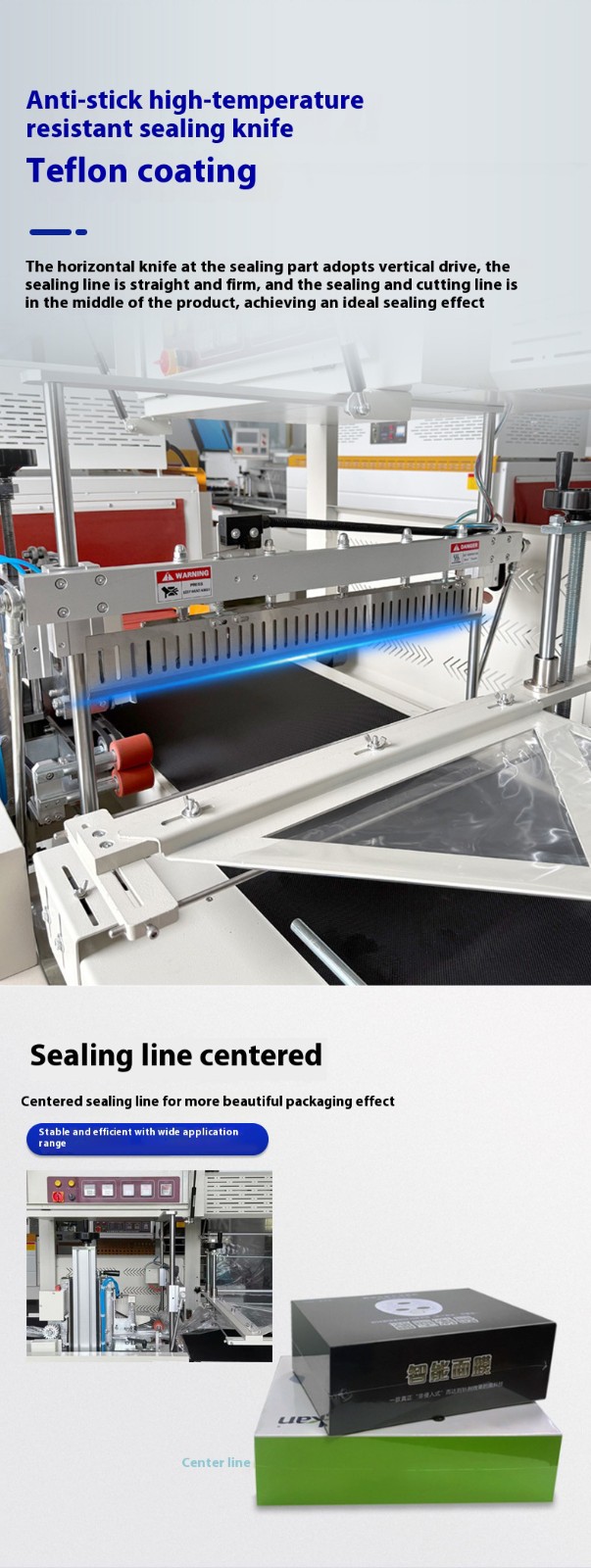

The core logic behind the wide applicability lies in its strong structural compatibility, high film adaptability, and flexible size adjustment, enabling it to meet the packaging needs of products with different shapes, sizes, and materials.

- By product shape: It can package regular-shaped products (such as boxed medicines, bottled beverages, and square cosmetics), irregular-shaped products (such as toy accessories, hardware tools, and special-shaped stationery), and even fragile items (such as glass jarred food and electronic screens). By adjusting the height of the conveyor line, the curvature of the sealing and cutting mold, and the heat shrink temperature, product damage due to pressure can be avoided while ensuring the film adheres tightly.

- By packaging specification: It supports "single-piece packaging" (such as a single lipstick or a single box of cookies) and "combination packaging" (such as 6-pack beverages, 10-pack pens, and tool sets). Only by adjusting the spacing of the feeding conveyor line and the film feeding length can the packaging specification be flexibly switched, without the need to replace core components.

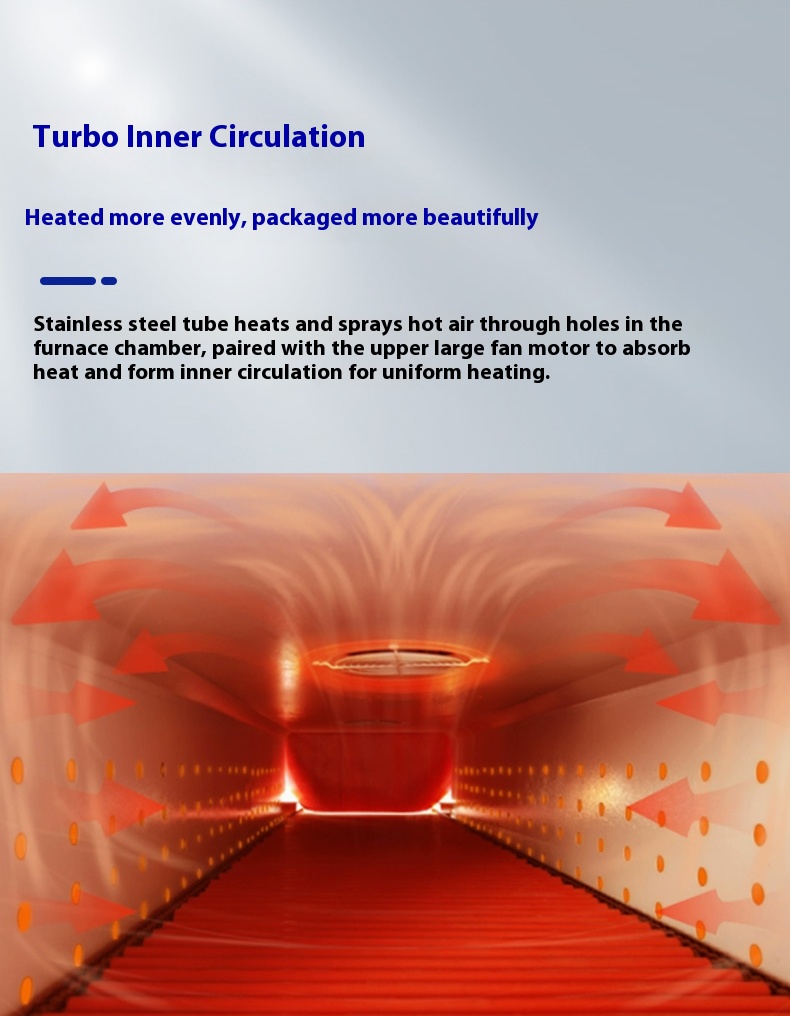

The equipment has extremely strong adaptability to shrink films and is compatible with mainstream film types on the market, covering the packaging standards of different industries:

- POF film (environmentally friendly, high transparency): Suitable for the food, cosmetics, and pharmaceutical industries, meeting hygiene and aesthetic requirements;

- PE film (puncture-resistant, high toughness): Suitable for hardware tools and household appliance accessories, preventing scratches and damage during transportation;

- PVC film (low cost, high shrinkage rate): Suitable for non-food products such as stationery and toys, balancing economy and packaging effect.

There is no need to replace the sealing and cutting components; only by adjusting the sealing and cutting temperature and heat shrink time can the equipment adapt to different film materials, reducing the equipment transformation cost when switching between industries.

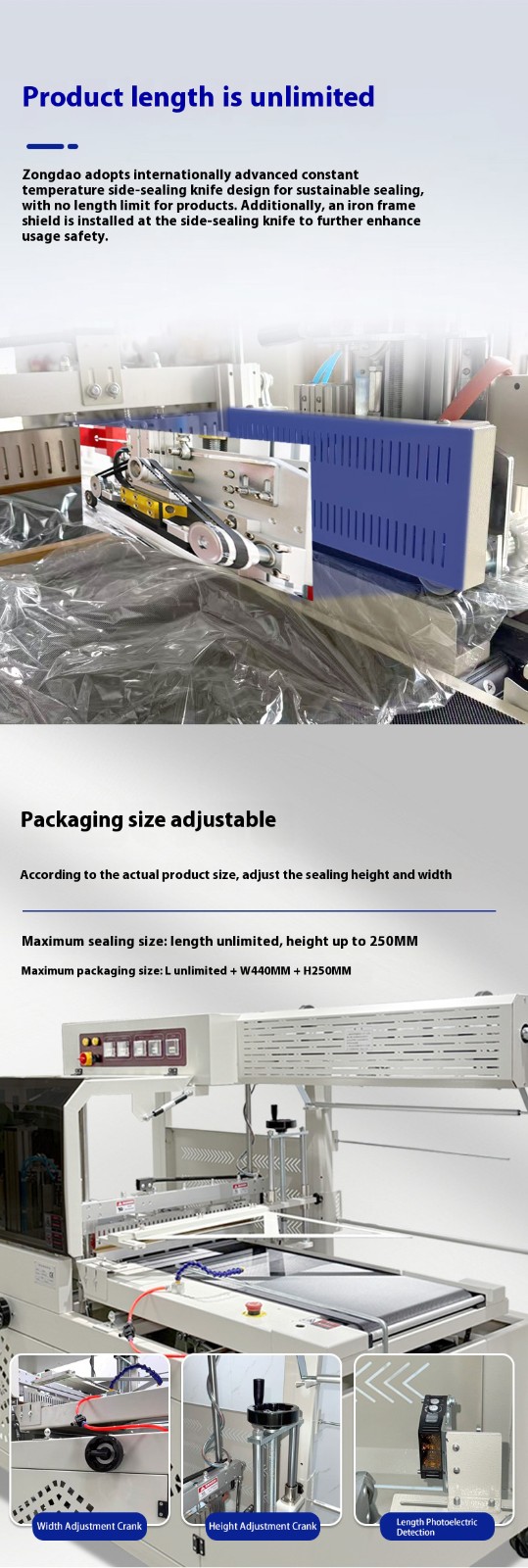

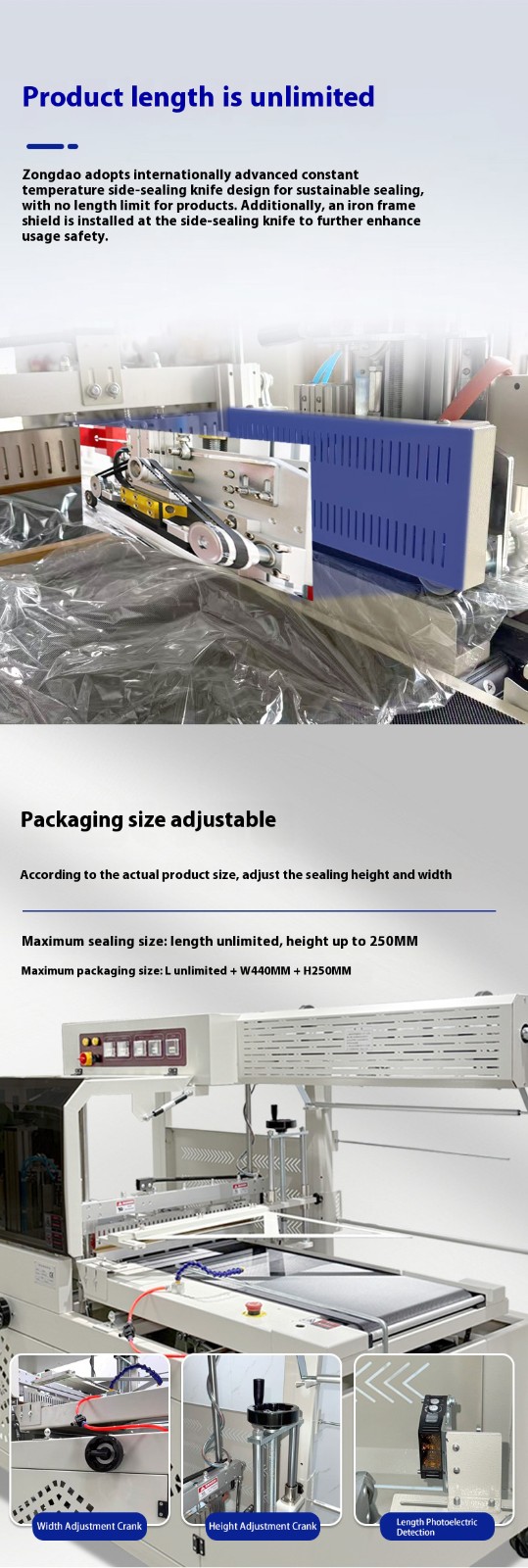

Most models support flexible adaptation to different product sizes through manual knobs or electric adjustment:

- Horizontal width: The spacing of the guide plates on both sides can be adjusted to adapt to products with a width of 50-500mm (e.g., from packaging 3cm-wide screw boxes to 30cm-wide household appliance remote controls);

- Vertical height: By lifting the sealing and cutting device or adjusting the height of the heat shrink tunnel, it can adapt to products with a height of 20-300mm (e.g., from packaging 5cm-high sticky notes to 25cm-high barrel-packed snacks);

- Some customized models can also expand the size range to meet the packaging needs of large products (such as small household appliances and toolboxes), further expanding the scope of application.

These two advantages are not independent; instead, they empower each other:

- Precisely because of its high degree of automation, when the equipment needs to switch to meet the packaging requirements of different industries or products, there is no need for extensive manual adjustment or component replacement. It can quickly adapt by simply setting parameters on the screen, turning the "theoretical possibility" of "wide applicability" into "efficient implementation".

- Also, because of its wide range of applicability, the equipment can handle the packaging of multiple types of products on the same production line (e.g., a food factory packaging cookies, candies, and beverages simultaneously). This prevents enterprises from purchasing special packaging equipment separately for different products, reducing equipment investment costs. Meanwhile, the high degree of automation further ensures efficiency when switching between multiple products, without reducing production capacity due to adapting to different products.