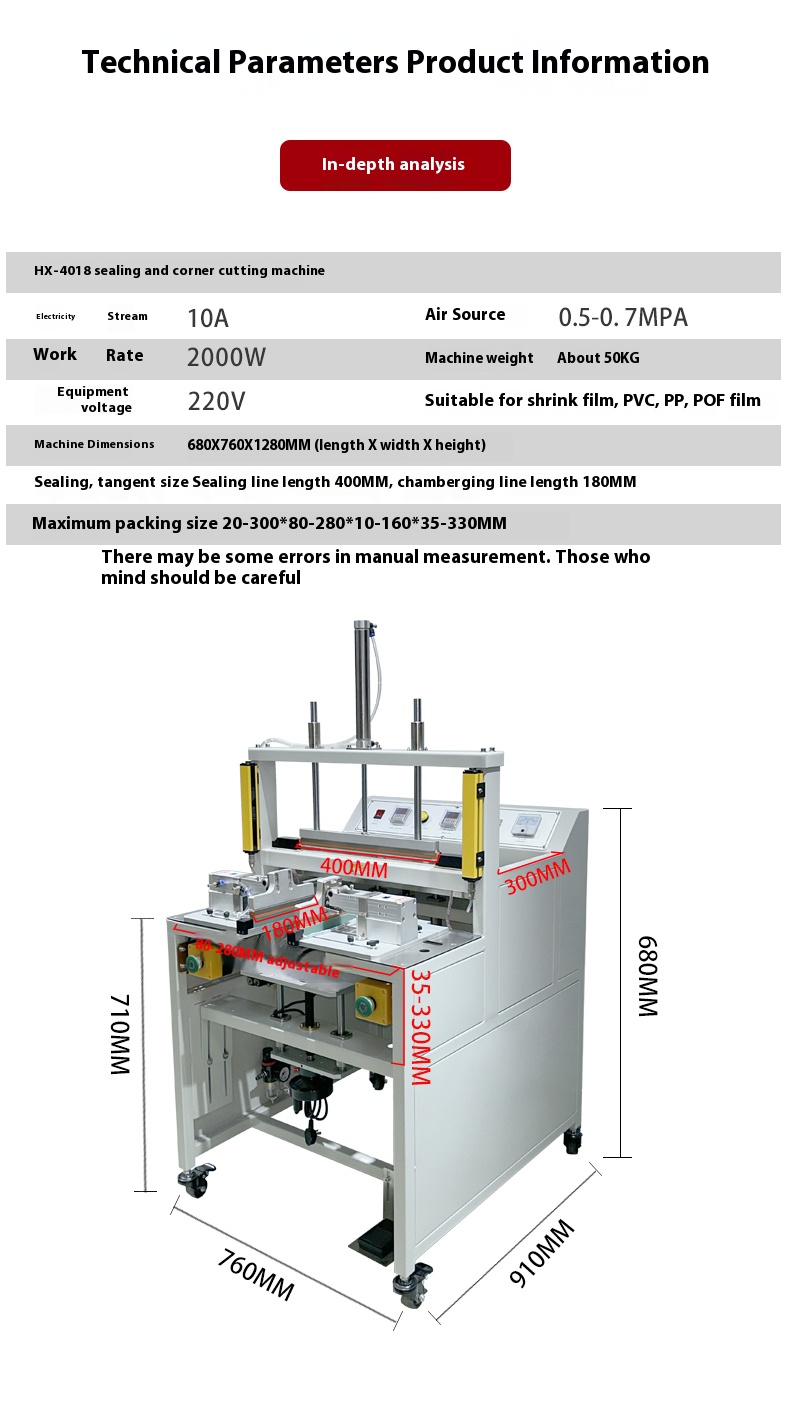

Packaging Materials: Different sealing and corner-cutting integrated machines have varying adaptabilities to packaging materials. If plastic films such as polyethylene (PE) and polypropylene (PP) are used, a device that can be well-matched with these materials should be selected to ensure a good heat-sealing effect. In the case of composite films or aluminum foil composite films, the heat-sealing temperature and pressure adjustment range of the equipment should be wide enough to meet the sealing requirements of multi-layer materials. For example, some high-end models are equipped with an intelligent temperature control system that can automatically adjust the heat-sealing parameters according to different materials, enabling better adaptation to a variety of packaging materials.

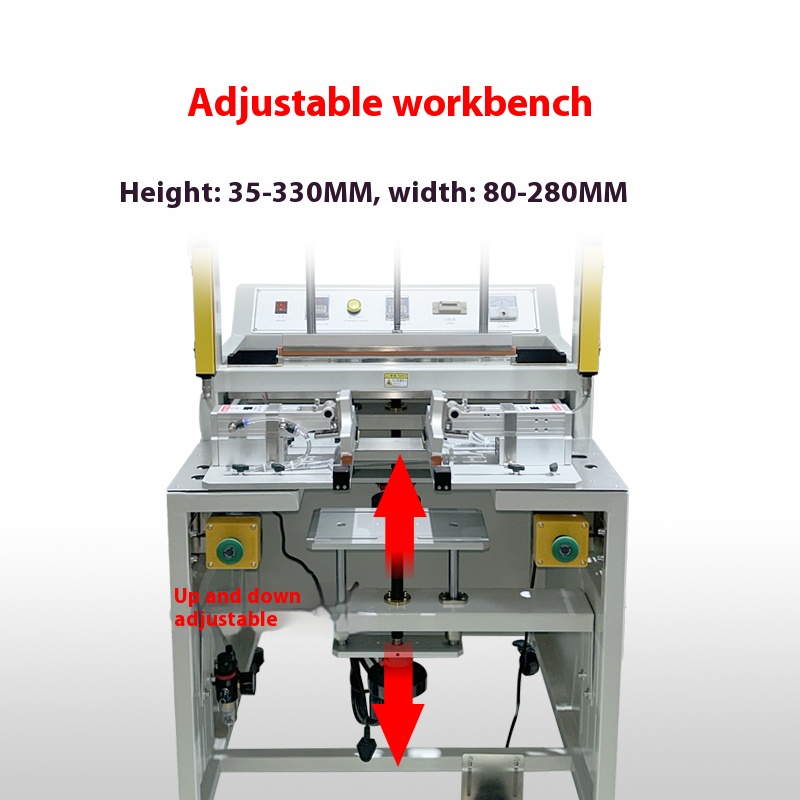

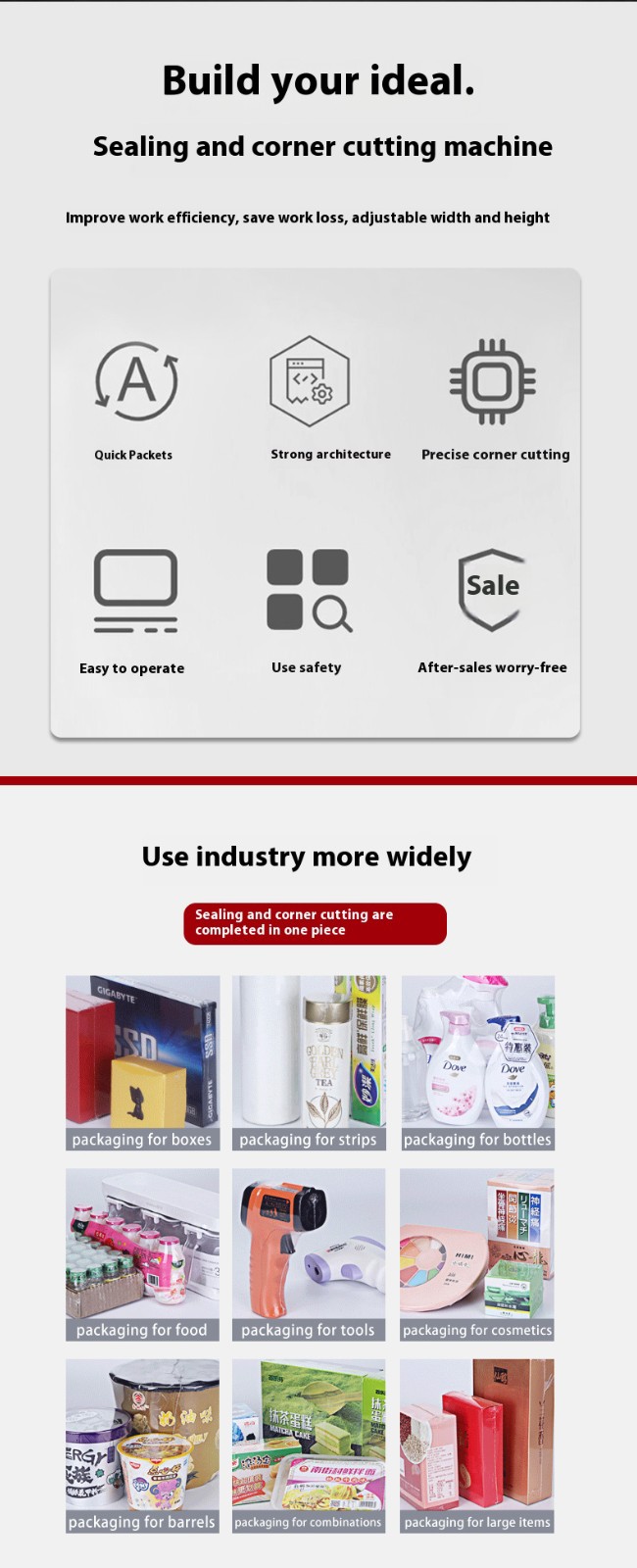

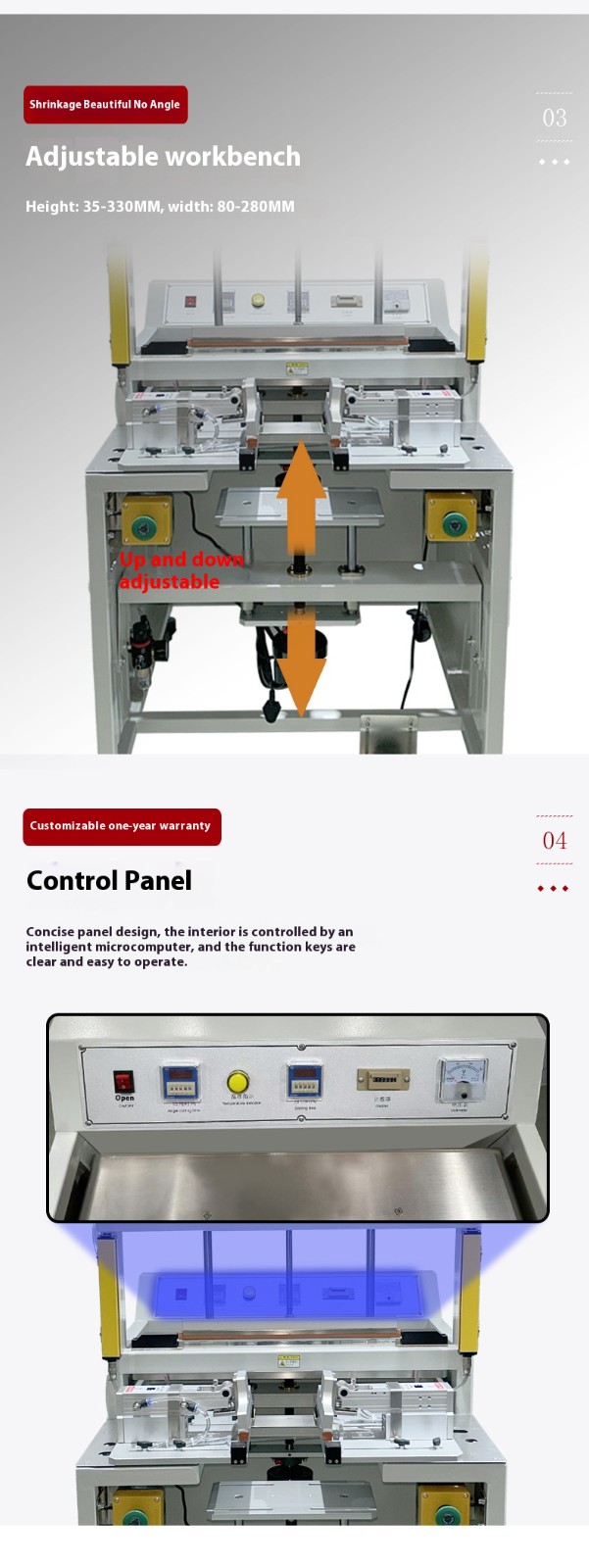

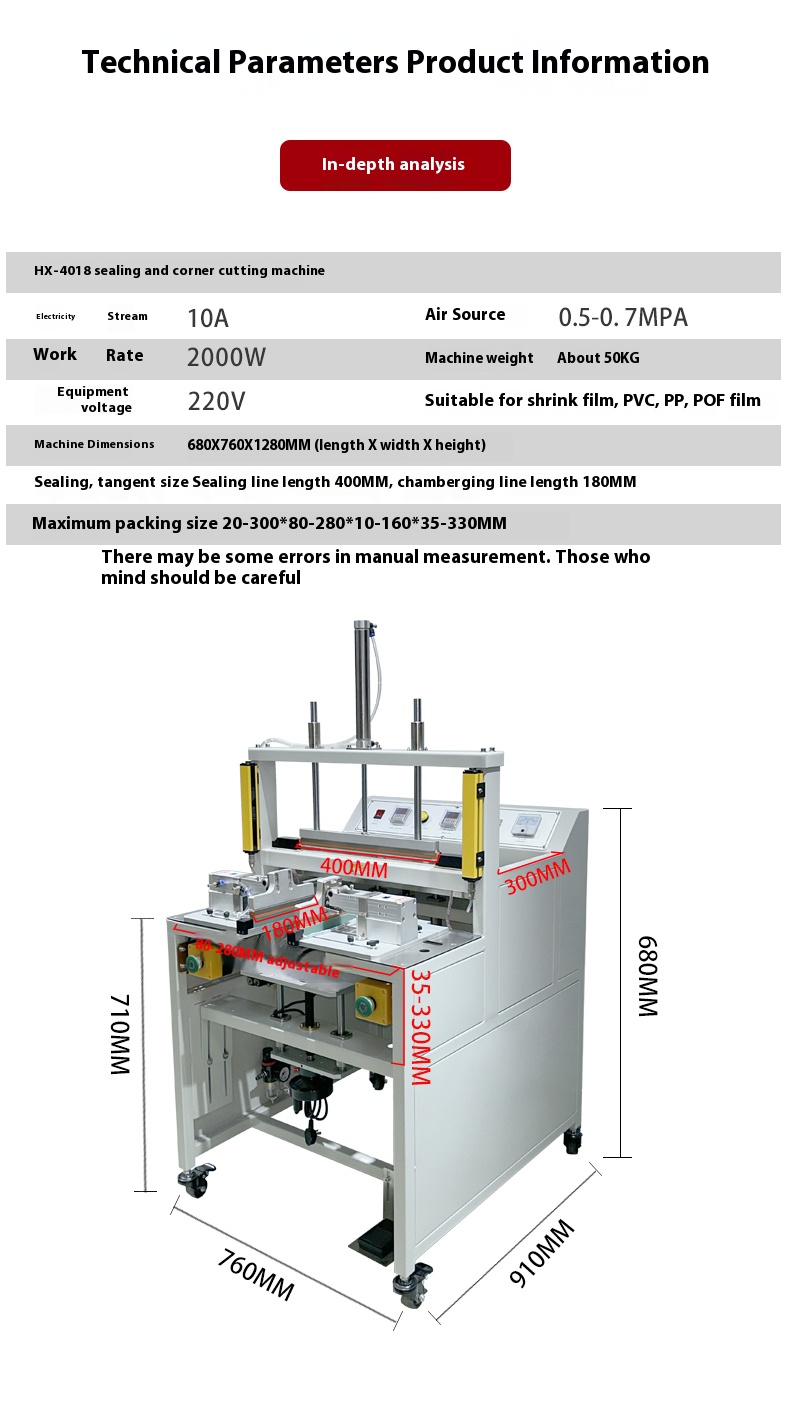

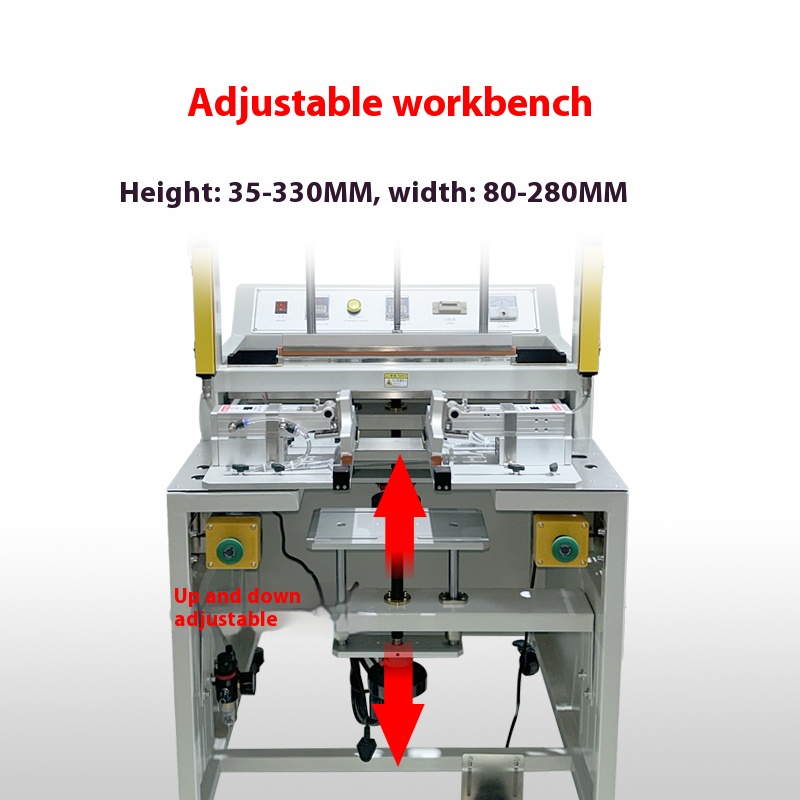

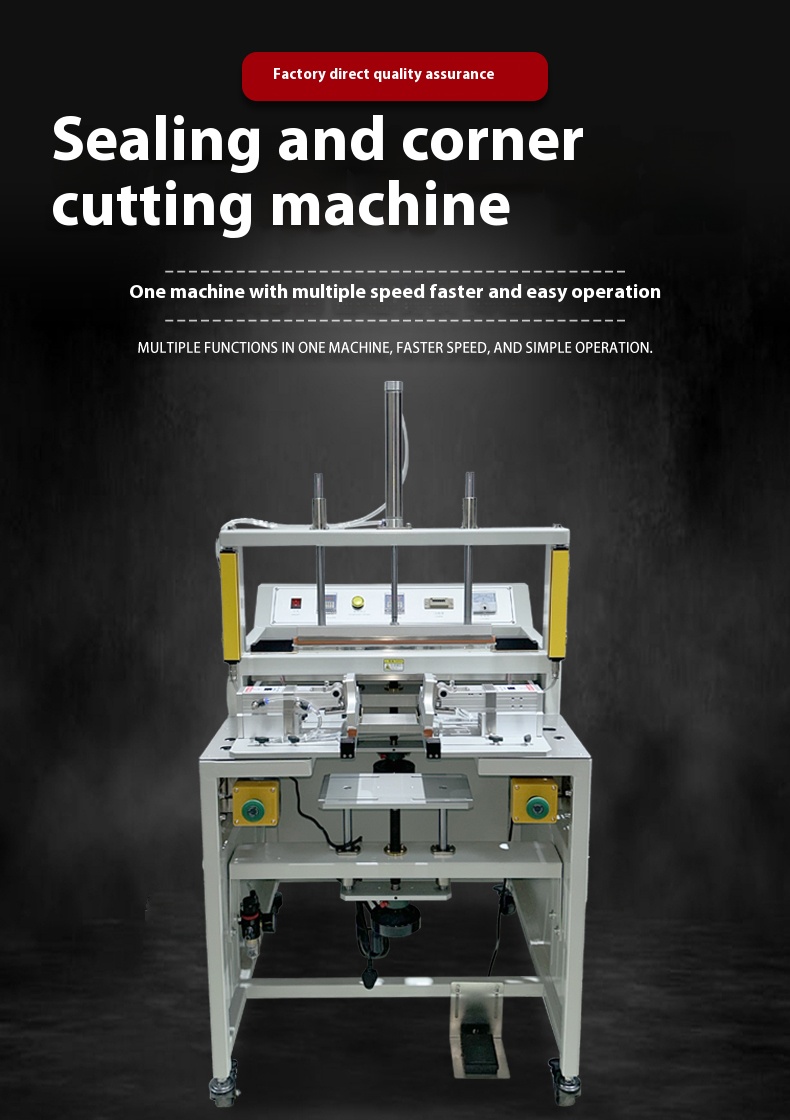

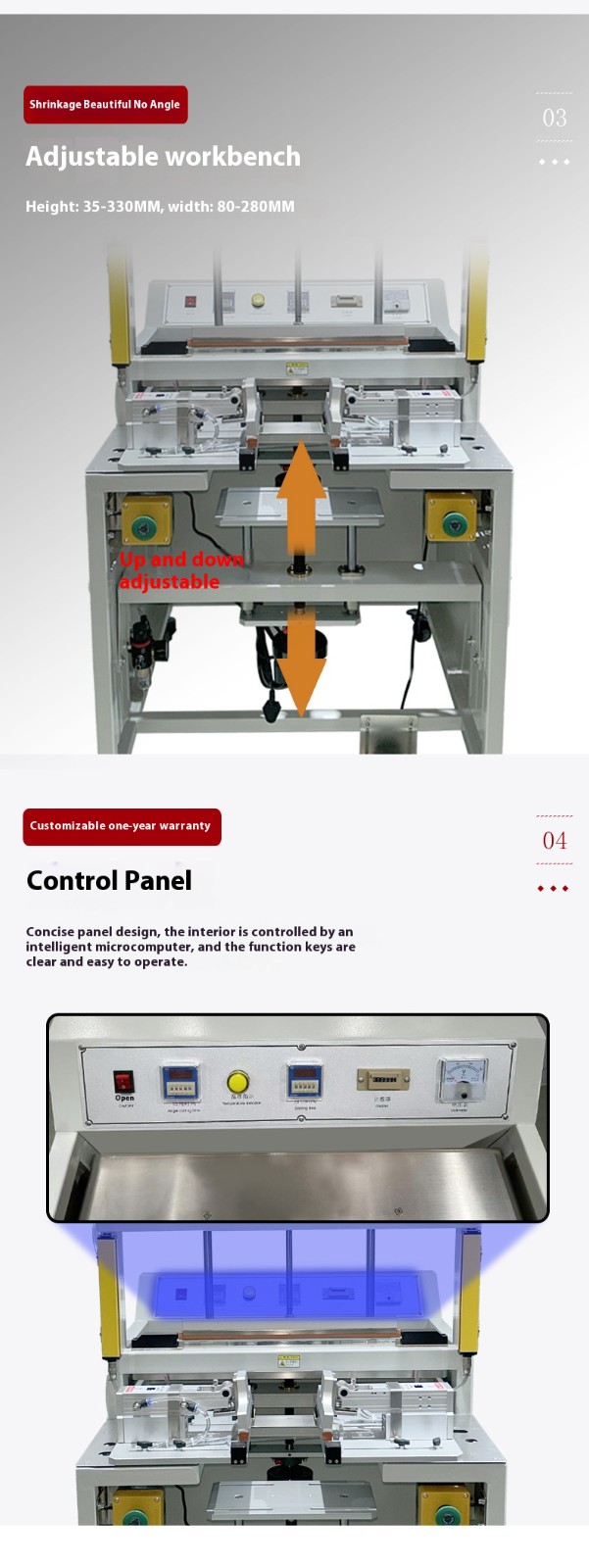

Packaging Size and Shape: The equipment should be selected according to the actual size and shape of the packaging. For small packaging bags, such as those for candies and tablets, a small sealing and corner-cutting integrated machine can be chosen. It has a compact structure and flexible operation, enabling precise handling of small-sized packaging. For large packaging boxes or coiled materials, a device with a large worktable surface and conveying capacity should be selected. Moreover, it is necessary to ensure that the corner-cutting device of the equipment can meet the requirements of special-shaped packaging. For example, custom corner-cutting molds may be required for irregularly shaped packaging.

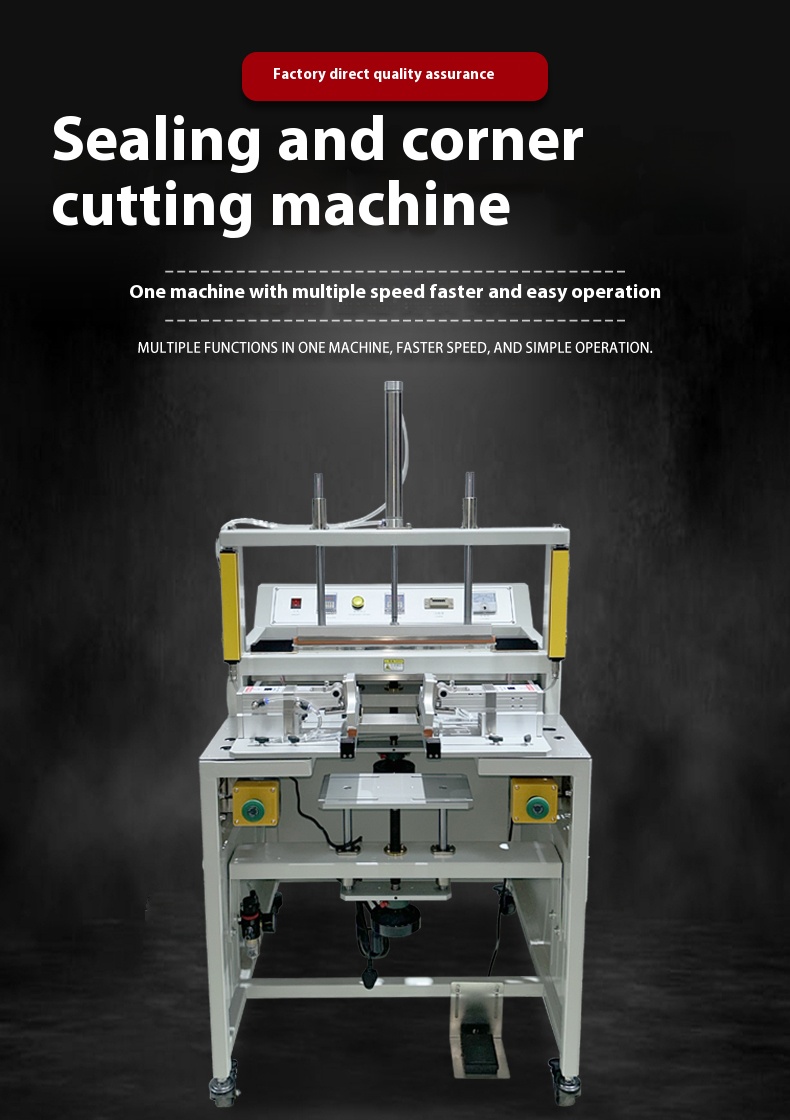

Production Efficiency: The production efficiency of the equipment should be determined according to the production scale and output requirements of the enterprise. For large-scale production, such as in the food and daily chemical industries with production lines, a high-speed sealing and corner-cutting integrated machine is needed. It can complete the sealing and corner-cutting operations of multiple packages per minute, meeting the requirements of the production line's rhythm. For small-batch production or laboratory use, a device with an ordinary speed can meet the needs, avoiding excessive investment in equipment.

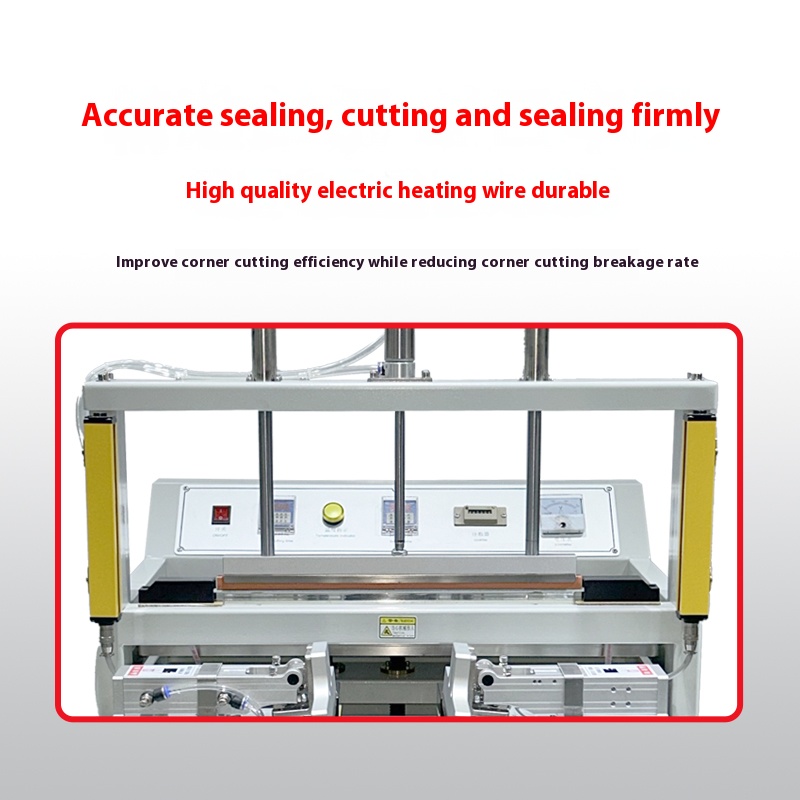

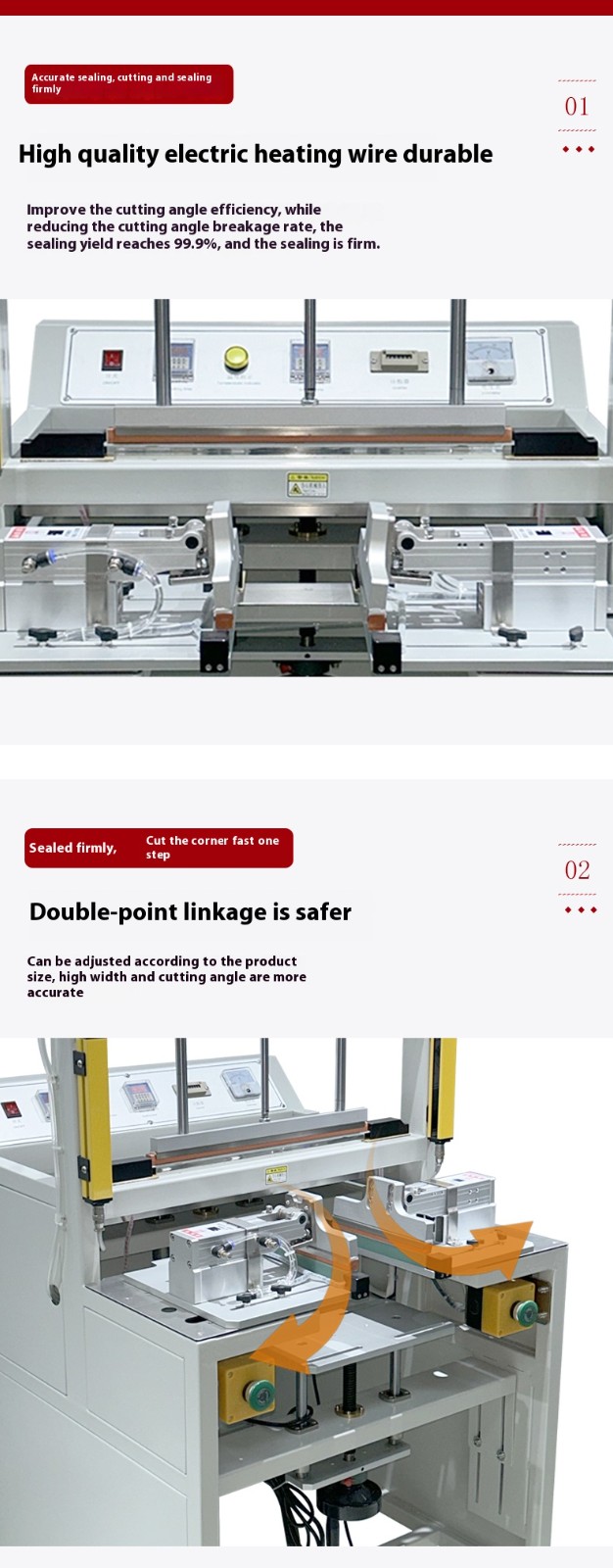

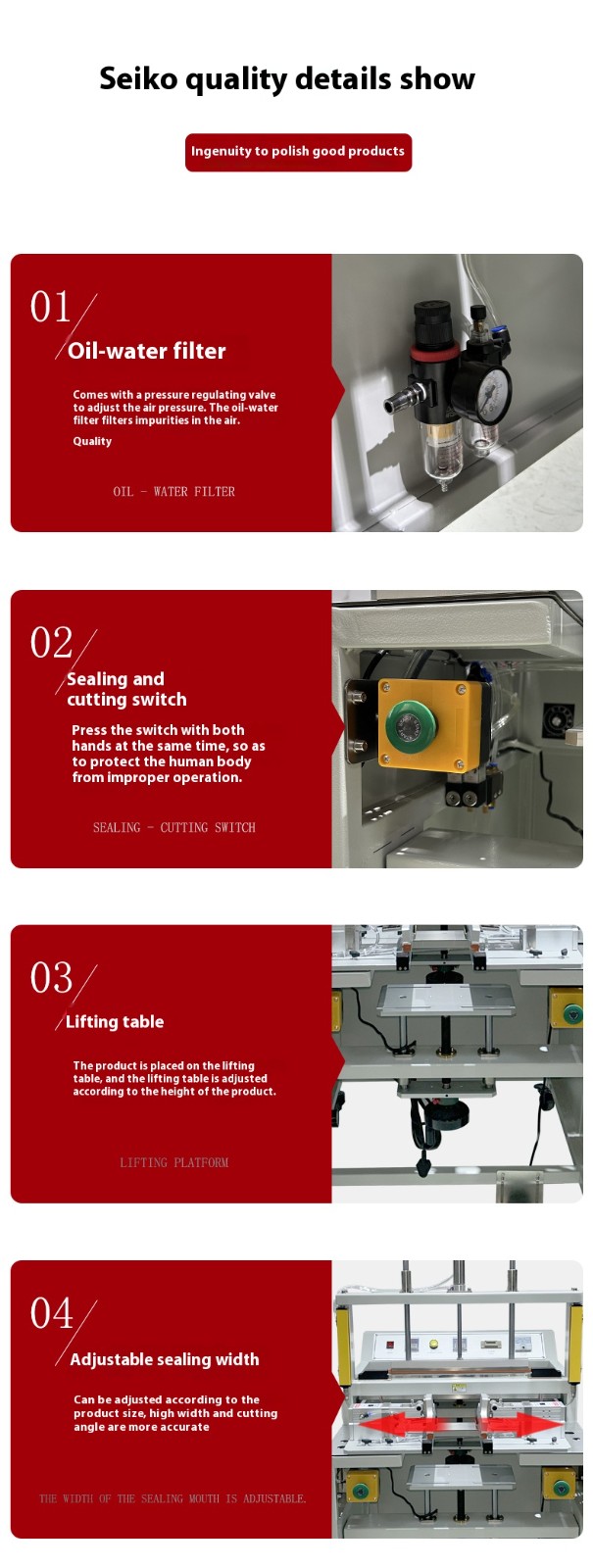

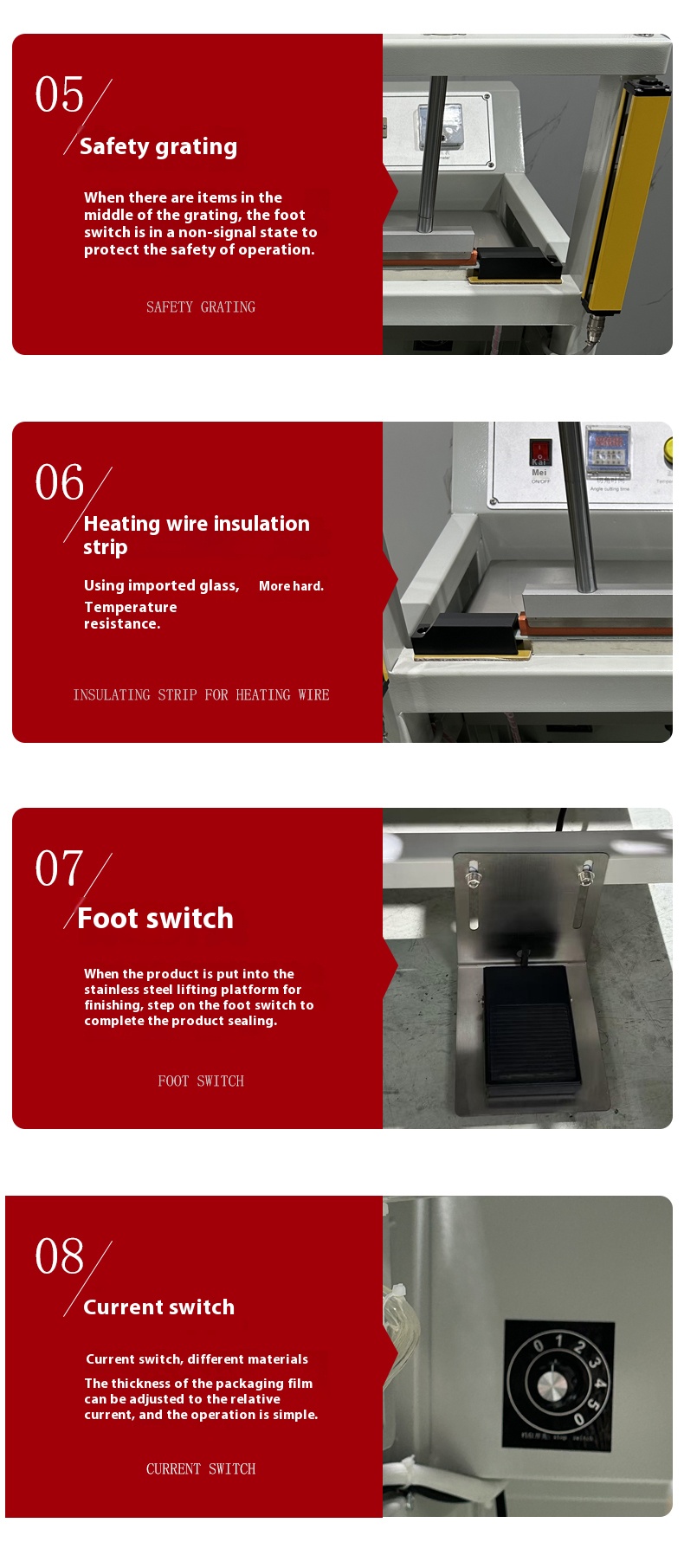

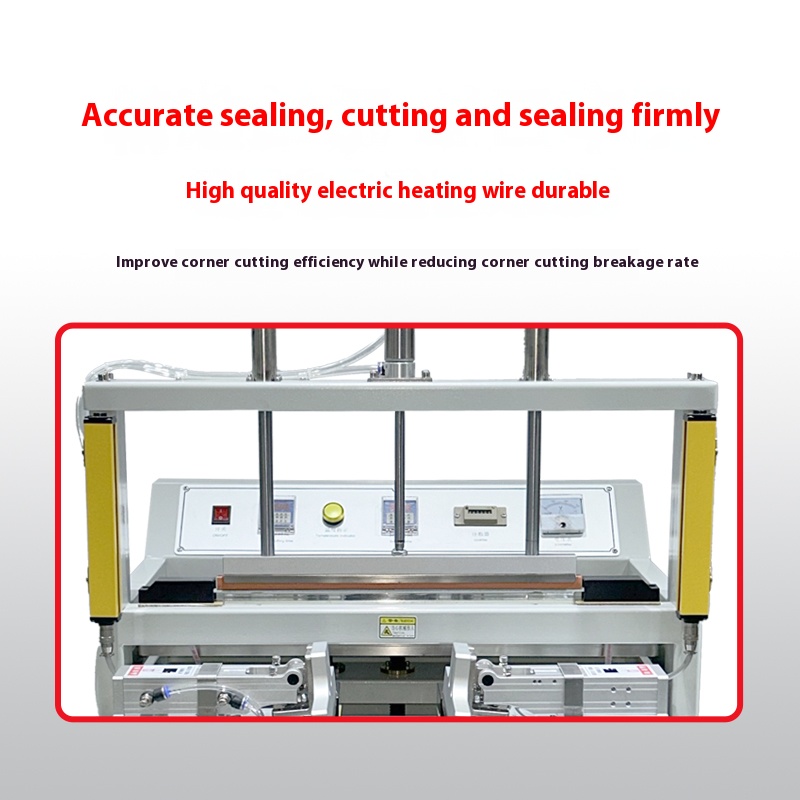

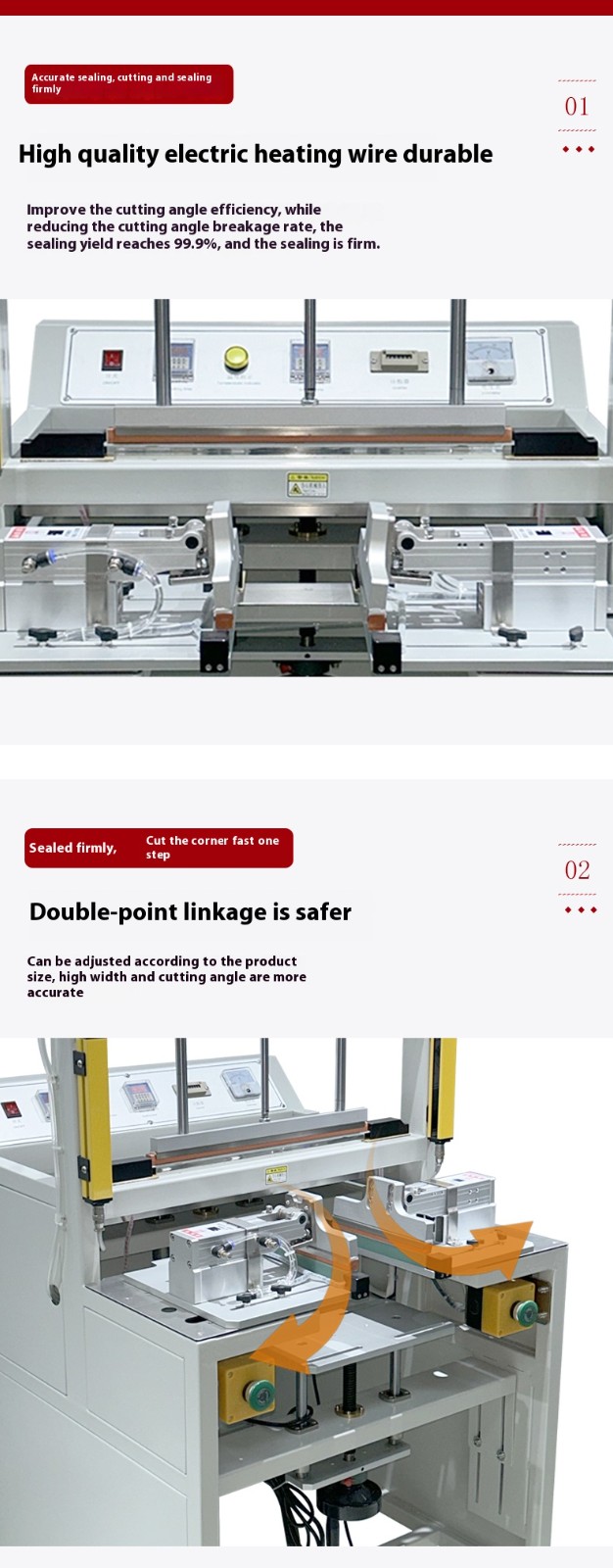

Sealing and Corner-cutting Quality: The sealing quality of the equipment directly affects the packaging effect and shelf life of the product. A high-quality sealing and corner-cutting integrated machine should have precise control over temperature, pressure, and time to ensure a firm, flat, and smooth seal without wrinkles, bubbles, or other defects. In terms of corner-cutting, it is necessary to ensure accurate corner-cutting dimensions with small errors and neat, burr-free edges. Some devices are equipped with a visual inspection system and high-precision corner-cutting tools, which can achieve precise corner-cutting positioning and cutting, effectively ensuring the corner-cutting quality.

Automation Level: Equipment with a high degree of automation can reduce manual operations, improve production efficiency and stability. For example, equipment with functions such as automatic feeding, automatic sealing, automatic corner-cutting, and automatic discharging can achieve full automation of the packaging process, reducing labor costs and labor intensity. At the same time, the intelligent control system can quickly set and adjust parameters, as well as automatically diagnose and alarm for faults, facilitating the management and maintenance of the equipment by operators.

Brand and After-sales Service: Choosing equipment from well-known brands usually ensures better quality and stability. For instance, some brands have years of research, development, and production experience in the packaging equipment field, and their products have been tested by the market for a long time, showing high reliability. In addition, good after-sales service is crucial, including equipment installation and commissioning, training, maintenance, and the supply of spare parts. Timely and effective after-sales service can ensure that the equipment can quickly resume operation in case of a failure, reducing downtime and minimizing the impact on production.

Budget: When choosing equipment, it is necessary to make a selection based on one's own economic strength and investment budget. Sealing and corner-cutting integrated machines of different brands and configurations have significant price differences. On the premise of meeting production requirements, a cost-effective device should be selected. However, it should be noted that price cannot be the sole criterion for measurement. Factors such as the performance, quality, and after-sales service of the equipment need to be comprehensively considered to avoid choosing equipment of poor quality due to a desire for low prices, which may lead to high maintenance costs and low production efficiency in the later stage.