The core working principle of a heat shrink packaging machine lies in utilizing the thermoplastic property of heat shrink film. By heating the film to make it shrink, the film tightly wraps around the surface of a single product or the exterior of a bundled package, achieving packaging effects such as fixation, protection, and aesthetic enhancement. Essentially, through the action of controllable heat, the heat shrink film (e.g., PVC, POF, PET, etc.) reverts to its shrunk state as it was during production, ultimately conforming closely to the shape of the product.

The operation process of a heat shrink packaging machine can be divided into four key steps: "Film Feeding → Sealing & Cutting → Heat Shrinkage → Cooling & Shaping". Although different types of equipment (such as drying tunnel type, hot air circulation type, infrared type, etc.) vary slightly in their heating methods, their core principles remain consistent:

According to the shape of the product, heat shrink film is wrapped around the surface of the product to be packaged (for individual products) or the exterior of bundled products (e.g., multiple bottled beverages tied together) via manual operation or an automatic film feeding mechanism. Some fully automatic models automatically unroll and cut the film from a film roll holder to form a film sleeve that matches the product.

If a roll of "open-end heat shrink film" is used, the equipment first uses a sealing and cutting device (such as a heat knife or ultrasonic sealer/cutter) to seal the film around the product into a closed "film bag". This ensures that during subsequent heating, the film shrinks in directions focused on wrapping the product. (This step can be omitted if pre-formed "shrink film bags" are used.)

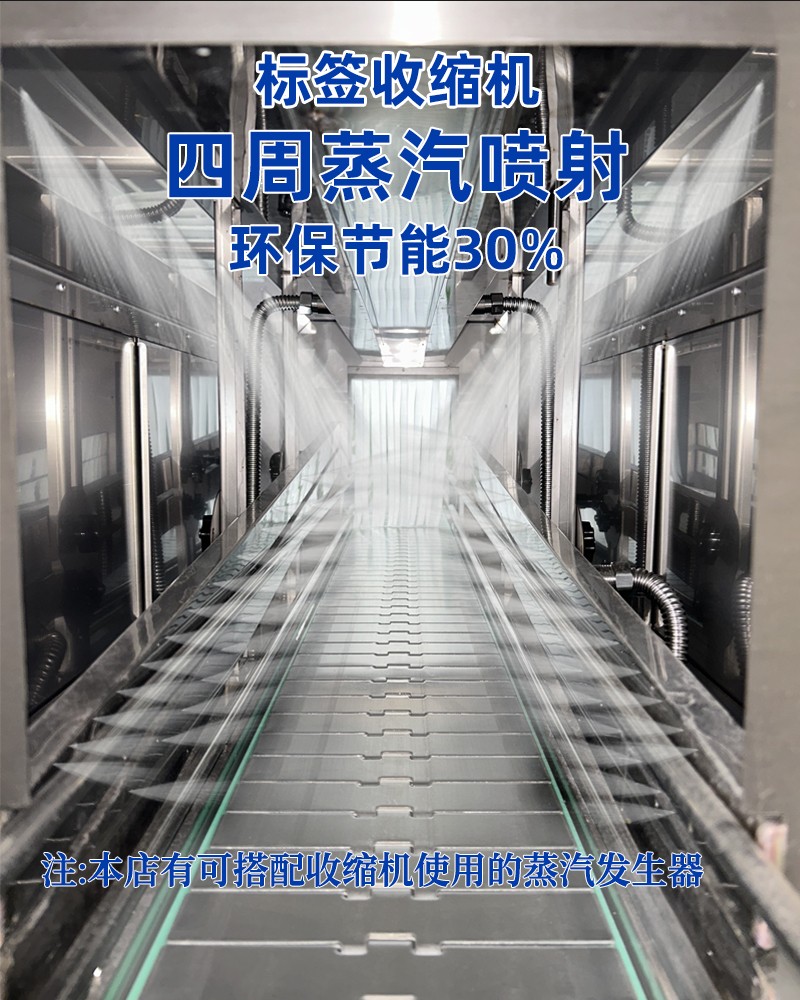

This is the key step to achieve "shrinkage". The equipment generates stable heat through its heating system. When the product covered with film enters the heating area (e.g., drying tunnel, shrink oven), the heat acts evenly on the heat shrink film:

- After being heated, the molecular chains of the heat shrink film become more active, breaking the original stretched state, and the film begins to shrink in the "shrinkage direction" (usually both horizontally and vertically).

- Since the film tightly wraps the product, the shrinkage force drives the film to conform to the contour of the product—whether it is a product with a regular shape (e.g., carton, glass bottle) or an irregular shape (e.g., toy, hardware part)—resulting in a tight packaging effect.

The differences between various heating methods mainly lie in the "form of heat transfer" (see "Common Heating Types" below).

The heat-shrunk film needs to be cooled quickly to fix its shrunk shape, preventing deformation or wrinkling caused by continuous heating. Some equipment is equipped with cooling devices (such as fans for blowing cold air, cooling channels) after the heating area to accelerate the solidification of the film and ensure the stability of the packaged product after shaping.

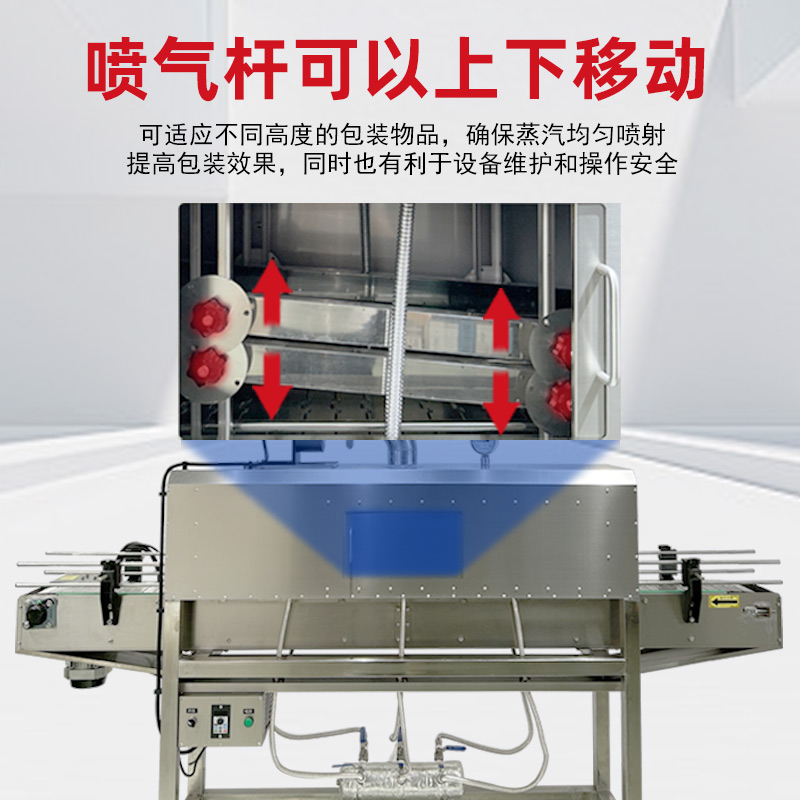

The structural design of a heat shrink packaging machine centers on "precise temperature control and uniform heating", with its core components directly serving the above-mentioned principles:

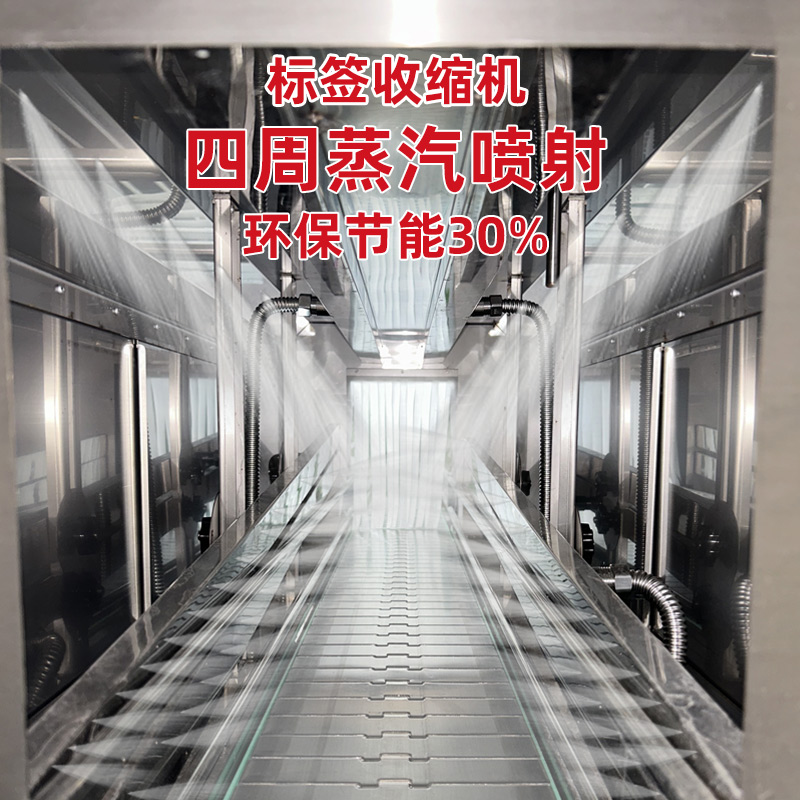

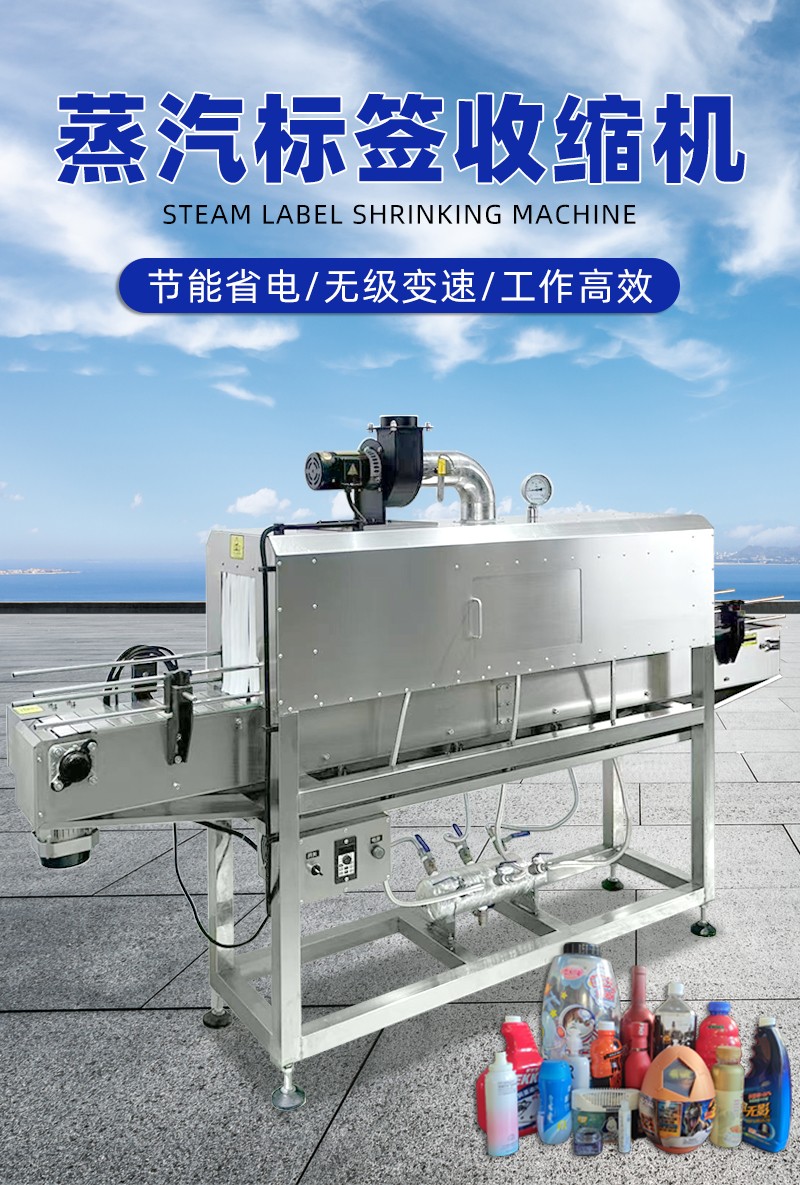

It determines the efficiency and uniformity of heat transfer and is the core for realizing the principle. Common types include:

- Hot Air Circulation Type: Uses fans to blow hot air generated by heating tubes evenly onto the film. It is suitable for most films and products, with excellent shrinkage uniformity.

- Infrared Heating Type: Emits heat through infrared tubes to act directly on the film surface. It features fast heating speed and low energy consumption, making it suitable for thin films or heat-sensitive products (e.g., electronic products).

- Quartz Tube Heating Type: Generates heat through quartz tubes, with concentrated heat output. It is suitable for films with high shrinkage rates (e.g., PVC film).

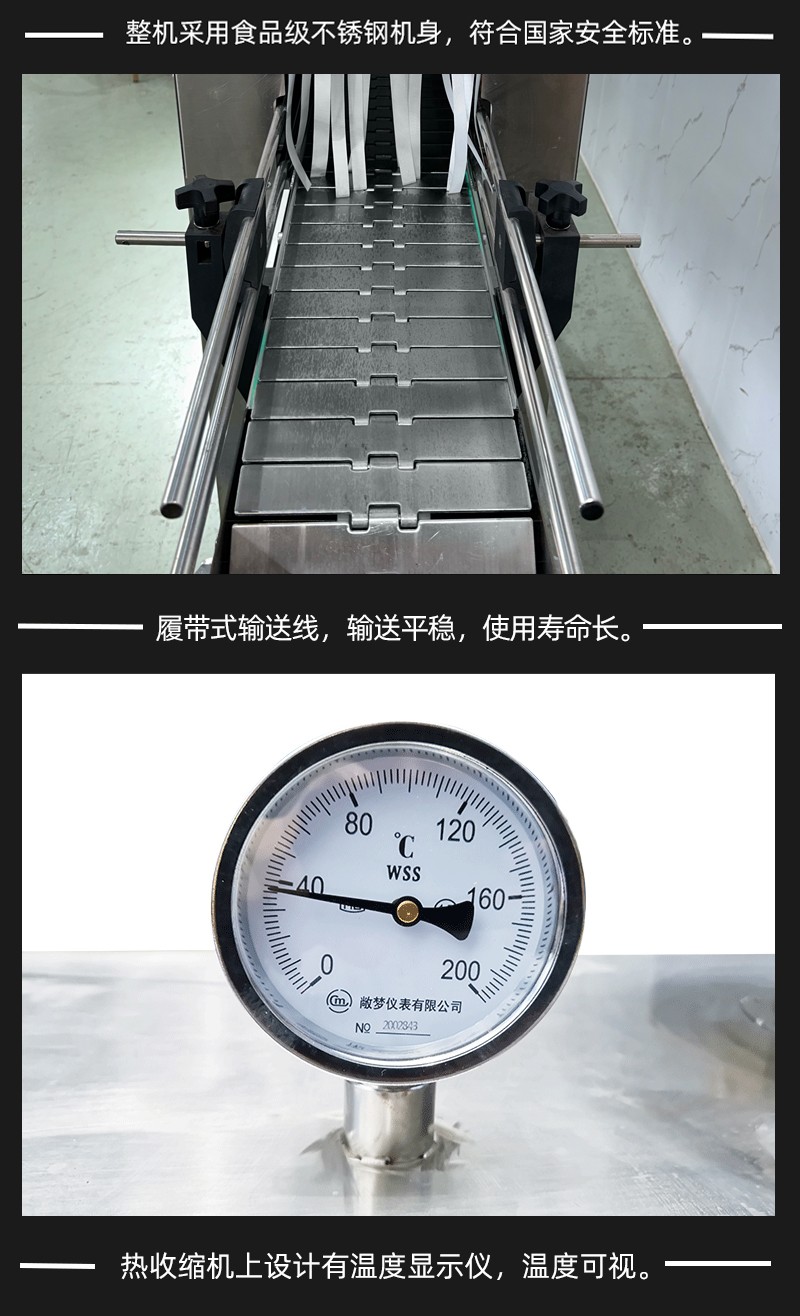

It monitors the temperature of the heating area in real time through thermocouples and temperature sensors, and cooperates with a controller to stabilize the temperature at the "optimal shrinkage temperature" of the film (different films have different temperature requirements—for example, POF film usually requires 120-180℃, while PVC film requires 80-120℃). This prevents film damage and charring due to excessively high temperatures, or insufficient shrinkage due to excessively low temperatures.

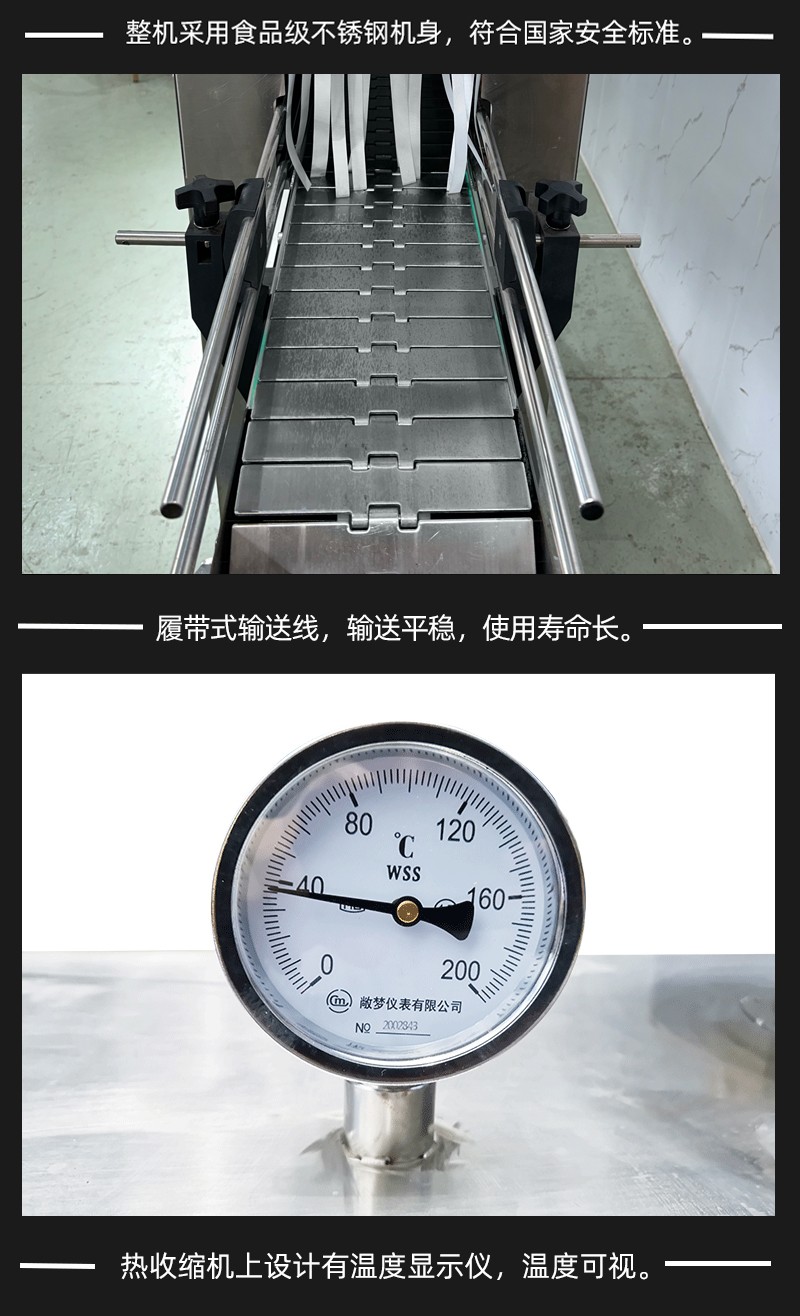

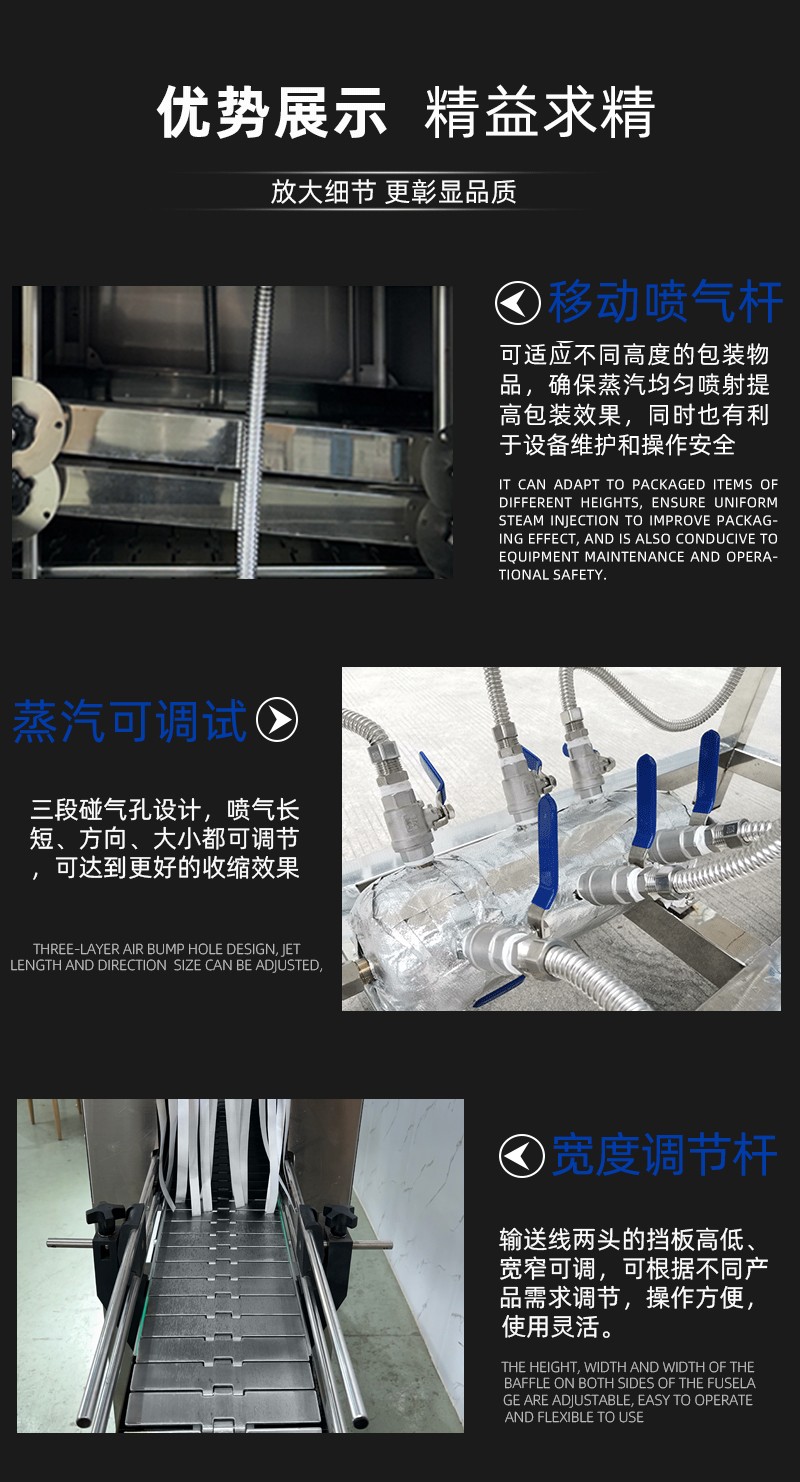

It uses a conveyor belt to transport products into the heating area at a constant speed, ensuring that all parts of the product stay in the heating area for the same duration. This avoids uneven shrinkage effects caused by local uneven heating (the speed of the conveyor belt can be adjusted according to the product size and film type).

The working principle of the heat shrink packaging machine relies on the special physical property of heat shrink film:

During production, heat shrink film undergoes a "stretching process" (e.g., longitudinal stretching, transverse stretching), which puts its molecular chains in a "stretched state" and sets them. When exposed to heat at a specific temperature again, the molecular chains revert to their "unstretched natural shrunk state", thereby generating a force that shrinks toward the center—this is the fundamental reason why the film can tightly wrap the product.

Heat shrink films of different materials vary in shrinkage rate (horizontal/vertical shrinkage ratio) and temperature resistance. Therefore, the heat shrink packaging machine needs to adjust parameters such as temperature and conveyor belt speed to adapt to the characteristics of the corresponding film, so as to achieve the ideal shrinkage effect.