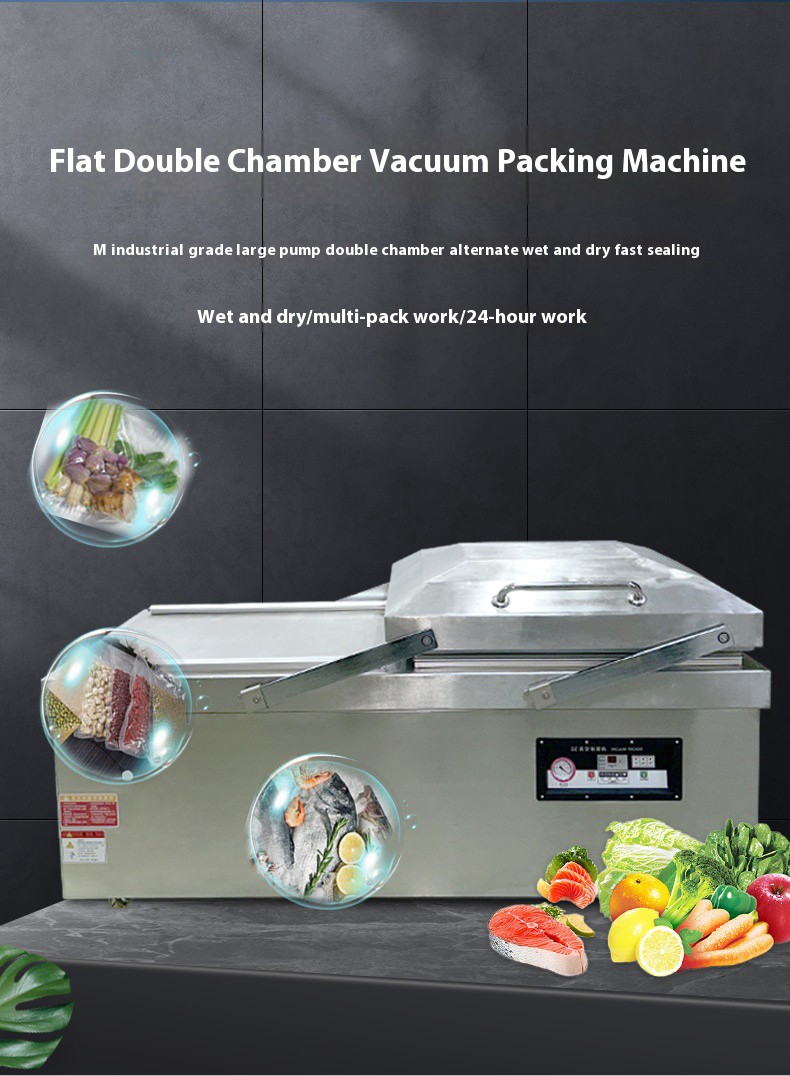

The performance of a flat-plate double-chamber vacuum packaging machine can be evaluated from core dimensions such as vacuum performance, sealing performance, work efficiency, stability, application range, operational convenience, cleaning and maintenance, and safety protection. The following is a detailed analysis:

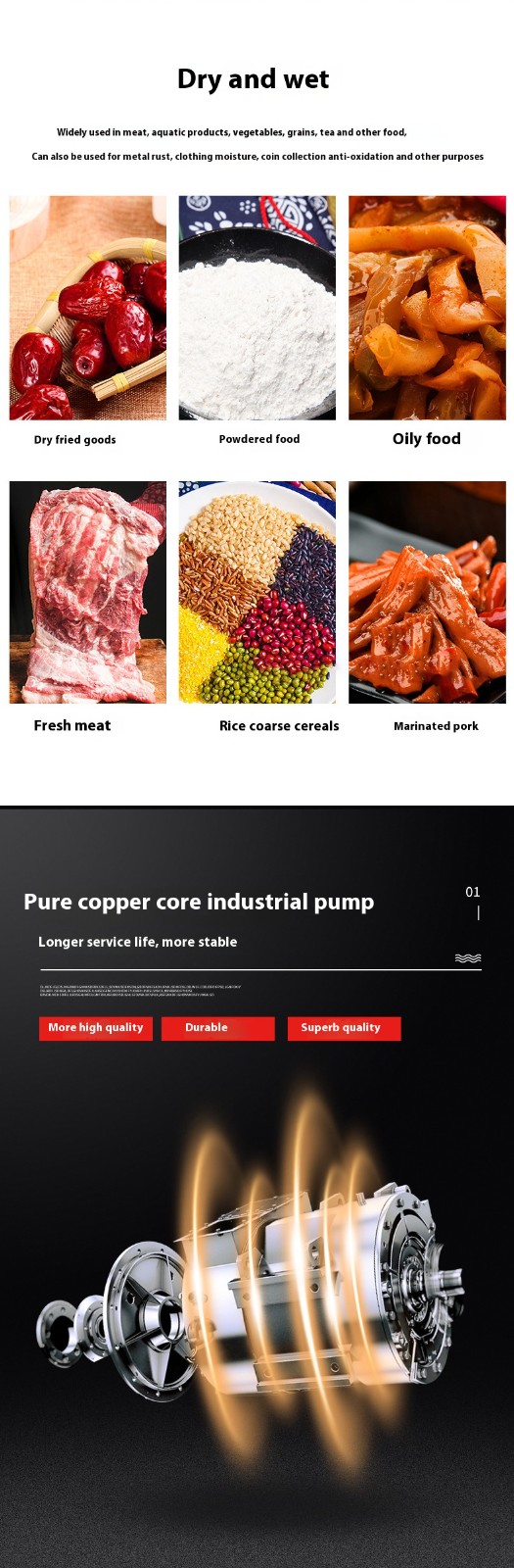

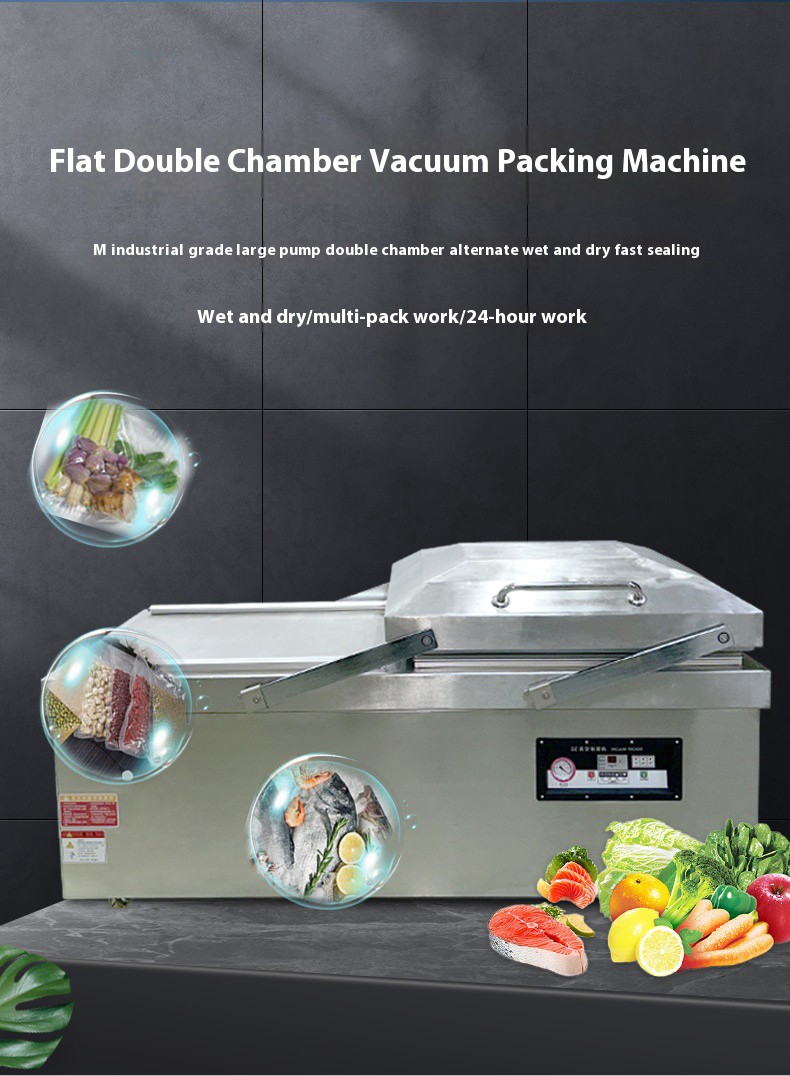

- Typically achieves -0.08MPa to -0.1MPa (close to ultimate vacuum), effectively removing air from packaging bags to inhibit bacterial growth and oxidation reactions. Suitable for scenarios requiring high vacuum levels, such as vacuum packaging of fresh meats, dried goods, and moisture-proof packaging of electronic components.

- Key influencing factors:

- Vacuum pump power (common: 2.2kW–5.5kW)

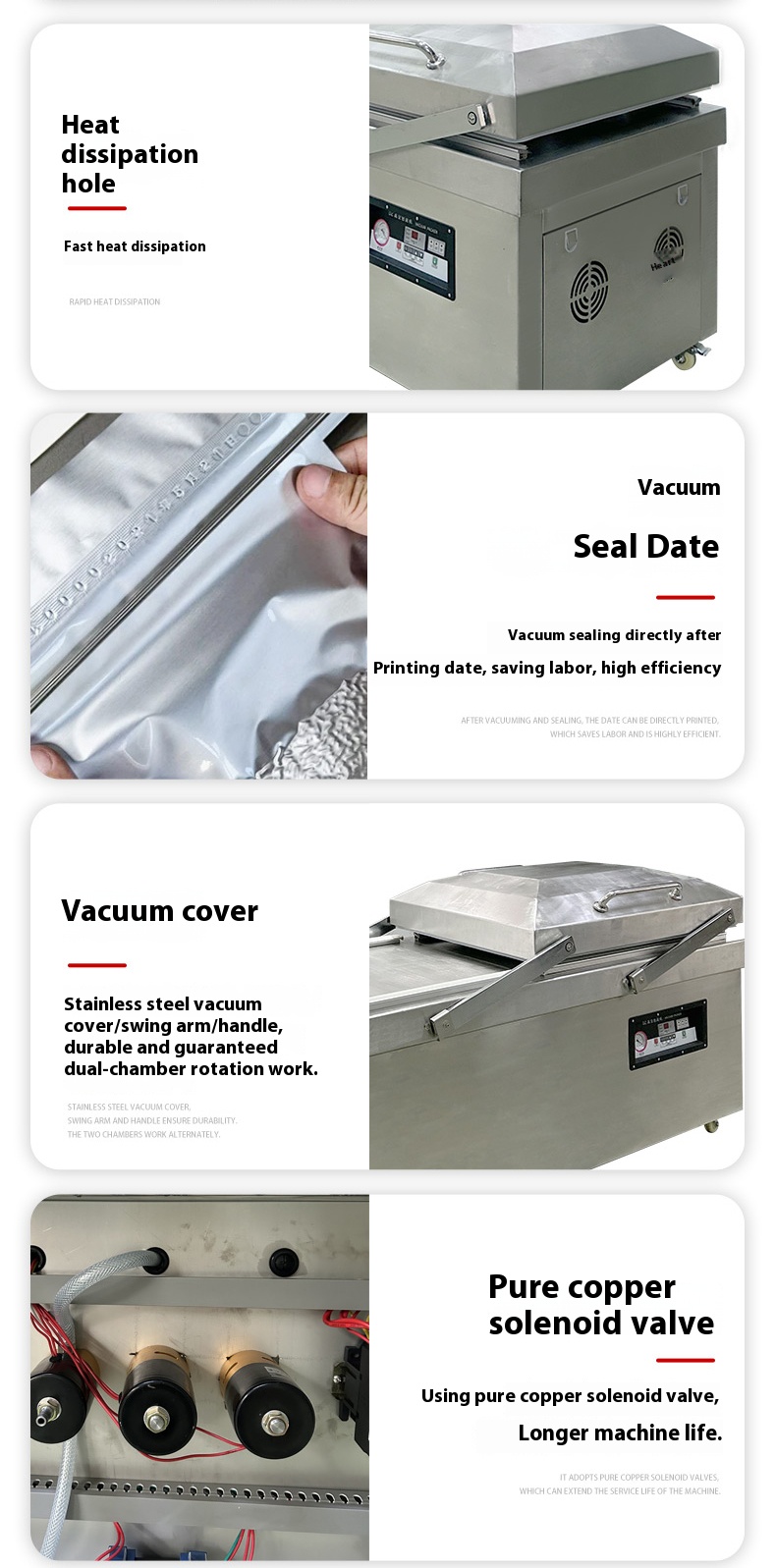

- Sealing performance of the vacuum chamber (silicone sealing strips + stainless steel material)

- Air extraction time (adjustable via the control system, typically 10–30 seconds)

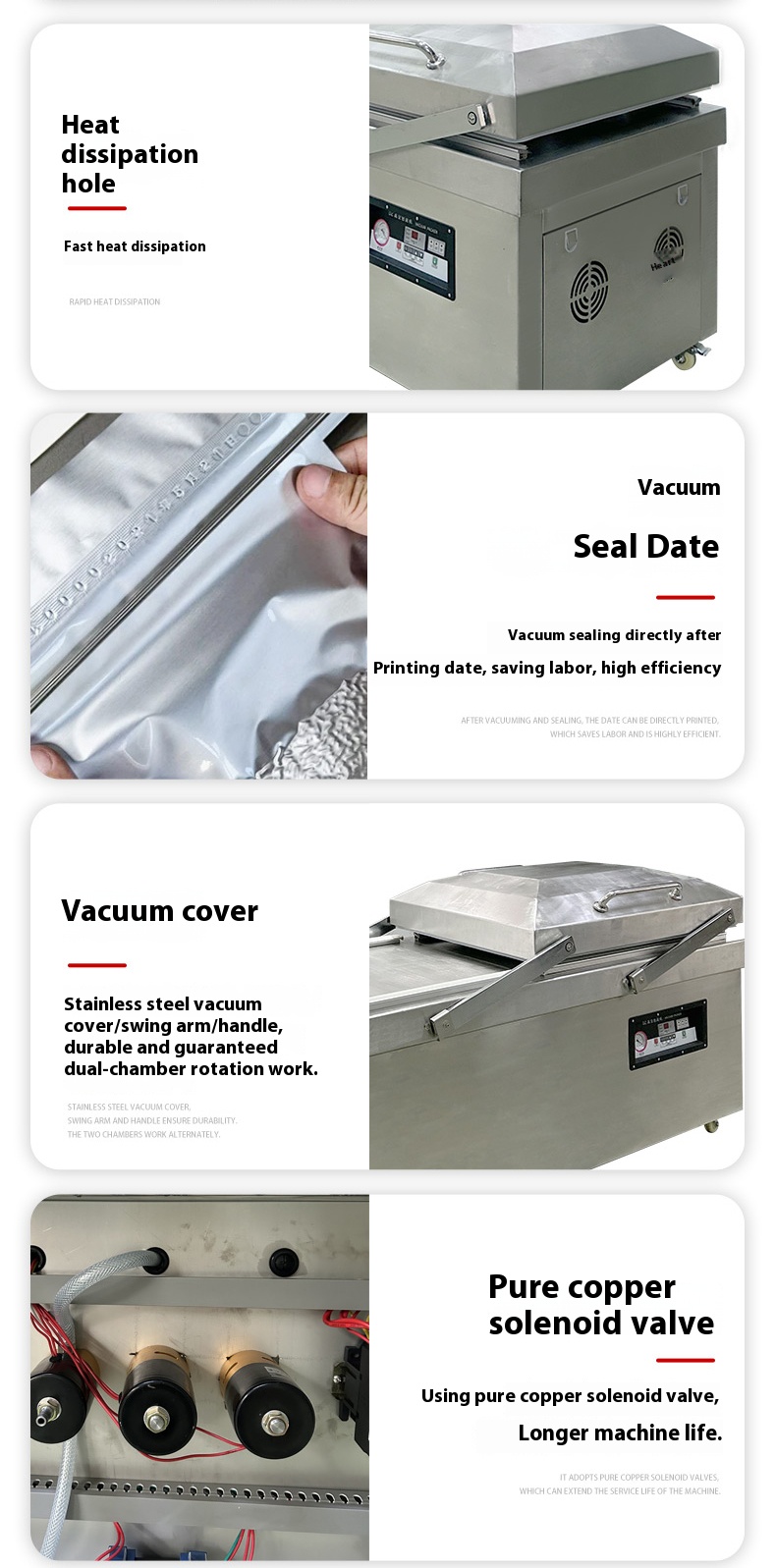

- Dual-chamber independent air extraction design ensures vacuum degree error within ±0.005MPa for each chamber, guaranteeing consistent vacuum effects for products in the same batch.

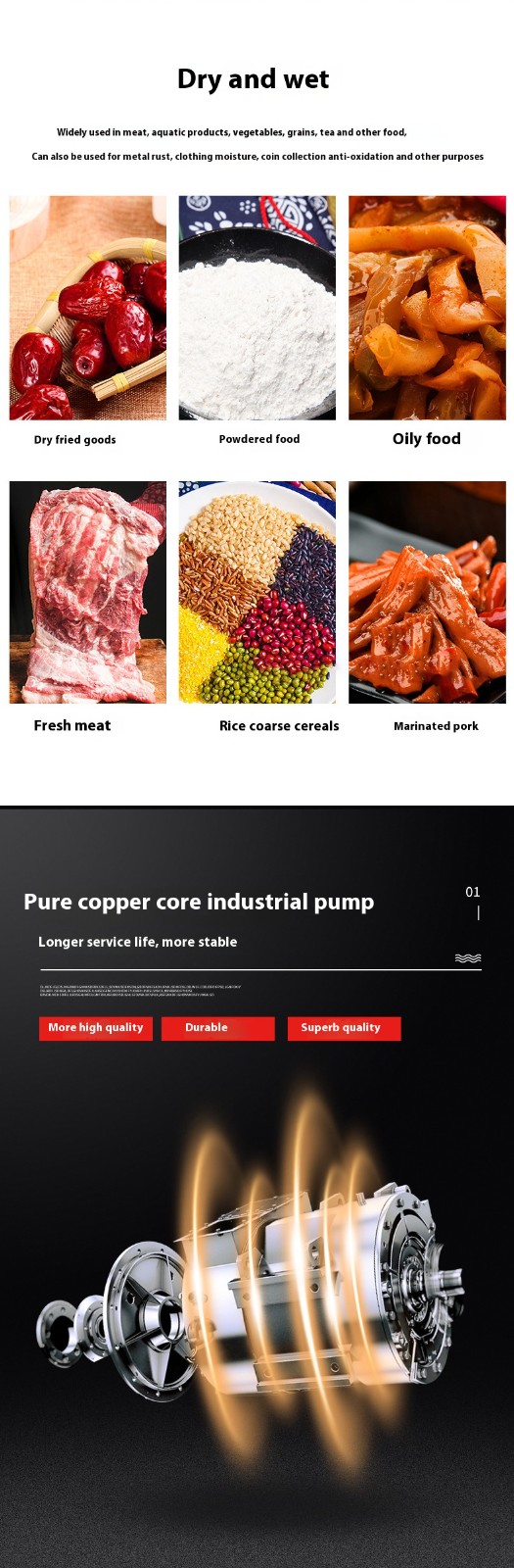

- Utilizes nickel-chromium alloy heating strips (temperature range: 100–250°C adjustable) + pneumatic/hydraulic pressure devices (pressure: 0.3–0.8MPa adjustable).

- Sealing width: typically 8–10mm; sealing firmness reaches ≥20N/15mm (tensile resistance test), preventing air leakage.

- Supports single or multiple sealing tracks (e.g., 2 parallel sealing lines), suitable for packaging liquids and semi-fluids (e.g., pickled vegetables, sauces) to avoid content leakage.

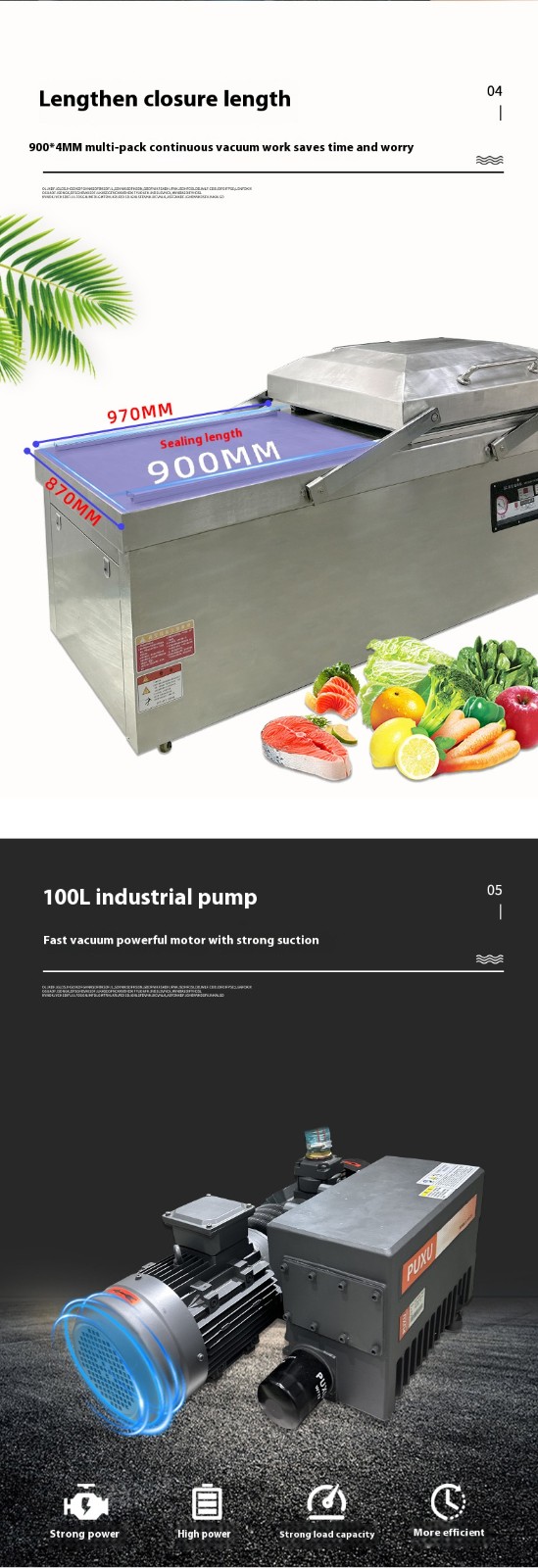

- Adjustable sealing time (5–15 seconds). With dual-chamber alternating operation, the equipment can complete 200–400 sealings per hour (specifically dependent on packaging size and parameter settings).

- Sealing position error ≤ ±1mm, ensuring neat packaging appearance—ideal for scenarios requiring high packaging aesthetics (e.g., gift foods).

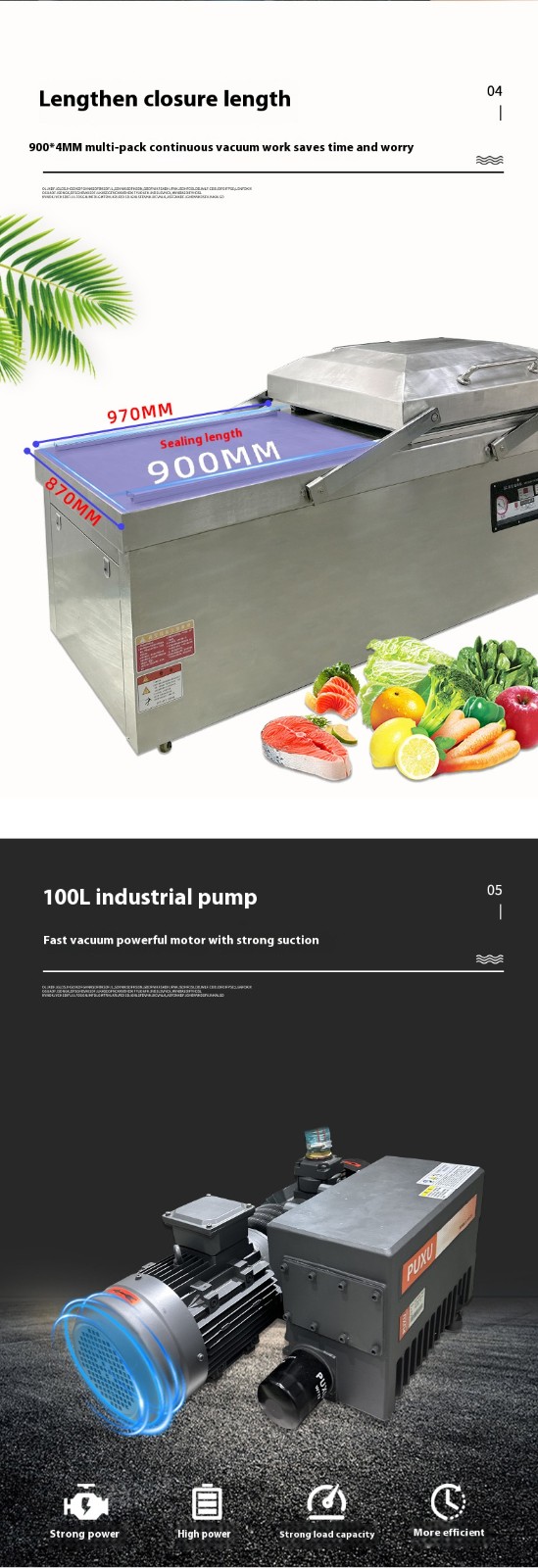

- The upper and lower vacuum chambers can simultaneously perform "vacuuming + sealing" and "loading + unloading," eliminating the need to wait for a single chamber to complete the entire process. Compared with single-chamber models, efficiency is increased by 50%–100%. For example:

- Single-chamber packaging cycle: vacuuming (20 seconds) + sealing (10 seconds) = 30 seconds per cycle.

- Dual-chamber alternating operation: 2 packages completed every 30 seconds (efficiency: 2 cycles/30 seconds).

- Some models support conveyor belt docking (optional), enabling integration into production lines for automatic loading—suitable for large-scale production scenarios (e.g., food processing plants).

- Vacuum pump: Mostly uses rotary vane or water ring vacuum pumps (e.g., German Busch, domestic Feiyue brands), with a continuous service life of ≥8,000 hours and support for 24-hour uninterrupted operation.

- Control system: Microcomputer PLC program control with strong anti-interference capability. The parameter memory function can store 10–20 groups of frequently used packaging programs, reducing repeated setup time