I. Core Efficiency Indicator: Cycles Per Minute (CPM)

The working efficiency of pneumatic external vacuum packaging machines is mainly quantified by the number of packaging cycles completed per minute (Cycle Per Minute, CPM). The efficiency range varies significantly among different types of equipment:

Small desktop machines (suitable for small batches, laboratories, or stores):

The single cycle time is approximately 10-20 seconds, with an efficiency of usually 3-6 cycles per minute (i.e., 180-360 cycles per hour). Limited by low pumping power and manual auxiliary operations (such as placing materials and adjusting films), they are suitable for packaging small items (e.g., snacks, small hardware).

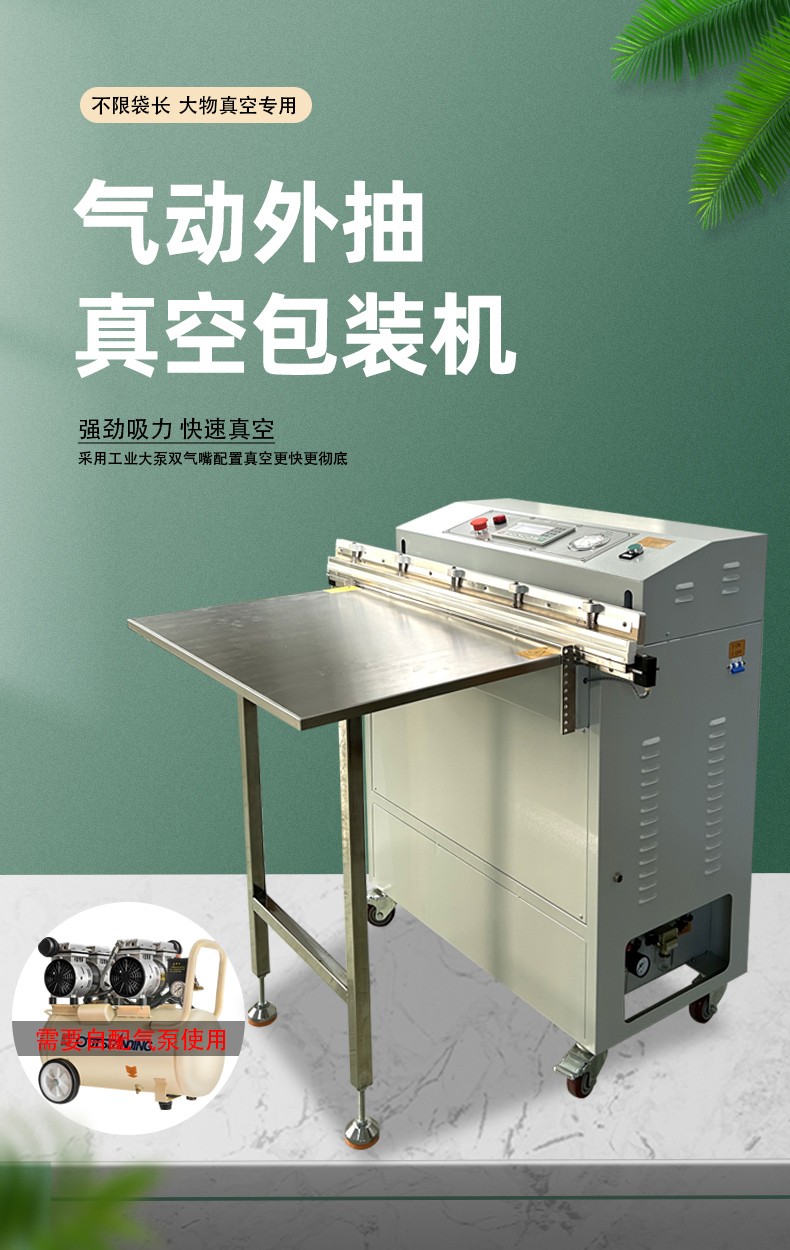

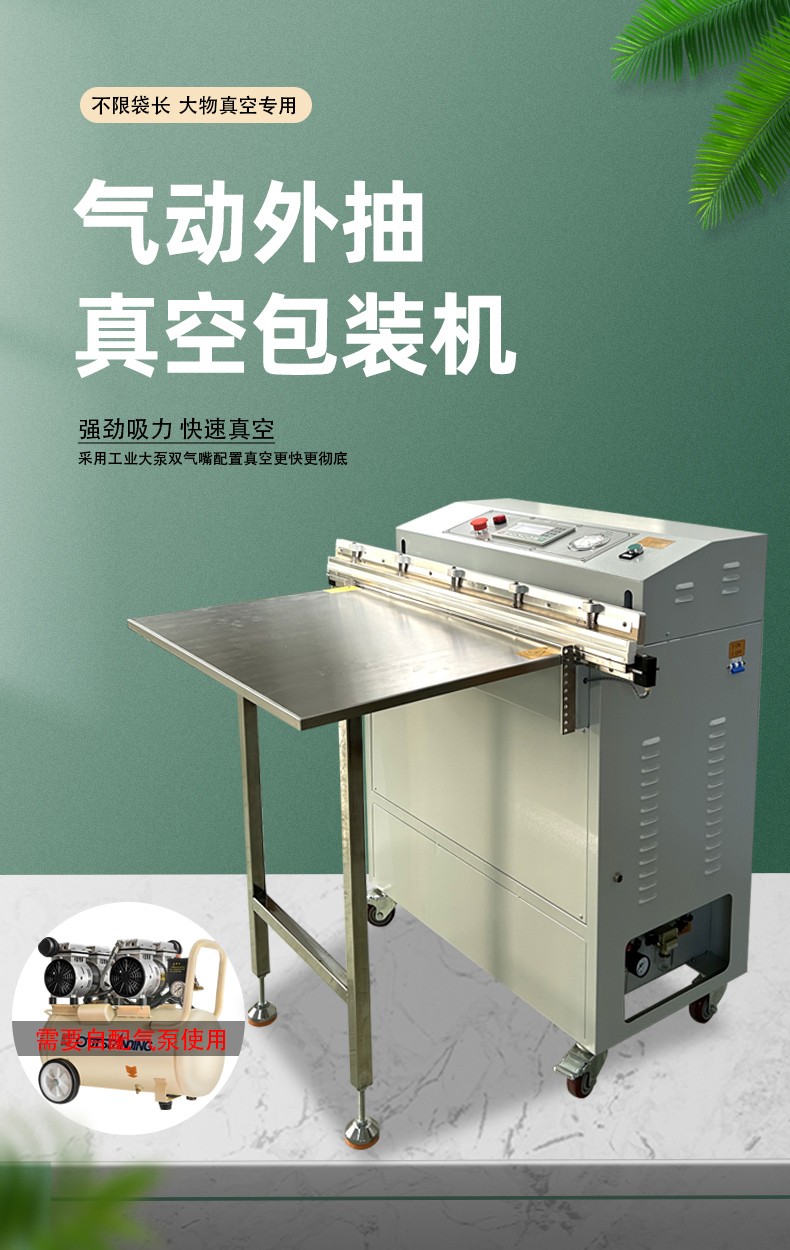

Medium semi-automatic machines (commonly used in industrial production lines):

The single cycle time is 8-15 seconds, with an efficiency of up to 4-8 cycles per minute (240-480 cycles per hour). Equipped with a pneumatically driven automatic sealing device, the pumping rate is faster, but manual placement of materials and films is still required. They are suitable for medium-batch, small to medium-sized items (e.g., meat, electronic components).

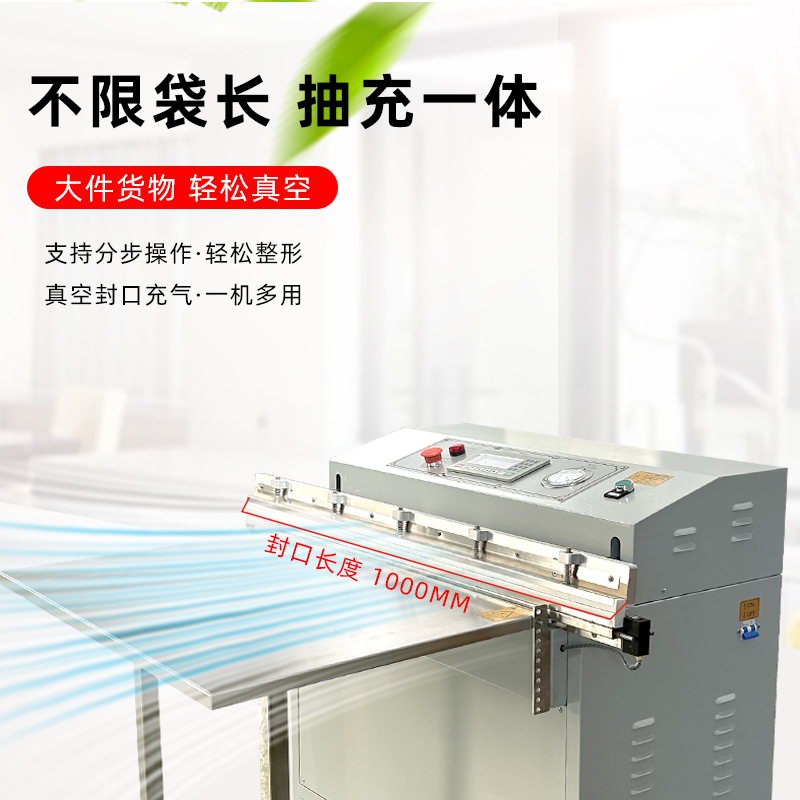

Large fully automatic machines (integrated into production lines):

The single cycle time is 5-10 seconds, with an efficiency of up to 6-12 cycles per minute (360-720 cycles per hour). Featuring automatic feeding via conveyor belts and positioning assisted by robotic arms, the pumping and sealing processes are fully automated. They are suitable for large-batch, standardized-sized items (e.g., food gift boxes, medical devices).

II. Key Factors Affecting Work Efficiency

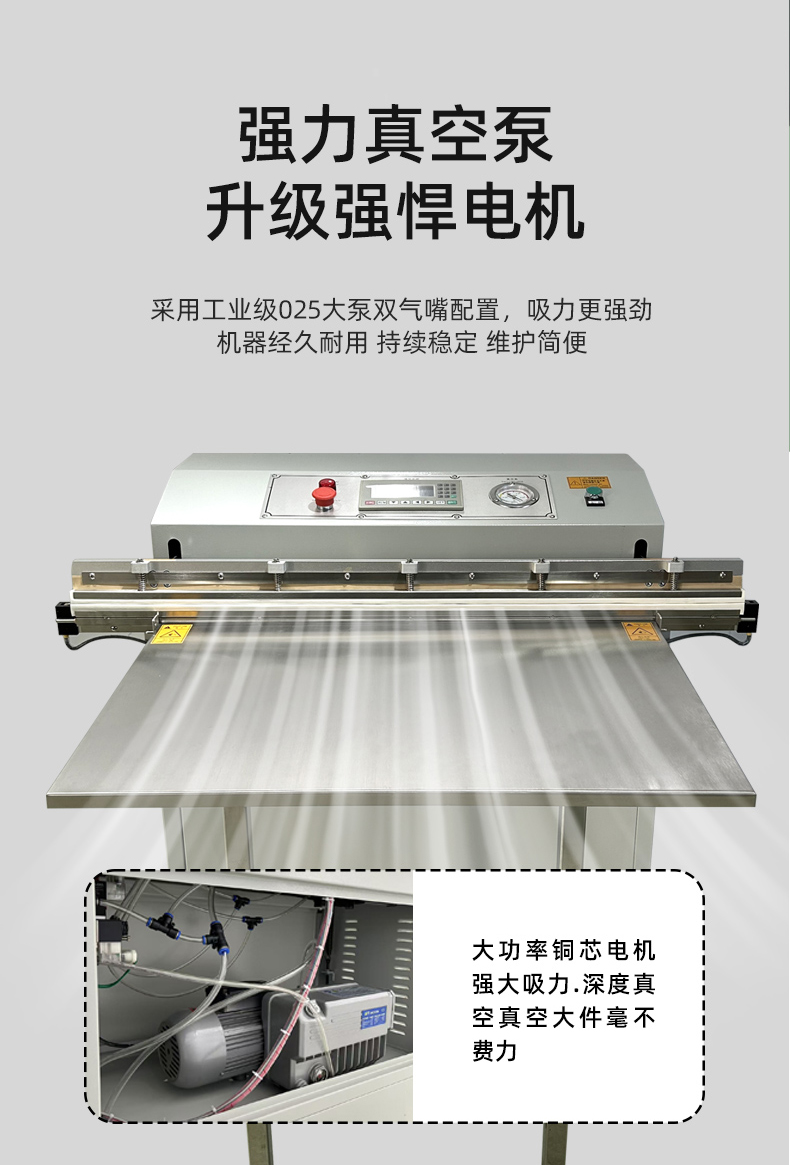

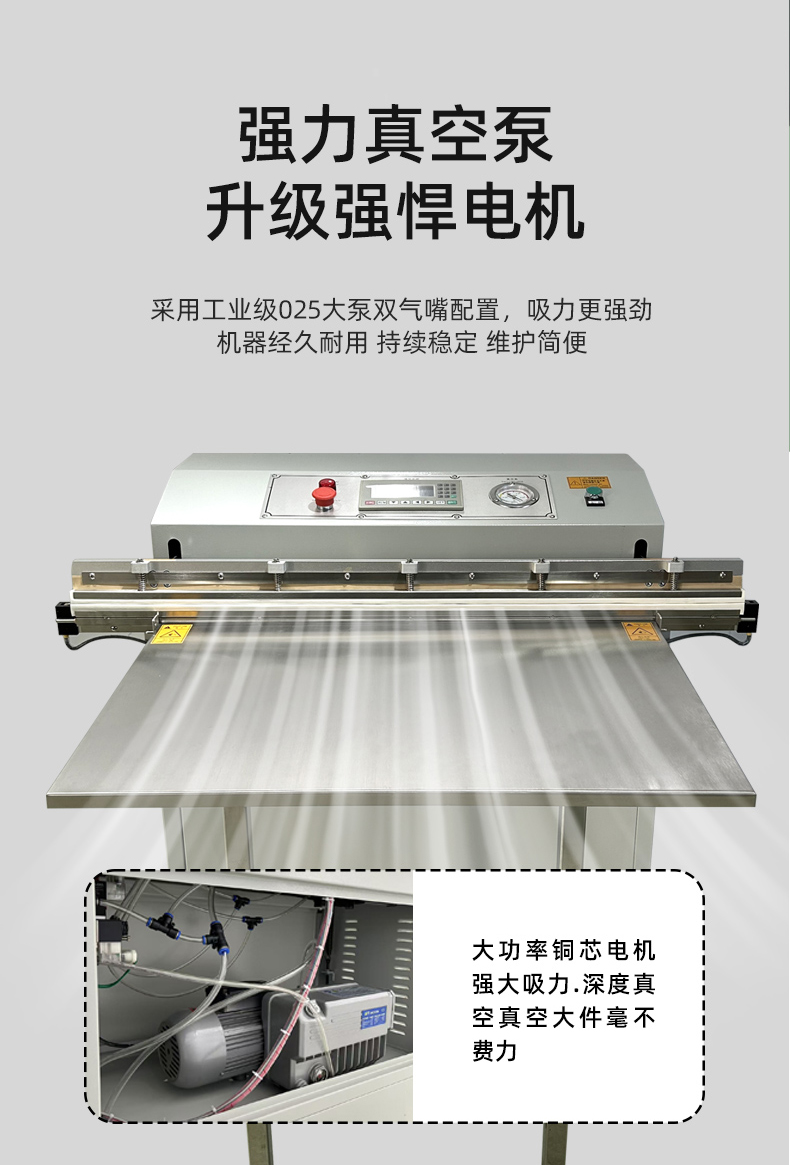

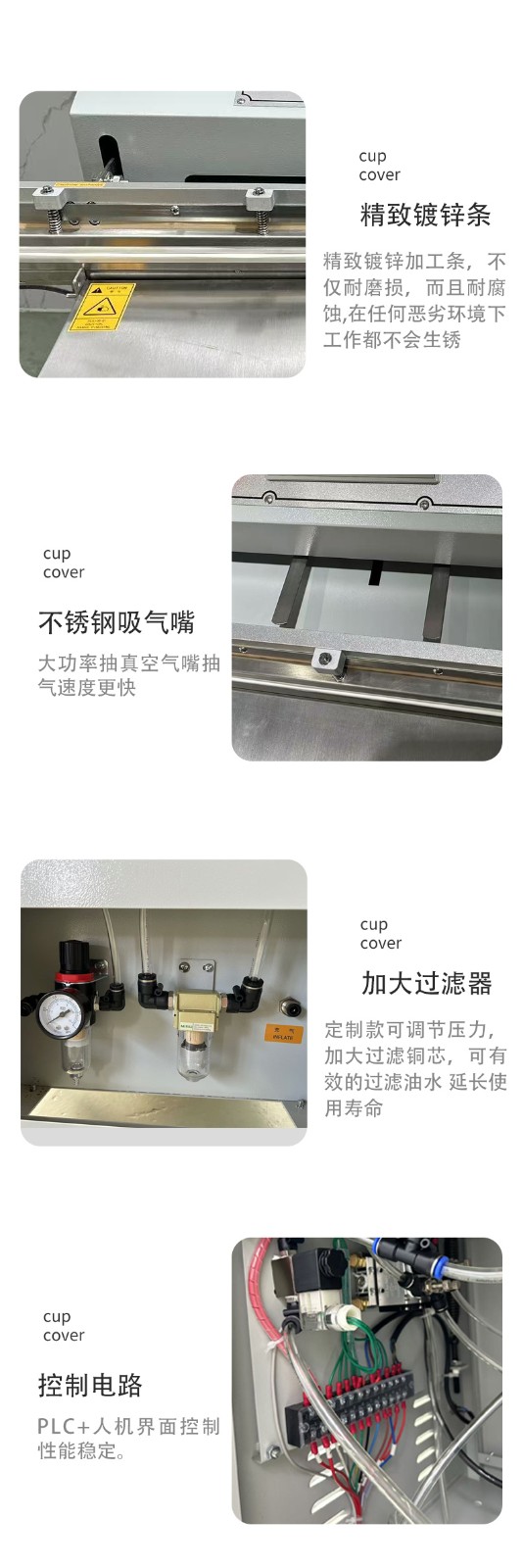

Pumping time

The pumping efficiency of external vacuum machines depends on the vacuum pump power (usually 1.5-5.5kW) and vacuum degree requirements:

- For materials requiring high vacuum (e.g., meat preservation with a vacuum degree of ≤-0.09MPa), the pumping time is extended (3-8 seconds), slowing down the overall cycle.

- For basic vacuum needs (e.g., moisture-proof packaging with a vacuum degree of -0.06~-0.08MPa), the pumping time can be shortened to 2-5 seconds, improving efficiency.

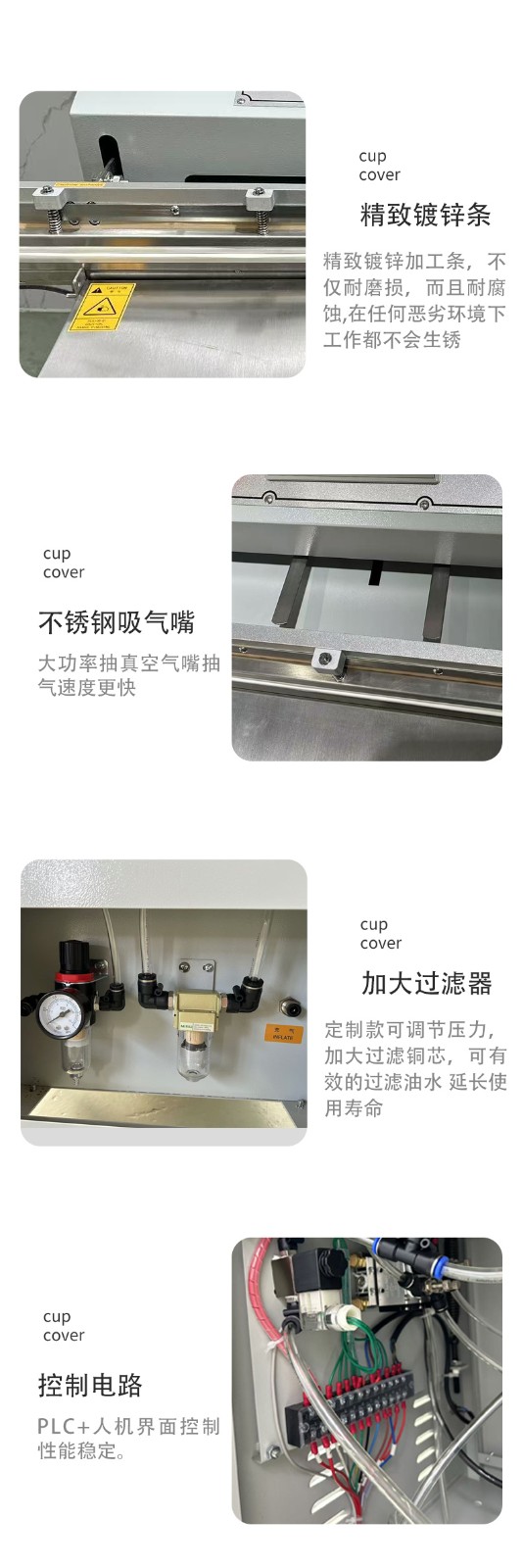

Sealing time and cooling time

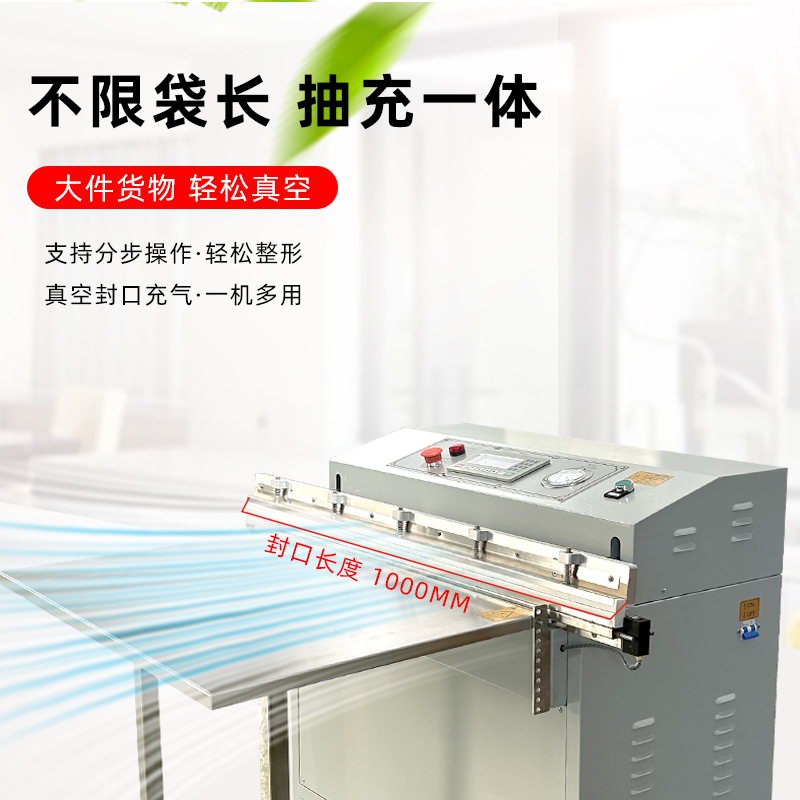

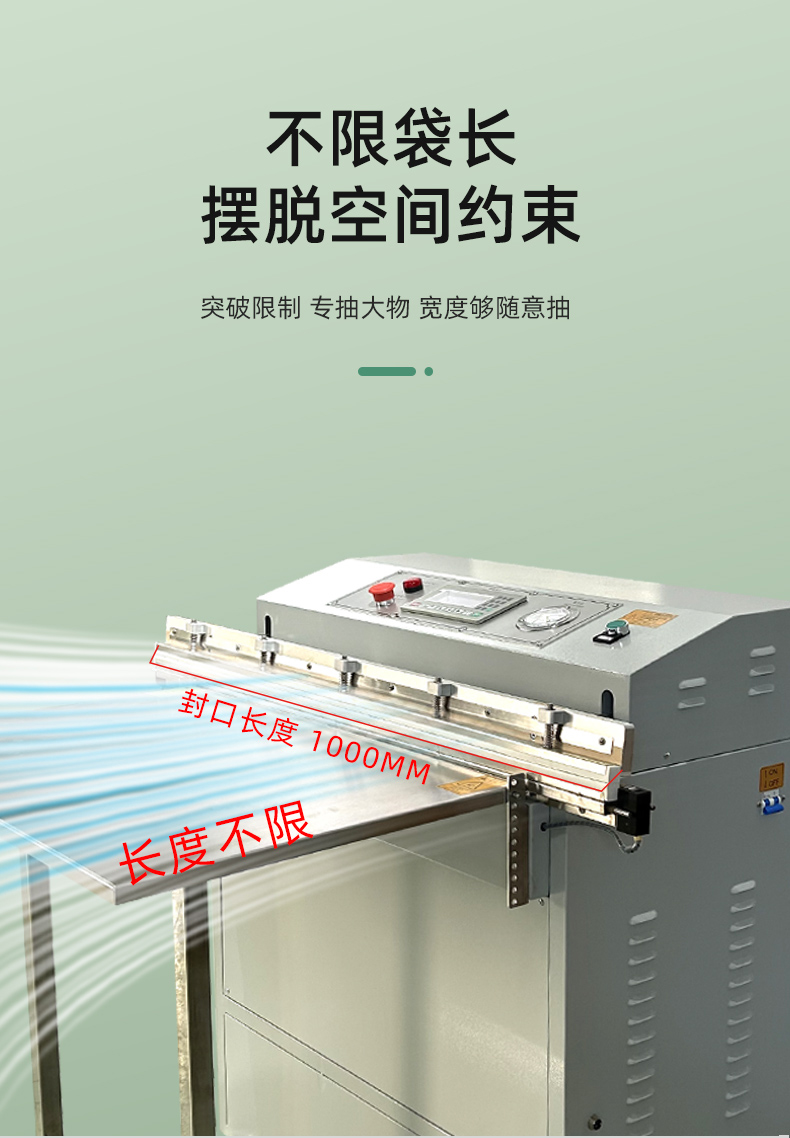

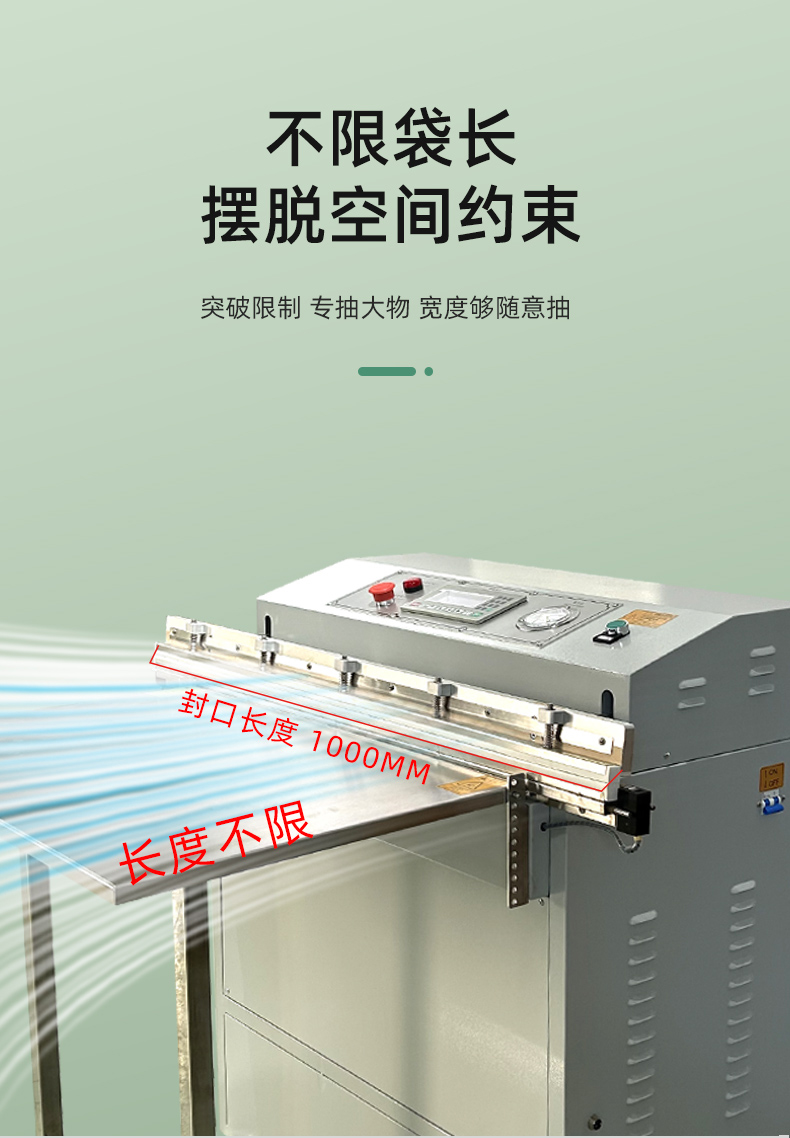

The sealing process requires heating (0.5-3 seconds) and cooling for shaping (1-3 seconds), which are affected by the length of the sealing strip and temperature settings:

- Long sealing strips (e.g., over 600mm) or thick films (e.g., composite films ≥0.15mm) require longer heating/cooling time, reducing efficiency.

- Short sealing strips (under 300mm) or thin films (≤0.1mm) can shorten the time and increase the cycle speed.

Operation mode

- Manual/semi-automatic: The time for manual material placement and film adjustment (2-5 seconds per cycle) significantly affects overall efficiency. It is suitable for flexible adjustment but limited batches.

- Fully automatic: Automated feeding and positioning eliminate manual intervention time, increasing efficiency by 30%-50%, but require standardized material sizes.

Material characteristics

- Loose/irregular materials (e.g., clothing, toys): Need manual sorting and placement, increasing single-operation time and reducing efficiency.

- Regular/hard materials (e.g., metal parts, block-shaped food): Can be positioned quickly, adapting to automated processes with more stable efficiency