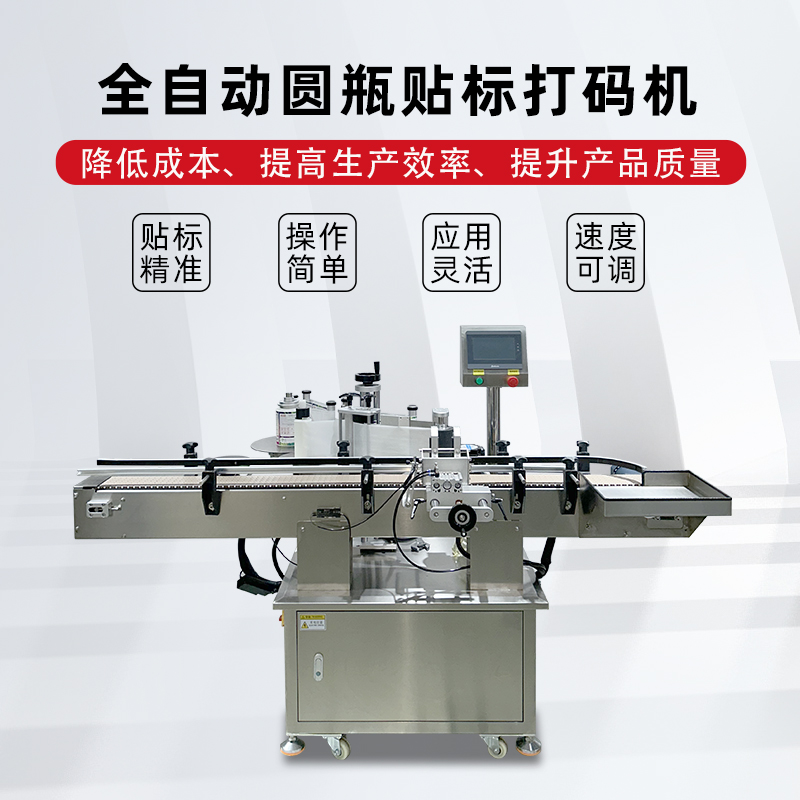

The working principle of the automatic round bottle positioning labeling machine is to realize the whole process of automatic conveying, positioning, labeling and pressing of round bottles through the coordinated cooperation of mechanical transmission, precise detection and intelligent control. The core lies in ensuring that the label is pasted at the specified angle or position of the bottle through a positioning mechanism. Its specific workflow can be divided into the following 6 key links:

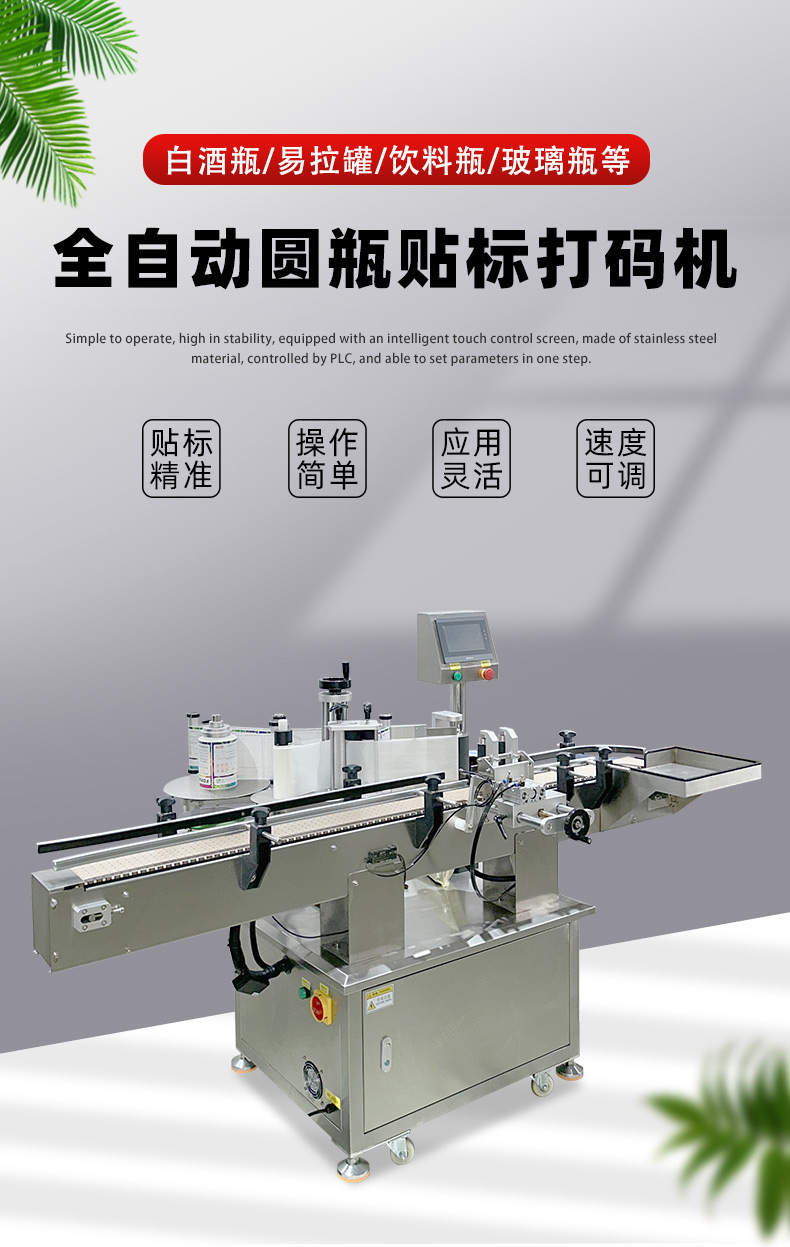

Automatic feeding and bottle conveying

Feeding stage: Round bottles to be labeled are orderly sent into the conveying track through a feeding mechanism (such as a vibrating plate, conveyor belt or manual auxiliary feeding device). The vibrating plate arranges the messy bottles into an upright state through vibration, and pushes them to the conveying line after uniform arrangement; The conveyor belt is suitable for continuous batch feeding, and ensures uniform spacing between bottles through baffles or guide rails.

Conveying stage: The bottles enter the conveying system composed of synchronous belts, chain plates or rollers. The adjustable baffles on both sides restrict the deviation of the bottles to ensure that they move forward stably along a fixed path, providing a stable foundation for subsequent positioning and labeling.

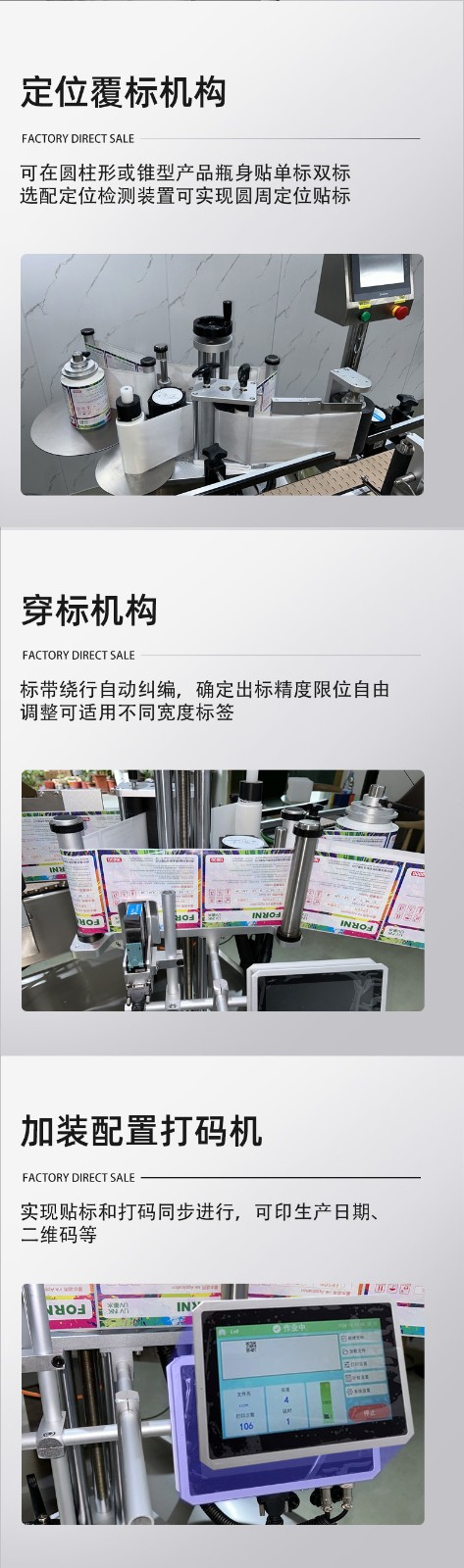

Bottle positioning detection (core link)

Positioning is the key to achieve "precision labeling", aiming to determine the reference position of the bottle (such as the bottle pattern, groove, bottle mouth, etc. that the label needs to be aligned with). The specific process is as follows:

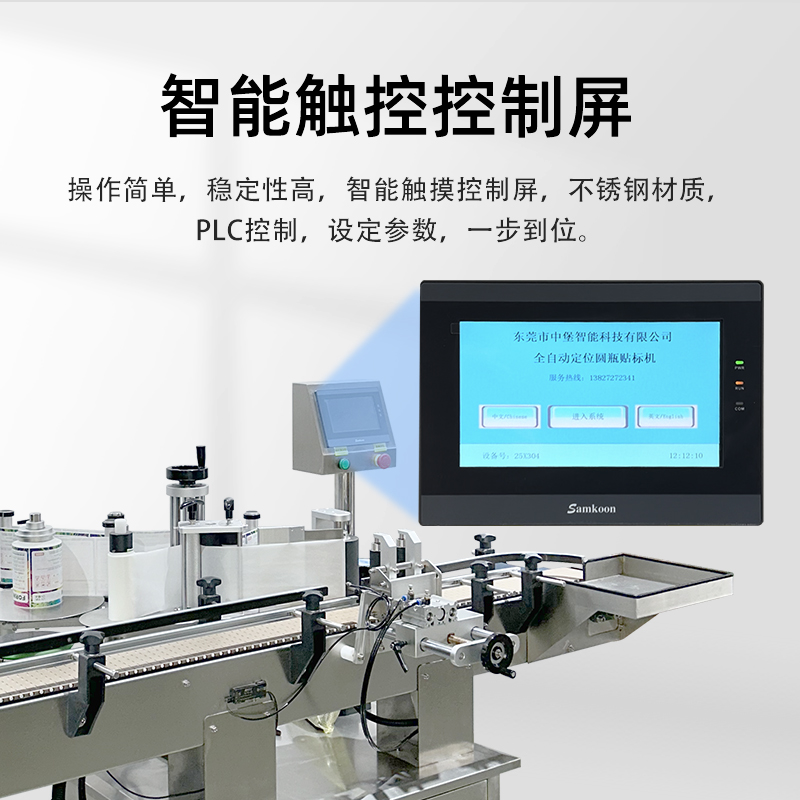

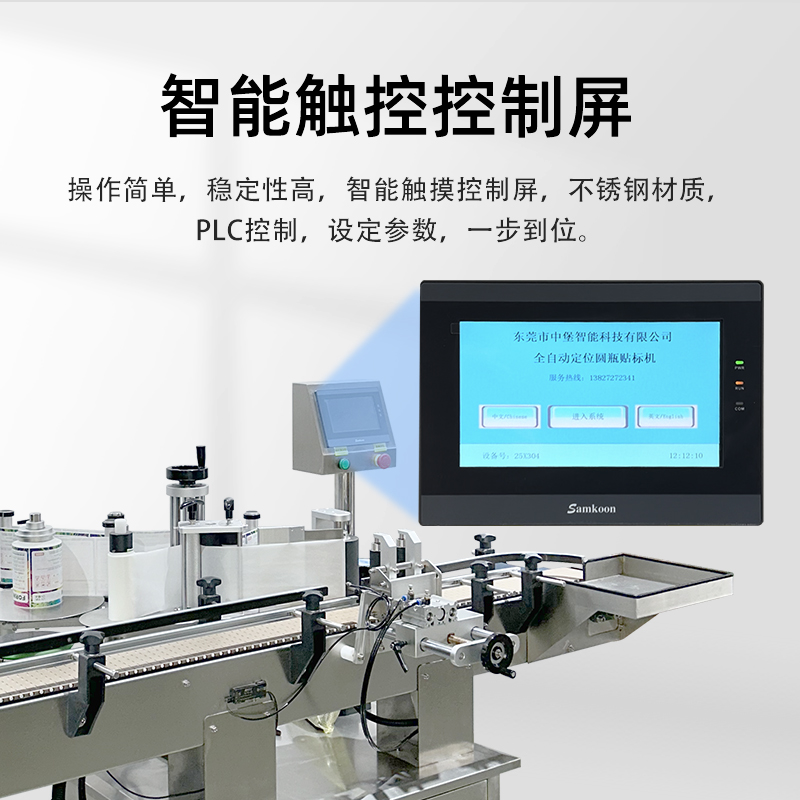

Trigger detection: When the bottle is conveyed to the positioning area, the photoelectric sensor (or proximity switch) detects the bottle and sends a signal to the control system (PLC) to start the positioning program.

Reference point identification:

- Mechanical positioning: The bottle is driven to rotate by a bottle-poking star wheel, rotating gripper or friction wheel. When the physical characteristics of the bottle (such as grooves, bumps) trigger the positioning sensor, the bottle stops rotating, which is the reference angle at this time.

- Visual positioning: High-end models are equipped with a vision system, which takes images of the bottle body and identifies specific patterns (such as logos, color marks). The required alignment angle is calculated through image algorithms, and the servo motor is controlled to drive the bottle to rotate to the target position, with an error controlled within ±0.1mm.

Angle locking: After positioning, the bottle is clamped or kept at a fixed angle by a synchronous conveying mechanism and enters the labeling area.

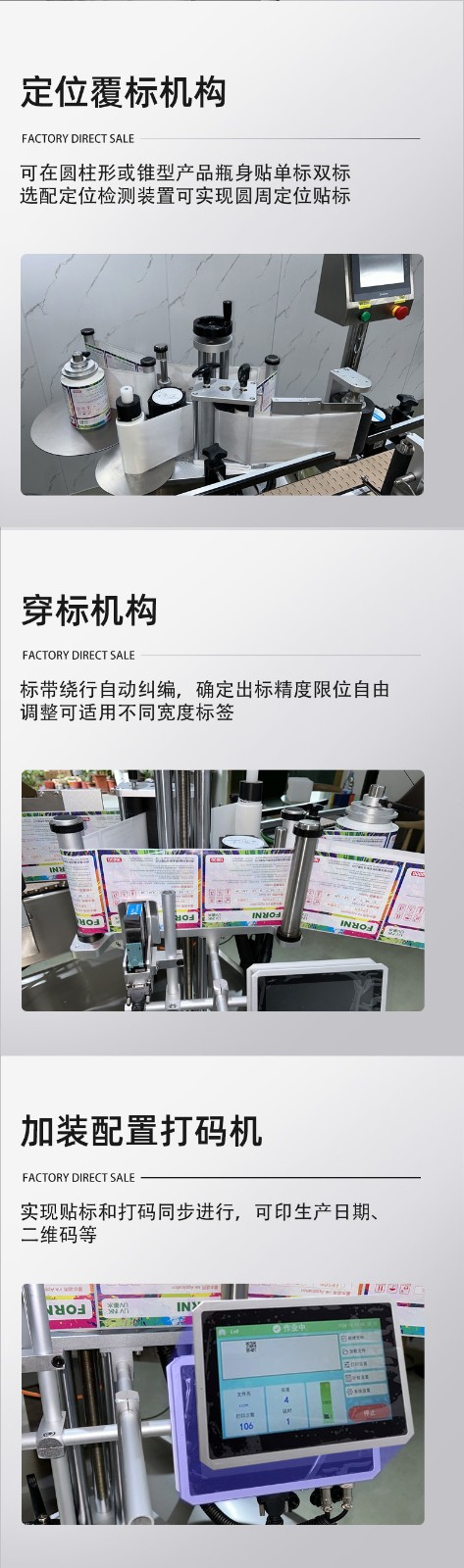

Label peeling and conveying

While the bottle is being positioned, the label mechanism completes label preparation synchronously:

Unwinding device: The label roll (base paper + label) is driven to rotate by an unwinding motor, and a stable unwinding speed is maintained through a tension controller to avoid label wrinkling or breaking.

Peeling process: When the label roll passes through the peeling plate (acute angle structure), the base paper bends due to its low material hardness, and the label is peeled off due to viscosity, standing upright at the edge of the peeling plate waiting for labeling.

Traction and counting: The traction motor drives the base paper to continue moving forward, and the encoder detects the label length in real time. When the length of the peeled label reaches the set value, the control system sends a labeling signal.

Precision labeling

When the positioned bottle reaches the labeling position, the labeling mechanism is precisely synchronized with the movement of the bottle:

Labeling trigger: The PLC controls the labeling roller (or brush) to press the front end of the peeled label on the specified position of the bottle according to the bottle position signal.

Synchronous fitting: The bottle keeps rotating during conveying (or the labeling head moves with the bottle), and the label is gradually fitted with the curved surface of the bottle under the pressure of the labeling roller to ensure that the label is flat without bubbles.

Base paper recycling: The base paper after label peeling is recycled by the rewinding device to avoid scattering and polluting the production line.

Label pressing

After labeling, the bottle enters the pressing area:

The pressing mechanism is usually composed of a sponge wheel, silicone roller or brush. It closely fits the label with the bottle through elastic pressure, especially for the curved surface of round bottles, which can eliminate bubbles, wrinkles or edge warping and ensure that the label adhesion meets the standard.

Some models will adjust the pressing force according to the bottle material (such as glass, plastic) to avoid bottle damage.